Flame-retardant composite material floor with sound isolating function and preparation method thereof

A composite material and flame-retardant technology, applied in the direction of chemical instruments and methods, adhesive types, carboxyl rubber adhesives, etc., can solve the problem of poor overall mechanical properties such as impact resistance, poor matrix toughness, and failure to meet the use requirements and other issues to achieve optimal structural design and good matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] The preparation method of the fire-retardant composite material floor with sound insulation function, low smoke and low toxicity, and flame retardant of the present invention comprises the following steps:

[0066] 1) Preparation of fiber-reinforced phenolic resin hot-melt prepreg:

[0067] 1.1) Add industrial alcohol, E51 epoxy resin, carboxy-terminated nitrile rubber prepolymer, aluminum hydroxide and DOPO in sequence in the low-speed stirring state of phenolic resin, and then carry out high-speed stirring for 60-150 minutes, and finally mix the stirred The solution was ground by three rolls to obtain the modified phenolic solution. The speed of low-speed stirring is 50-100r / min; the speed of high-speed stirring is 300-750r / min:

[0068] The phenolic resin is liquid barium phenolic resin prepared with a aldehyde-phenol ratio in the range of 2.0:1-1.6:1.

[0069] The mass parts of said industrial alcohol, E51 epoxy resin, carboxyl-terminated nitrile rubber prepolymer...

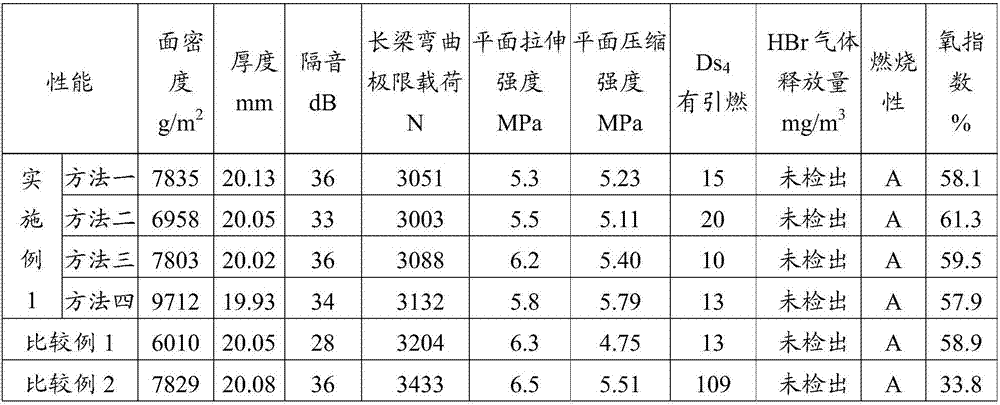

Embodiment 1

[0097] Composite sandwich panels with a thickness of 20mm are required to be installed on rail transit vehicles as floors. The plane tensile strength requirements are ≥3.5MPa, the plane compression strength requirements are ≥5.0MPa, the sound insulation capacity is ≥33dB, and the flame retardancy meets the requirements of DIN5510. , the preparation method is:

[0098] 1) Preparation of skin prepreg with hot melt method

[0099] 1.1) Add 50kg of commercially available barium hydroxide catalyzed phenolic resin and 15kg of industrial alcohol into a 100L reaction kettle with self-heating and stirring functions, stir at a speed of 100r / min, then add 2.5kg of E51 epoxy resin, 2.5kg of Carboxyl-terminated nitrile rubber prepolymer and 1.5kg aluminum hydroxide and 0.5kg DOPO were stirred for 100 minutes at a rotating speed of 500r / min afterwards to obtain a modified phenolic resin solution;

[0100] 1.2) Evacuate the alcohol solvent in the modified phenolic resin solution obtained in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com