Patents

Literature

50results about How to "Improve mass transfer conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

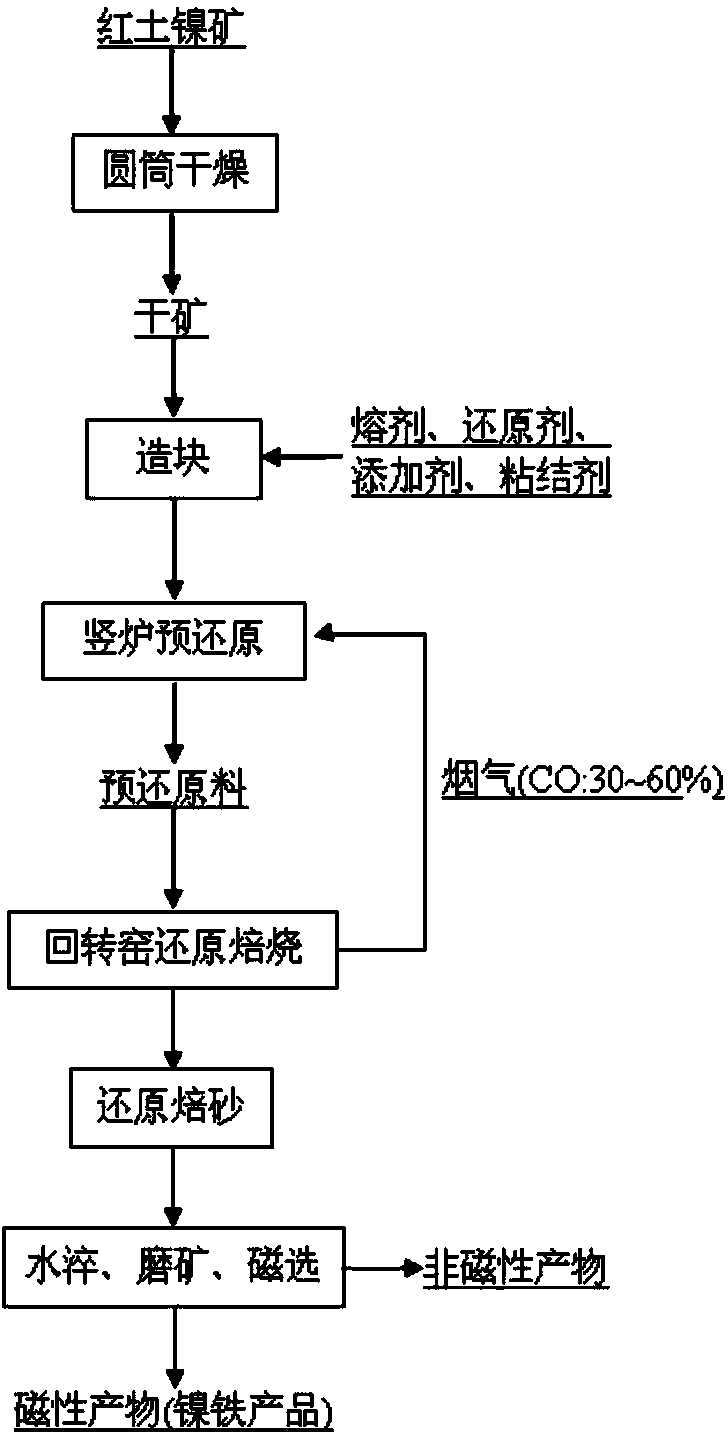

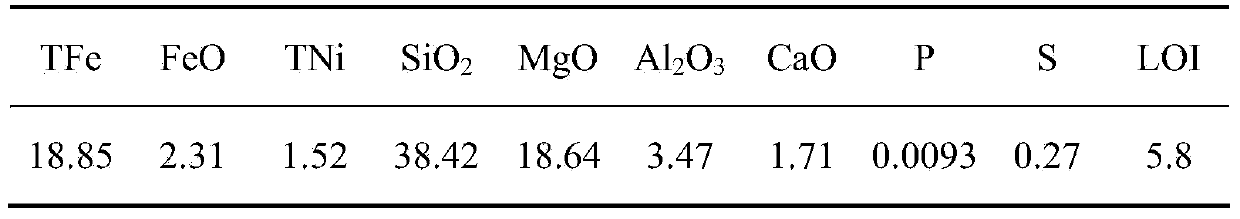

Process for preparing ferric-nickel from laterite-nickel ore

ActiveCN104195279AImprove mass transfer conditionsPromote particle growthRotary drum furnacesSolventLaterite

The invention discloses a process for preparing ferric-nickel from laterite-nickel ore. The process comprises the following steps: crushing laterite-nickel ore, drying, adding an additive, a reducing agent, a solvent and a binding agent, uniformly mixing, briquetting, putting into a vertical furnace, performing pre-reducing roasting by using high-temperature fume in a rotary kiln, further putting into a coal medium in the rotary kiln, and performing reducing roasting, water quenching cooling and grinding and magnetic separation, thereby obtaining a powder ferric-nickel product with high nickel content. The process is short in procedure, simple to operate, low in energy consumption, low in cost and high in metal recycling rate, and the defects that the energy consumption is high, the metal recycling rate is low and the production cost is high when the ferric-nickel is prepared from reduced laterite-nickle ore directly in a conventional rotary kiln in the prior art are overcome.

Owner:CENT SOUTH UNIV

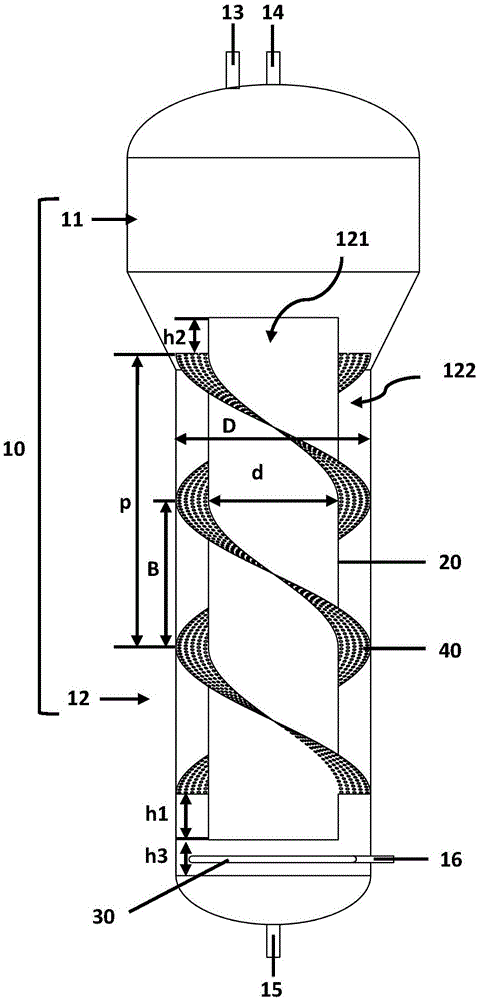

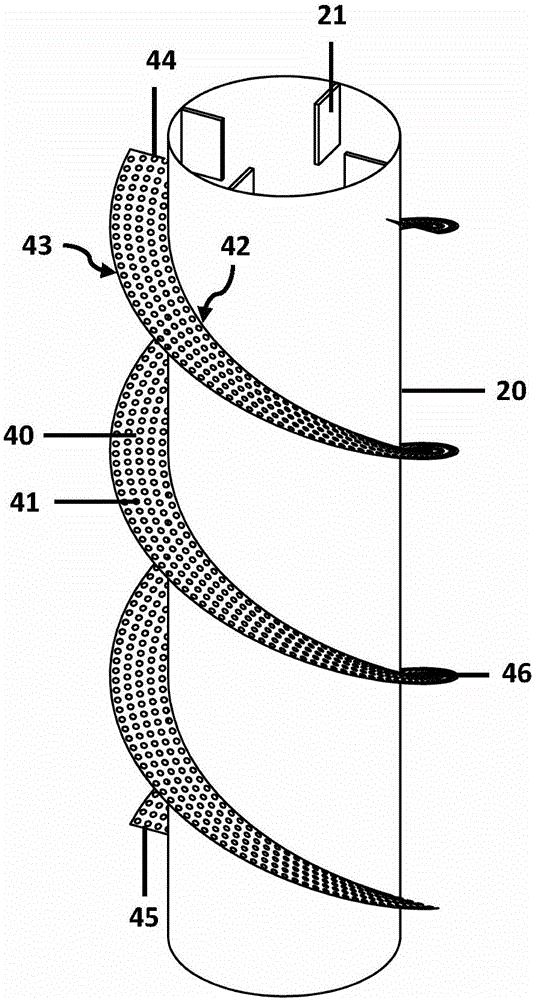

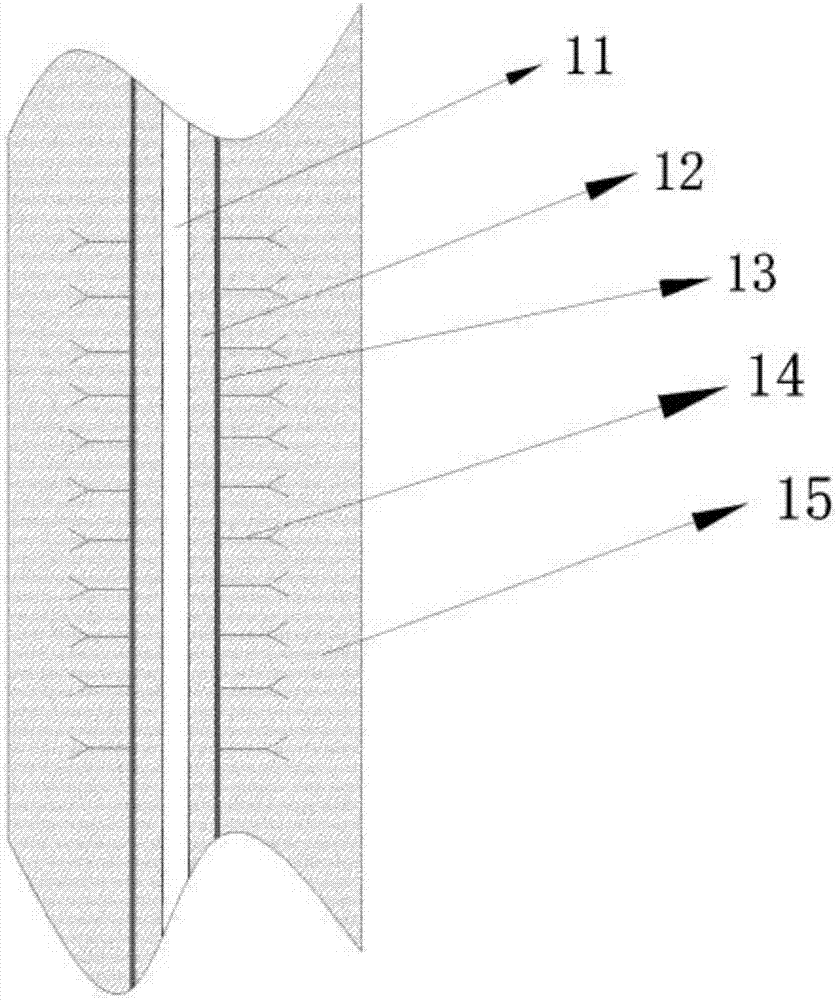

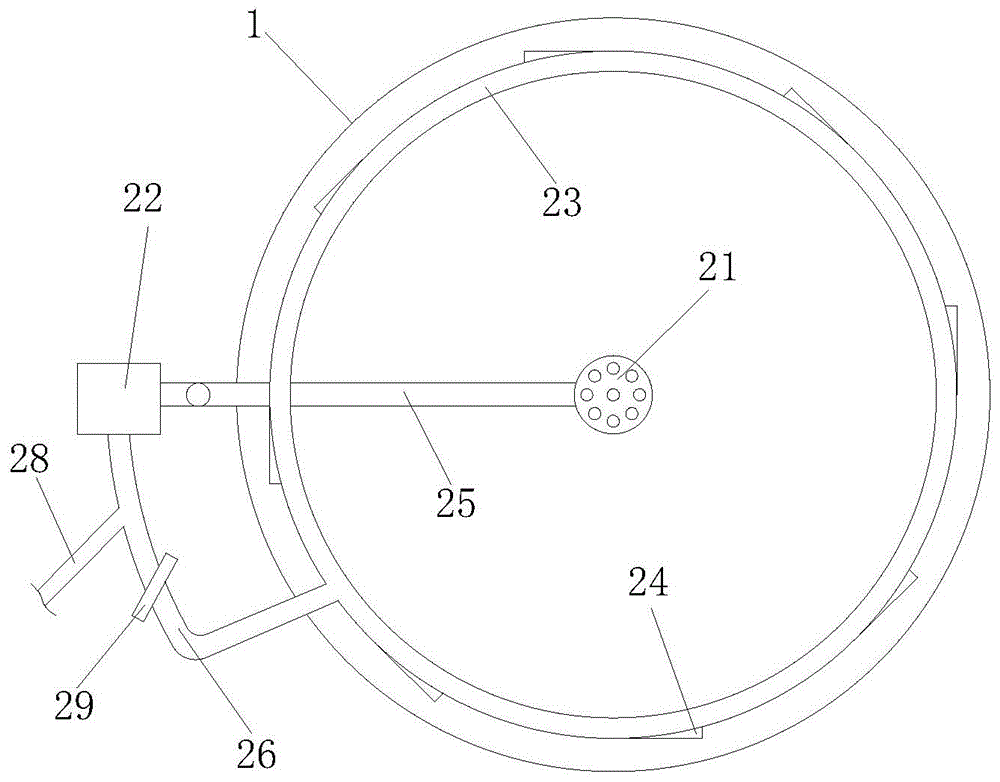

Airlift reactor having spiral porous sieve plate

ActiveCN106552560AExtended effective operating rangeExtended stayBioreactor/fermenter combinationsBiological substance pretreatmentsAirlift reactorEngineering

The invention discloses an airlift reactor having a spiral porous sieve plate. The reactor includes a reaction tank body. A flow guide cylinder and a gas distributor are arranged in the reaction tank body. The gas distributor is disposed under a raising section of the flow guide cylinder. A spiral porous sieve plate is arranged in the raising section of the flow guide cylinder. The body of the spiral porous sieve plate is in a spirally raising shape, so that a part of two / three-phased flow in the raising section is guided. There are a plurality of sieve pores in the body of the spiral porous sieve plate, so that the rest of the two / three-phased flow in the raising section is subjected to flow guiding and bubble breaking. The airlift reactor considers both macroscope mixing and microscope mixing, wherein the liquid is driven by ejected gas to flow cyclically, so that raising large bubbles are broken into small bubbles. The reactor can effectively inhibit aggregation of bubbles, increases gas holdup, and increases volume mass transfer coefficient.

Owner:JIANGNAN UNIV

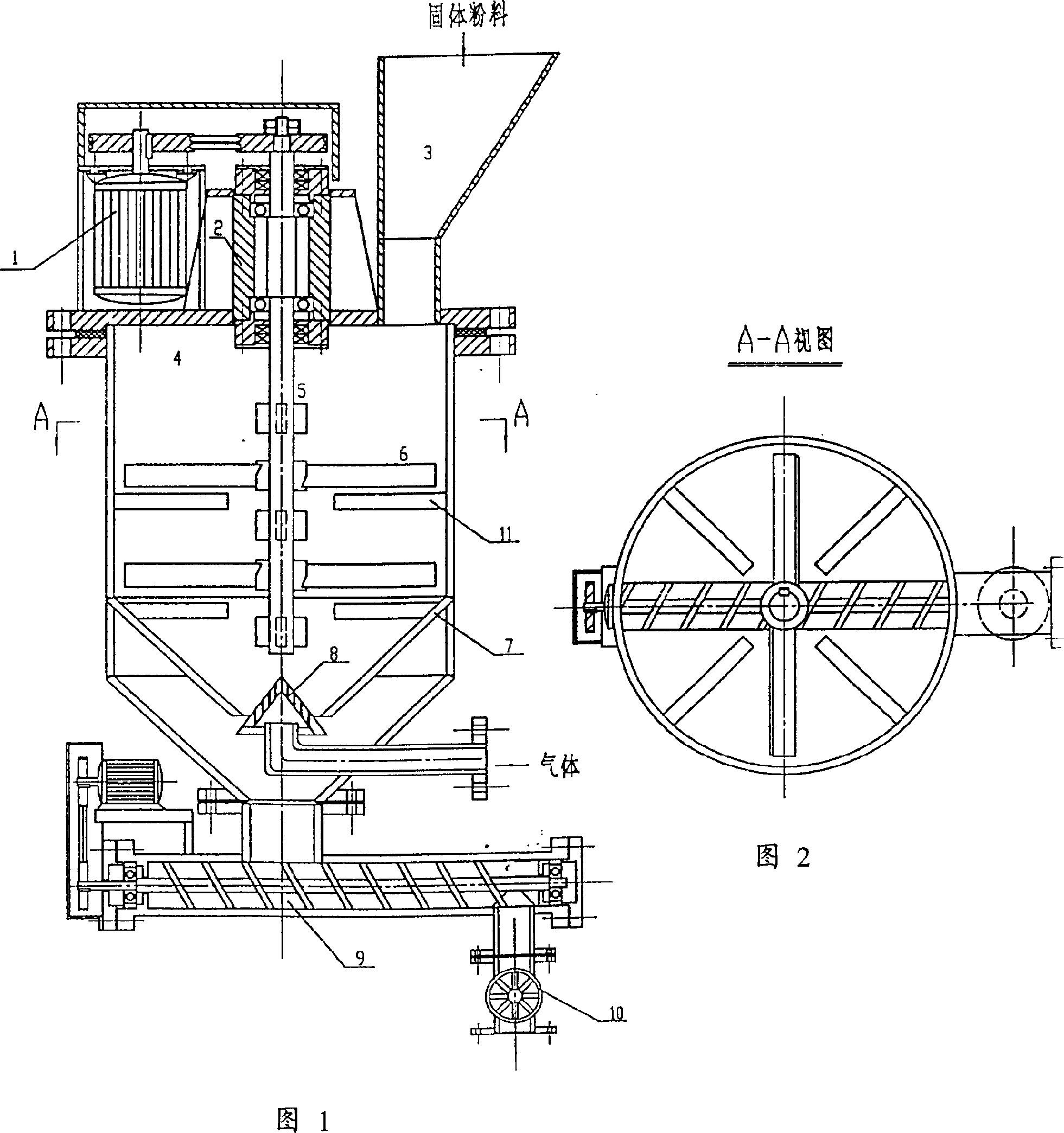

Gas-solid reactor

InactiveCN1448211ATake advantage ofImprove mass transfer conditionsMixing gases/vapours with solidsGas solidSpool valve

The gas-solid reactor includes the main parts of main body, solid feeding port, tail gas exhausting port, stirring shaft, stirring blades, truncated cone solid discharger, turned conic gas distributor, screw conveyor, air sealed slide valve and baffle. The main body includes cylindrical upper part and conic lower part; the solid feeding port and the tail gas exhausting port are in the top of thereactor; the stirring shaft with fixed stirring blades is perpendicular to the central axis of the reactor; the inner wall of the reactor has one or several layers of baffles set; the solid discharger is in the lower part of the reactor; the gas distributor with homogeneously distributed holes is below the solid discharger; and the bottom of the reactor is connected to the screw conveyor; and theslide valve is set on the material discharging pipe of the screw conveyor.

Owner:CHINA PETROLEUM & CHEM CORP +1

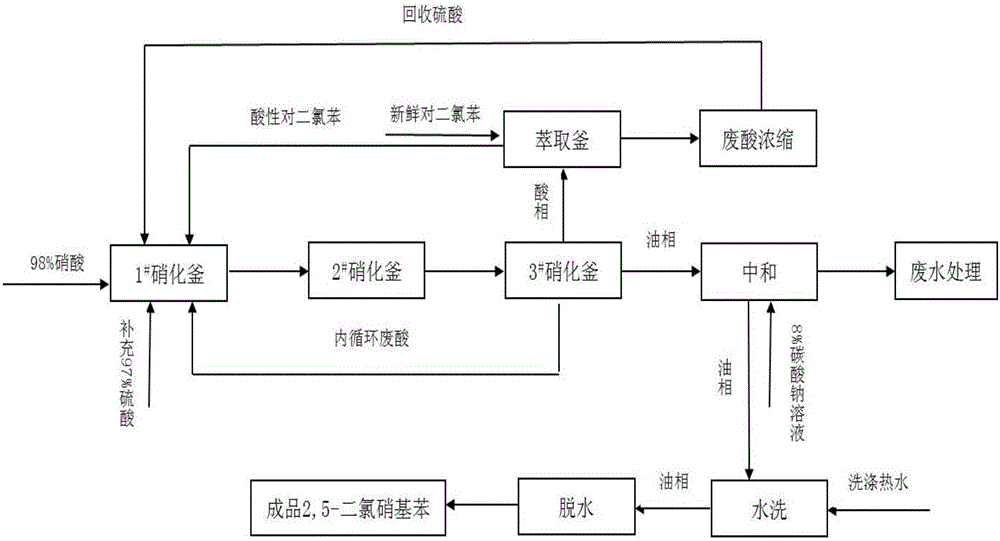

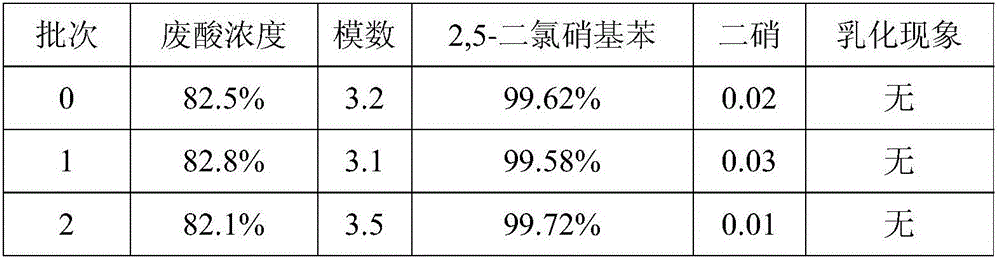

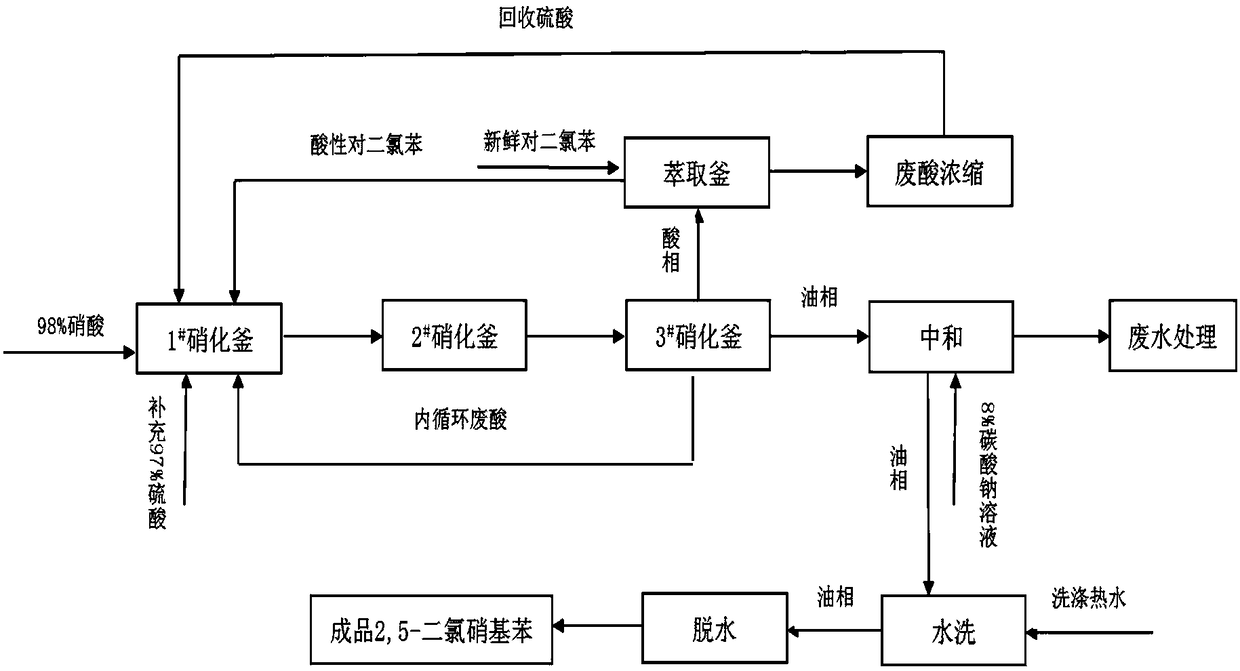

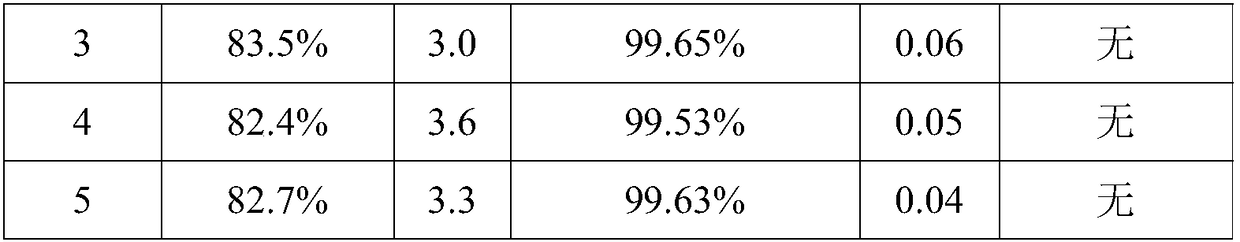

Method for preparation of 2, 5-dichloronitrobenzene by continuous nitration

ActiveCN106083596AOptimize process flowWith automatic separation functionNitro compound preparationNitrationOil phase

The invention discloses a method for preparation of 2, 5-dichloronitrobenzene by continuous nitration. The method comprises the steps of: adopting three-stage kettle type continuous reaction, adding sulfuric acid, nitric acid and p-dichlorobenzene in an extraction kettle into a first stage nitrification kettle simultaneously to carry out nitrification reaction, letting nitrification liquid enter a next stage nitrification kettle through self-carried raisers of all nitrification kettles in order to react, at the end of reaction in a third stage nitrification kettle, separating an oil phase and an acid phase, carrying out neutralization, washing and dehydration on the oil phase so as to obtain 2, 5-dichloronitrobenzene, internally recycling part of waste acid in the acid phase back to the first stage nitrification kettle, letting the residual waste acid enter an extraction kettle, and performing p-dichlorobenzene extraction, and then conducting separation to obtain acidic p-dichlorobenzene and extracted waste acid, concentrating the extracted waste acid into concentrated sulfuric acid, and making the concentrated sulfuric acid and acidic p-dichlorobenzene enter the first stage nitrification kettle for recycling. The method provided by the invention adopts automation control, cancels a mixed acid preparation procedure, simplifies the technological process, can realize continuous nitrification reaction, continuous nitrification liquid separation and continuous waste acid extraction.

Owner:江苏拓孚工程设计研究有限公司

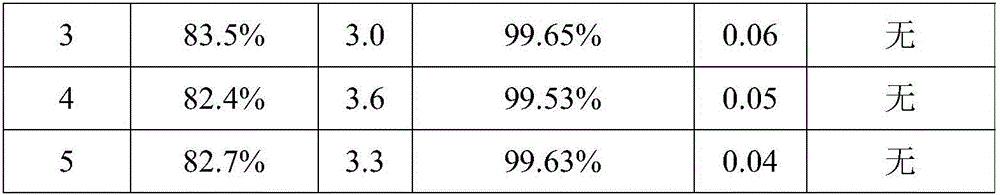

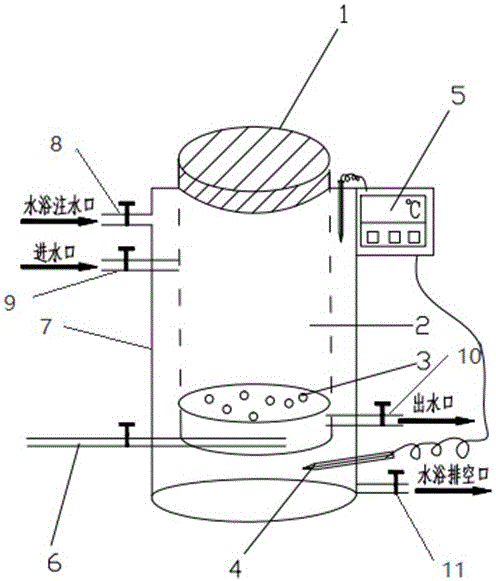

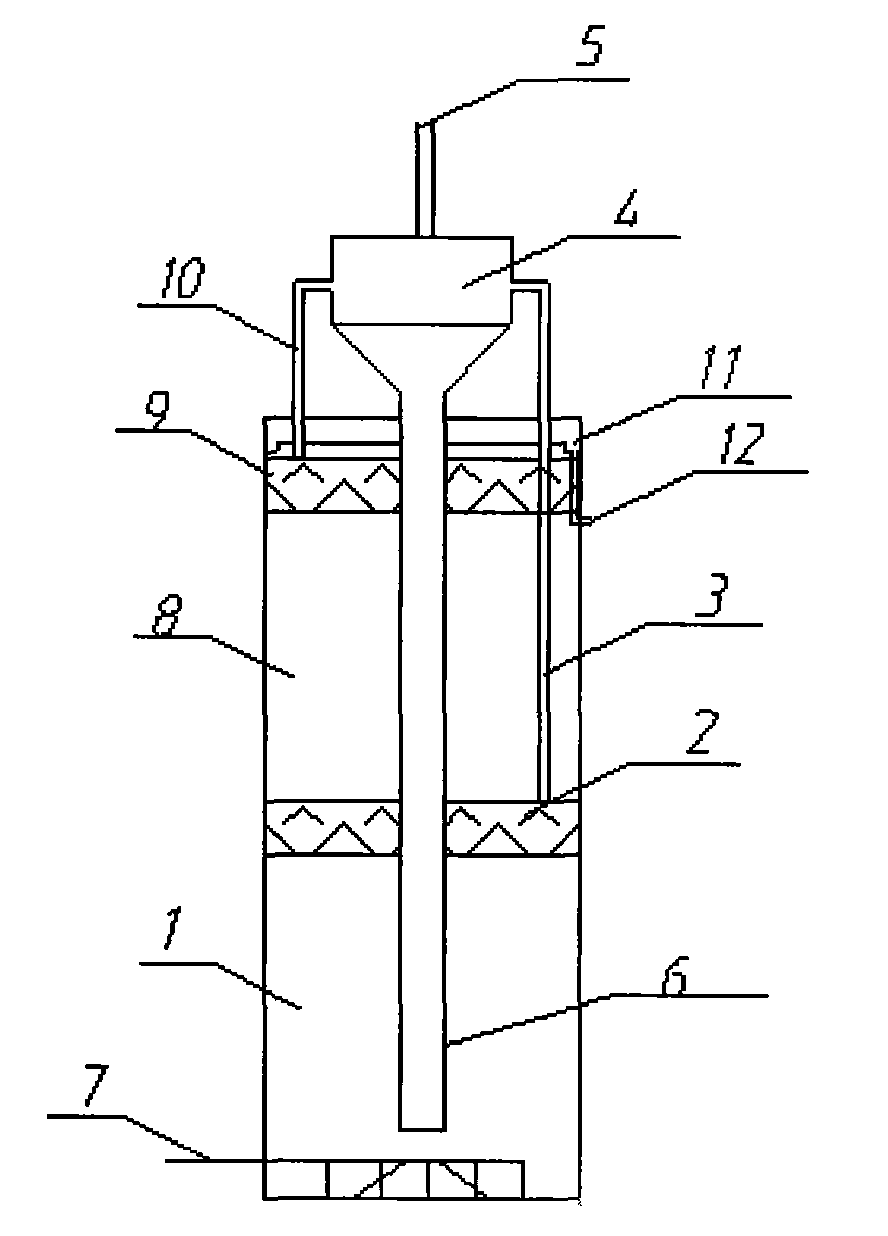

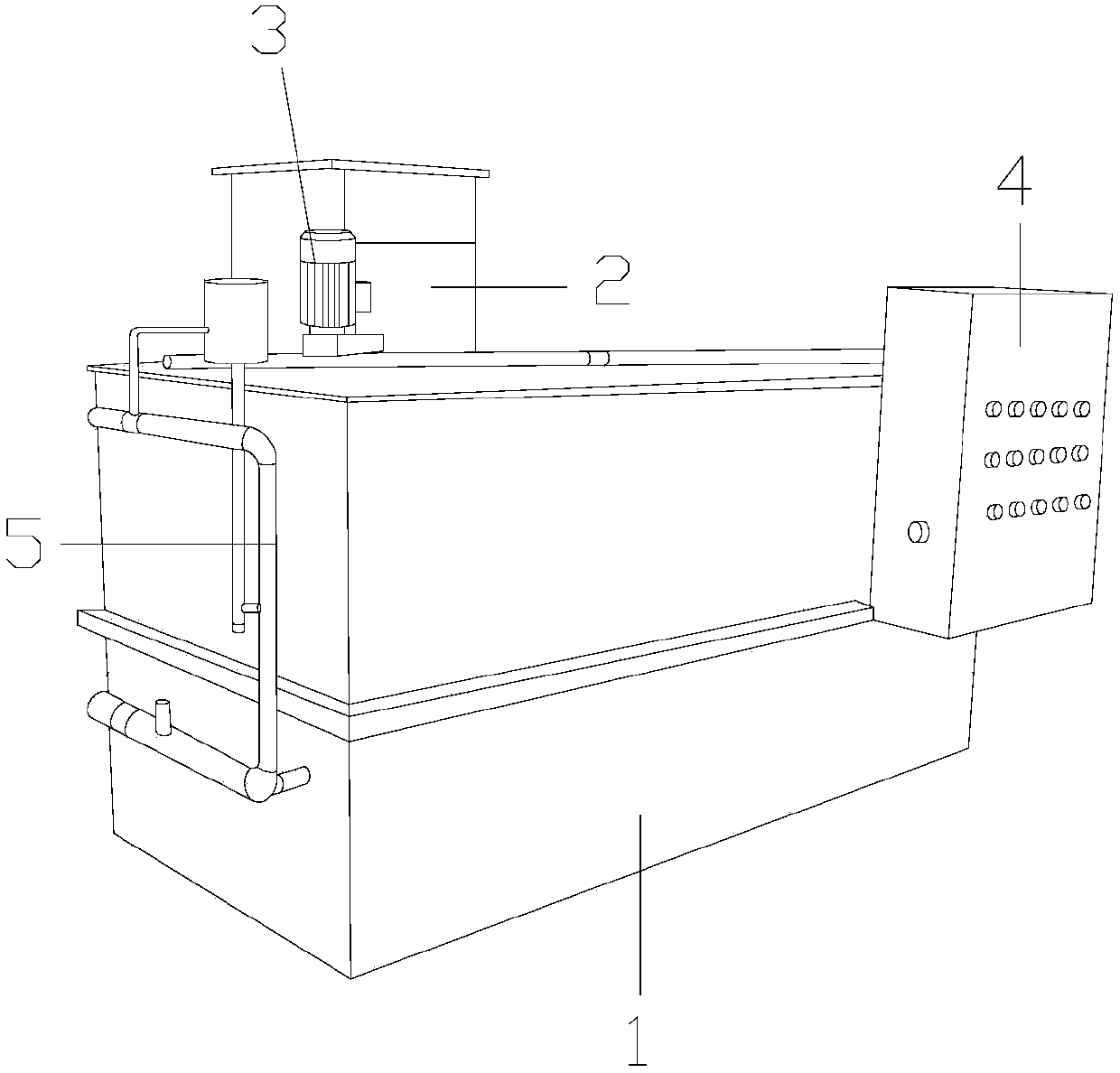

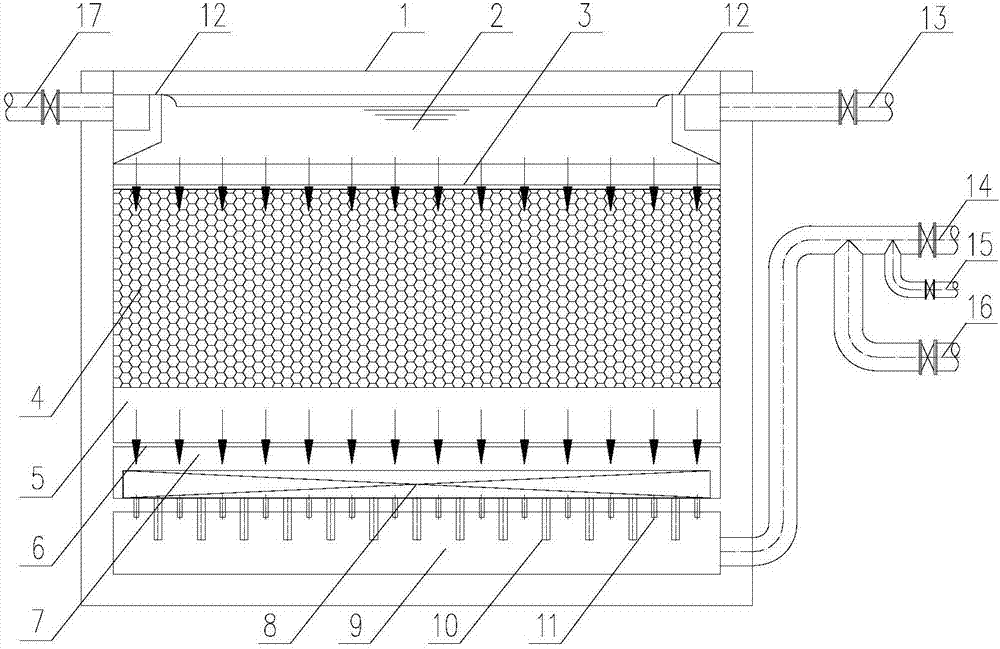

Experimental device and method for treating antibiotic wastewater through iron-carbon micro-electrolysis method

InactiveCN106630026AImprove biodegradabilityReach the environmental protection effect of "reduction"Multistage water/sewage treatmentNature of treatment waterTreatment effectElectrolysis

The invention discloses an experimental device and method for treating antibiotic wastewater through an iron-carbon micro-electrolysis method. An iron-carbon micro-electrolysis device comprises a top cover, a stuffing region, a multihole plate supporting layer, a heating stick, a temperature controller and an aeration pipe. The invention further discloses a method for treating the antibiotic wastewater by using the device. The method comprises the following steps: injecting the antibiotic wastewater into an adjustment pool, adjusting pH to be 2.0 to 4.0, then injecting the antibiotic wastewater into a reactor through a water inlet of an iron-carbon micro-electrolysis reactor, and enabling a fan to blow air through an air inlet for aeration, wherein discharged water flows back into the reactor from the water inlet through a backflow pump; enabling the water to stay for 4 to 8 hours, and then discharging the water from a water outlet, thus completing treatment of the wastewater. The experimental device has the advantages of good treatment effect, long service life, simple operation and low cost.

Owner:TONGJI UNIV

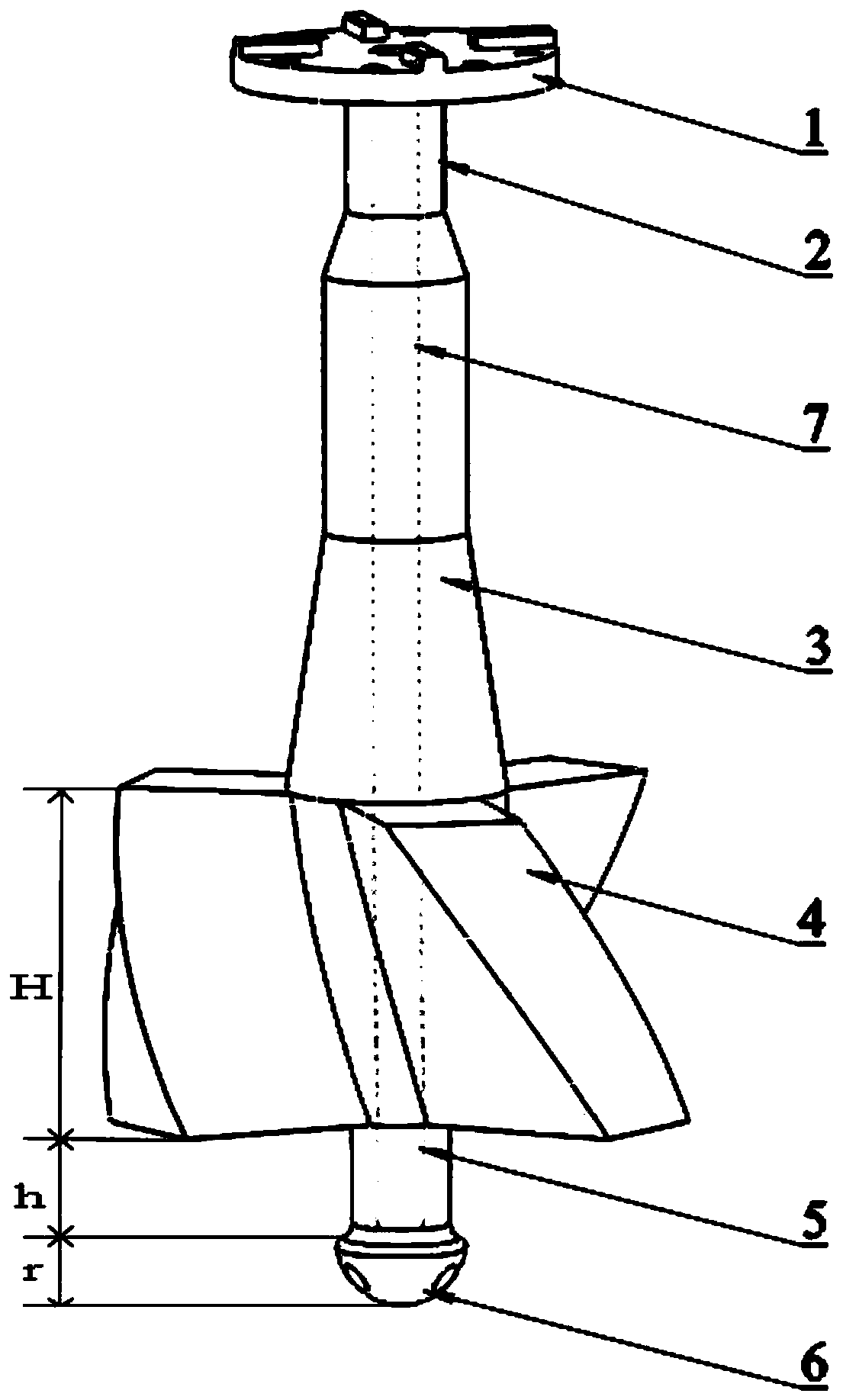

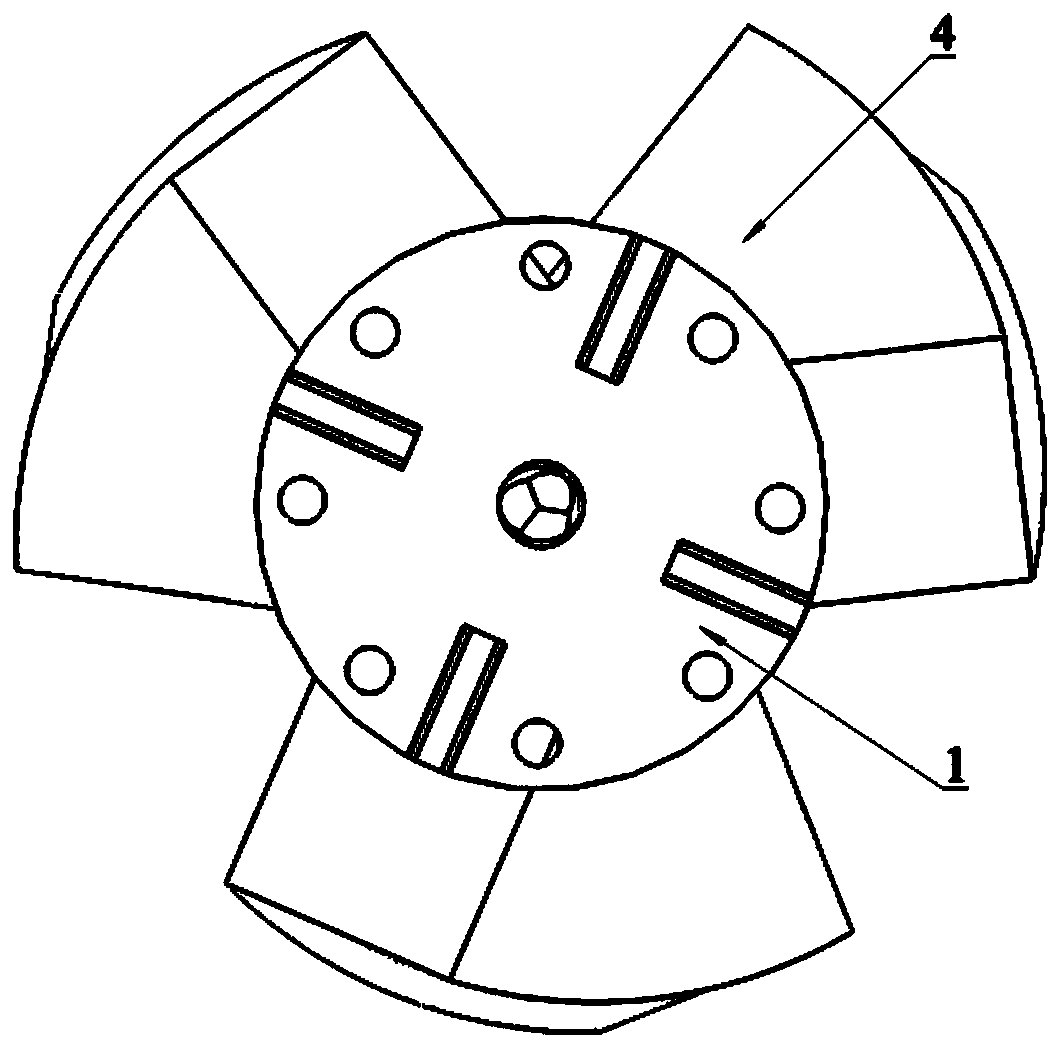

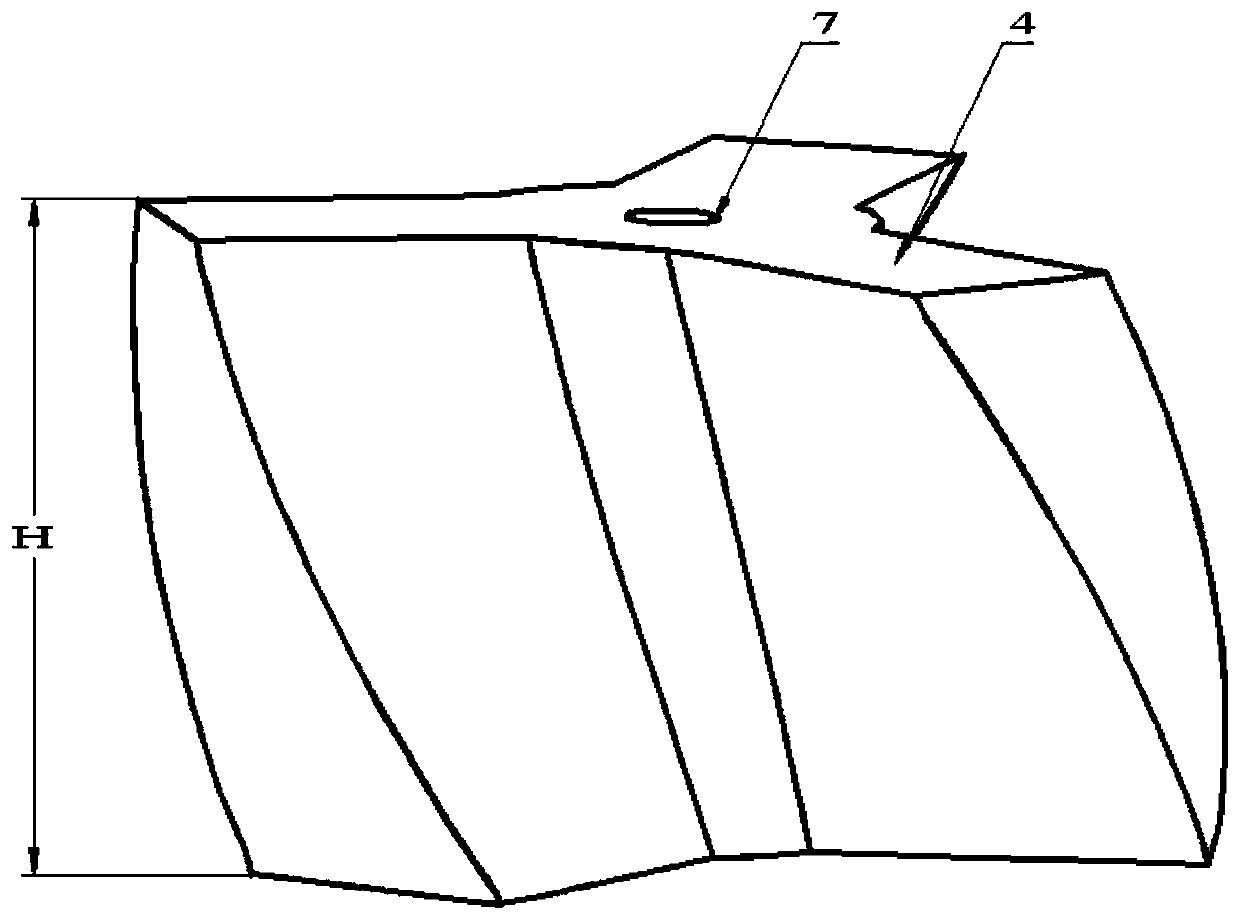

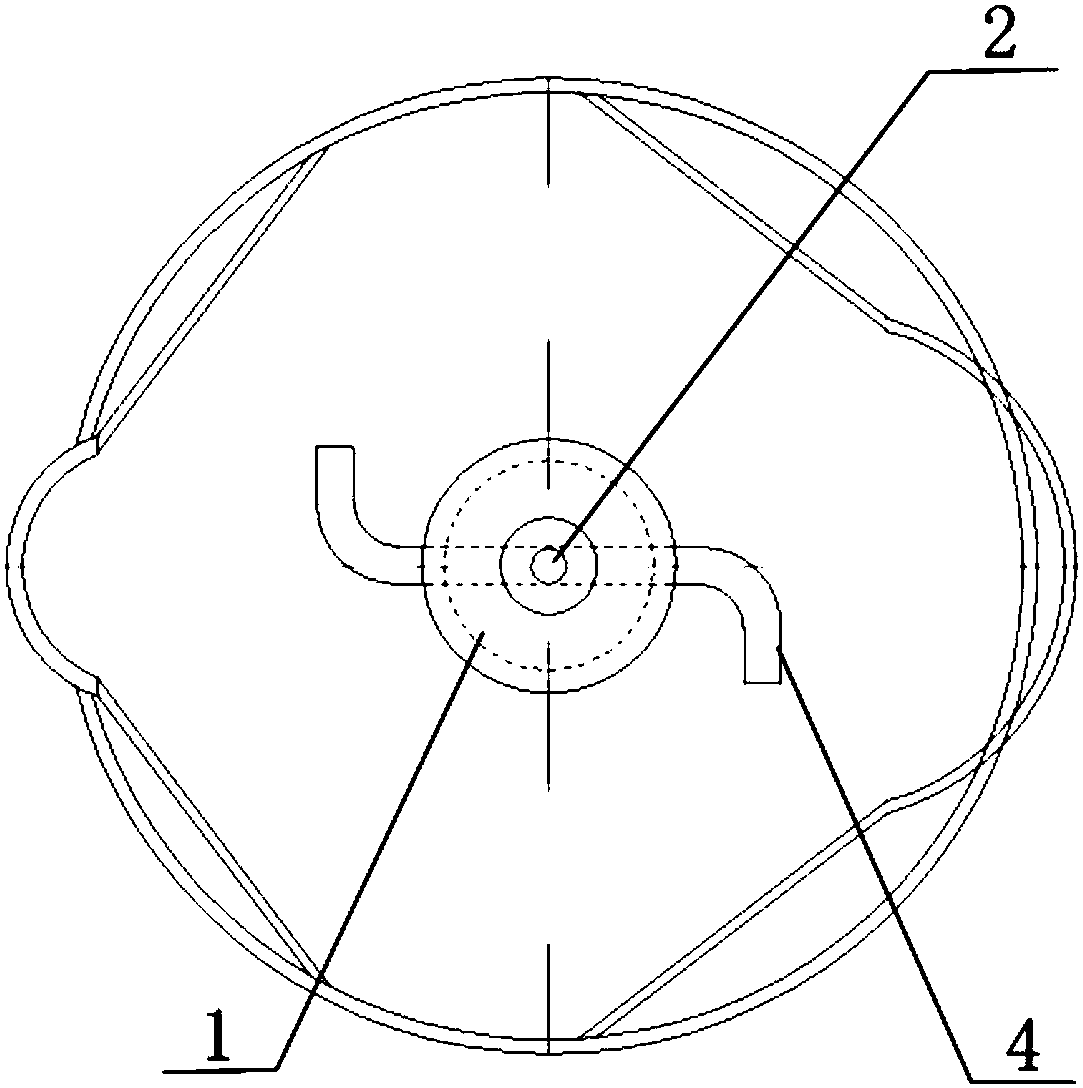

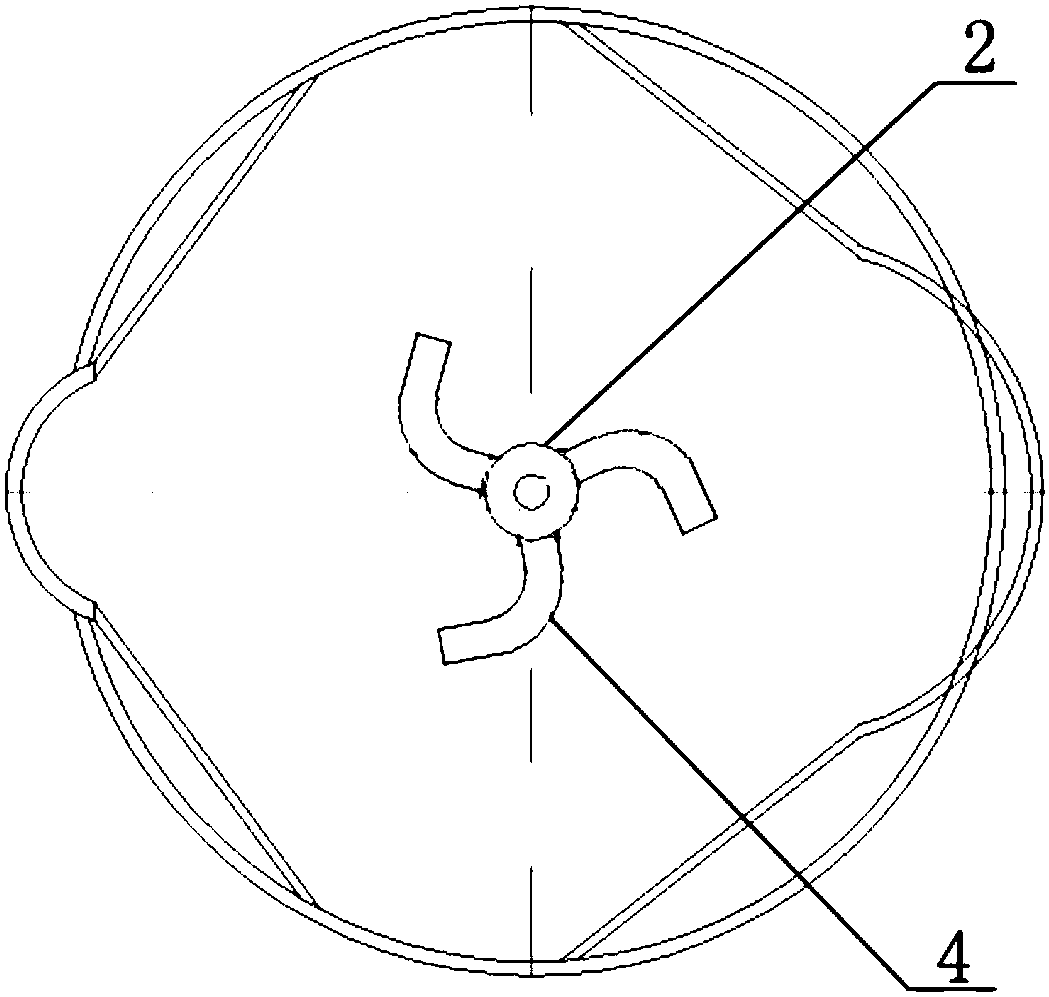

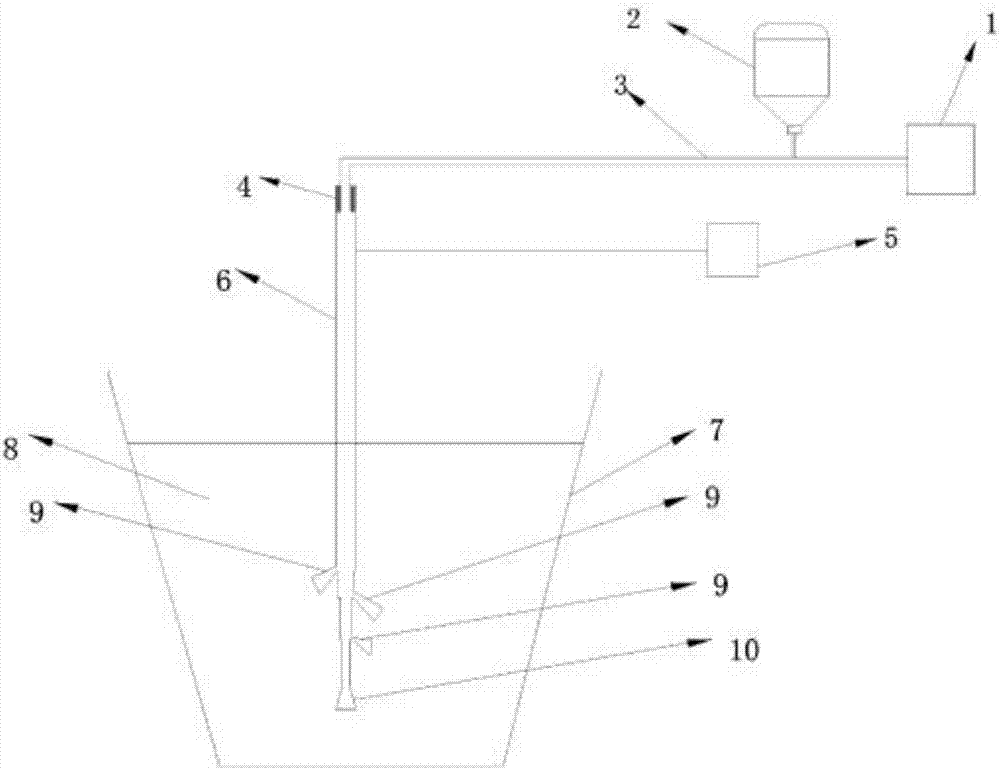

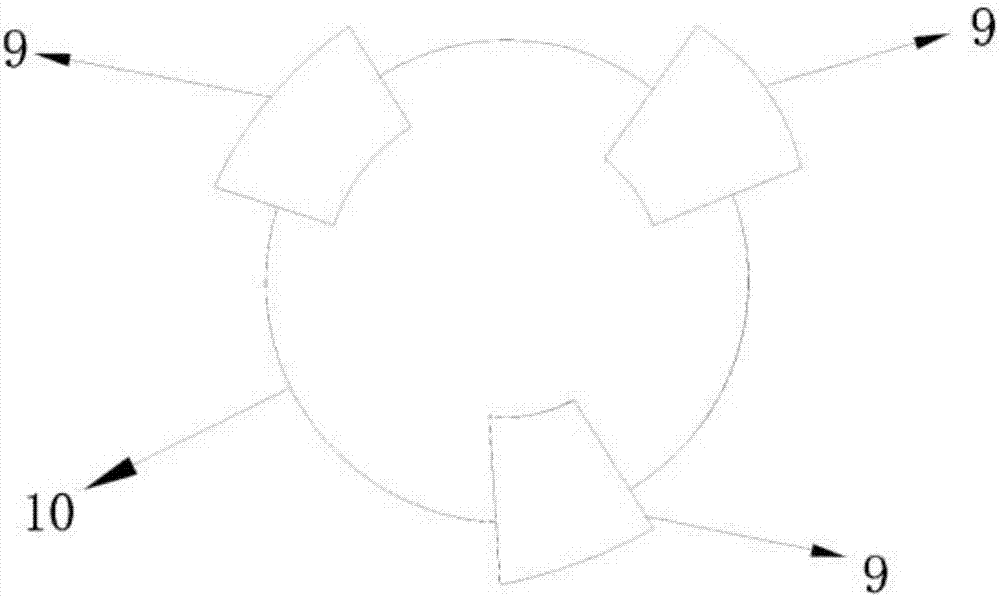

Injection type spiral stirrer for molten iron desulphurization

ActiveCN110699508AIncrease entrainment cycle flowReduce shear power consumptionRotary stirring mixersTransportation and packagingChemistryEngineering

The invention discloses an injection type spiral stirrer for molten iron desulphurization. A porous injection head (6) and spiral stirring blades (4) are arranged on a stirring shaft. All the stirringblades (4) are uniform in size and are distributed circumferentially evenly at intervals. The center of the whole stirring shaft achieves communication vertically to form a cavity-shaped straight-through injection pipe (7). The lower end of the straight-through injection pipe (7) forks at the porous injection head (6) to form a plurality of small injection conduits (8) in a through mode. All thesmall injection conduits (8) penetrate through the outer surface of the porous injection head (6), and thus a desulfurizer passes through the straight-through injection pipe (7) to be injected to theoutside of the porous injection head (6) in multiple directions from top to bottom. The stirring blades can enlarge the mixed area of axial and radial stirring of the desulfurizer, roll-suction circulation flow is increased, shear power consumption is lowered, and the stress conditions of the stirring blades are improved. The motion mode of desulfurizer vapor in molten iron can be further improved, thus the desulfurizer vapor does spiral rising motion, the dissolution degree is increased, and desulphurization is effective. The injection type spiral stirrer adapts to a long and thin type desulphurization molten iron ladle and meets the current desulphurization process requirements of stirring and injection.

Owner:WUHAN UNIV OF SCI & TECH

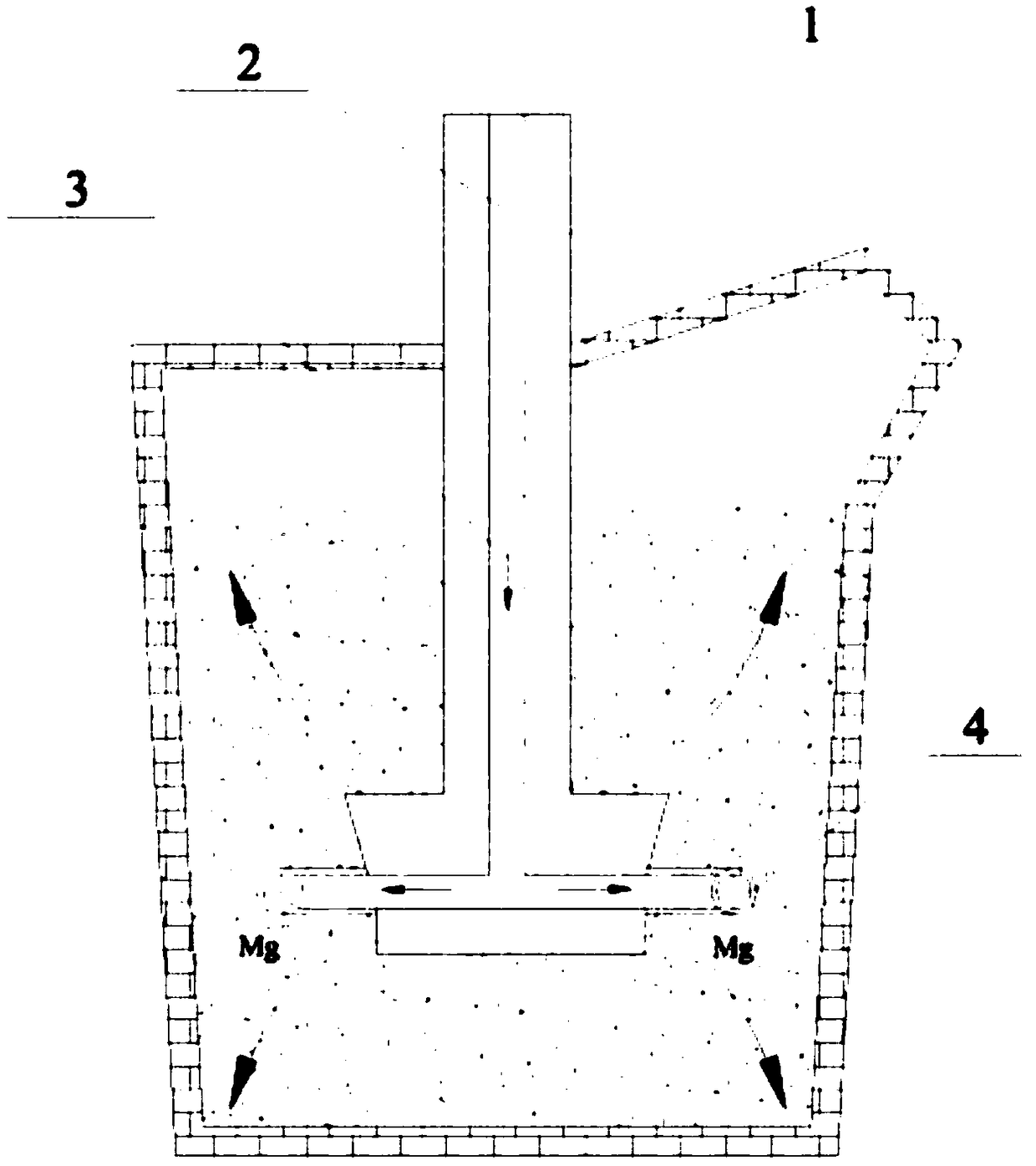

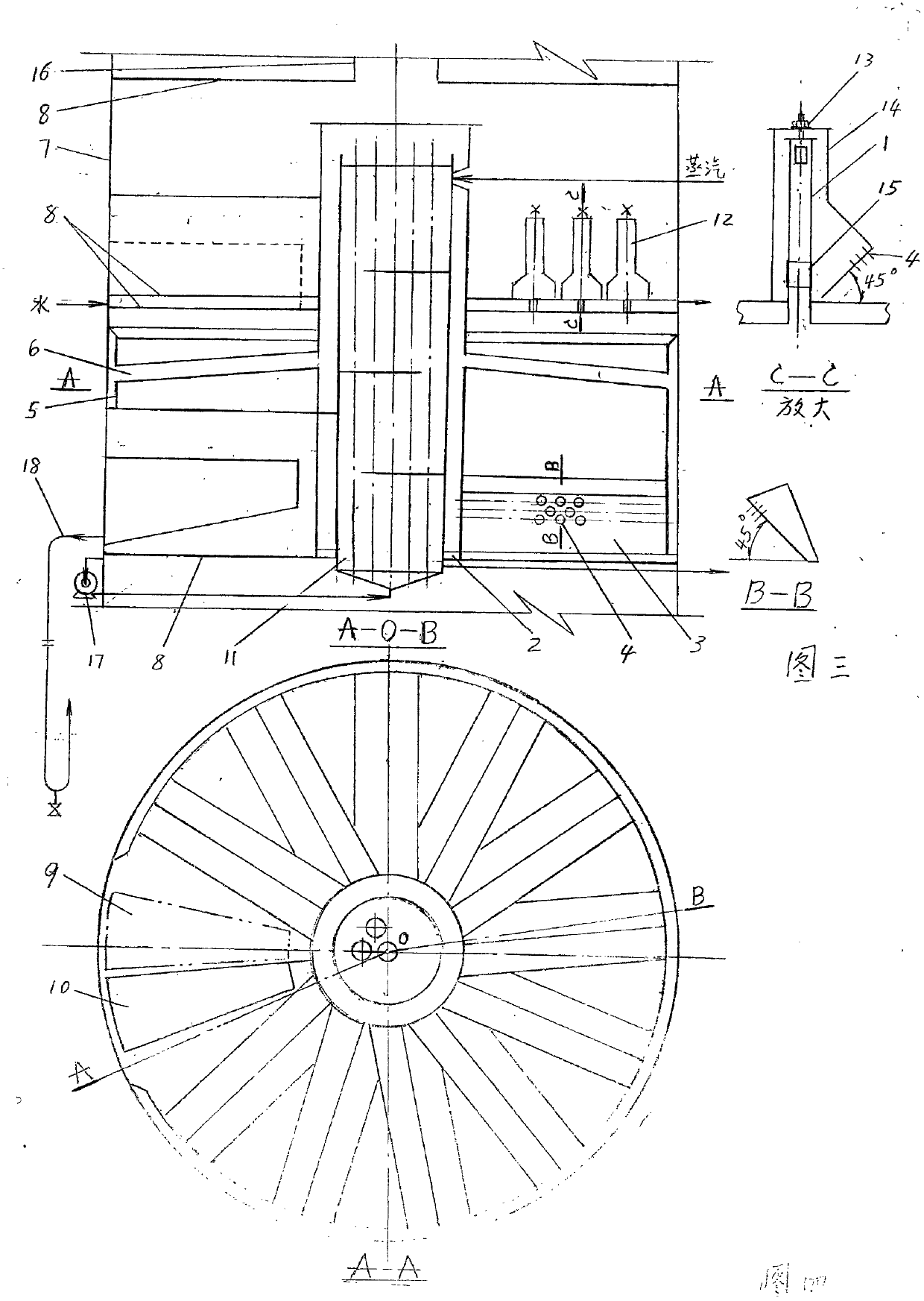

Horizontal type smelting furnace

InactiveCN101324401AImprove heat transfer performanceImprove mass transfer conditionsRotary drum furnacesInsulation layerCoal

A horizontal melting furnace comprises a furnace body support and a furnace body, wherein a housing, a heat insulation layer and a fireproof layer are sequentially arranged on the furnace body from outside to inside; the tail end of the furnace body is connected with a flue; the head of the furnace body is communicated with a pulverized coal inlet; the furnace body is horizontally arranged on the furnace body support; the horizontal melting furnace also comprises a rotating mechanism and a tilting mechanism; the rotating mechanism is arranged between the furnace body; and the tilting mechanism is arranged on the bottom of the furnace body support. The horizontal melting furnace solves the technical problems existing in the prior melting furnace in the background technology, such as poor heat transfer and mass transfer condition in the furnace, difficult material discharge, and environment pollution caused by escaped gas. The horizontal melting furnace has the advantages of high melting quality, simple discharge and no environment pollution.

Owner:XIAN HUAYING INDAL

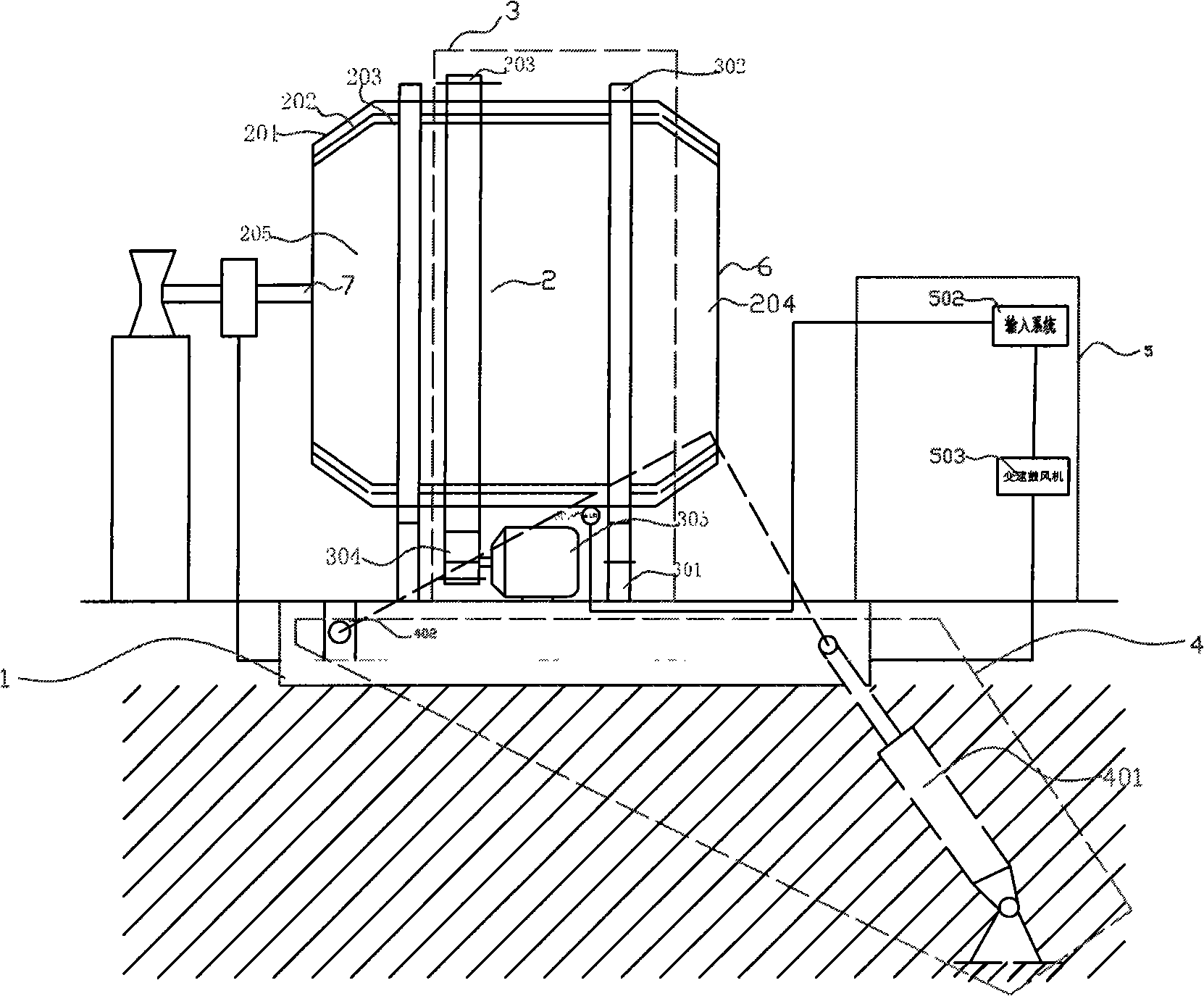

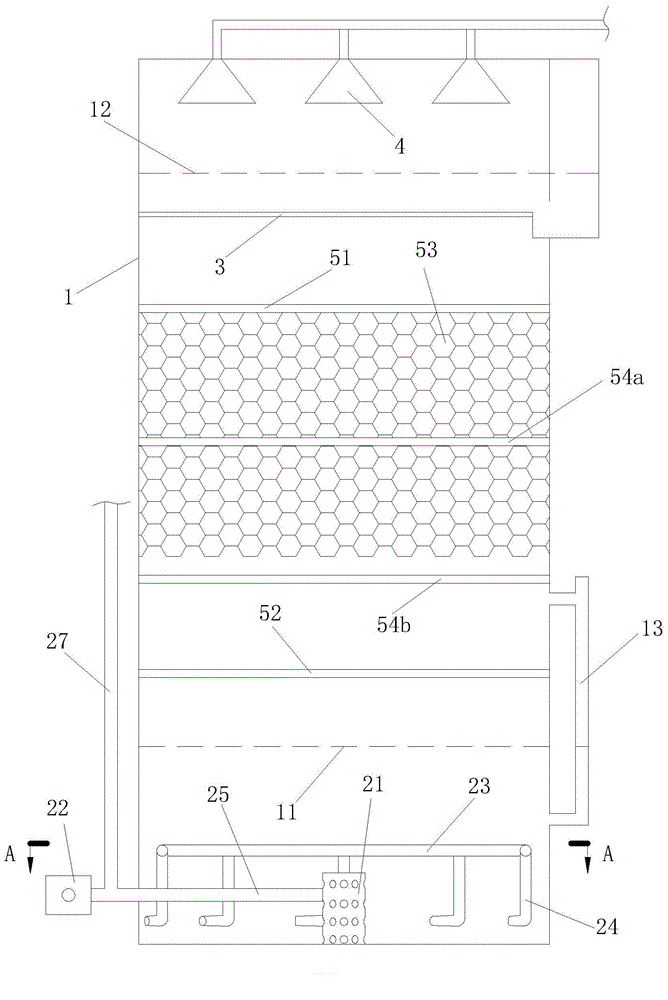

Biogas-lift reinforced anaerobic reactor and application thereof

InactiveCN101597561AImprove stabilityEasy loadingGas production bioreactorsWaste based fuelHigh concentrationReaction rate

A biogas-lift reinforced anaerobic reactor and application thereof belong to the waste recycling processing technical field. In the invention, the anaerobic reactor consists of two anaerobic reaction chambers one above to the other in series. The biogas generated by a first anaerobic chamber at the lower part is taken as power to realize internal recycle of mixed liquid at the lower part, so that reinforced pretreatment can be carried out on waste water; post treatment is continuously carried out on the waste water in a second anaerobic reaction chamber at the upper part, so that water discharge can meet the predetermined treating requirement. The invention has the advantages of high stability and loading and can deal with waste water with high-concentration poisonous substance to generate biogas. In the invention, the composite recycle method containing internal recycle, external recycle and biogas recycle is used to improve mass transferring condition between microorganism and matrix, quicken reaction rate and increase waste water processing efficiency.

Owner:JIANGNAN UNIV

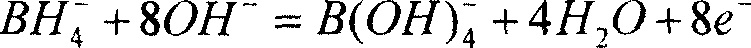

Method for using three-dimensional electrode as direct anode of hydroboron fuel cell

InactiveCN101013752ALarge mass transfer areaImprove mass transfer conditionsElectrolyte holding meansCell electrodesIon-exchange membranesAlkali hydroxide

The invention relates to one 3D electrode for direct borane fuel battery anode method, which is characterized by the following steps: processing filling bed electrode or multi-hole electrode as three dimensional anode and alkalinity liquid fuel, wherein, the cathode contacts oxygen, air and auricome agent and the middle ion exchange isolation film forms direct borane fuel battery system; borane fuel materials touching three dimensional electrode and alkalinity compound with materials feeding type as through or back entering type.

Owner:TAIYUAN UNIV OF TECH

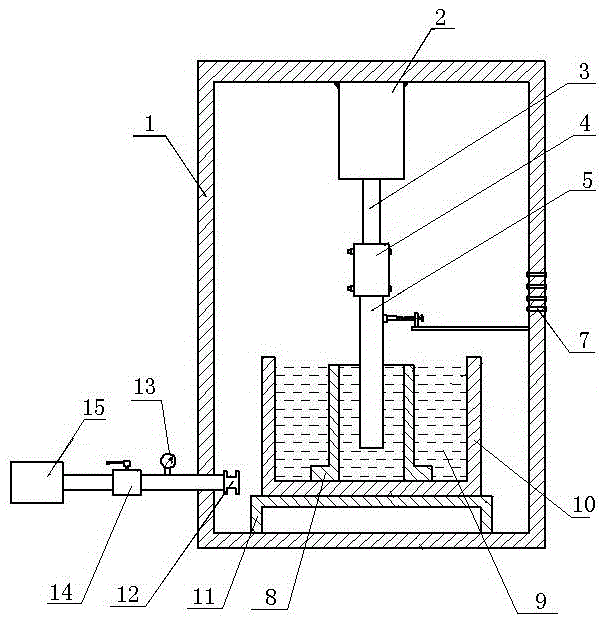

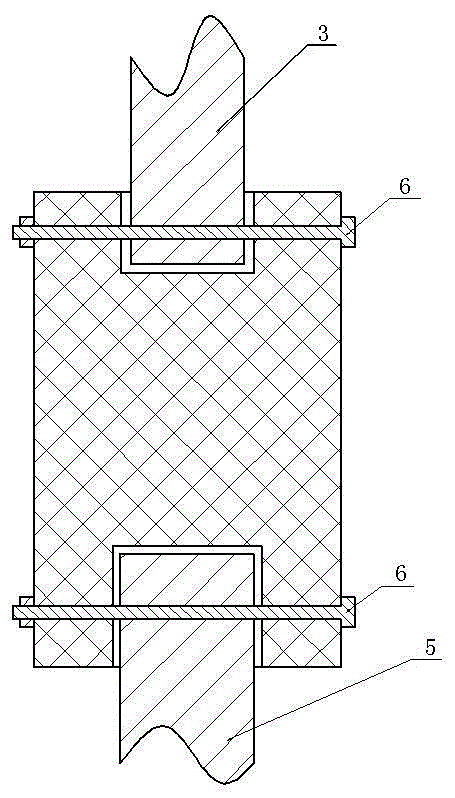

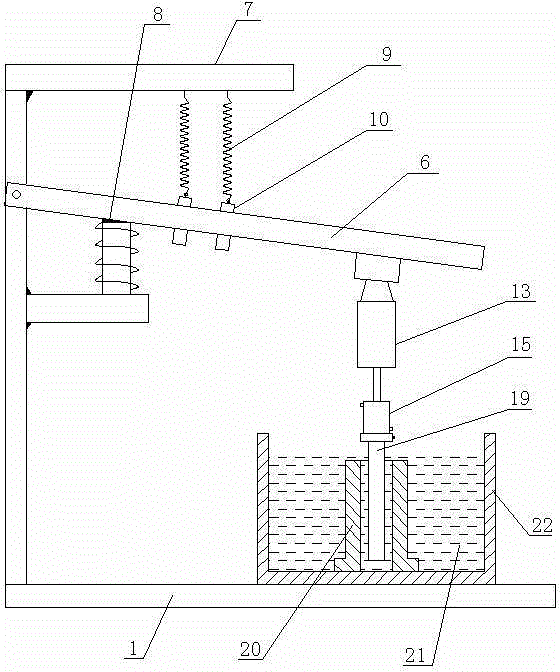

Anode rotary vacuum plating device based on PLC (Programmable Logic Controller) control

ActiveCN105063735AReduce hydrogen contentImprove bindingCellsPulse electroplatingProgrammable logic controller

The invention relates to an anode rotary vacuum plating device based on PLC (Programmable Logic Controller) control. A plating tank of the anode rotary vacuum plating device based on PLC control is placed in a vacuum box, a cathode is placed in the plating tank, a binding post of the cathode is welded on the upper surface of the cathode, an anode is inserted into the cathode and is connected with a motor through a clamping and fixing device, a carbon brush of an anode connecting device is propped against the anode, a plurality of wiring holes are formed in the vacuum box, a wiring sealing block is arranged in each wiring hole, an external electrode wire of the anode is connected with the positive pole of a pulse electroplating power supply through the corresponding wiring sealing block, an external electrode wire of the cathode is connected with the negative pole of the pulse electroplating power supply through the corresponding wiring sealing block, and two external electrode wires of a motor are connected with a PLC through the corresponding wiring sealing blocks respectively. The anode rotary vacuum plating device based on PLC control solves the problem of difficulty in electroplating of negative plating parts having large sizes or complicated structures is solved, and the operation difficulty is lowered.

Owner:JINING XINRUIDA INFORMATION TECH CO LTD

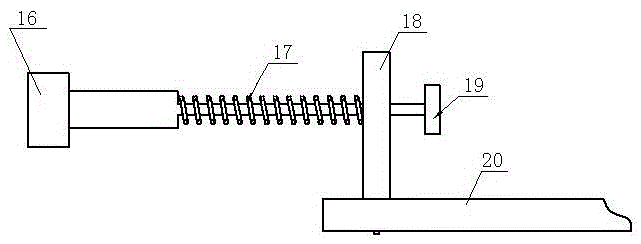

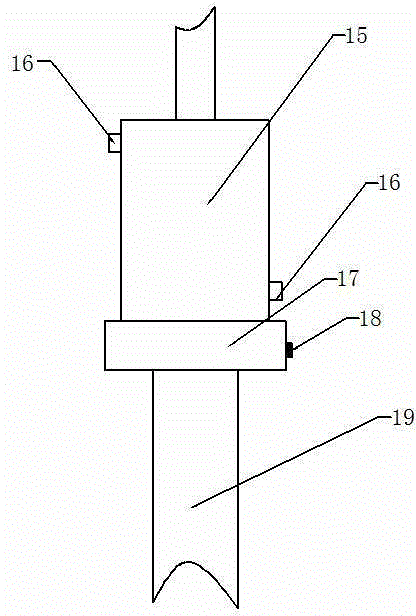

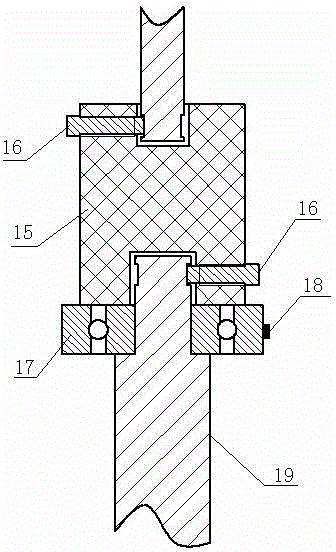

Slurry pump cylinder sleeve internal surface electroplating restoration anode rotation vibrating apparatus

ActiveCN104790021ASame concentrationPromote precipitationElectrodesAutomatic controlConcentration polarization

The invention relates to a slurry pump cylinder sleeve internal surface electroplating restoration anode rotation vibrating apparatus. The slurry pump cylinder sleeve internal surface electroplating restoration anode rotation vibrating apparatus comprises a support, a vibration beam, an electromagnet, a spring, an anode rotation device, a plating bath and a programmable logic controller (PLC), one end of the vibration beam is movably connected with the support through a pin, the spring is arranged between the vibration beam and a support crossbeam at the upper portion of the vibration beam, the lower end surface of the vibration beam is fixedly provided with a contact, the electromagnet is arranged just below the contact, the lower end surface of the vibration beam is also fixedly provided with a suspension block, the lower portion of the suspension block is provided with an inverted-U-shaped hole, a suspension rope traverses through the inverted-U-shaped hole and then is fixedly connected with the motor of the anode rotation device, the anode rotation device is connected with anode nickel, a cylindrical roller bearing is arranged outside the anode nickel, a terminal is welded outside the cylindrical roller bearing, the anode nickel is inserted into a cathode slurry pump cylinder sleeve, and the cathode slurry pump cylinder sleeve is placed in the plating bath; and the electromagnet and the motor are respectively connected with the programmable logic controller. The apparatus improves a concentration polarization phenomenon and improves the compactness of a plating layer through realizing automatic control of electroplating restoration.

Owner:海宁市黄湾镇资产经营有限公司

Efficient molten iron desulphurization spray gun

The invention provides an efficient molten iron desulphurization spray gun which comprises a guide pipe and a nozzle, wherein one end of the guide pipe is an immersing end which stretches into a ladle, and the guide pipe is immersed under the molten iron liquid level if being used; the other end of the guide pipe is located out of the ladle and is separately connected to a magnesium source and a pneumatic air source; the nozzle is an arc-shaped pipefitting and is connected to the outlet of the immersing end of the guide pipe for spraying magnesium steam out, so that magnesium steam moves spirally in the molten iron. The efficient molten iron desulphurization spray gun adopts the arc-shaped nozzle, so that particle magnesium rotates in the molten iron, and the magnesium ascends spirally inthe molten iron under the action of buoyancy force; under the same deep desulphurization condition, the contact time of the magnesium steam and the molten iron is prolonged greatly, and meanwhile, high pressure nitrogen carrying the magnesium steam ascends spirally to play a certain stirring role in the molten iron, too, so that the transfer speed of the magnesium steam is improved, the solubilityof magnesium is improved, and the desulphurization efficiency is further improved.

Owner:DAYE SPECIAL STEEL CO LTD

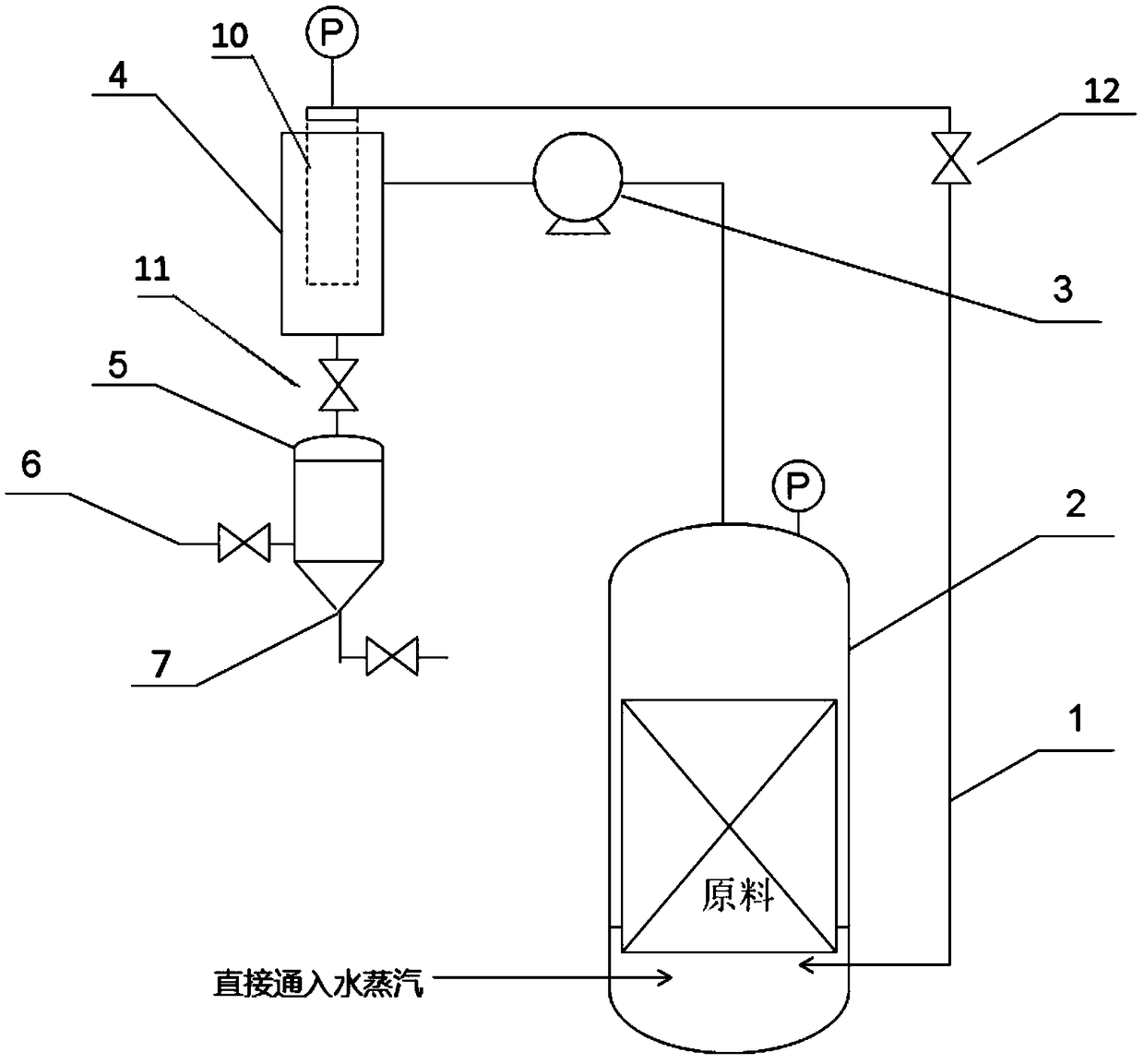

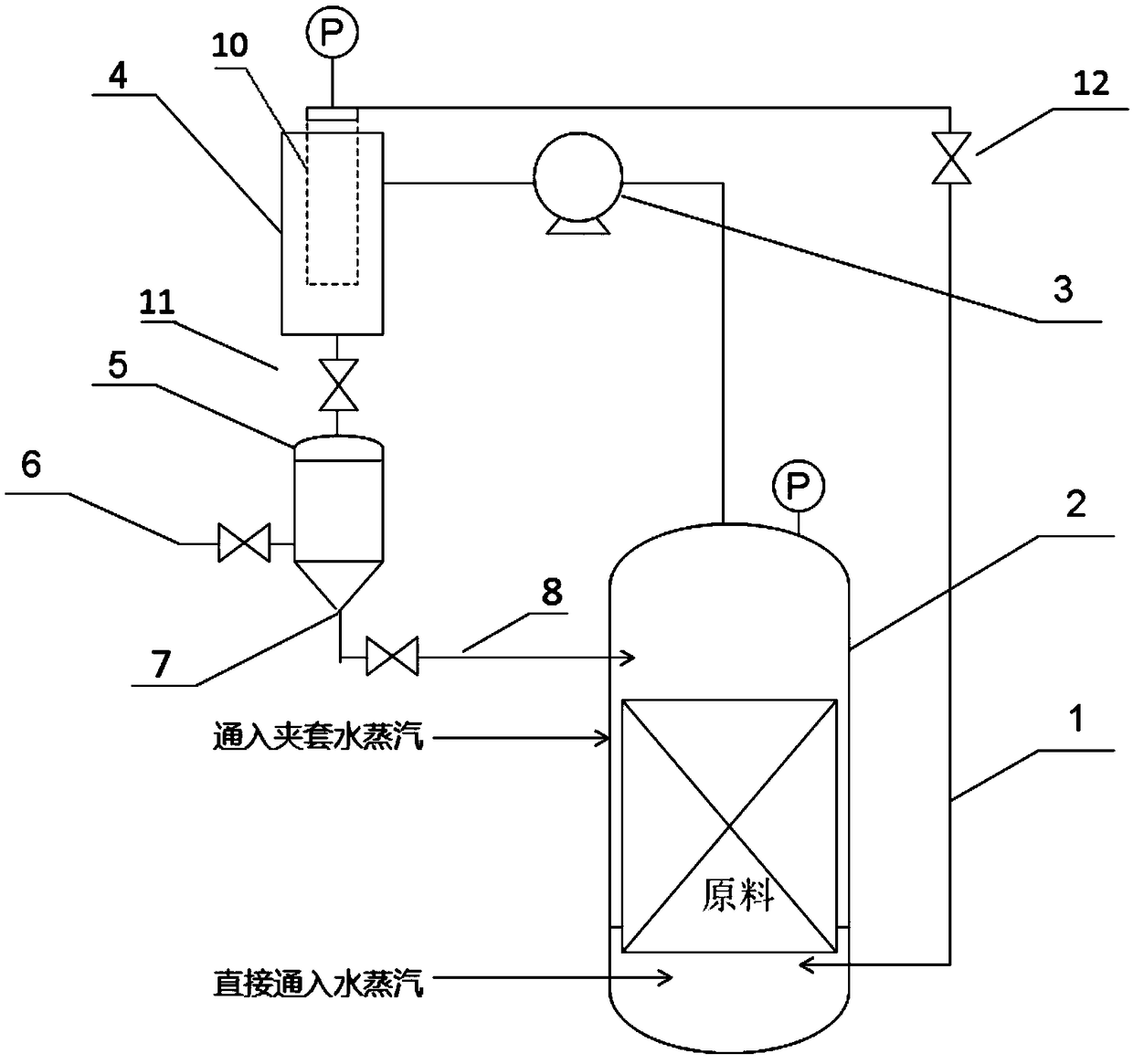

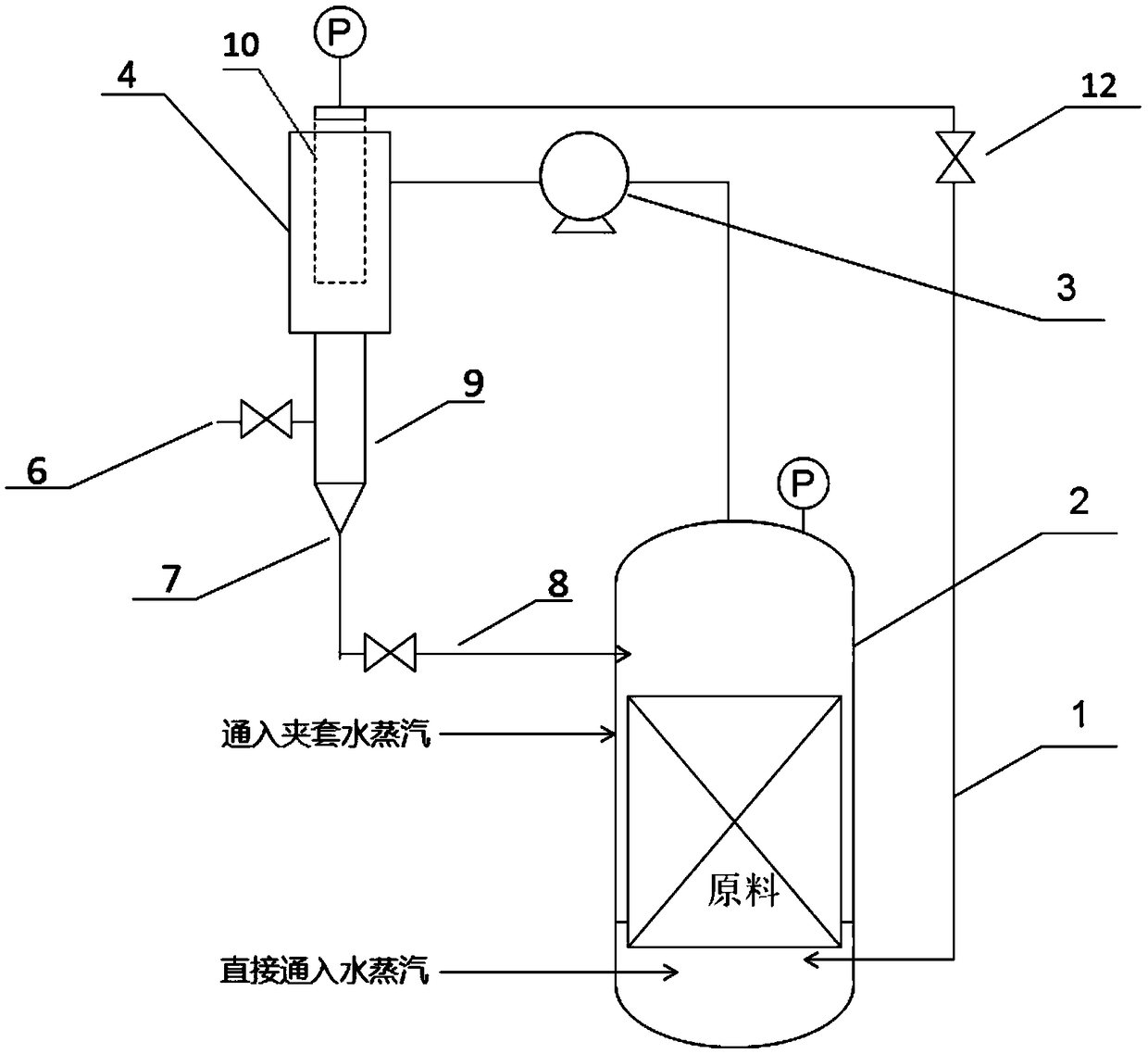

Extraction device and extraction method for volatile plant essential oil

ActiveCN109207262AReduce residual lossReduce lossesDistillation in boilers/stillsVapor condensationGas phaseWater vapor

An extraction device and an extraction method for volatile plant essential oil are disclosed. The device includes a distillation kettle, a gas phase booster pump, a partial condensation and liquid separation unit and a gas phase circulating pipeline. An outlet of the distillation kettle communicates with an inlet of the gas phase booster pump. An outlet of the gas phase booster pump communicates with an inlet of the partial condensation and liquid separation unit. The top of the partial condensation and liquid separation unit communicates with the distillation kettle through the gas phase circulating pipeline provided with a valve. The partial condensation and liquid separation unit is provided with an essential oil product outlet and an aromatic water outlet. The device can effectively increase the extraction efficiency of volatile essential oil, can greatly reduce steam consumption, can be achieved through upgrading and rebuilding a conventional industrial steam distillation device and has a wide application and promotion prospect.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Treatment method applied to chemical industrial wastewater

InactiveCN106007207ASolve processing problemsReduce the content of harmful substancesWater treatment parameter controlTreatment using aerobic processesHazardous substanceTherapeutic effect

The invention discloses a treatment method applied to chemical industrial wastewater. The treatment method comprises the following treatment steps of (a) chemical industrial wastewater pretreatment, (b) biochemical treatment of chemical industrial wastewater and (c) physical treatment of chemical industrial wastewater. According to the treatment method, the chemical industrial wastewater is sequentially subjected to the chemical industrial wastewater pretreatment, the biochemical treatment of chemical industrial wastewater and the physical treatment of chemical industrial wastewater, and the chemical industrial wastewater reaching the discharge standard is obtained. The treatment method is especially suitable for treatment of organic chemical industrial wastewater having strong biological toxicity and poor biochemical properties and can deeply treat chemical industrial wastewater, the harmful matter content in the treated wastewater is reduced to the most degree, the lower treatment degree is avoided, and accordingly the problem that treated wastewater still cause large environmental pollution is solved. In addition, in the wastewater treatment process, all links can be performed in order, the treatment method is simple in structure, scientific, convenient, strong in pertinence, high in automation degree, low in actural application cost, advanced in technology and good in treatment effect, and the chemical industrial wastewater treatment problem is well solved.

Owner:衢州市协成化工有限公司

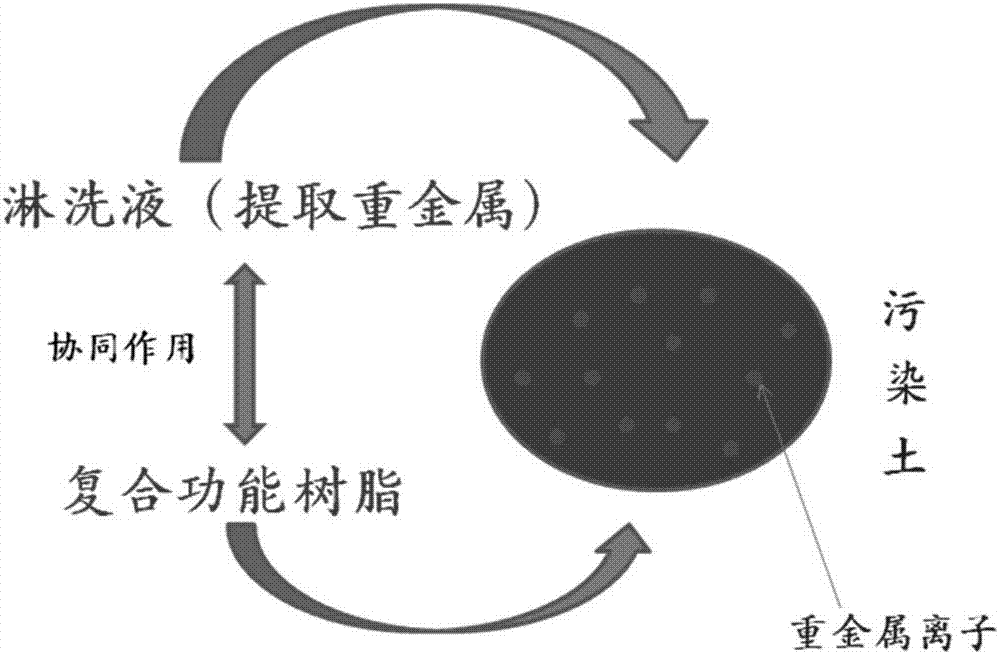

In-situ repairing method of heavy metal polluted soil

ActiveCN107303586AImprove mass transfer conditionsEasy farmingContaminated soil reclamationSodium acetateCrop cultivation

The invention discloses a method for repairing heavy metal polluted soil, and particularly discloses an in-situ repairing method of heavy metal polluted soil by utilizing compound functional resin and leacheate. The method comprises the following steps: (1) embedding the compound functional resin into heavy metal polluted soil; and (2) wetting the heavy metal polluted soil with the leacheate, wherein the compound functional resin is metal compound loaded ion exchange resin, and the metal compound is zirconium phosphate or zirconium dioxide; and the leacheate is citric acid, sodium acetate, sodium nitride or ammonium nitrate solution. By adopting the method, the soil structure and property are not changed during in-situ soil repairing, and late crop cultivation is facilitated; and the compound functional resin can be recycled, does not generate secondary pollution, can be used for reducing cost and increasing economic benefit, is not influenced by environmental conditions, and is simple in method.

Owner:QINHUANGDAO CLOUD CUBE ENVIRONMENTAL ENG

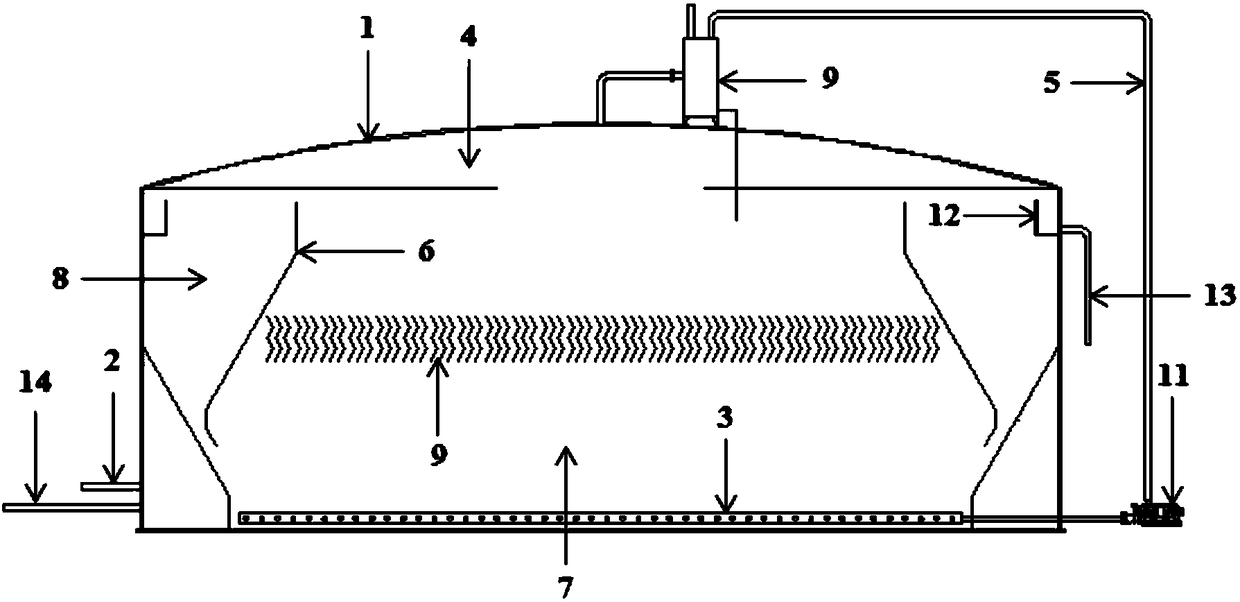

Anaerobic reactor for sewage treatment

PendingCN108358312ALow profileThe shape can be designed lowBioreactor/fermenter combinationsBiological substance pretreatmentsActivated sludgeSewage

The invention relates to the field of anaerobic reactors, and discloses an anaerobic reactor for sewage treatment. The anaerobic reactor comprises a tank (1), a sewage inlet pipe (2) arranged on one side of the tank (1), an aerating pipe network (3) arranged on the bottom of the tank (1), and a methane gathering area (4) located on the top of the tank (1), anaerobic activated sludge for degradingorganic pollutants in sewage is arranged in the tank (1), and the methane gathering area (4) is communicated with the aerating pipe network (2) through a methane return pipe (5). The anaerobic reactorutilizes methane return to enhance the mass transfer condition in the anaerobic reactor, consequently, the shape of the anaerobic reactor can be designed to be short in order to realize heat preservation, and moreover, high treatment efficiency can be kept as well.

Owner:安徽久吾天虹环保科技有限公司

Adding method of antimony in smelting process of antimony-containing steel

ActiveCN107177772AReduce volatilityImprove mass transfer conditionsAntimony compoundsSmelting process

The invention discloses an adding method of antimony in the smelting process of antimony-containing steel. The adding method comprises the steps that an aluminium alloy and an antimony alloy are put into a steel packing tin; then the steel packing tin is heated to 700-900 DEG C through a heating method, and heat preservation is conducted for 0.5-2 h, and thus the two alloys in the packing tin are molten, but the steel packing tin is not molten; in the converter tapping process, the steel packing tin containing the liquid aluminium alloy and the liquid antimony alloy is added into liquid steel in a ladle, the steel packing tin is molten by the liquid steel, and the liquid aluminium alloy and the liquid antimony alloy are fused into the liquid steel; and the mass ratio of the antimony alloy to the aluminium alloy is 1:1-4:1. According to the adding method, volatilization of antimony and antimony compounds can be reduced.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

Desulfurization spraying gun

ActiveCN106987684AReduce the chance of overflowIncrease the range of responseEngineeringMechanical engineering

The invention discloses a desulfurization spraying gun. The desulfurization spraying gun comprises a gun body; a primary spraying head and a plurality of secondary spraying heads are arranged on the gun body; the primary spraying head is arranged at the bottommost part of the gun body; the secondary spraying heads are arranged at the lower middle part of the gun body in a scattered manner; a blowing-spraying channel is formed in the gun body; and the primary spraying head and the secondary spraying heads are connected with the blowing-spraying channel. The desulfurization spraying gun can increase the magnesium utilization rate and improve the desulphurization efficiency.

Owner:SHANDONG IRON & STEEL CO LTD

Strengthening method for removing ammonia nitrogen and organic matters in rear activated carbon filter for ultrafiltration

InactiveCN103539279AReduce cloggingSolve the problem of insufficient dissolved oxygenWater contaminantsWater/sewage treatment bu osmosis/dialysisActivated carbonUltrafiltration

The invention discloses a strengthening method for removing ammonia nitrogen and organic matters in a rear activated carbon filter for ultrafiltration, particularly discloses a strengthening method for removing ammonia nitrogen and organic matters in the rear activated carbon filter for ultrafiltration in drinking water treatment, and aims to solve the problem that the capacity of the activated carbon filter for removing the ammonia nitrogen and the organic matters is limited. The strengthening method comprises the steps of firstly, arranging a coagulation sedimentation unit in front of an activated carbon filter, and arranging an ultrafiltration unit at the rear of the activated carbon filter; then, adopting different strengthening measures according to different concentrations of ammonia nitrogen and organic matters in inlet water of the activated carbon filter. The method comprises the following concrete steps: (1) when the concentration of the ammonia nitrogen is less than 1.5mg / L and the index of potassium permanganate is less than 3mg / L, changing the activated carbon filter to be in an upward flowing way; (2) when the index of the potassium permanganate is greater than 3mg / L, additionally arranging an ozone unit in front of the activated carbon filter in the step (1); (3) when the concentration of the ammonia nitrogen is greater than 1.5mg / L, aerating at the bottom of the activated carbon filter in the step (1); (4) when the concentration of the ammonia nitrogen is greater than 1.5mg / L and the concentration of the permanganate is greater than 3mg / L, combining the step (2) and the step (3).

Owner:HARBIN INST OF TECH

A kind of method for preparing 2,5-dichloronitrobenzene by continuous nitration

ActiveCN106083596BOptimize process flowWith automatic separation functionNitro compound preparationThree stageNitration

The invention discloses a method for preparation of 2, 5-dichloronitrobenzene by continuous nitration. The method comprises the steps of: adopting three-stage kettle type continuous reaction, adding sulfuric acid, nitric acid and p-dichlorobenzene in an extraction kettle into a first stage nitrification kettle simultaneously to carry out nitrification reaction, letting nitrification liquid enter a next stage nitrification kettle through self-carried raisers of all nitrification kettles in order to react, at the end of reaction in a third stage nitrification kettle, separating an oil phase and an acid phase, carrying out neutralization, washing and dehydration on the oil phase so as to obtain 2, 5-dichloronitrobenzene, internally recycling part of waste acid in the acid phase back to the first stage nitrification kettle, letting the residual waste acid enter an extraction kettle, and performing p-dichlorobenzene extraction, and then conducting separation to obtain acidic p-dichlorobenzene and extracted waste acid, concentrating the extracted waste acid into concentrated sulfuric acid, and making the concentrated sulfuric acid and acidic p-dichlorobenzene enter the first stage nitrification kettle for recycling. The method provided by the invention adopts automation control, cancels a mixed acid preparation procedure, simplifies the technological process, can realize continuous nitrification reaction, continuous nitrification liquid separation and continuous waste acid extraction.

Owner:江苏拓孚工程设计研究有限公司

Novel industrial wastewater treatment equipment

InactiveCN107935170AImprove mass transfer conditionsActive influenceWater treatment parameter controlMultistage water/sewage treatmentIndustrial wastewater treatmentPollutant

The invention discloses novel industrial wastewater treatment equipment. The novel industrial wastewater treatment equipment structurally comprises an equipment main body, a water inlet pipe, a motor,a control box, a water pipe structure, an adsorption precipitation device, a plug-flow aeration device and a temperature induction connection mechanism, wherein the water inlet pipe is vertically connected to the rearmost part of an upper end surface of the equipment main body; the adsorption precipitation device vertically penetrates through the leftmost part of an inner cavity of the equipmentmain body and is interpenetrated with the inner part of the water inlet pipe; the left half part of the plug-flow aeration device is mechanically connected to the middle part of an inner bottom surface of the adsorption precipitation device. According to the novel industrial wastewater treatment equipment disclosed by the invention, parts including the plug-flow aeration device, the temperature induction connection mechanism and the like are mutually matched, so that the temperature of industrial wastewater flowing through an adsorption precipitation part of the equipment can be detected in anindustrial wastewater treatment process, and mass transferring conditions of pollutants in a water treatment process are enhanced; a condition that water temperature is too high so that the activityof sludge is influenced is avoided; the industrial wastewater treatment effect of the equipment is ensured and the stable performance of the equipment is effectively improved.

Owner:泉州市西决三维科技有限公司

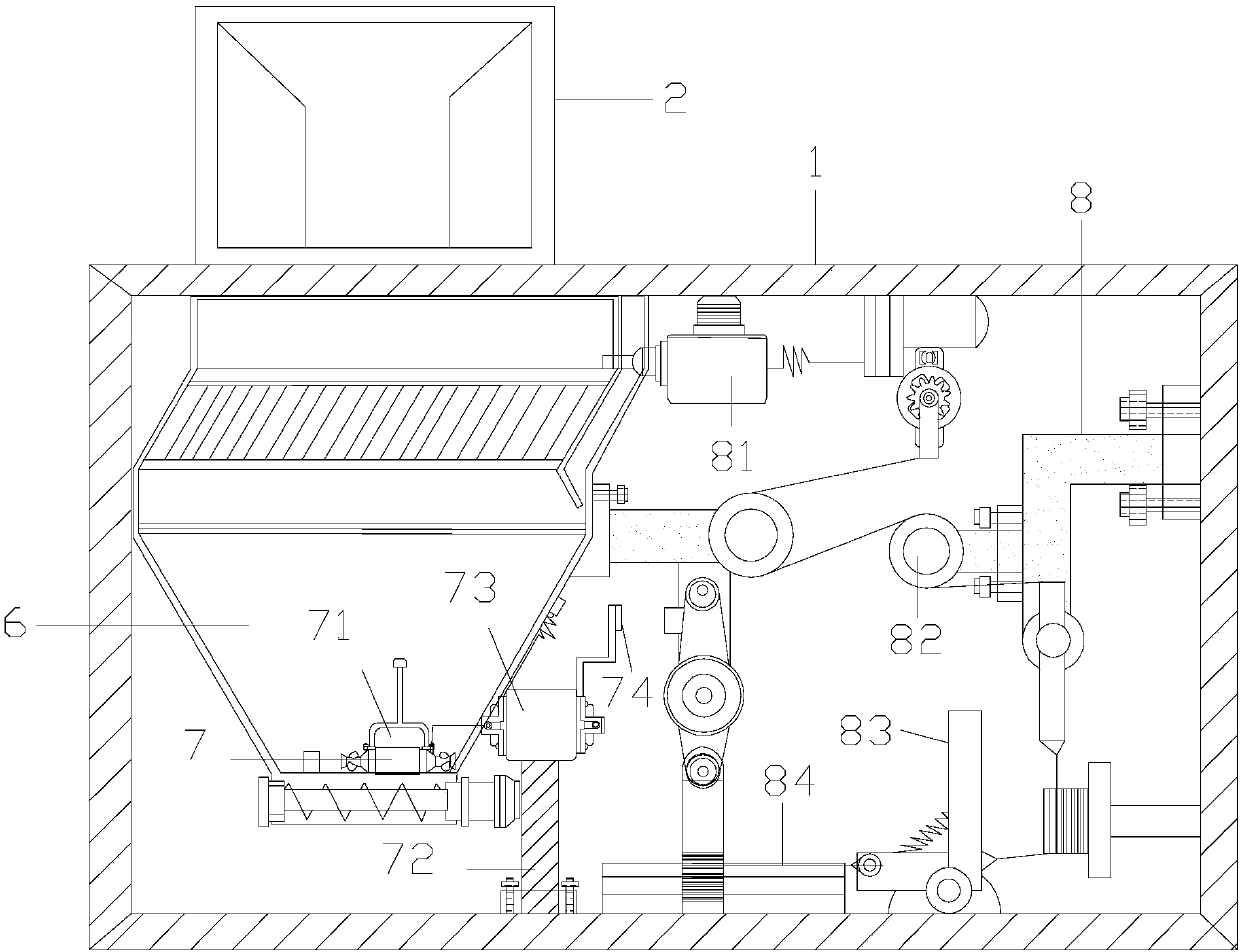

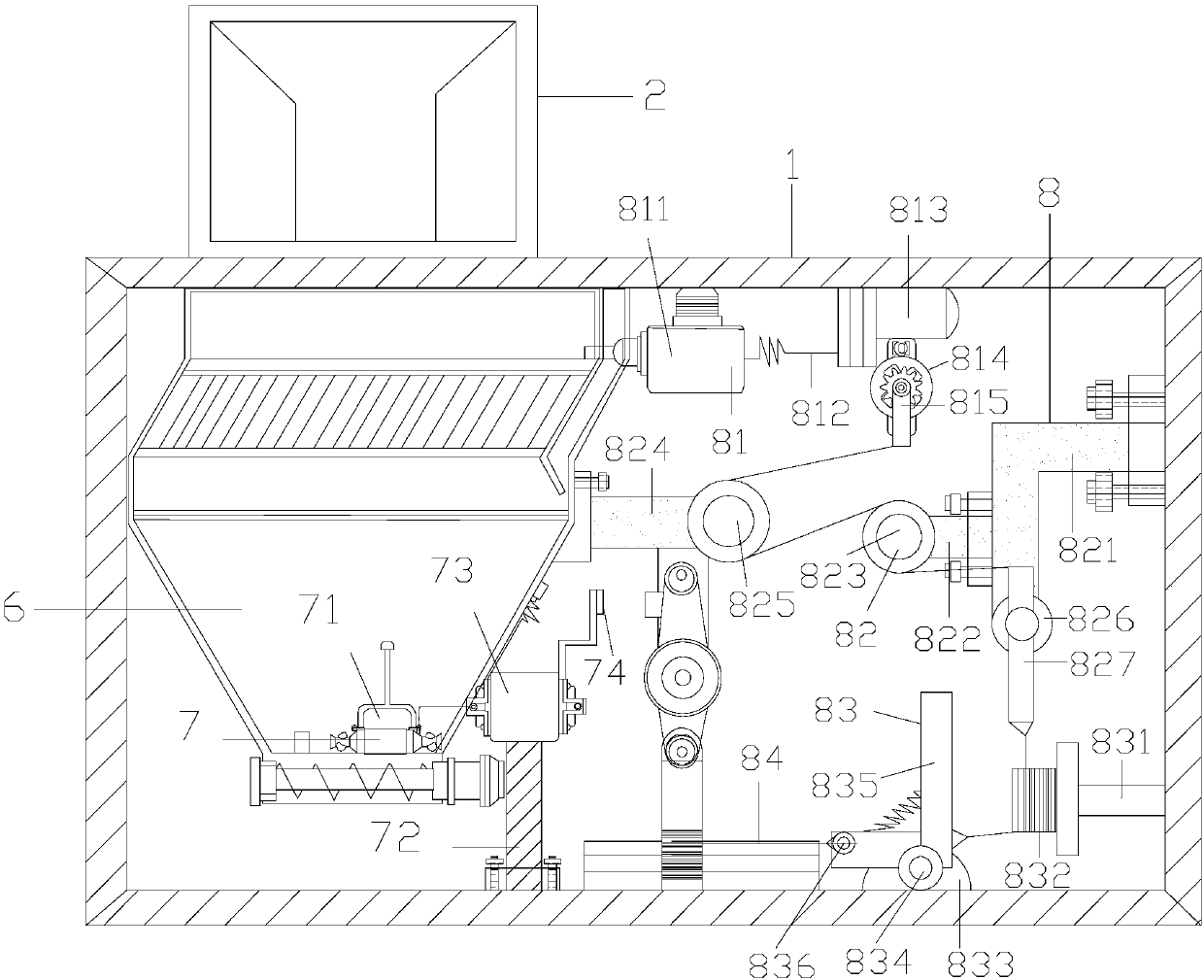

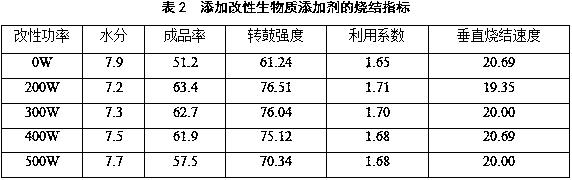

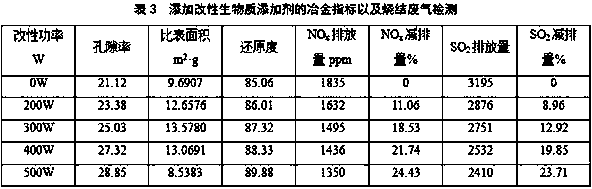

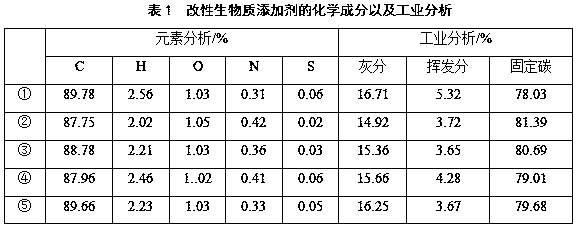

Preparation method of modified biomass iron ore sintering additive

The invention belongs to the field of additive preparation and particularly relates to a preparation method of a modified biomass iron ore sintering additive, in particular to a preparation method ofa modified biomass additive capable of lowering exhaust emission in production of iron ores and improving the iron ore sintering quality. The preparation method comprises the following steps of step 1, crushing a biomass material, and putting the crushed biomass material in an industrial microwave oven for modification treatment; step 2, spraying the treated biomass material with a Ca2+ mother liquor; and step 3, fully and uniformly mixing the materials, performing continuous pressing for 1-2mins under the effect of pressure of 20Mpa, and preparing massive particles with the particle size being 8-12mm to obtain the modified biomass additive. The technical scheme of the invention has important significance of reasonably utilizing clean energy, increasing the utilization ratio of resources and promoting emission reduction and benefit increase of the sintering industry.

Owner:UNIV OF SCI & TECH LIAONING

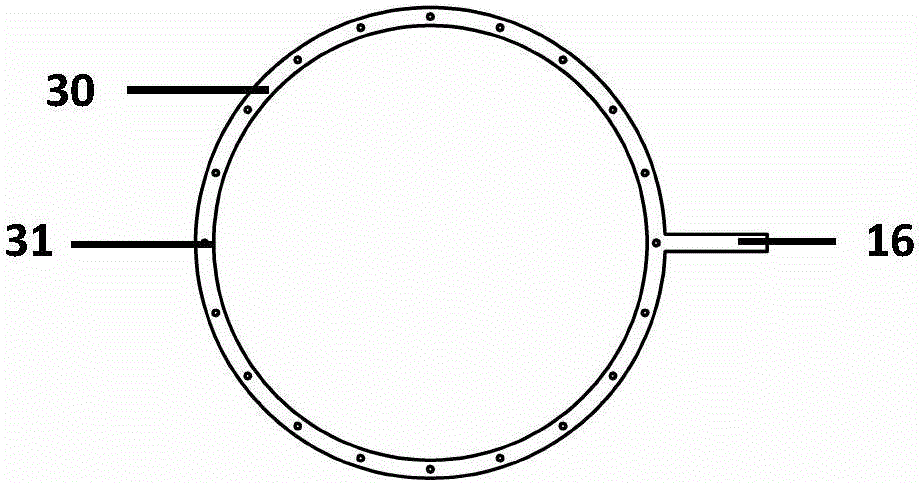

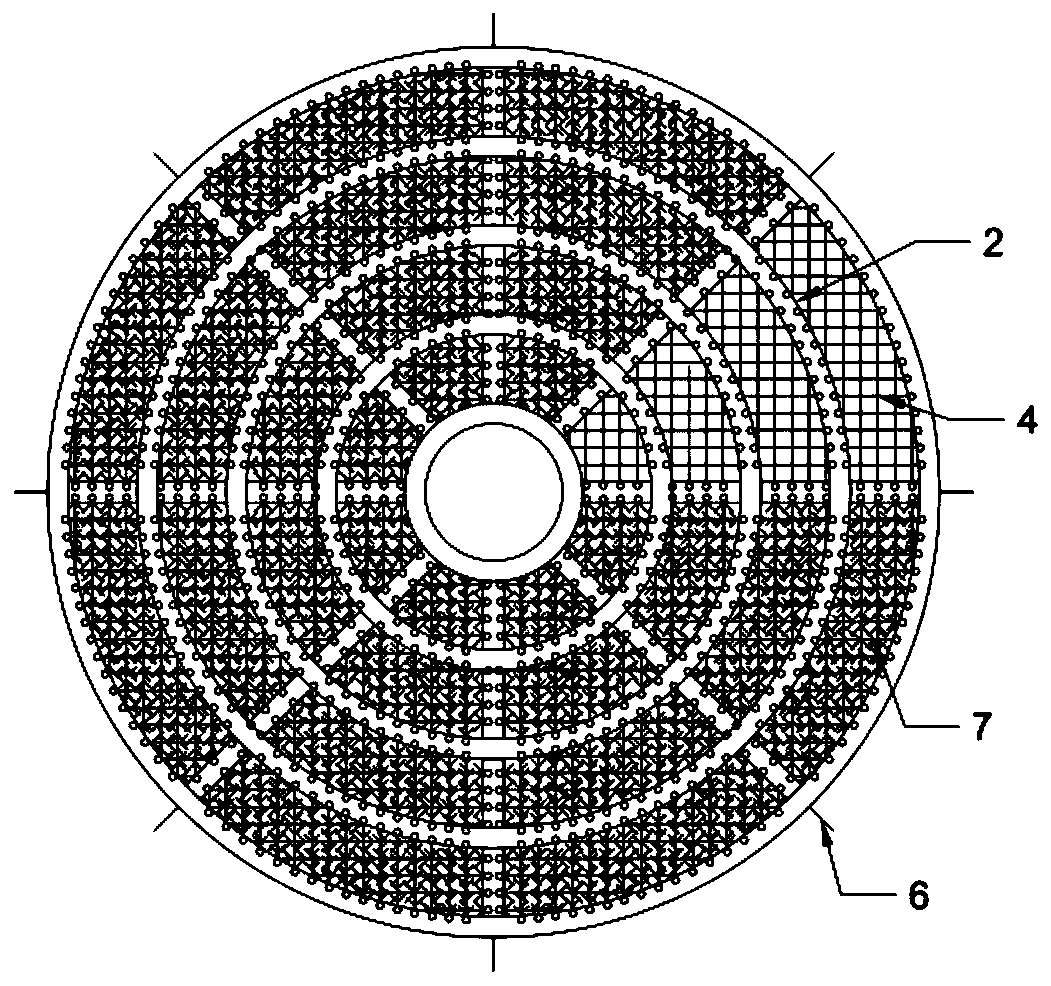

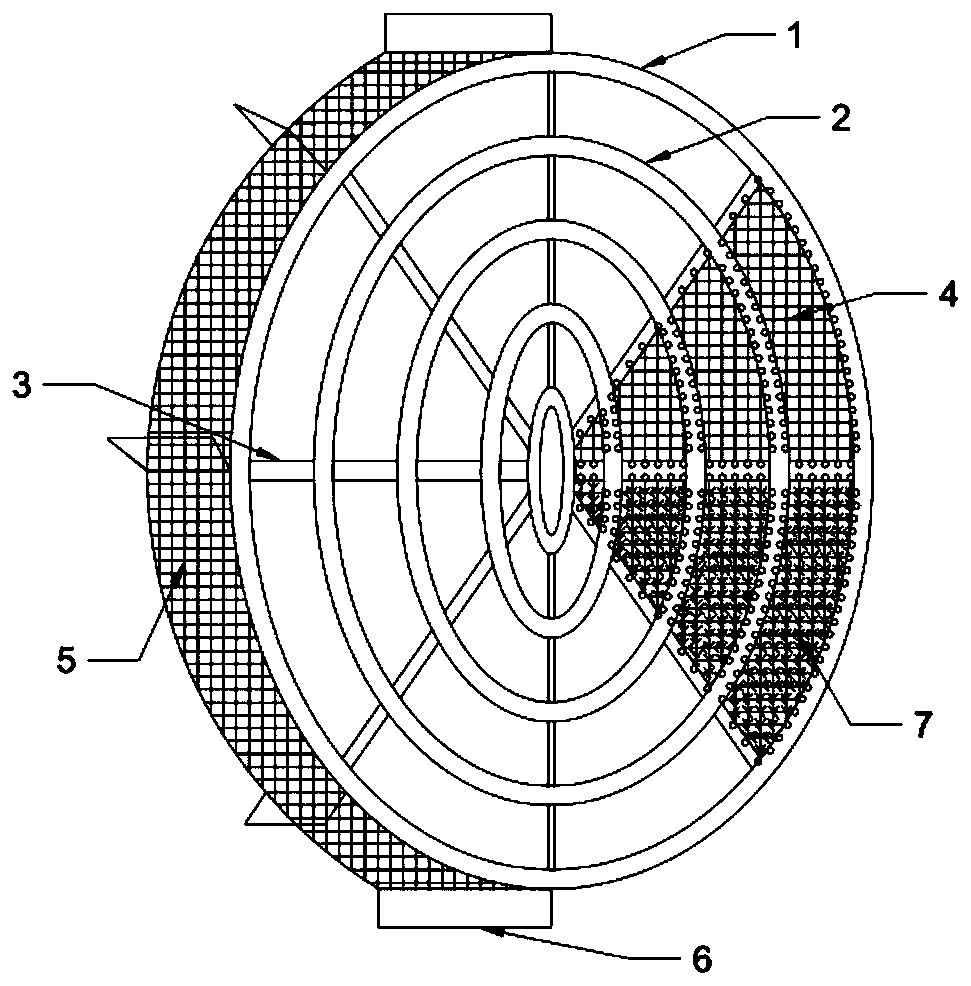

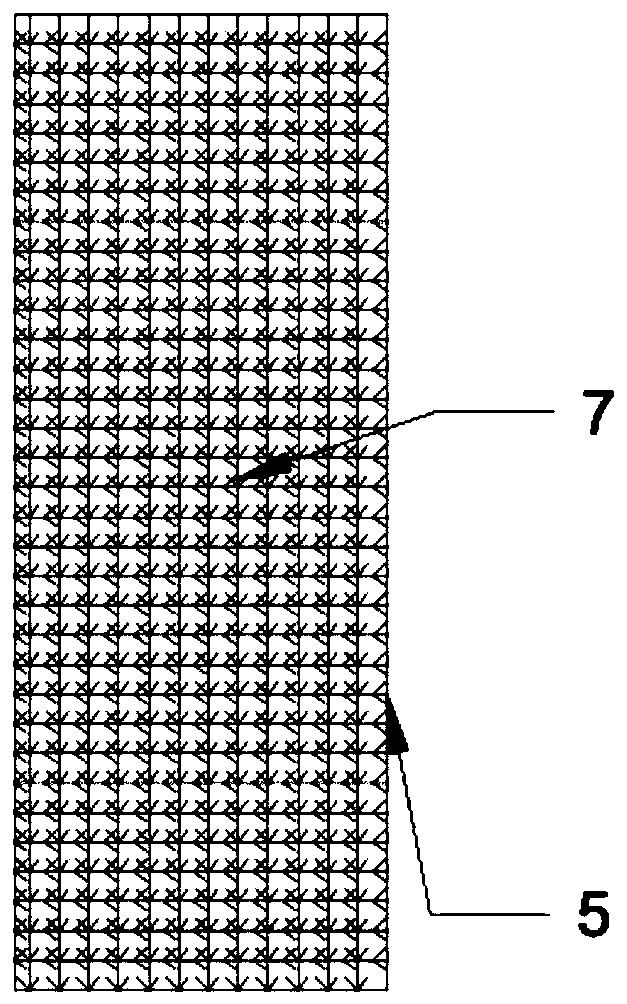

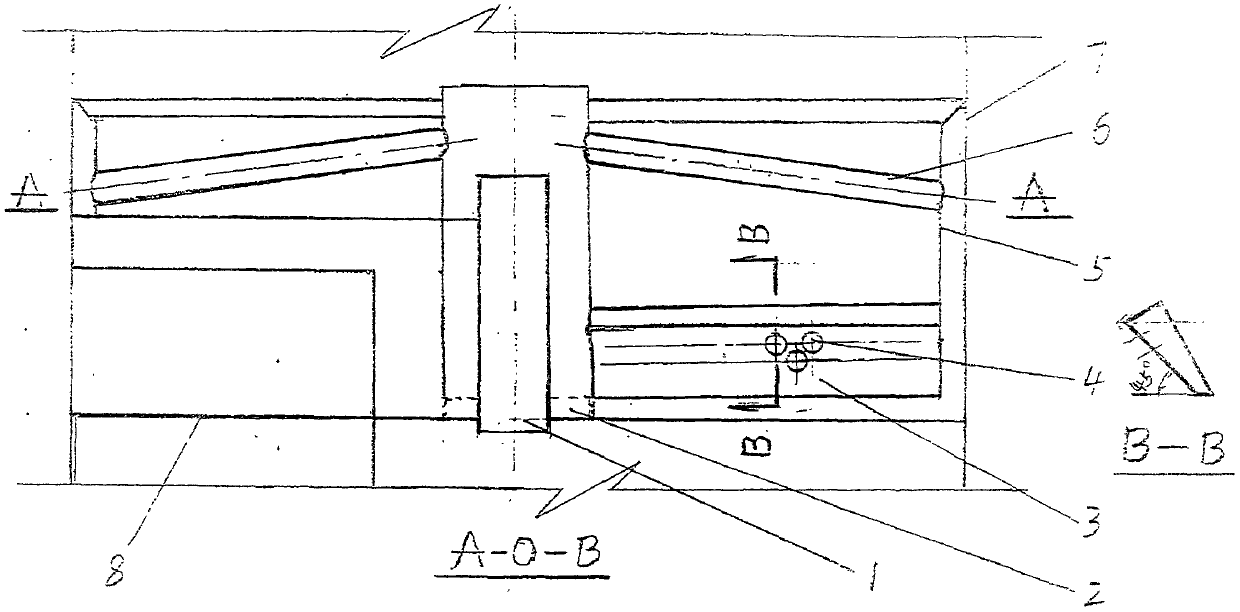

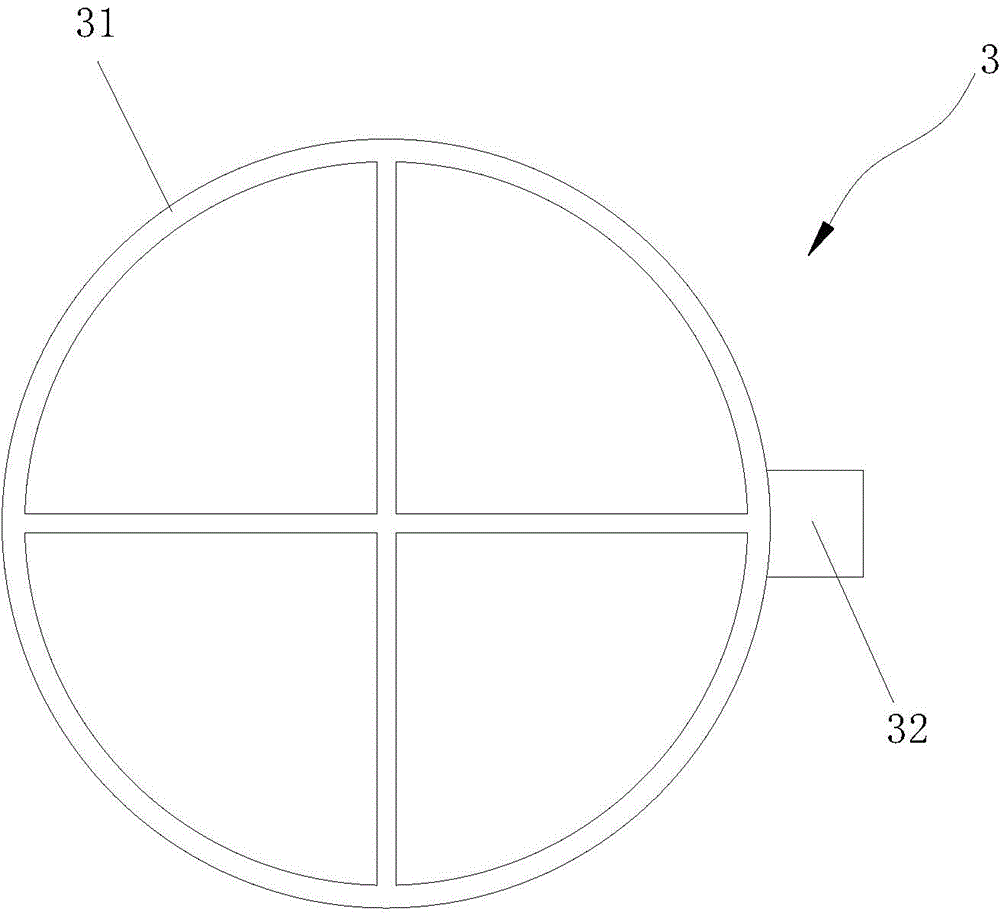

Biological rotating disc sheet capable of improving biofilm culturing amount

InactiveCN111377539AImprove space utilizationGood decontamination effectTreatment with aerobic and anaerobic processesBiotechnologyBiofilm

The invention discloses a biological rotating disc sheet capable of improving a biofilm culturing amount. The biological rotating disc sheet comprises a disc-shaped framework of a hollow-out structureand a net-shaped disc surface arranged on the disc-shaped framework. Three-dimensional elastic filler is fully distributed on the net-shaped disc face, and the disc-shaped framework is filled with polyurethane sponge filler. According to the biological rotating disc provided by the invention, the biofilm culturing rate of the disc sheet is increased, and the defects that the biofilm culturing amount of an anoxic layer is low, and a biofilm is not easy to be implanted, easy to agglomerate, not easy to be stripped and the like are effectively improved. According to the invention, different fillers are utilized to create a proper environment for aerobic bacteria and anaerobic bacteria on the same disc sheet, so that the growth of biological membranes of an aerobic layer and an anoxic layer is facilitated, the membrane forming rate is greatly improved, and biochemical organic pollutants in water are efficiently treated.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +1

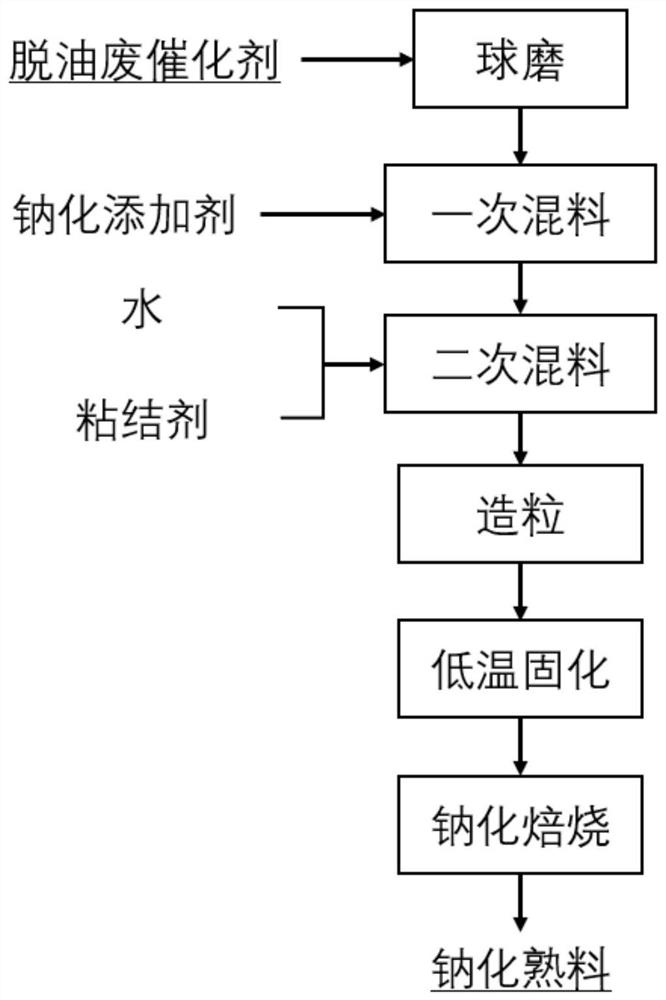

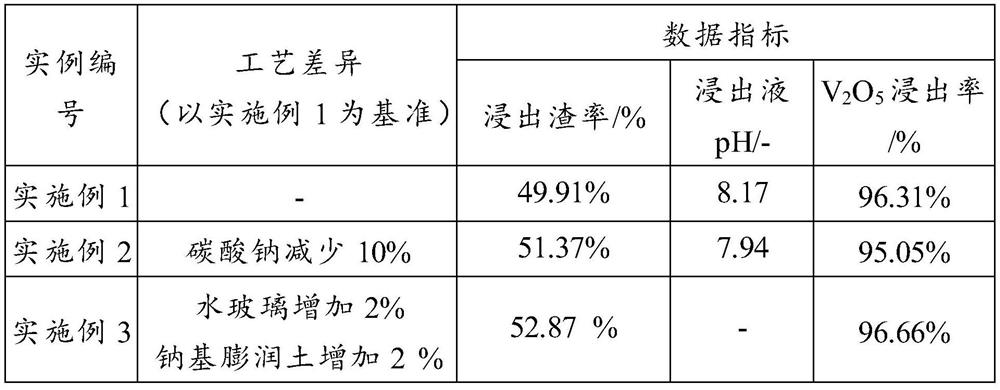

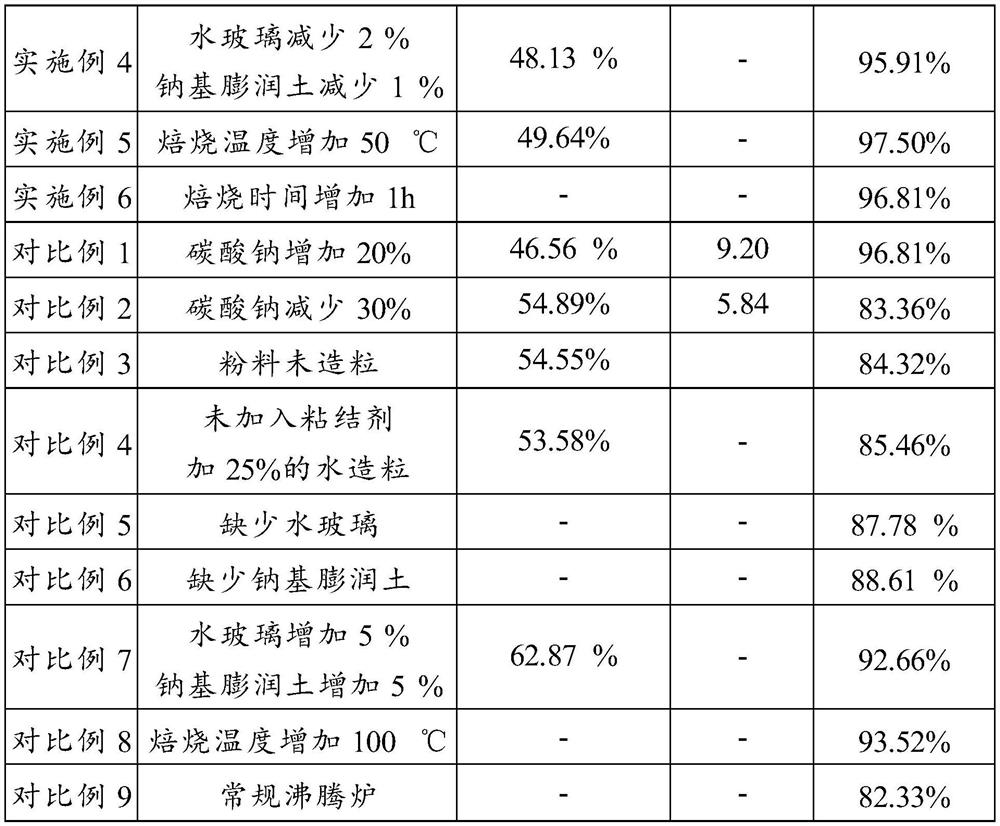

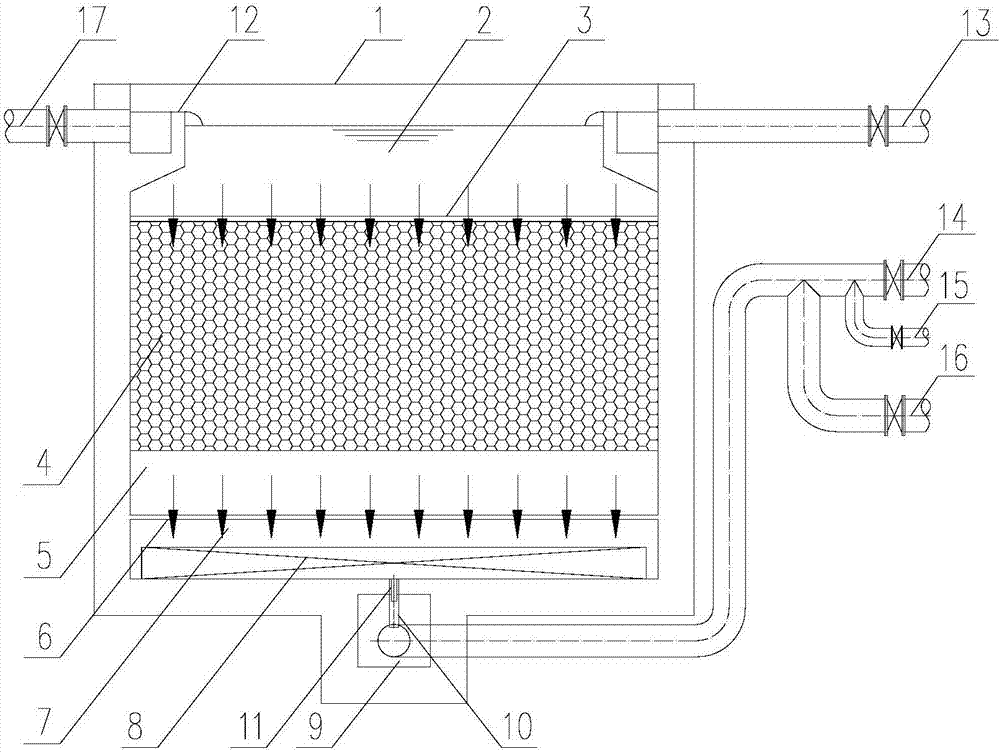

Method for treating vanadium-containing waste catalyst

InactiveCN112760486AImprove leaching rateEvenly heatedProcess efficiency improvementChemical reaction kineticsPtru catalyst

The invention provides a method for treating a vanadium-containing waste catalyst. The method comprises the following steps of, A) carrying out ball-milling on the deoiled waste catalyst to obtain a powdery waste catalyst; B) mixing the powdery waste catalyst to obtain a mixed material; C) granulating the mixed material, and drying to obtain mixed material particles; and D) cooling and solidifying the mixed material particles, and roasting in a fluidized bed furnace to obtain sodium modified clinker. According to the method, sodium salt roasting in the fluidized bed furnace is realized, the contact between a sodium salt additive and the vanadium-containing waste catalyst and the contact between cold solid particles and air are strengthened, the chemical reaction kinetic conditions of sodium salt roasting are improved, the leaching rate of vanadium in the sodium salt clinker is increased, and the vanadium leaching rate of the sodium salt clinker can reach 95% or above; the problems that the temperature of a rotary kiln is not easy to control and the rotary kiln is easy to knot are solved, and organization and implementation of production are facilitated; and during sodium salt roasting, self-heating generated by oxidation of carbon and sulfur in the waste catalyst is utilized, so that the production cost is reduced.

Owner:BEIJING PRUDENT CENTURY TECH CO LTD +2

Biological fluidized bed reaction zone process

InactiveCN112520843ASolve the blockageStable gas supplyBiological treatment apparatusSustainable biological treatmentNutrientParticulate material

The invention discloses a biological fluidized bed reaction zone process, relates to the technical field of biological fluidized beds, and in particular relates to a biological fluidized bed reactionzone process which comprises the following steps: a) selecting a proper granular material to construct an original BFB biological membrane, wherein because BFB adopts granules or even powder filler, the surface area is large, higher microbial biomass can be maintained in a fluidized bed, and the microbial biomass is 40-50 g / L. According to the biological fluidized bed reaction zone process, ceramsite, rubber, plastic carriers and the like are used as microbial carriers, and air or pure oxygen with a certain flow rate is introduced, so that sewage, compressed air and the microbial carriers flowupwards in the up-flow zone and flow downwards in the down-flow zone to form hydraulic circulation; and organic matters and nutrient substances in the sewage are adsorbed, oxidized and decomposed byutilizing a biological membrane continuously growing on the surface of the carrier, so that pollutants in the sewage are removed.

Owner:BEIJING HUANERKANG TECH DEV

Downward flow type denitrification and phosphorous removal expanded bed biological filter and method for treating sewage by applying same

PendingCN107082490AIncrease contact timeExtended reaction timeTreatment with anaerobic digestion processesWater/sewage treatmentEnvironmental chemistryWater district

The invention discloses a downward flow type denitrification and phosphorous removal expanded bed biological filter and a method for treating sewage by applying the same. The downward flow type denitrification and phosphorous removal expanded bed biological filter comprises a water distribution region, a filter screen plate, a floating ceramsite filter bed, a filter bed fluidization and buffering region, a filter-head filter plate, a water outlet region, a bottom water collection and gas distribution device and a water collection and gas distribution channel box, wherein the floating ceramsite filter bed is composed of crushed shale floating ceramsite arranged between the filter screen plate and the filter-head filter plate; the crushed shale floating ceramsite has an irregular shape and the density of water wetted particles is 0.95g / cm<3>+ / -0.5g / cm<3>; shale ceramsite is coarse and hydrophilic so that biofilm colonization is easy to realize; backwashing is adopted so that the activity of a biofilm is easy to maintain, the de-mold is not liable to occur and a denitrification biological nitrogen removal function is prominent; after sewage is subjected to primary micro-flocculation in the water distribution region, phosphorous-containing floc has a deep penetration distance in an expanded filter bed gap and a phosphorous removal effect is facilitated; the crushed ceramsite and the relatively large filter bed depth ensure the phosphorous removal and filtering capability. By adopting the downward flow type denitrification and phosphorous removal expanded bed biological filter, the loss of a filtering water head of an expanded bed is small and a filtering material is easy to fluidize and is not hardened.

Owner:SOUTH CHINA UNIV OF TECH

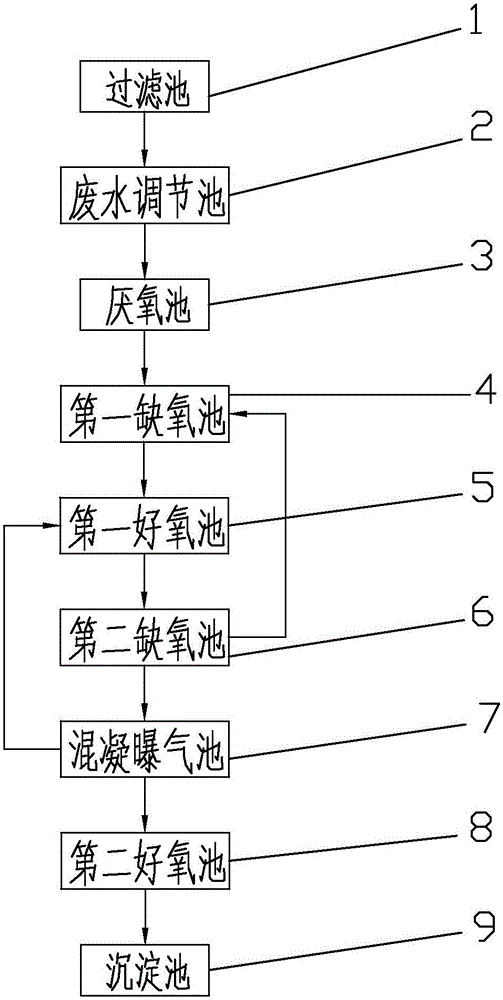

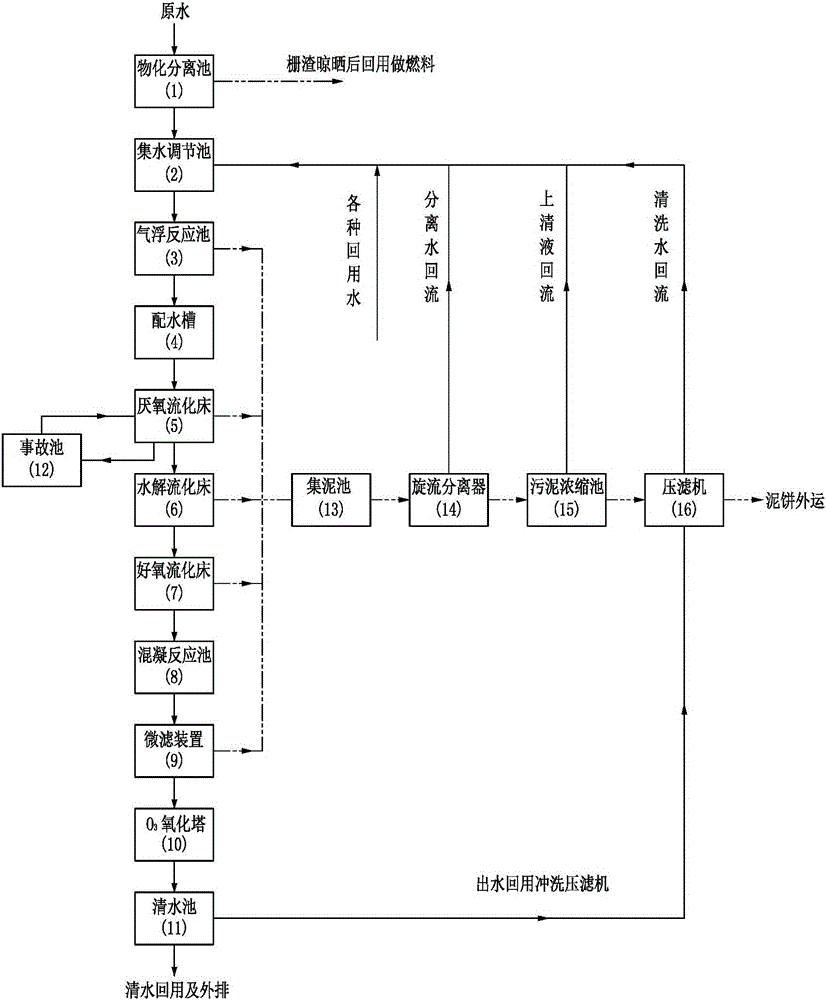

A wood-based panel waste water treatment system and process

ActiveCN104261634BHigh volume loadImprove mass transfer conditionsWater contaminantsTreatment involving filtrationSludgeFixed bed

The invention provides an artificial board wastewater treatment system and technology. The artificial board wastewater treatment system comprises a physical-chemical separating tank, a water collecting and regulating tank, an air flotation reaction tank, a water distributing trough, an anaerobic fluidization bed, a hydrolysis fluidization bed, an aerobic fluidization bed, a coagulation reaction tank, a micro-filtering device, an O3 oxidation column, a clear water tank and an accident tank, wherein the machine is characterized in that three grade biological fluidization beds of the anaerobic fluidization bed, the hydrolysis fluidization bed and the aerobic fluidization bed are combined to perform biological wastewater treatment. Compared with the conventional artificial board wastewater treatment technology by using a fixing bed and an activated sludge system, the machine disclosed by the invention is adopted for treating artificial board waste water by designing the technological parameters of relevant working procedures, and the machine has unique advantages in the aspects of treating organic waste water which is high in concentration and difficult to degrade. Key equipment of the system is small in volume, the whole system has stronger resistance to impact load, the sludge is sufficiently degraded, and the problem of sludge bulking is solved.

Owner:NANNING JINKE ENVIRONMENTAL ENG

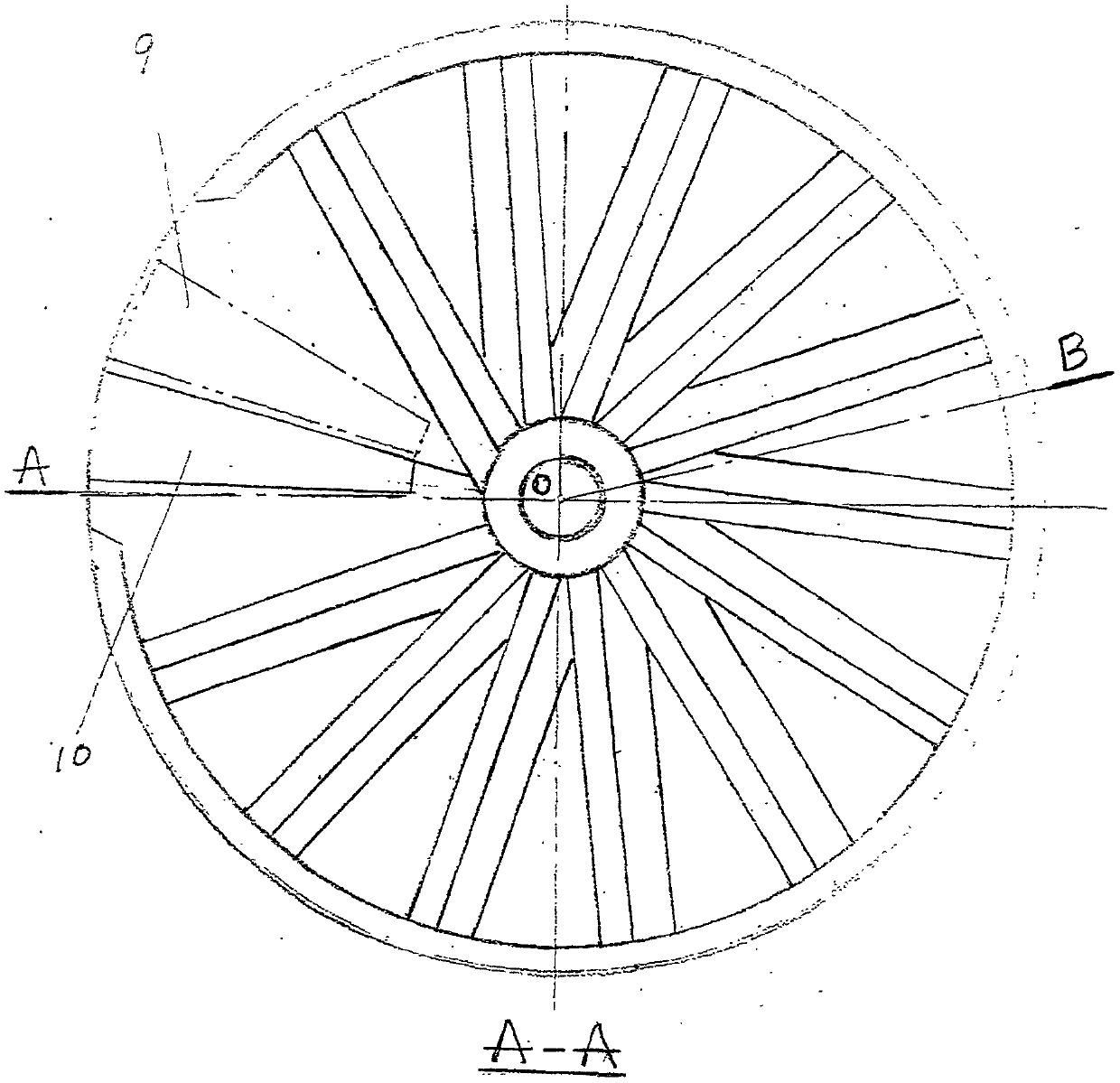

Rotary vortex jetting tray

InactiveCN110215803AGet rid of dependenceOvercome the illsDispersed particle separationFractional distillationChemical industryAbsorption column

This invention relates to a tray for mass transfer absorption columns and rectification columns in the chemical industry. The tray includes a radial jetting pipe or a jetting hood, a tray plate, and the like. Ascending gas enters the jetting pipe or the jetting hood through ascending and descending gas passages, and is then jetted from jetting holes in a high speed to generate a large amount of vortexes artificially; after liquid is pushed by the gas to rotate by nearly a round, the liquid enters a tray of the next layer through a fan-shaped overflow pipe. The tray overcomes a plurality of disadvantages of existing trays, greatly increases the contact time and area of gas and liquid phases by utilizing the vertex function, and greatly increases the tray efficiency and the operation flexibility. A heat transfer device can be additionally arranged on the tray. The tray is applicable to pressurized and vacuum absorption columns and various distillation columns.

Owner:范锦红

Up-flow anaerobic biological filter bed reactor

InactiveCN104649411AEasy to handleWell mixedWaste based fuelTreatment with anaerobic digestion processesBiological filterDistribution system

The invention discloses an up-flow anaerobic biological filter bed reactor which comprises a reactor body, wherein a biological mud bed area, a biological mud suspension area and a methane overflow area are sequentially arranged in the reactor body from bottom to top; a biological mud circulating system is arranged at the bottom of the biological mud bed area of the reactor body; a floating packing layer is arranged in the biological mud suspension area; and a discharge system is arranged at the top of an upper clarification area of the reactor body. According to the up-flow anaerobic biological filter bed reactor, a balanced water distribution system, a stirring device and a gas striping structure with a complicated structure in the prior art are replaced with the biological mud circulating system, so that sewage is fully mixed with the biological mud to obtain a relatively good mass transfer condition; and the bacteria storage amount of anaerobic biological bacteria is increased by arranging the floating packing layer in the biological suspension area, so that the sewage treatment capacity of the up-flow anaerobic biological filter bed reactor can be effectively improved and maintained for a long period of time.

Owner:SHANGHAI JINBUTI ENVIRONMENTAL PROTECTION TECH DEV

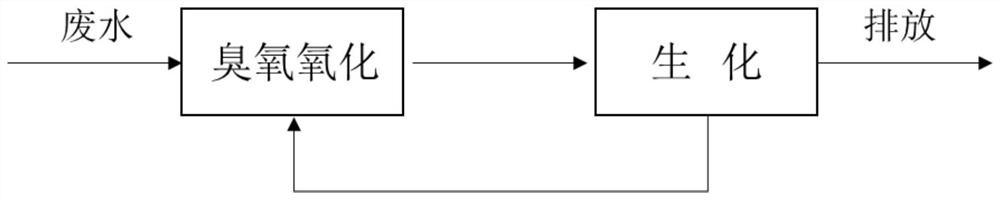

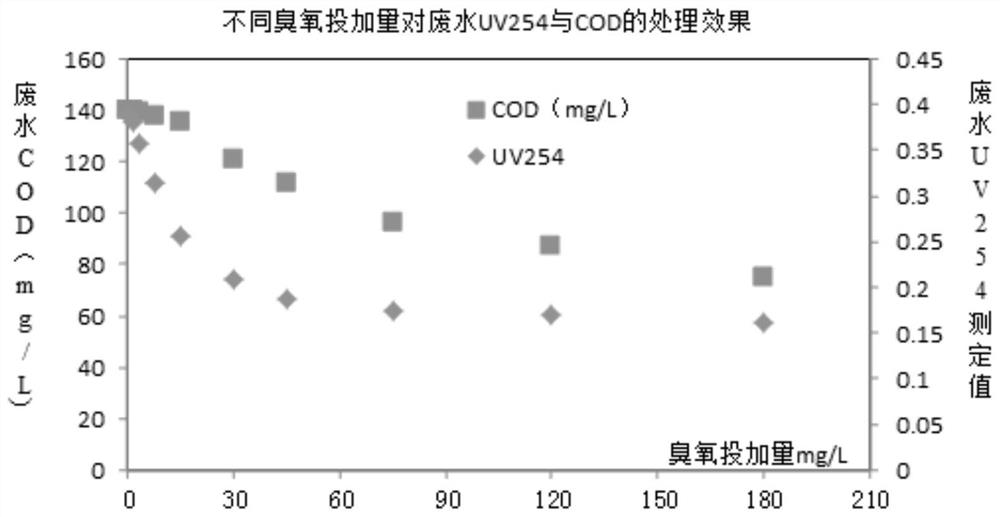

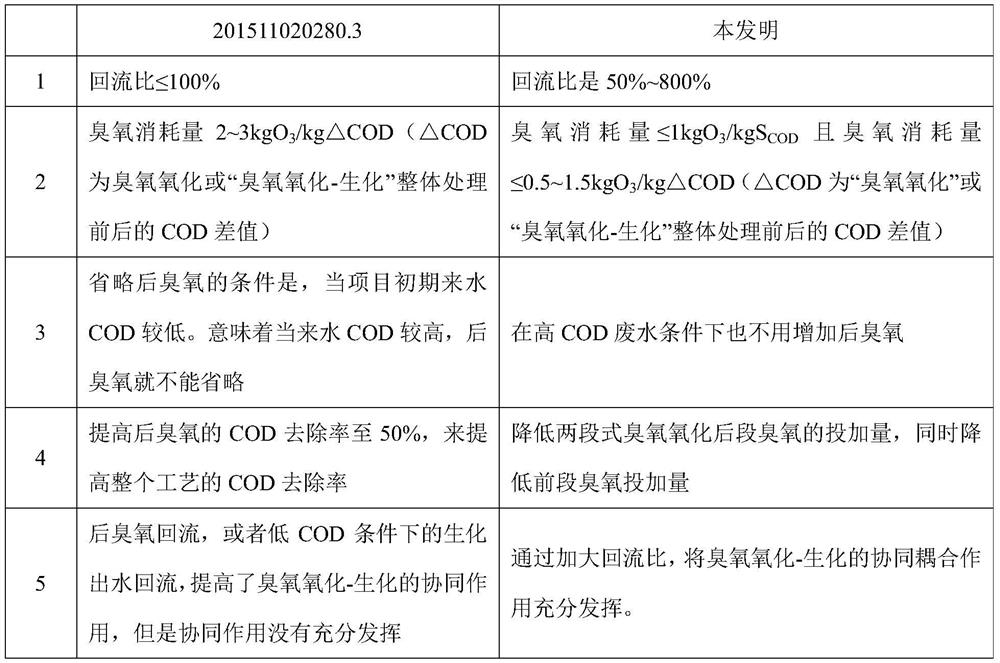

Ozonation-biochemical coupled water treatment method

PendingCN111747600AReduce the dosage of ozoneHigh operating costsWater treatment parameter controlWater/sewage treatment by irradiationBiotechnologyMedicine

The invention discloses an ozonation-biochemical coupled water treatment method which comprises the following steps: sequentially carrying out front-end ozonation treatment and rear-end biochemical treatment on water to be treated, returning rear-end biochemical effluent to front-end ozonation inlet water, and carrying out flow return to circularly treat the water to be treated in an ozonation-biochemical system for multiple times. Due to the fact that the biodegradability of the to-be-treated water is improved to a certain extent in the ozonation stage each time, biodegradable ozonation products in each time are degraded in time in the biochemical treatment stage, and the synergistic coupling effect of biodegradability improvement of ozonation and low-cost biochemical mineralization is enhanced by controlling the biochemical effluent return ratio. According to the method, the treatment efficiency can be improved under the condition of the determined total ozone addition amount, the ozone consumption can be reduced under the condition of the determined removal rate, and the investment cost, the operation cost and the engineering land occupation of water treatment are reduced.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com