Ozonation-biochemical coupled water treatment method

A technology of ozone oxidation and biochemical treatment, applied in the field of water treatment, can solve the problem of high treatment cost and achieve the effect of increasing investment and land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

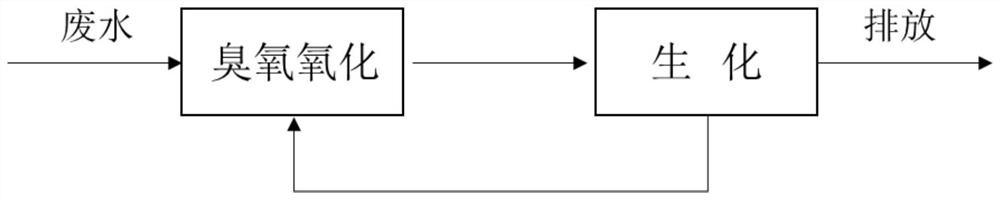

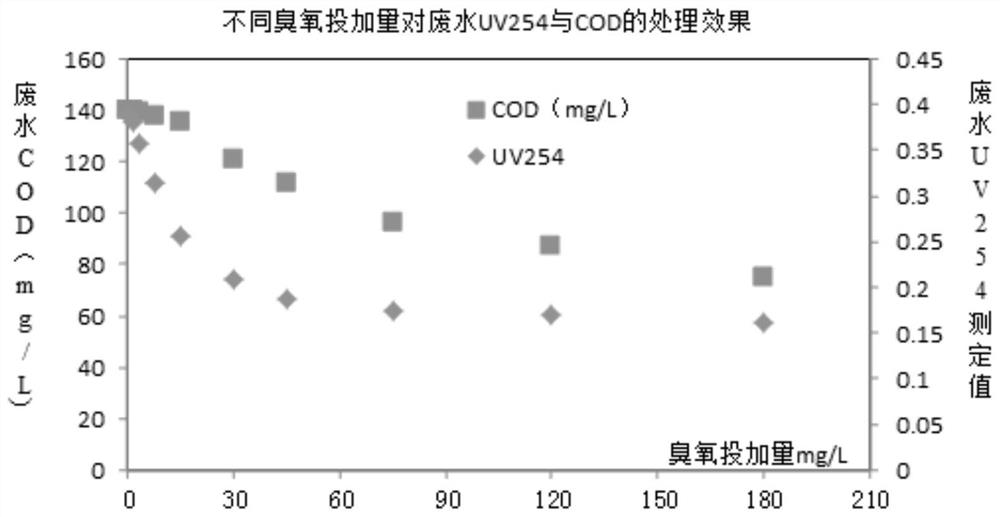

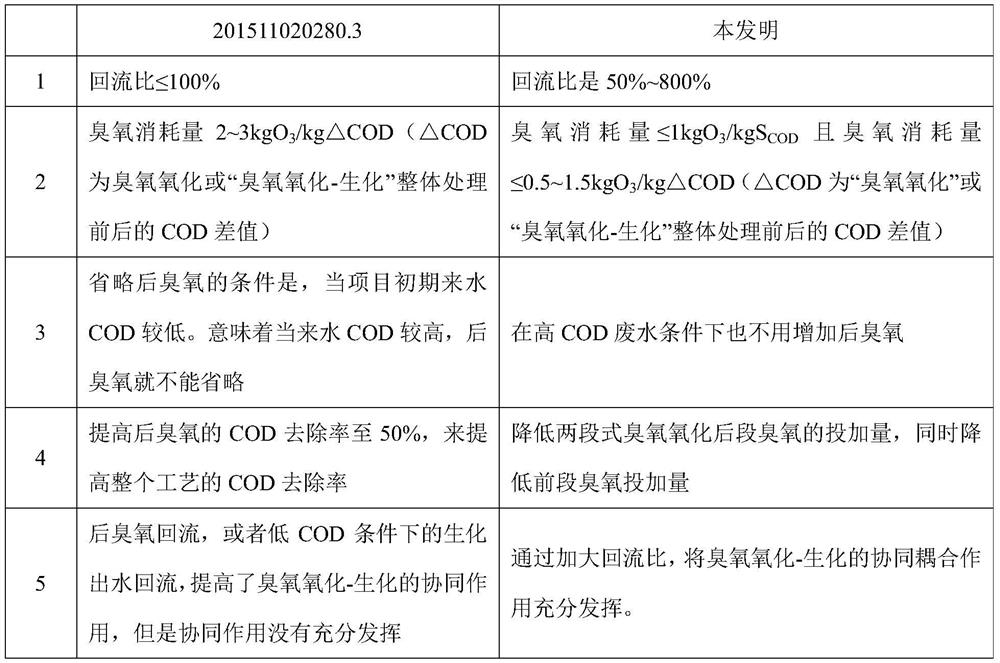

Method used

Image

Examples

Embodiment 1

[0069] Embodiment 1 (claim 1,2,3,4,5,6,7 and technical effect 1.)

[0070] A kind of tail water after two-stage biochemical treatment, COD150mg / L, SS30mg / L, TDS11000mg / L, use method A, method B and method C to treat wastewater respectively, and the scale of wastewater treatment is Q=1m 3 / h, the ozone reaction time is 60min, and the residence time of the biochemical device is 2h; the return flow rate of the ozone oxidation-biochemical coupling device q=1~6m 3 / h, and the dosage of ozone is 50mg / L. The wastewater treatment effects of different methods and conditions are shown in the table below.

[0071] The treatment effect of ozone oxidation-biochemical method under the different conditions of table 1

[0072]

[0073] When the total ozone dosage is the same, compared with method A (ozone oxidation-biochemical with external reflux) and method B (ozone oxidation without external reflux-biochemical), the COD concentration in the effluent is lower; compared with method C (mu...

Embodiment 2

[0074] Embodiment 2 (claims 1, 2, 3, 4, 5, 6, 7 technical effects 2.)

[0075] A kind of tail water after two-stage biochemical treatment, COD150mg / L, SS30mg / L, TDS11000mg / L, use method A and method C to treat wastewater respectively, wastewater treatment scale Q=1000m 3 / h, the ozone reaction time is 60min, and the residence time of the biochemical device is 2h; the return flow rate of the ozone oxidation-biochemical coupling device is q=1000~3000m 3 / h, and the dosage of ozone is 50mg / L. The floor area and investment cost of different methods and conditions are shown in the table below.

[0076] The treatment effect of ozone oxidation-biochemical process under different conditions in table 2

[0077]

Embodiment 3

[0078] Embodiment 3 (claims 5, 6, 7, 8, 9)

[0079] A kind of tail water after two-stage biochemical treatment, COD150mg / L, SS30mg / L, TDS11000mg / L, using method A with different conditions to treat wastewater, wastewater treatment scale Q=1m 3 / h, the ozone reaction time is 60min, and the residence time of the biochemical device is 2h; the return flow rate of the ozone oxidation-biochemical coupling device q=0.11~2.3m 3 / h, and the dosage of ozone is 50mg / L. The wastewater treatment effect of method A under different conditions is shown in the table below.

[0080] The treatment effect of ozone oxidation-biochemical process under different conditions in table 3

[0081]

[0082]

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com