Aluminum alloy smelting-purifying device and smelting-purifying method

A purification device and aluminum alloy technology, which is applied in the direction of improving process efficiency, etc., can solve problems such as easy cracks in aluminum alloys, low purity in smelting and purification, and easy corrosion at cracks, so as to improve performance, high purity in smelting and purification, and equipment compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

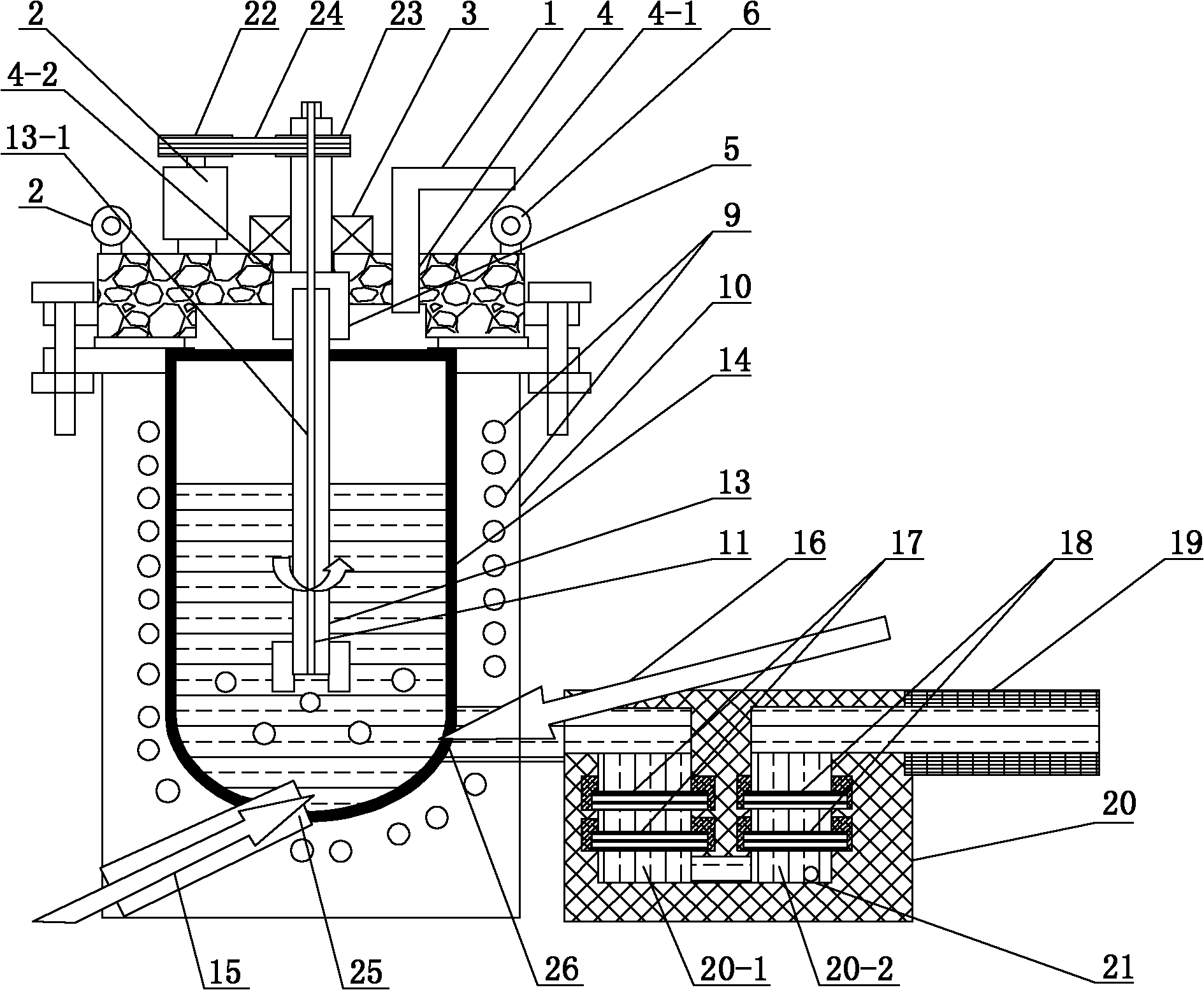

[0025] Specific implementation mode one: as figure 1 As shown, the aluminum alloy smelting and purification device of the present embodiment includes an air guide pipe 1, a motor 2, a bearing 3, a furnace cover 4, a steel sleeve 5, a furnace body 10, an argon gas pipe 11, a graphite rotor 13, a crucible 14, a launder 19, Filter box 20, first pulley 22, second pulley 23, belt 24, a plurality of heating pipes 9, a plurality of first filter ceramic sheets 17 and a plurality of second filter ceramic sheets 18, the bottom end surface of the crucible 14 is open There is a discharge port 25, the furnace cover 4 is provided with an air guide hole 4-1, the lower end of the air guide pipe 1 is inserted into the air guide hole 4-1, and the outer wall of the crucible 14 is embedded in the furnace body 10, The furnace body 10 is provided with a plurality of heating tubes 9, the furnace cover 4 is covered on the upper end surface of the furnace body 10, the center of the furnace cover 4 is ...

specific Embodiment approach 2

[0026] Specific implementation mode two: as figure 1 As shown, the smelting and purifying device in this embodiment further includes a steel sleeve 5, the steel sleeve 5 is fitted on the graphite rotor 13, and the upper end surface of the steel sleeve 5 is in contact with the shoulder of the stepped hole 4-2. With such a design, the molten aluminum alloy can be filtered multiple times, and the smelting purification has high purity. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0027] Specific implementation mode three: as figure 1 As shown, the smelting and purifying device in this embodiment further includes a steel sleeve 5, the steel sleeve 5 is fitted on the graphite rotor 13, and the upper end surface of the steel sleeve 5 is in contact with the shoulder of the stepped hole 4-2. Such a design can increase the stability of the graphite rotor 13 . Other compositions and connections are the same as those in the first or second embodiment.

[0028] Specific implementation mode four: as figure 1 As shown, the smelting and purification device in this embodiment further includes two lifting rings 6 fixedly mounted on the upper end surface of the furnace cover 4 . Designed in this way, the furnace cover 4 is conveniently hoisted. Other components and connections are the same as those in the third embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com