Hollow fiber ceramic membrane element and component thereof

A technology for ceramic membranes and membrane elements, applied in the field of hollow fiber ceramic membrane elements and their components, can solve the problems of inability to modularize installation, high temperature resistance, strong acid, etc., to simplify connection and assembly, expand application scope, and ensure service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

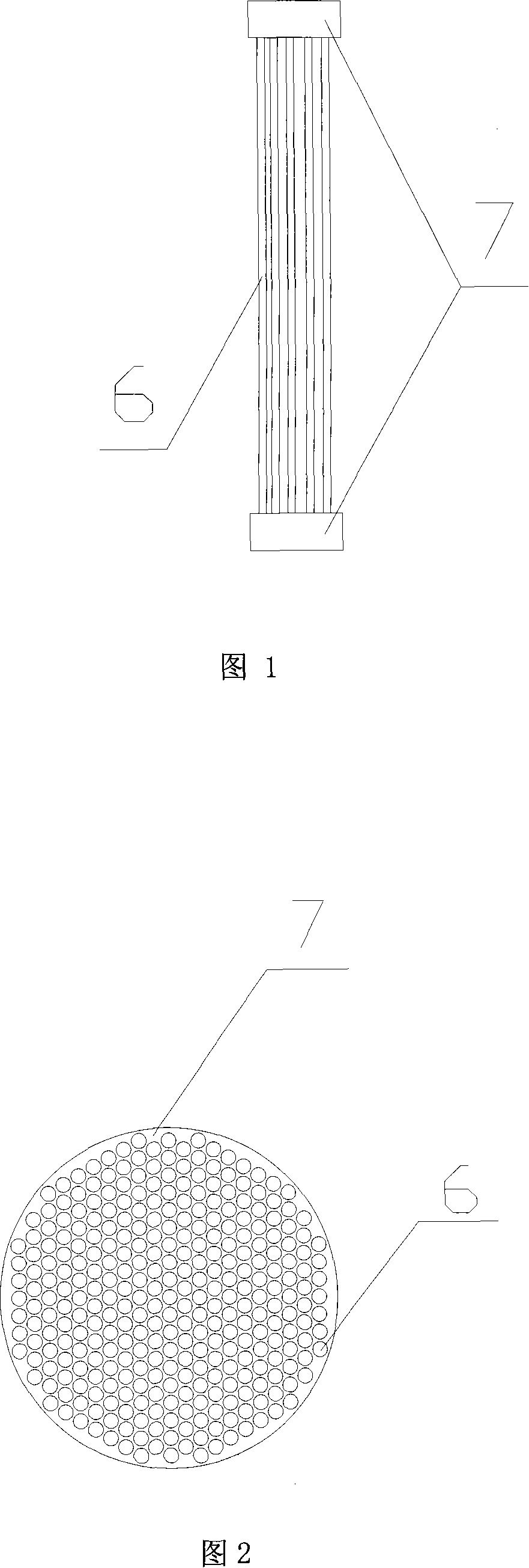

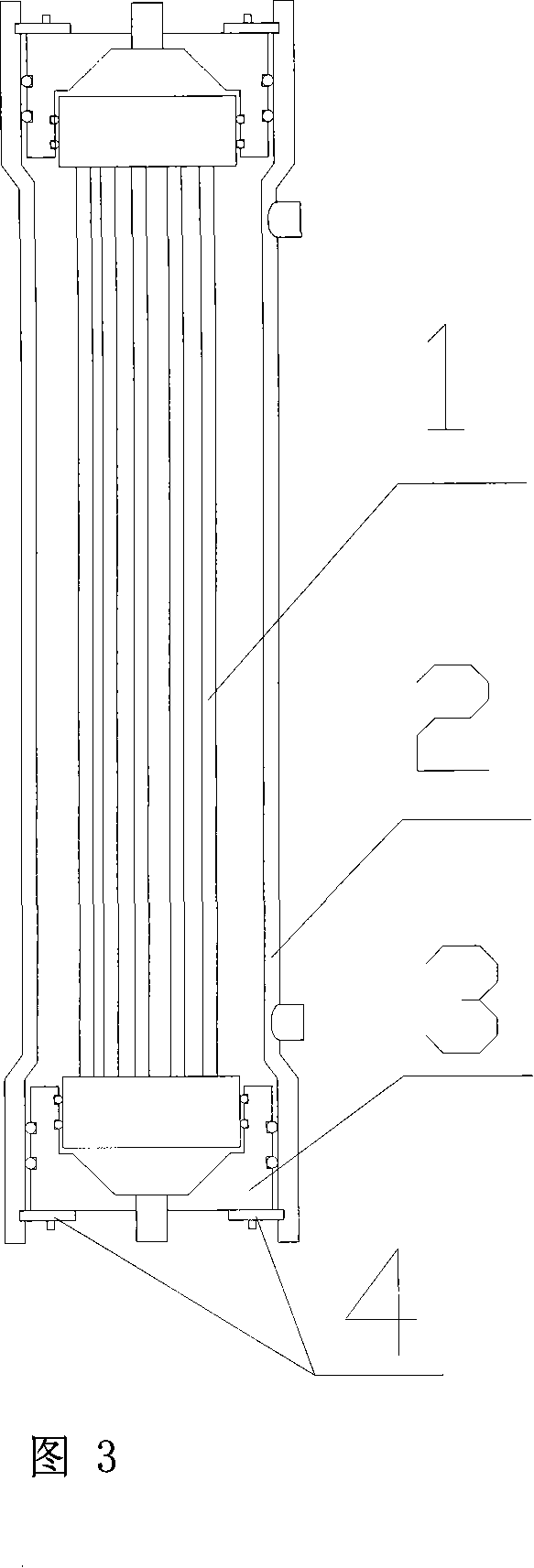

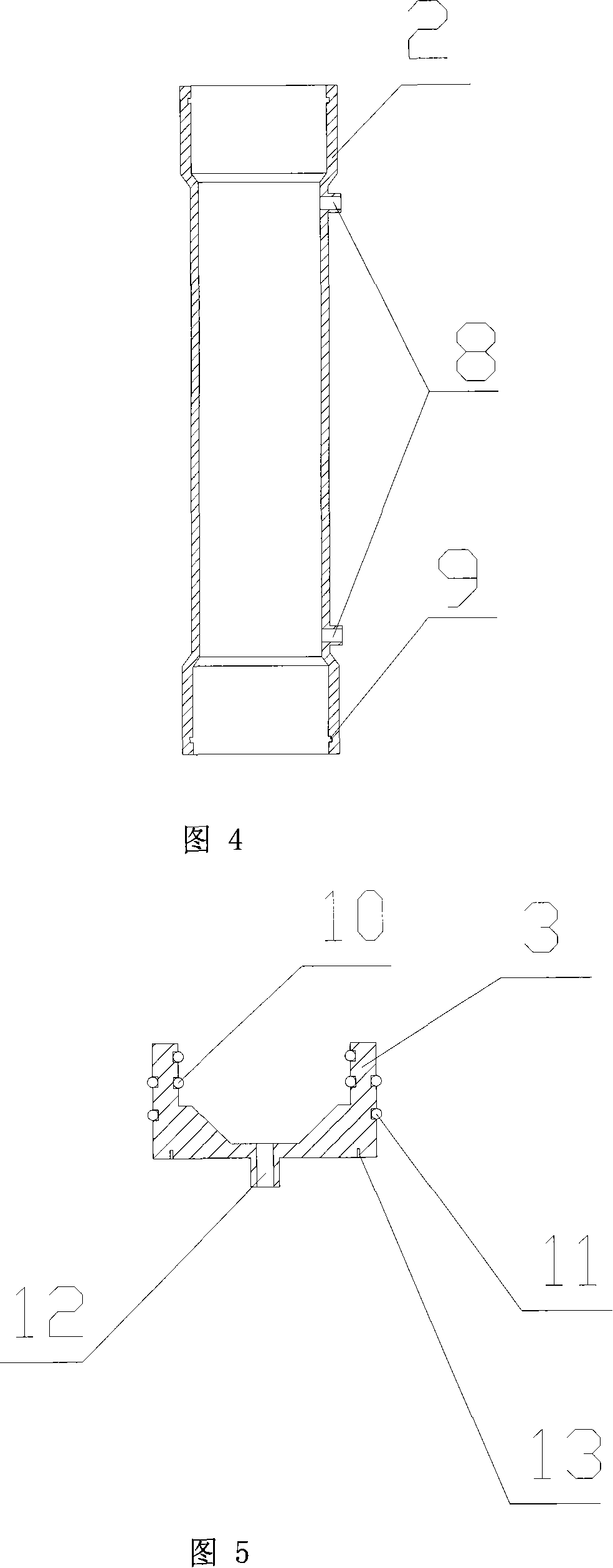

[0044] Add 5g of phenolic resin to 100g of alumina powder and 12g of bentonite, mix evenly through high-speed stirring and ultrasonic dispersion, and make packaging materials, and then 35 hollow fibers with a length of 500mm, an outer diameter of 3.5mm, and an inner diameter of 1.5mm One end of the ceramic membrane is packaged on the packaging mold and left to stand for 12 hours to complete the curing of one end of the hollow fiber membrane element, and then repeat the above steps for the other end to complete the curing of the other end.

[0045]The above-cured components were sintered in the kiln at 900°C in an air atmosphere for 1.5 hours, and cooled naturally to obtain a membrane element with an outer diameter of 31mm and a length of 500mm. The membrane element is installed in a membrane casing with an inner diameter of 35mm and a length of 600mm, and the two ends are sealed with end caps to form the final filtration system.

Embodiment 2

[0047] Add 20g of 40% by mass methyl cellulose aqueous solution into 130g of titanium oxide powder, 70g of alumina powder, 4g of kaolin and 1g of magnesia, mix uniformly through high-speed stirring and ultrasonic dispersion, and make an encapsulation material, then 35 hollow fiber ceramic membranes with a length of 250 mm, an outer diameter of 3.5 mm and an inner diameter of 1.5 mm are packaged on the packaging mold, and left to stand for 8 hours to complete the curing of one end of the hollow fiber membrane element, and then repeat the above steps for the other end. Finish curing on the other end.

[0048] The above cured components were sintered in the kiln at 500°C in the air atmosphere for 4 hours, and the temperature was naturally lowered to obtain a membrane element. The outer diameter of the membrane element was 31mm and the length was 250mm.

[0049] Refer to the above method to prepare two identical membrane elements, and then install the three membrane elements in a ...

Embodiment 3

[0051] Add 30g of polyvinyl alcohol aqueous solution with a mass percentage of 15% to 200g of zirconia powder, 50g of titanium oxide powder, 50g of alumina powder, 5g of kaolin and 1g of magnesia, and mix uniformly through high-speed stirring and ultrasonic dispersion to prepare Then, 35 hollow fiber ceramic membranes with a length of 250 mm, an outer diameter of 3.5 mm, and an inner diameter of 1.5 mm are packaged on the packaging mold, and left to stand for 8 hours to complete the curing of one end of the hollow fiber membrane element, and then the other end Repeat the above steps to complete the curing of the other end.

[0052] The above cured components were sintered in the kiln at 970°C in the air atmosphere for 7 hours, and the temperature was naturally lowered to obtain a membrane element. The outer diameter of the membrane element was 31mm and the length was 250mm.

[0053] Refer to the above method to prepare two identical membrane elements, and then install 5 membra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com