Snap ring machining process for asynchronous motor

An asynchronous motor and processing technology, which is applied in the field of processing technology of a snap ring for asynchronous motors, can solve the problems affecting the use of components, changes in the size and shape and position tolerances of the half-end parts, and inconsistent dimensional changes, so as to save costs, ensure accuracy, Guaranteed success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

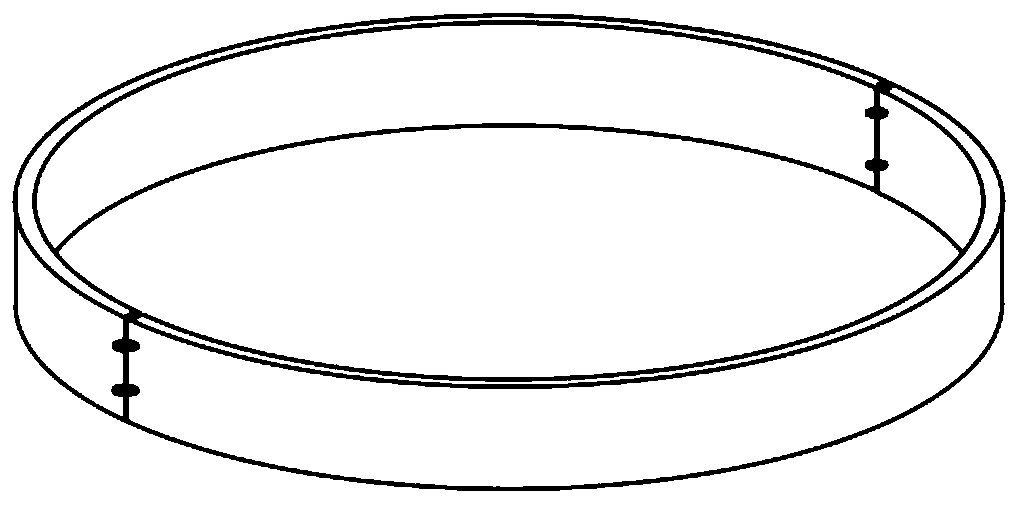

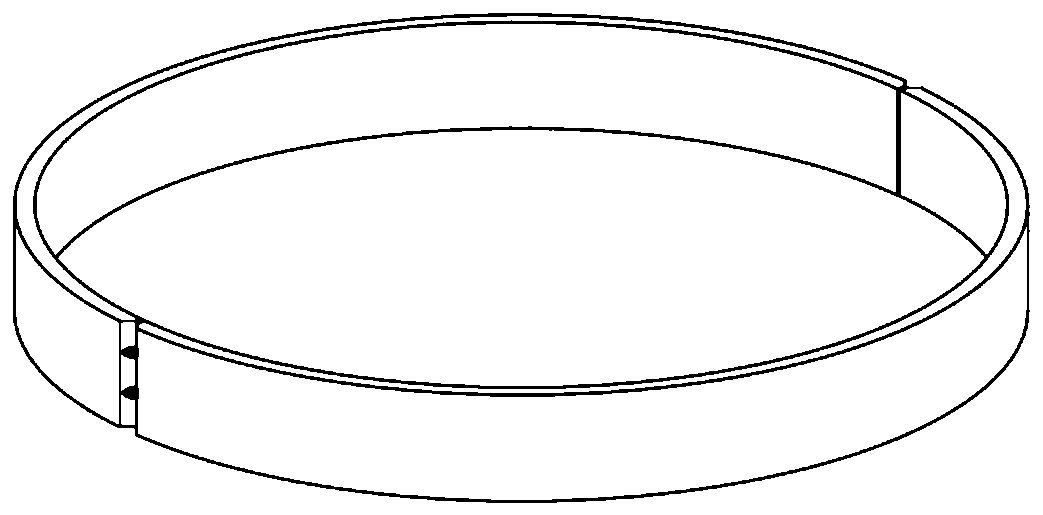

[0020] a) After alignment, the whole piece of snap ring for asynchronous motor is cut into two halves by wire cutting;

[0021] b) Plan the two halves of the joint surface of the snap ring for asynchronous motor flat, with a roughness of at least Ra3.2;

[0022] c) Align the two halves of the snap ring for the asynchronous motor after b) and use the chuck jaws to assist in clamping the workpiece. The gap between the two halves should not be greater than 0.02mm. Spot weld the two halves of the asynchronous motor together with the snap ring. One point of spot welding on both ends of the snap ring for asynchronous motors, and two spot welding points on the joints of the inner circle and outer circle of the snap ring for asynchronous motors;

[0023] d) The snap rings for asynchronous motors that are spot welded together by rough turning, process the inner circle, outer circle and upper end face of the snap rings for asynchronous motors, leave a machining allowance of 4 mm for the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com