600Mpa level weather-proof bolting steel self-corrosion matching method for transmission tower

A technology for transmission iron towers and bolt steel, which is applied in the field of self-corrosion matching of 600Mpa-level weather-resistant bolt steel for transmission iron towers. It can solve problems such as high coating costs, 600Mpa-level bolts do not have atmospheric corrosion resistance, and environmental pollution. The effect of atmospheric corrosion resistance and excellent self-corrosion matching performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention adopts 150 and 200mm 2 Continuous casting slabs are used in the production of φ12-24mm wire rods and bars, and bolts are made by downstream bolt processing plants to obtain excellent mechanical, weather resistance and self-corrosion matching properties.

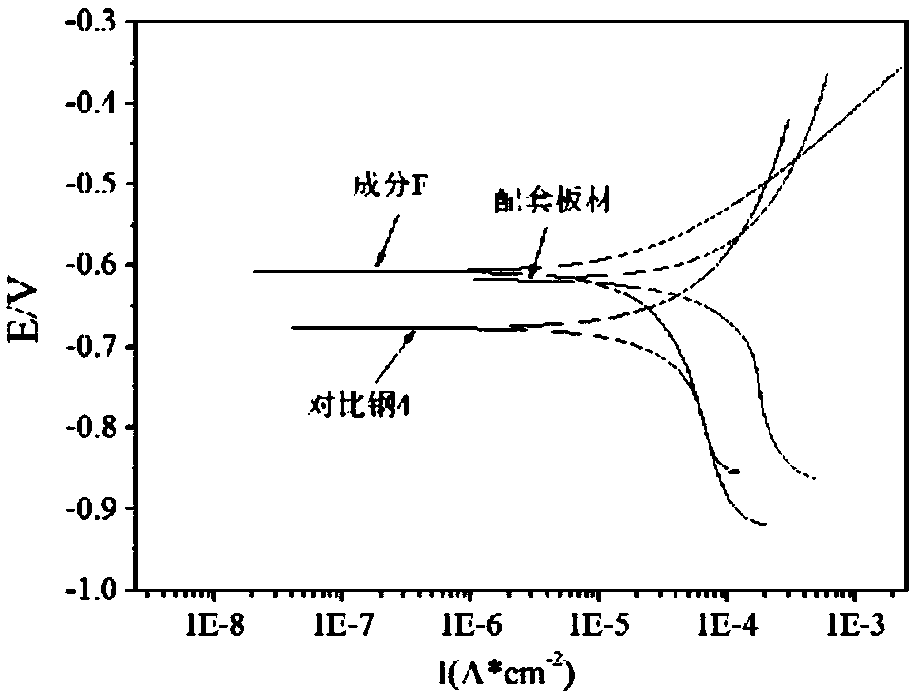

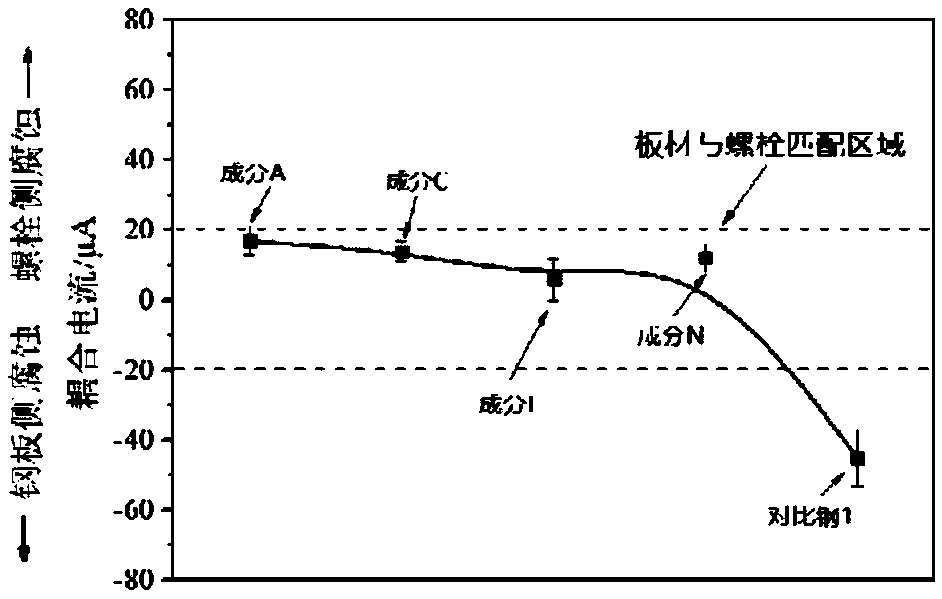

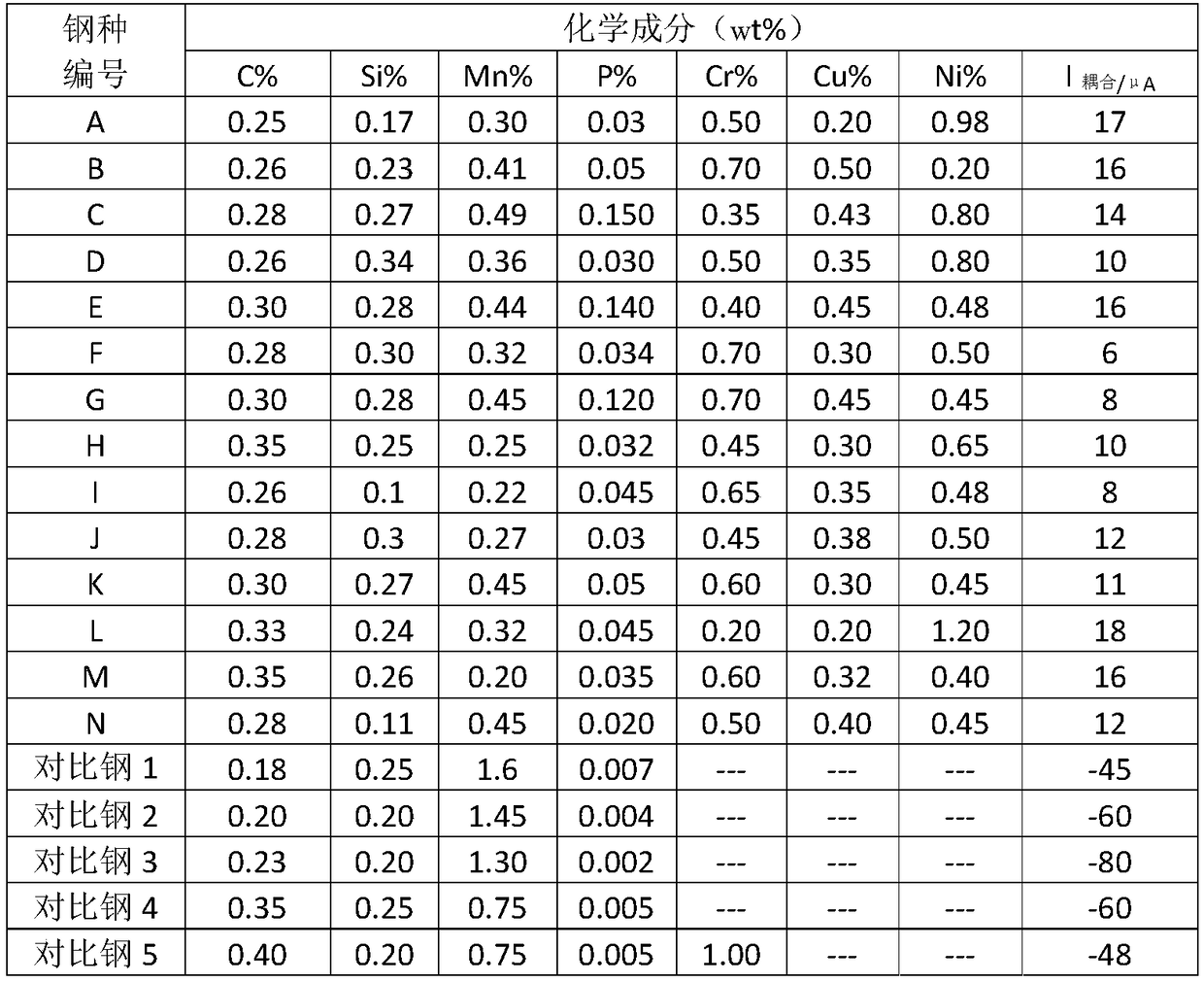

[0020] 1, in the specific embodiment, the coupling current of design steel grade chemical composition, corrosion resistance index I and supporting plate is shown in Table 1; figure 1 The potential difference between the invention component steel F and the supporting plate is controlled at the level of 0.015V. figure 2 The coupling current between Zhongming 600Mpa grade weather-resistant bolt steel and matching plate is controlled within ±20μA, which has good self-corrosion matching performance;

[0021] 2. Use high-strength wire and bar to roll hot-rolled materials for high-strength bolts, and the rolling specifications are φ12, 20 and 24mm;

[0022] 3. After the fastener processing factory mak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com