Up-flow anaerobic biological filter bed reactor

An upflow anaerobic and biological filter bed technology, applied in the field of upflow anaerobic biological filter bed reactors, can solve the problems of easy loss of anaerobic sludge, partial flow, poor mass transfer conditions, etc., and improve sewage treatment ability, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make it easy to understand the technical means, creative features, objectives and effects achieved by the present invention, the following embodiments will specifically illustrate the upflow anaerobic biological filter bed reactor provided by the present invention in conjunction with the accompanying drawings.

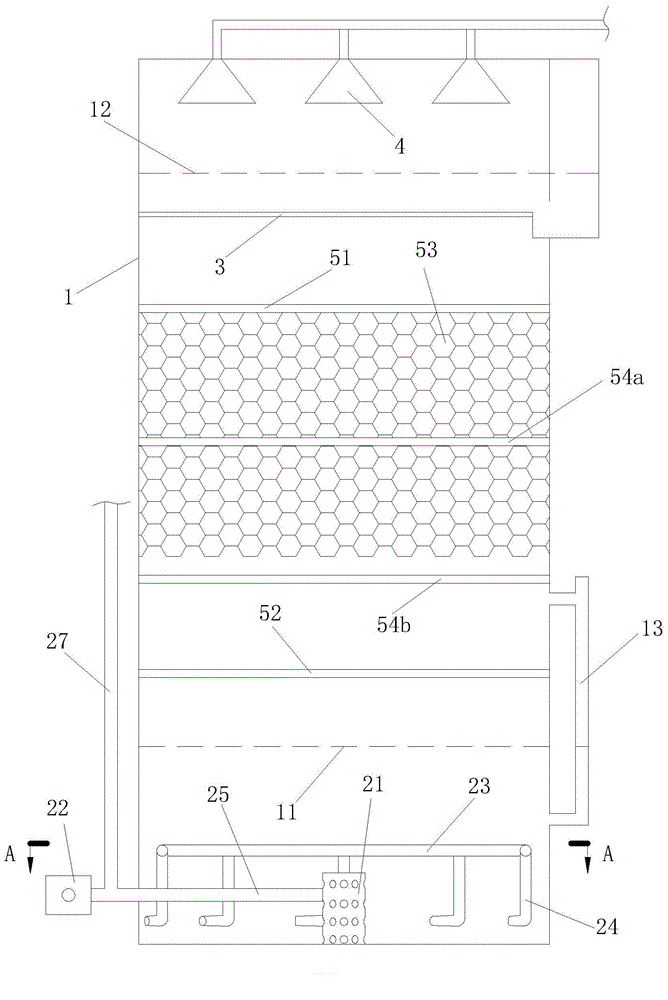

[0029] Such as figure 1 As shown, the up-flow anaerobic biological filter bed reactor provided in this embodiment includes a cylindrical reactor body 1, and the inside of the reactor body 1 is sequentially provided with a biological mud bed zone, a biological Mud suspension area, and biogas overflow area. Among them, the dotted line 11 is the dividing line between the biological mud bed area and the biological mud suspension area, and the dotted line 12 is the dividing line between the biological mud suspension area and the biogas overflow area.

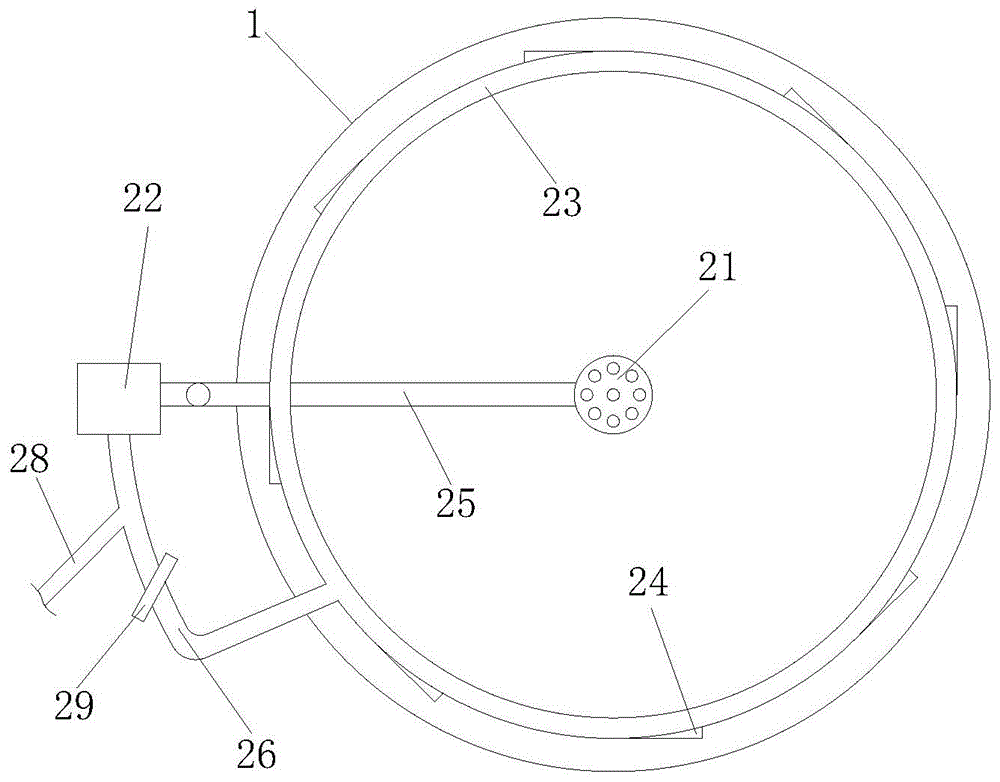

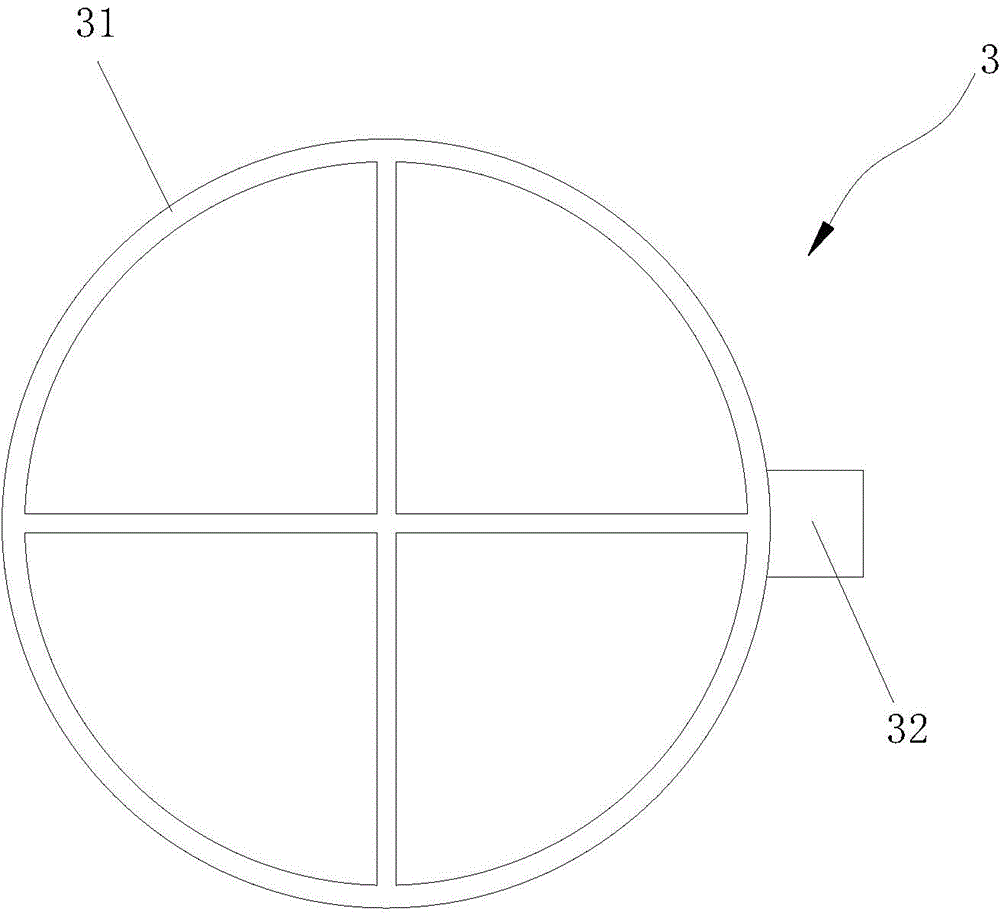

[0030] Specific, such as figure 1 with figure 2 As shown, the reactor body 1 is provided with a biological m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com