Method for rolling and shaping structural steel high cylindrical ring forged piece

A technology of ring forgings and high cylinders, which is applied in the field of rolling forming of ring forgings, can solve the problems of small machining allowance, poor structural rigidity of thin-walled high-tube ring forgings, flattening of ring forgings, etc., and achieve high dimensional accuracy and saving The effect of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0038] The main chemical element content (percentage by weight) of the alloy is: C content 0.34%-0.42%, Mn content 0.50%-0.80%, Si content 0.17%-0.37%, S content ≤ 0.015%, P content ≤0.025%, Cr content 0.08%~1.10%, Ni content ≤0.40%, Cu content ≤0.25, balance iron.

[0039] The process steps of the alloy from the bar to the production of qualified high-tube ring forgings are as follows:

[0040] Step 1: Blank making.

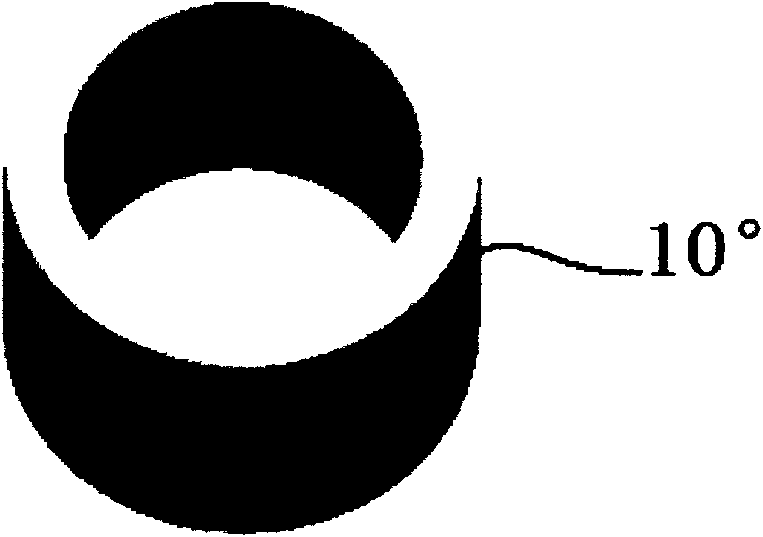

[0041] After heating, upsetting, punching, elongating and pre-rolling the 38CrA alloy bar blanked according to the specification, the pre-rolled billet 10° is produced, and its shape is as follows: figure 1 shown.

[0042] Step 2: Install the computer.

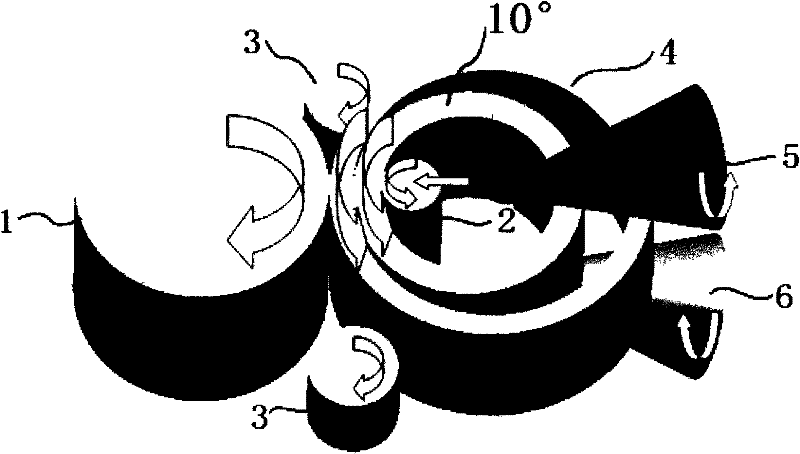

[0043] Such as figure 2As shown, the follower die set 4 is preheated to 230°C to 280°C in the forging heating furnace, then loaded into the ring rolling machine and placed flat on the chassis of the machine (not shown in the figure), the follower die set 4 The core roll 2 of the ring rolling machine is ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com