Roll forming method of GH4033 high-temperature alloy thin-wall ring piece

A high-temperature alloy and thin-walled ring technology, which is applied in metal rolling and other directions, can solve problems such as poor structural rigidity of thin-walled rings, unreachable shape and size of rings, and influence on alloy structure and performance, so as to save precious titanium alloy materials, The effect of high molding dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

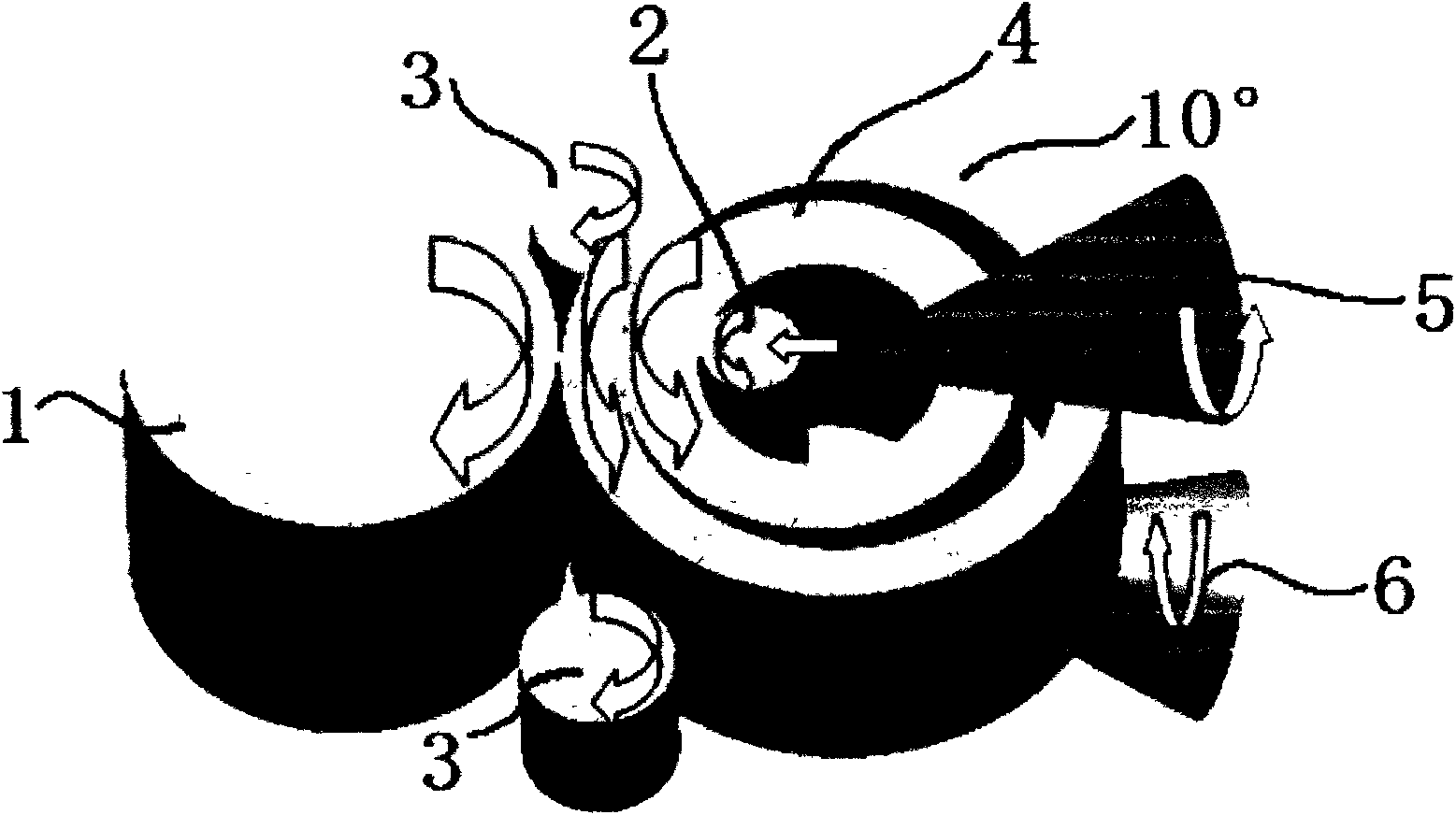

[0032] Implementing the roll forming method of the GH4033 superalloy thin-walled ring according to the present invention needs to provide forging heating furnace, press, ring rolling machine, manipulator and other equipment.

[0033] The main chemical element content (percentage by weight) of the alloy is: 0.03% to 0.08% of C, 19.0% to 22.0% of Cr, 0.60% to 1.00% of Al, 2.40% to 2.80% of Ti, 2.40% to 2.80% of Ti, Fe content≤4.0%, B content≤0.010%, Ce content≤0.010%, Mn content≤0.35%, Si content≤0.65%, P content≤0.015%, S content≤0.007%, balance For you.

[0034] The process steps of the alloy from the bar to the production of qualified thin-walled rings are as follows:

[0035] Step 1: Blank making.

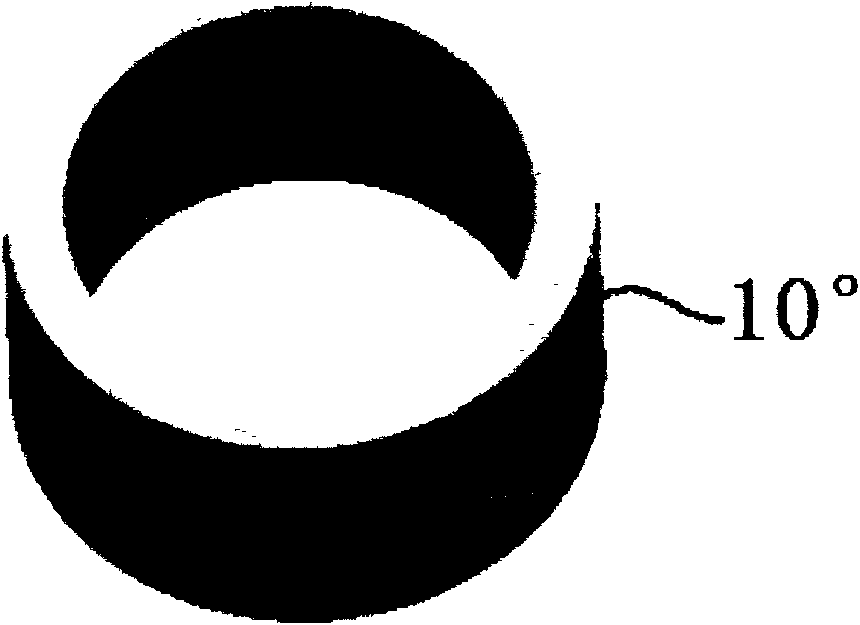

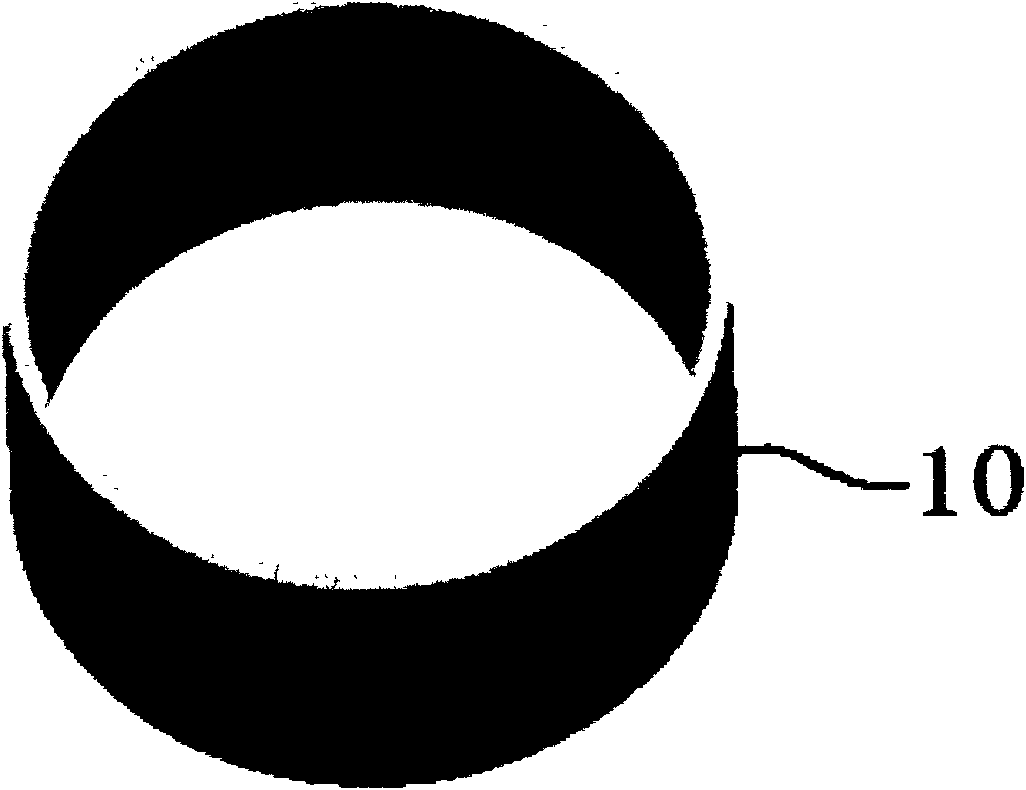

[0036] After heating, upsetting, punching, elongating and pre-rolling, the GH4033 high-temperature alloy bar material blanked according to the specification is prepared to obtain a pre-rolled billet 10°, and its shape is as follows: figure 1 shown.

[0037] Step 2: Install th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com