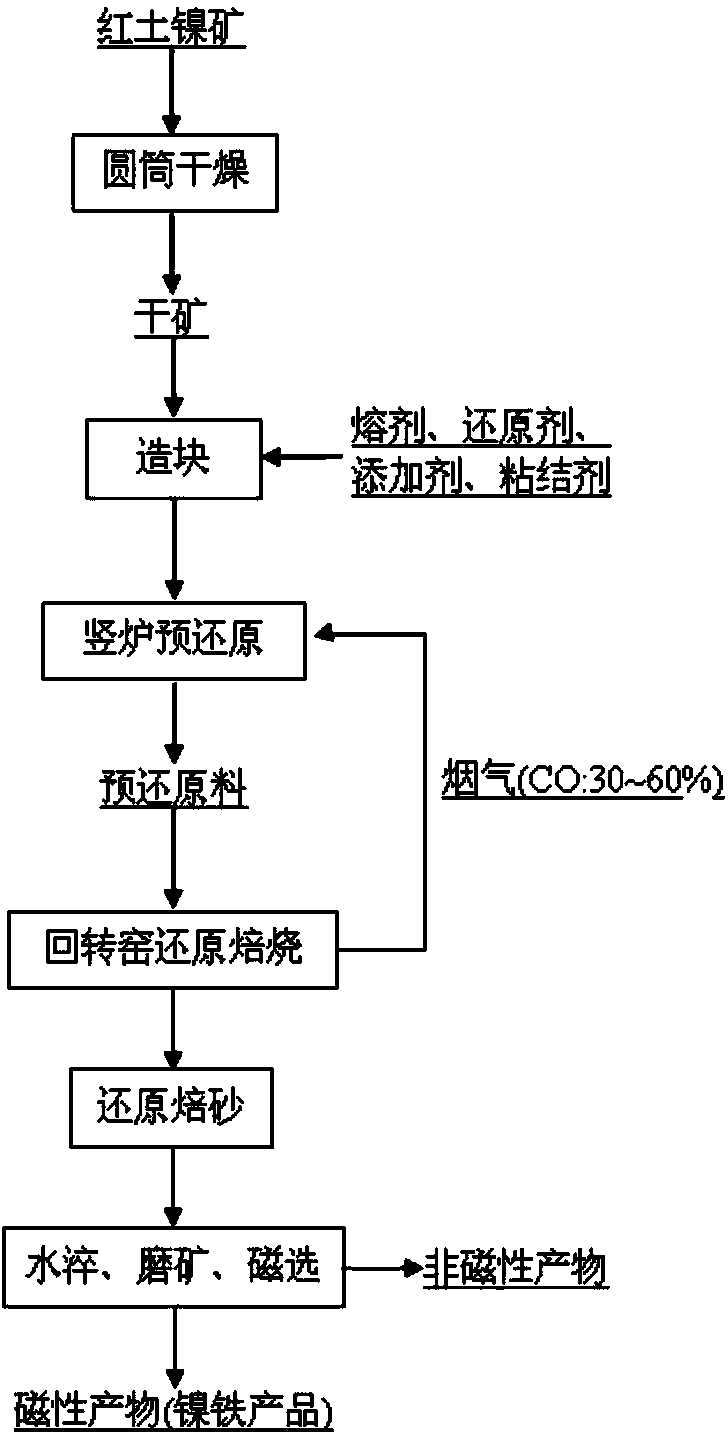

Process for preparing ferric-nickel from laterite-nickel ore

A lateritic nickel ore and process technology, applied in the field of metallurgy, can solve the problems of difficult separation of reduced roasted products, increased production costs, and low metal recovery rate, and achieve the goals of avoiding ring formation in rotary kilns, saving production costs, and improving roasting efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

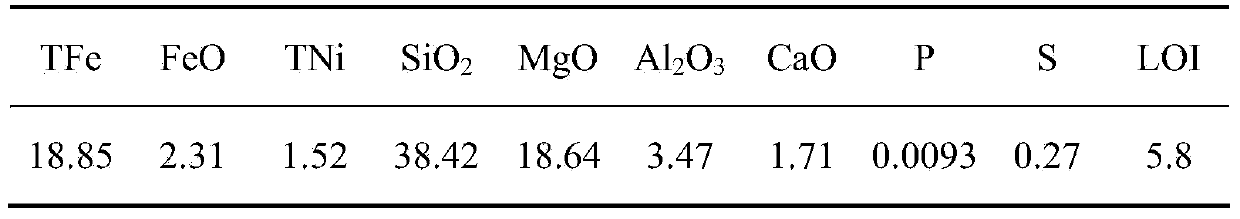

[0047] After the laterite nickel ore is dried and crushed, it is mixed with 10% sodium sulfate, 5% lime, 5% lignite, and 3% starch glue in mass fraction, and then agglomerated. It is pre-reduced by shaft furnace gas, and the reduction gas of the shaft furnace comes from the rotary kiln. , so that the shaft furnace temperature reaches 650 ° C, the mass percentage of CO is 65%, the pre-reduction time is 2 hours, the reduction rate of NiO is 54.3%, the pre-reduction product in the shaft furnace is hot-packed in the rotary kiln, and the Reduction and roasting for 6 hours, the reduction products were water quenched, crushed, ore-grinded, and magnetically separated. The grinding fineness of 74 μm accounted for 90%, and the magnetic field strength was 1000Gs. The grades of nickel and iron in the obtained nickel-iron alloy product were 8.3% and 85.6%, respectively. The iron recoveries were 94.8% and 72.6%, respectively.

Embodiment 2

[0049]After the laterite nickel ore is dried and crushed, it is mixed with 7% sodium sulfate, 7% lime, 5% lignite, and 2% humic acid extracts to form agglomerates. It is pre-reduced by shaft furnace gas, and the shaft furnace reduces the gas From the rotary kiln, make the temperature of the shaft furnace reach 650 °C, the mass percentage of CO is 60%, the pre-reduction time is 2h, the reduction rate of NiO is 51.6%, the pre-reduction product in the shaft furnace is hot-charged in the rotary kiln, at 1000 Reduction and roasting at ℃ for 4 hours, the reduction product undergoes water quenching, crushing, grinding, and magnetic separation. The grinding fineness is 74 μm, accounting for 90%, and the magnetic field strength is 1000Gs. The grades of nickel and iron in the obtained nickel-iron alloy product are 8.5% and 83.9% respectively , nickel and iron recovery rates were 97.2% and 71.4%.

Embodiment 3

[0051] After the laterite nickel ore is dried and crushed, it is mixed with 13% sodium sulfate, 4% lime, 4% lignite, and 2% humic acid extract, and then agglomerated. It is pre-reduced by shaft furnace gas, and the shaft furnace reduces the gas From the rotary kiln, make the shaft furnace temperature reach 550°C, the mass percentage of CO is 50%, the pre-reduction time is 3h, the reduction rate of NiO is 47.3%, the pre-reduction product in the shaft furnace is hot-packed in the rotary kiln, at 1050 Reduction and roasting at ℃ for 5 hours, the reduction products were water quenched, crushed, ground, and magnetically separated. The grinding fineness was 74 μm, accounting for 90%, and the magnetic field strength was 1000Gs. The grades of nickel and iron in the obtained nickel-iron alloy products were 8.6% and 88.2% respectively. , nickel and iron recovery rates were 95.7% and 76.1%.

[0052] It can be seen from the above examples that by using the high temperature and high CO con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com