Method for accurately straightening spindle of centrifugal compressor in cold state

A technology for centrifugal compressors and spindles, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., and can solve problems such as the influence of the mechanical properties of the spindle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

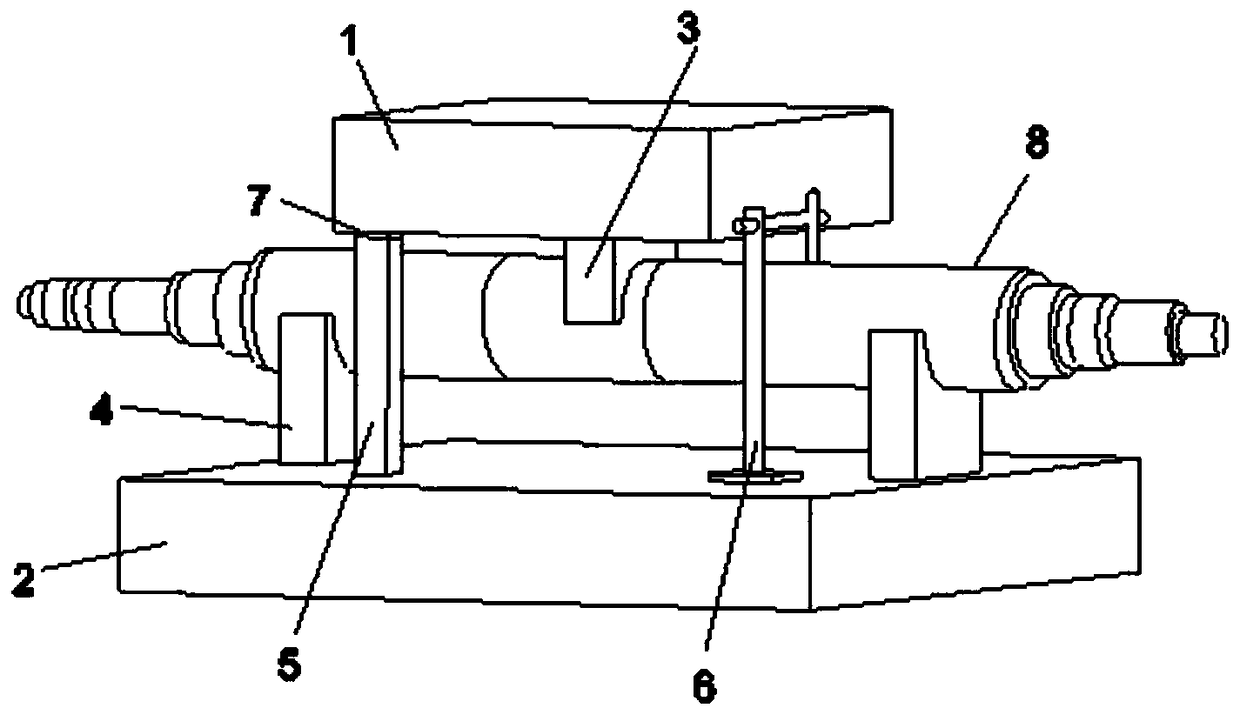

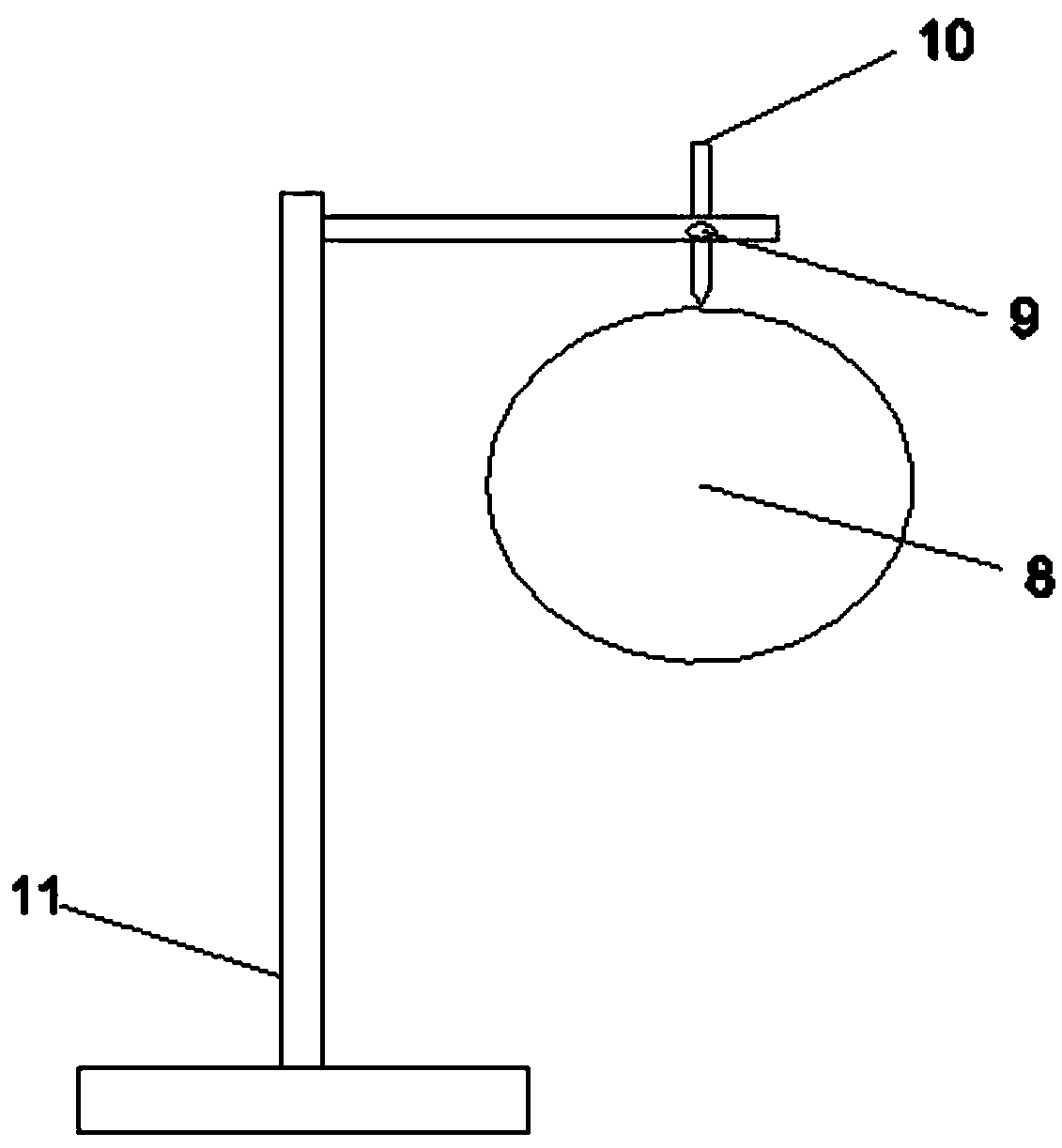

Method used

Image

Examples

specific Embodiment

[0030] 1. The material of the main shaft is 1Ni9 material, the thickest diameter is 320mm, the main shaft is bent after cryogenic treatment, the maximum deflection is 0.70mm after the meter is measured, it is located in the middle, and the deflection on both sides is digitally decreasing. Using the main shaft correction scheme of the present invention, the normal direction The main shaft produces a plastic correction effect after the compression deformation is 6mm. After many times of correction and measurement, the deflection value after correction is 0.05mm, and the correction amount is 0.65mm, which meets the requirements of use. It passed the high-speed dynamic balance smoothly, and the vibration value of the test run meets the requirements. on the product.

[0031] 2. The material of the main shaft is 1Ni9 material, the thickest diameter is 330mm, the main shaft is bent after cryogenic treatment, the maximum deflection is 0.68mm after the meter is measured, it is located i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com