Patents

Literature

104results about How to "Improve roasting efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

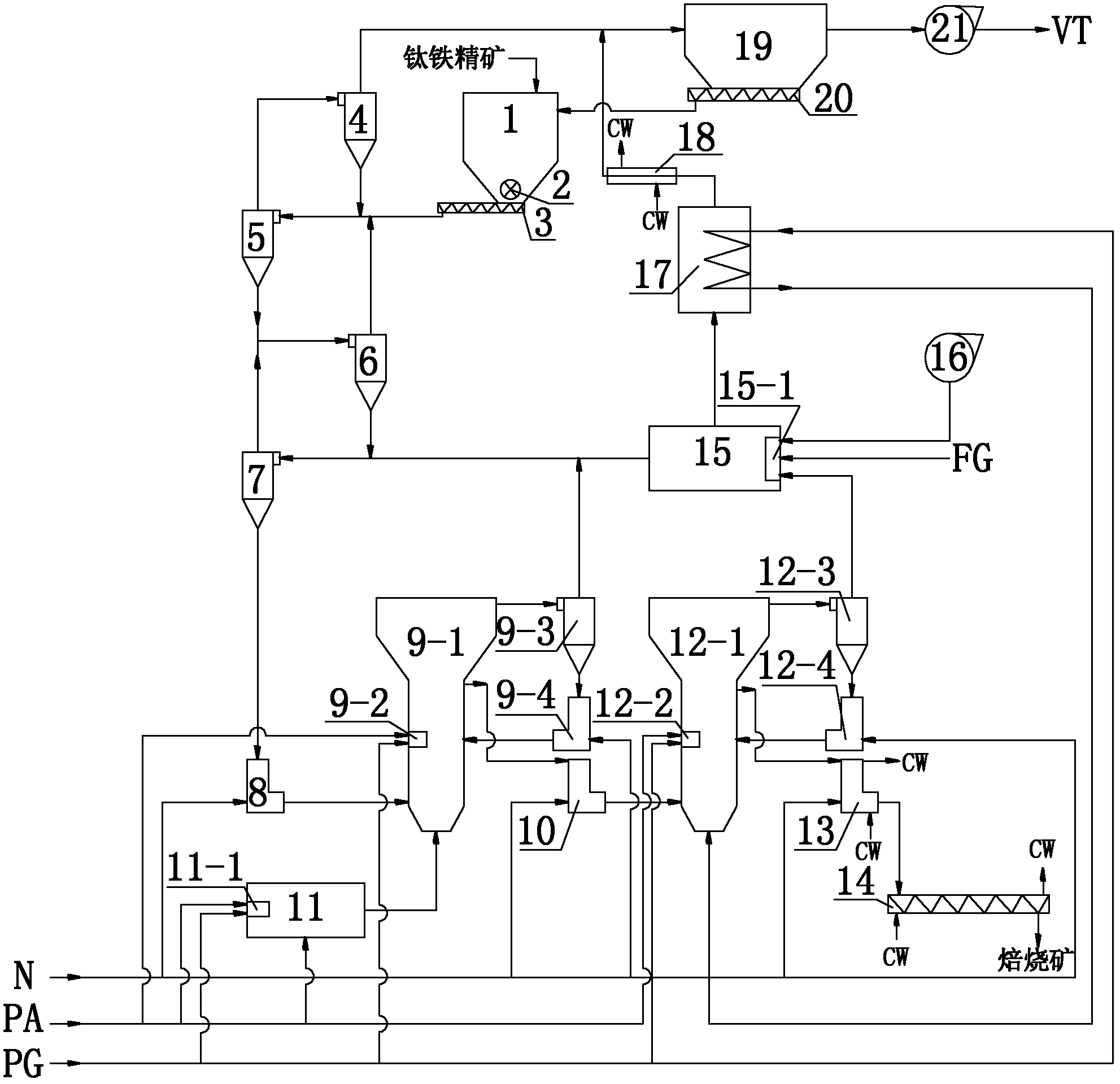

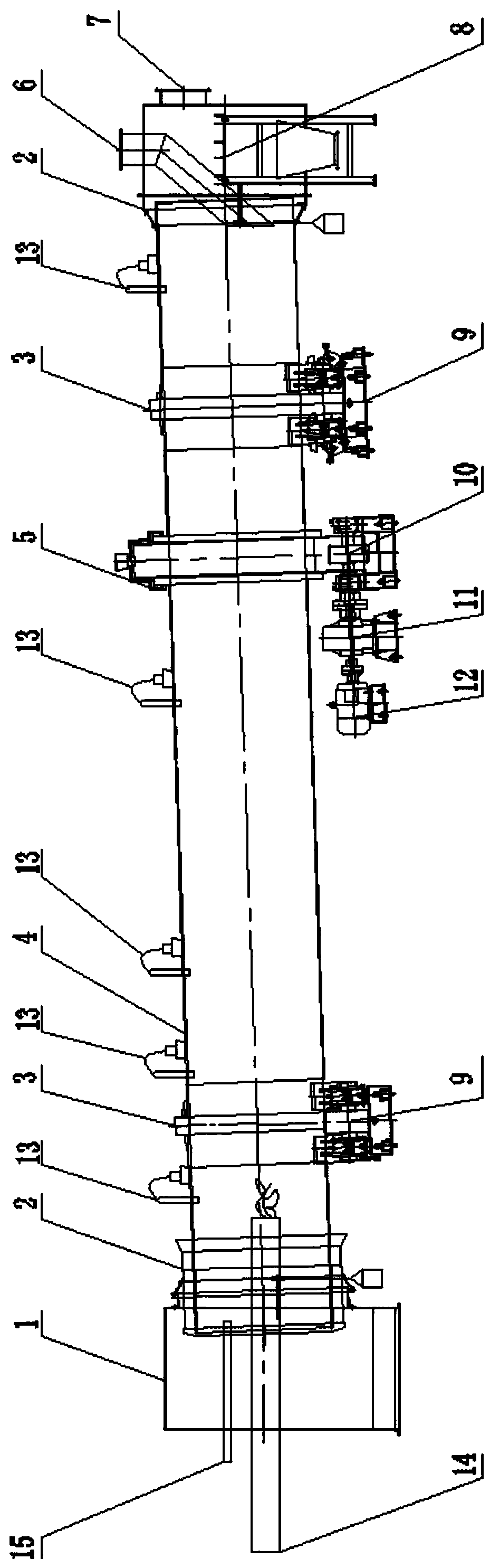

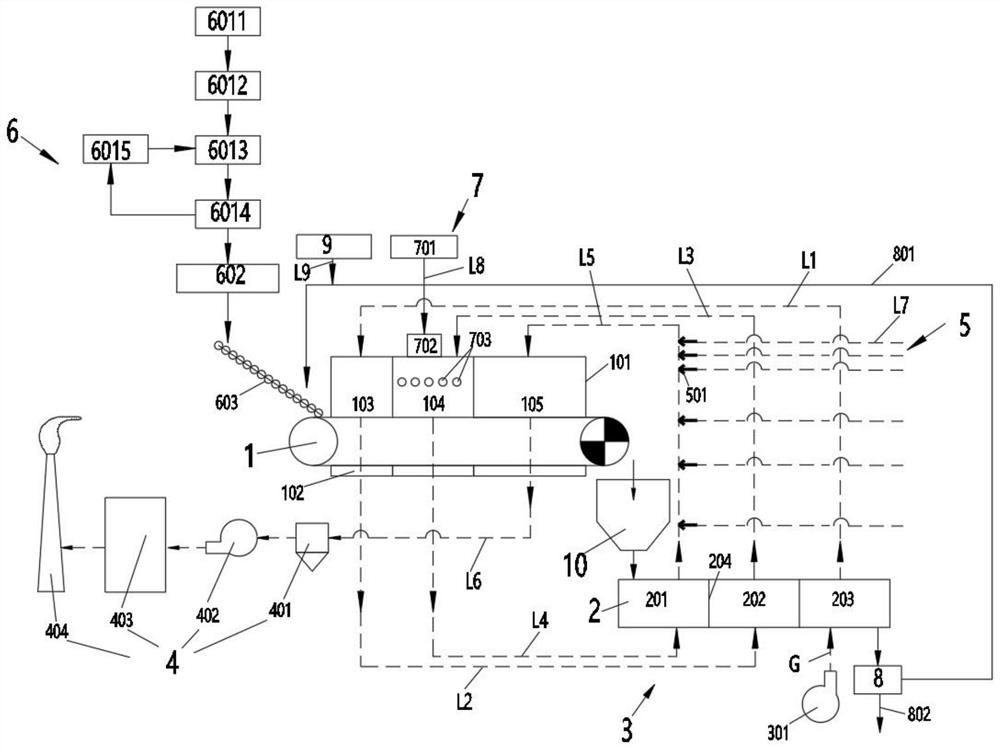

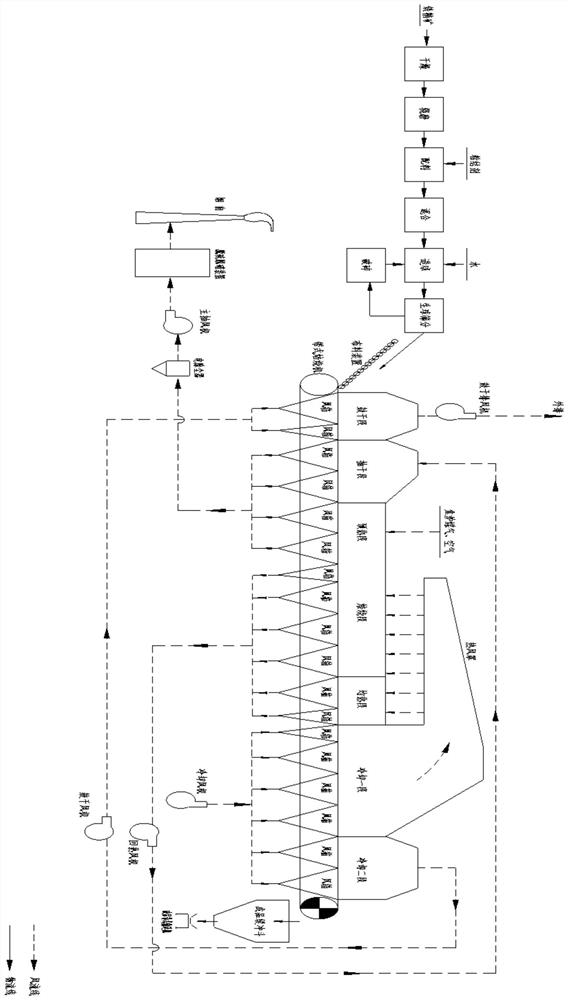

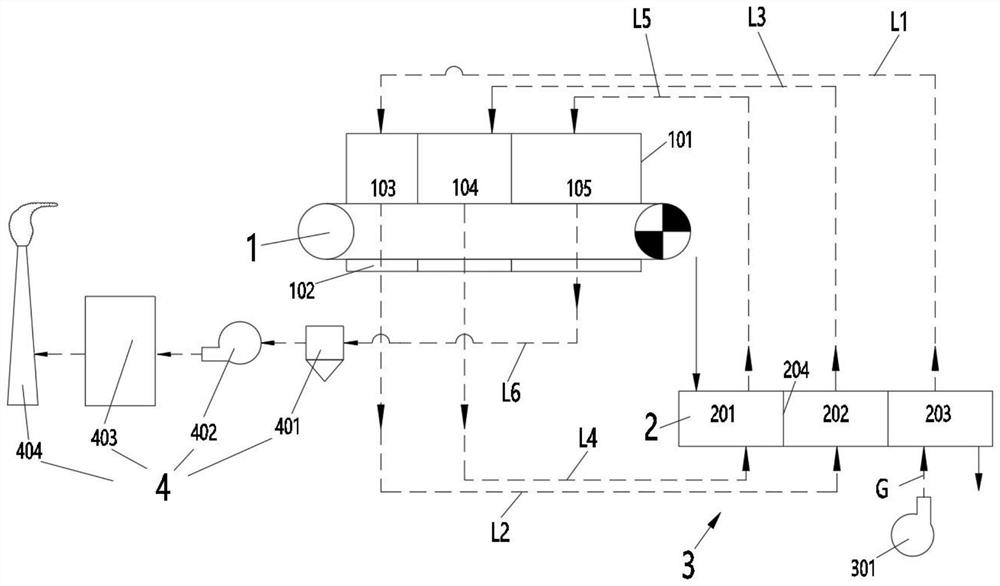

System for fluidized oxidizing/reducing roasting modification of titaniferous iron concentrate and roasting process

The invention discloses a system for fluidized oxidizing / reducing roasting modification of titaniferous iron concentrate and a roasting process. A fluidized bed oxidation reactor is adopted for the oxidizing roasting of titaniferous iron concentrate powder, and fluidized air is preheated by a hot blast heater and mineral powder is preheated by a multistage cyclone preheater so as to provide heat for oxidizing roasting; the oxidized mineral powder enters the fluidized bed reduction reactor for reducing roasting, and heat is provided for the reducing roasting through heating coal gas by a coal gas preheater; and latent heat of unreacted reducing gas in roasting tail gas of the reduction reactor is firstly released through combustion in a combustion chamber, one path of hot flue gas after the combustion is mixed with the tail gas of the oxidation reactor and then enters the multistage cyclone preheater to exchange heat with the cold titaniferous iron concentrate powder, heat is recycled while the titaniferous iron concentrate is preheated, and the other path of hot flue gas is used for preheating cold coal gas to warm the fluidized coal gas entering a reducing furnace so as to strengthen a reducing condition. The system has the advantages of high oxidizing / reducing efficiency, high heat utilization efficiency in a roasting process and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

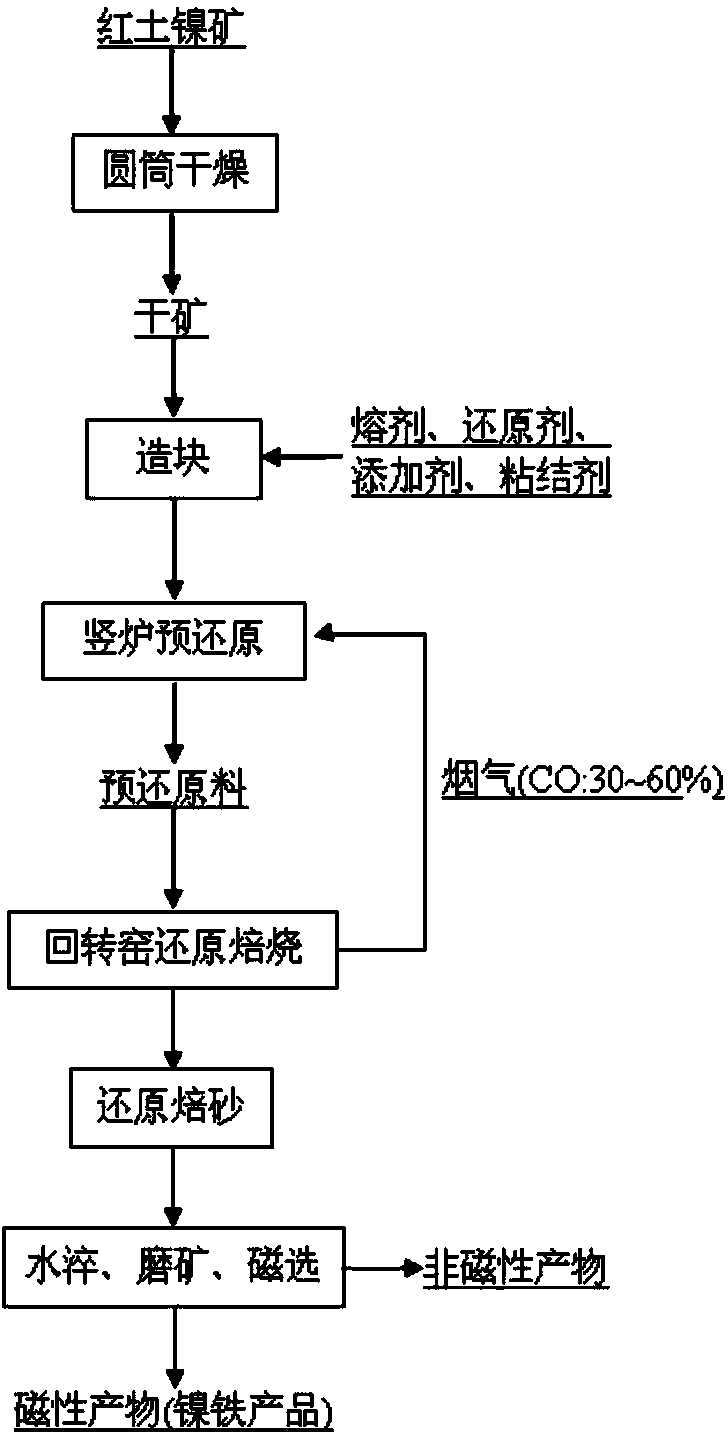

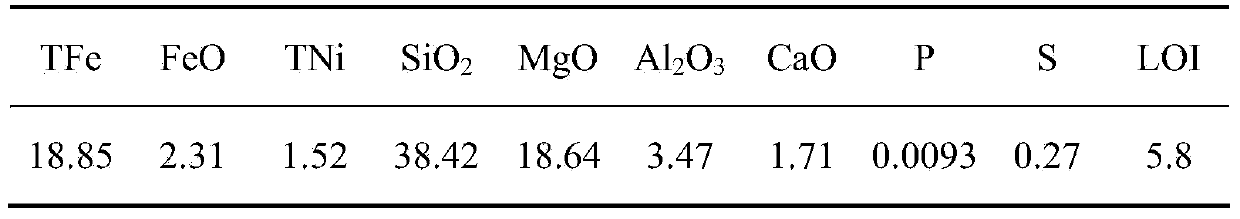

Process for preparing ferric-nickel from laterite-nickel ore

ActiveCN104195279AImprove mass transfer conditionsPromote particle growthRotary drum furnacesSolventLaterite

The invention discloses a process for preparing ferric-nickel from laterite-nickel ore. The process comprises the following steps: crushing laterite-nickel ore, drying, adding an additive, a reducing agent, a solvent and a binding agent, uniformly mixing, briquetting, putting into a vertical furnace, performing pre-reducing roasting by using high-temperature fume in a rotary kiln, further putting into a coal medium in the rotary kiln, and performing reducing roasting, water quenching cooling and grinding and magnetic separation, thereby obtaining a powder ferric-nickel product with high nickel content. The process is short in procedure, simple to operate, low in energy consumption, low in cost and high in metal recycling rate, and the defects that the energy consumption is high, the metal recycling rate is low and the production cost is high when the ferric-nickel is prepared from reduced laterite-nickle ore directly in a conventional rotary kiln in the prior art are overcome.

Owner:CENT SOUTH UNIV

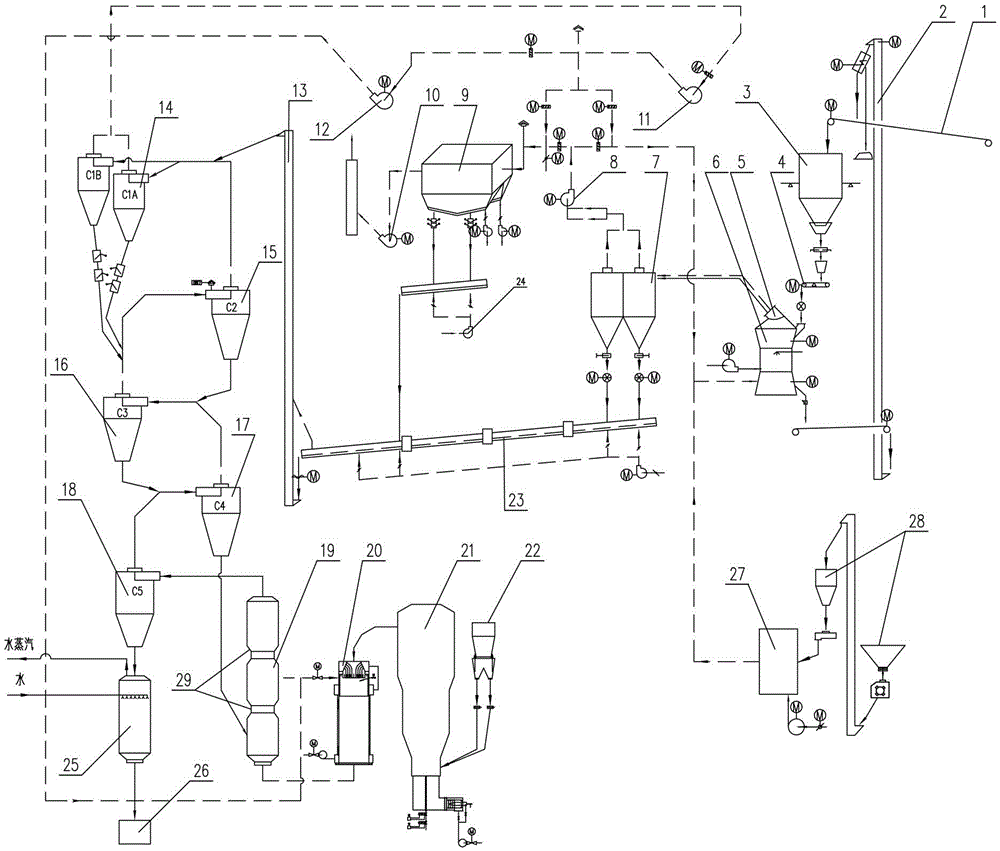

Preparation method for producing strong-magnetism magnetite through refractory weak-magnetism oxidized iron ore

The invention relates to the production techniques of iron ore concentrate of refractory ore, in particular to a preparation method for producing strong-magnetism magnetite through refractory weak-magnetism oxidized iron ore. The method comprises the following steps that firstly, the crushed iron ore is ground into fine ore; then the fine ore is subjected to low-temperature roasting, and during the low-temperature roasting, the fine ore is made to be in a roasting system to be preheated and roasted; the roasted ore enters a cooling system to be cooled; and then the cooled roasted ore is subjected to size mixing and sent to a magnetic separation system to be separated, and high-grade iron ore concentrate is obtained through separation. According to the method, the process is simple, the temperature and air flow are distributed uniformly, control is easy, the automation degree is high, the number of operation components of equipment is small, refractory siderite and limonite can be treated, the magnetizing roast efficiency of the refractory iron ore is high, heat is substantially recycled during roasting, the roasted ore is stable in quality and high in magnetic separation efficiency, and the technical indexes that the grade of the iron ore concentrate is larger than 60%, and the iron recycling rate is larger than 85% can be achieved.

Owner:湖北华方装备有限公司

Process for roasting waste sand into precoated sand material

InactiveCN102688982AHigh temperature heat exchange time is shortEvenly heatedMould handling/dressing devicesExchange timeMaterials science

The invention relates to a process for roasting waste sand into a precoated sand material. The process comprises the steps of shakeout, magnetic separation, crushing, screening, magnetic separation, roasting, dedusting, cooling and storage. When crushed and magnetically separated sand is roasted, the sand is required to be fed into a preheater for preheating, and then is fed into a roasting furnace for roasting. A passage for bearing the sand is stepped when the sand is in the preheater, the sand in the stepped passage is in a flocculated flow state, and when the sand is roasted, natural gas is jetted from three direction-adjustable jet tips in the roasting furnace to process the sand. Before being roasted, the sand is required to be preheated, so that the high-temperature heat exchange time of the sand in the roasting furnace is short, and the roasting efficiency and the roasting quality are improved. The sand is roasted at high temperature by the natural gas, so that the generation of an inert gas during the roasting is avoided. In addition, the three adjustable natural gas jet tips are adopted, so that the sand can be uniformly heated when roasted.

Owner:西峡县众德汽车部件有限公司

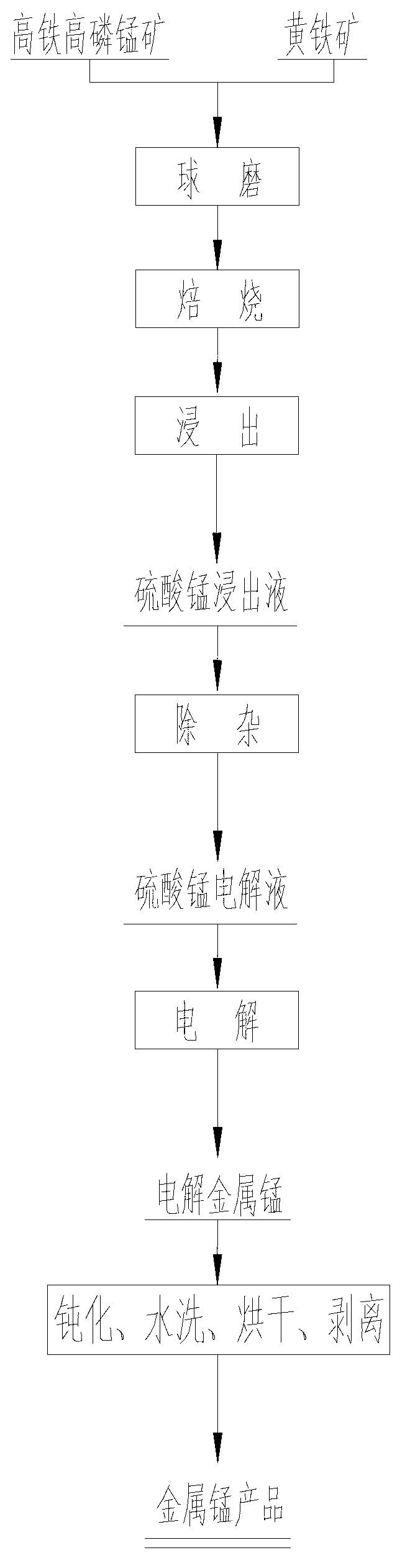

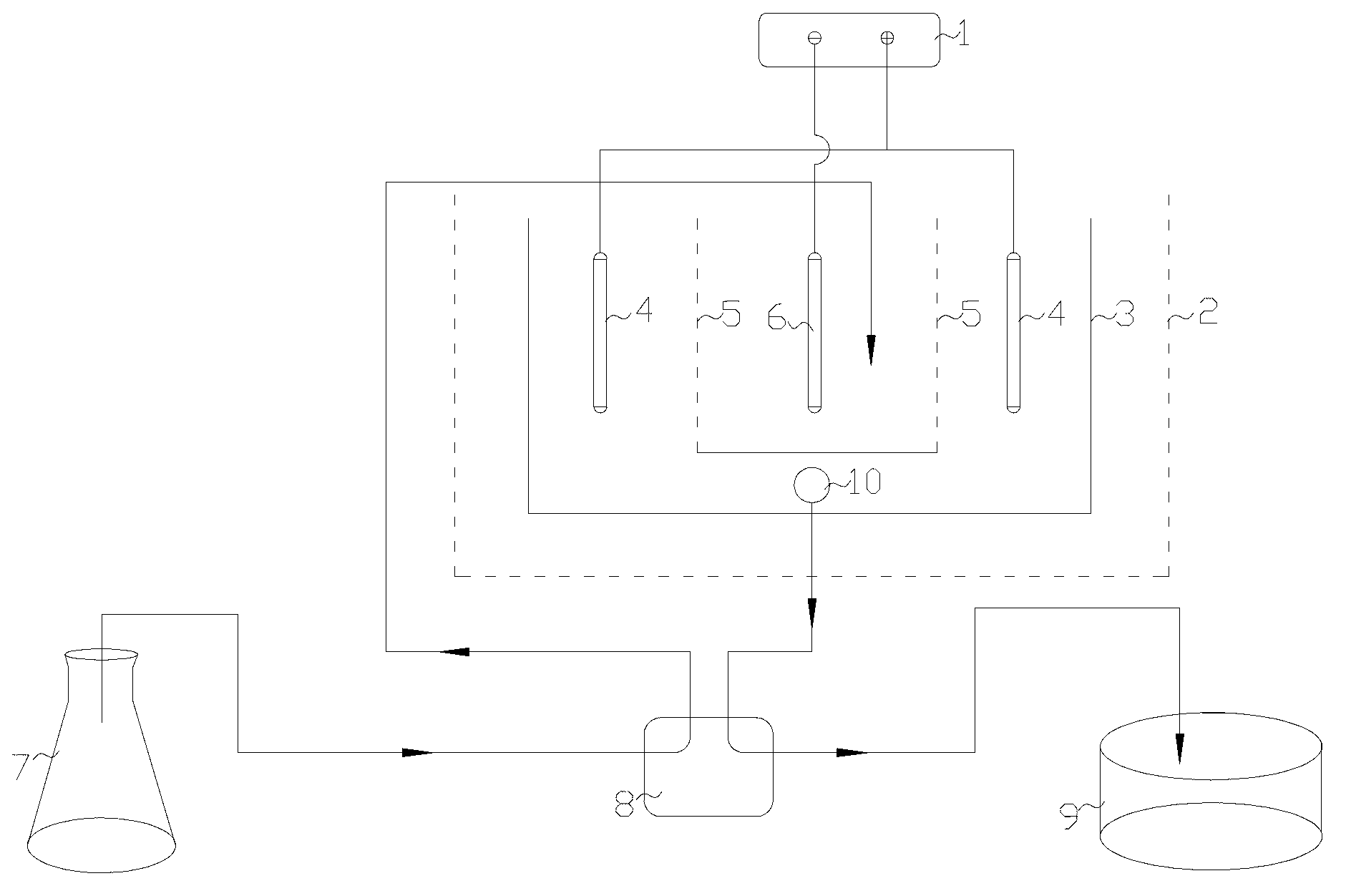

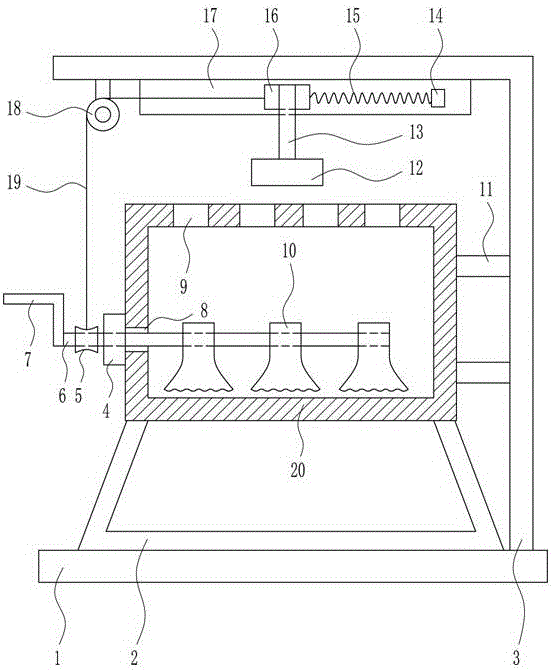

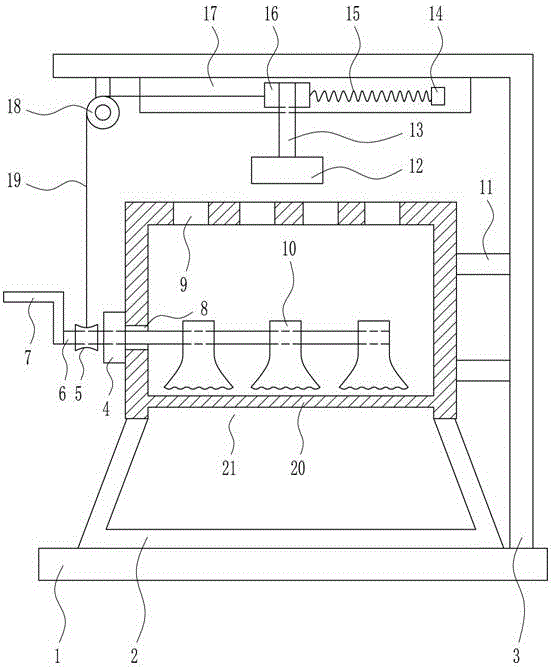

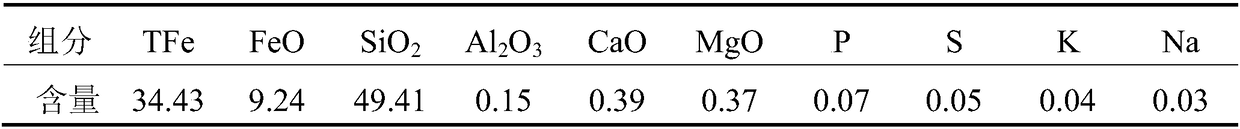

Method for preparing electrolytic manganese metal by using high-iron and high-phosphor manganese ores

InactiveCN103194768ASuppresses deposition de edge effectsAvoid leachingPhotography auxillary processesManganeseBuffering agent

The invention relates to a method for preparing electrolytic manganese metal by using high-iron and high-phosphor manganese ores. The method comprises the following steps of: respectively carrying out ball-milling on high-iron and high-phosphor manganese ores and iron pyrites to form powders, mixing the powders in proportion and roasting in a self-manufactured roasting device, leaching the mixture subjected to sulfating roasting by taking water as a leaching agent to obtain a manganese sulfate solution, removing impurities from the manganese sulfate solution to obtain a manganese sulfate electrolyte, adding an electrolysis additive to the manganese sulfate electrolyte, simultaneously adding ammonium salt serving as a buffering agent to the solution, putting the electrolyte into an electrolytic cell, switching on direct current and maintaining constant temperature so that an electroextraction effect is generated to separate out the manganese metal on a cathode, purifying, washing, drying and peeling the separated manganese metal, thus obtaining the electrolytic manganese metal product. The method is short in technological process, hardly pollutes the environment and and is suitable for development and application of low-grade high-iron and high-phosphor manganese ores.

Owner:CENT SOUTH UNIV +1

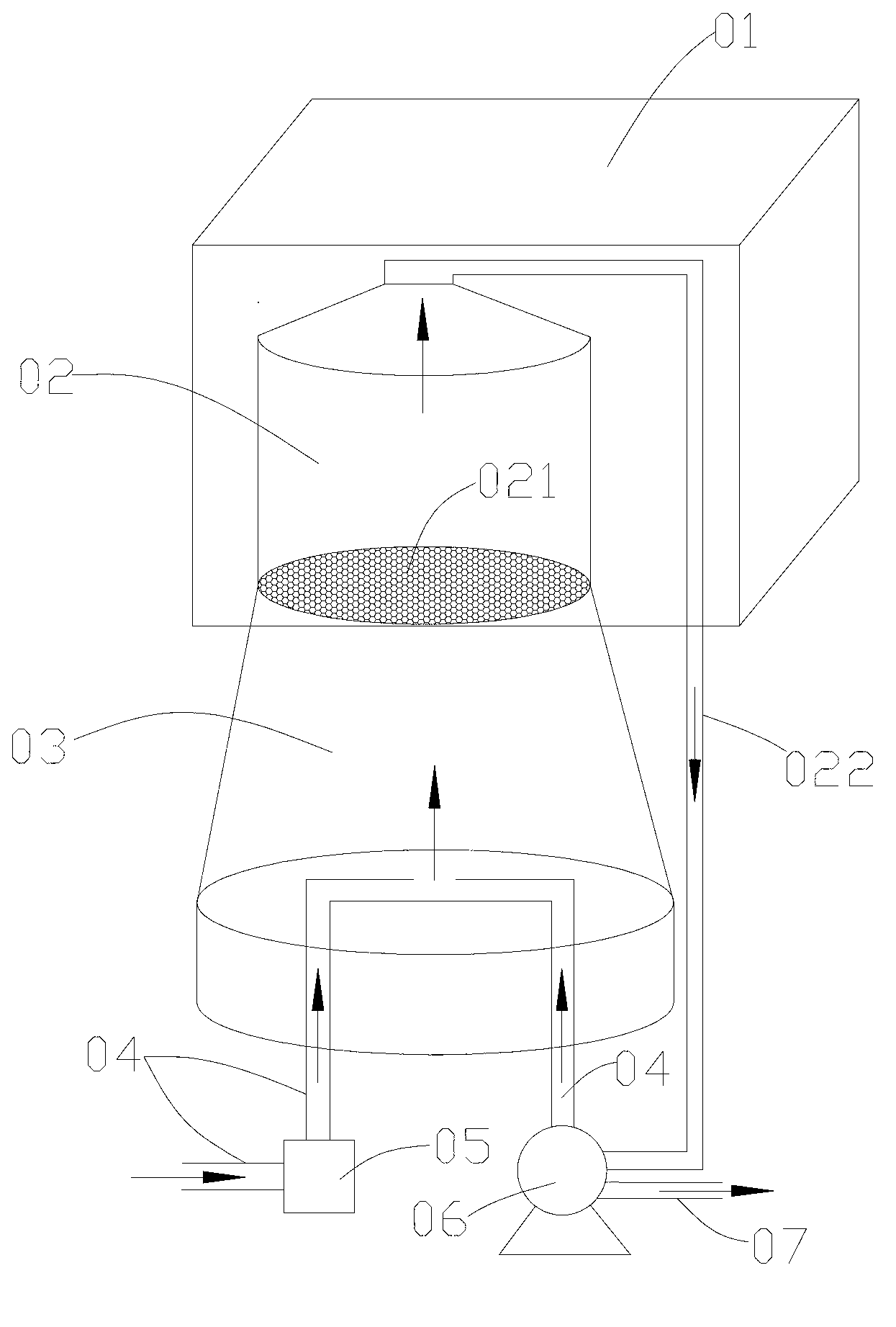

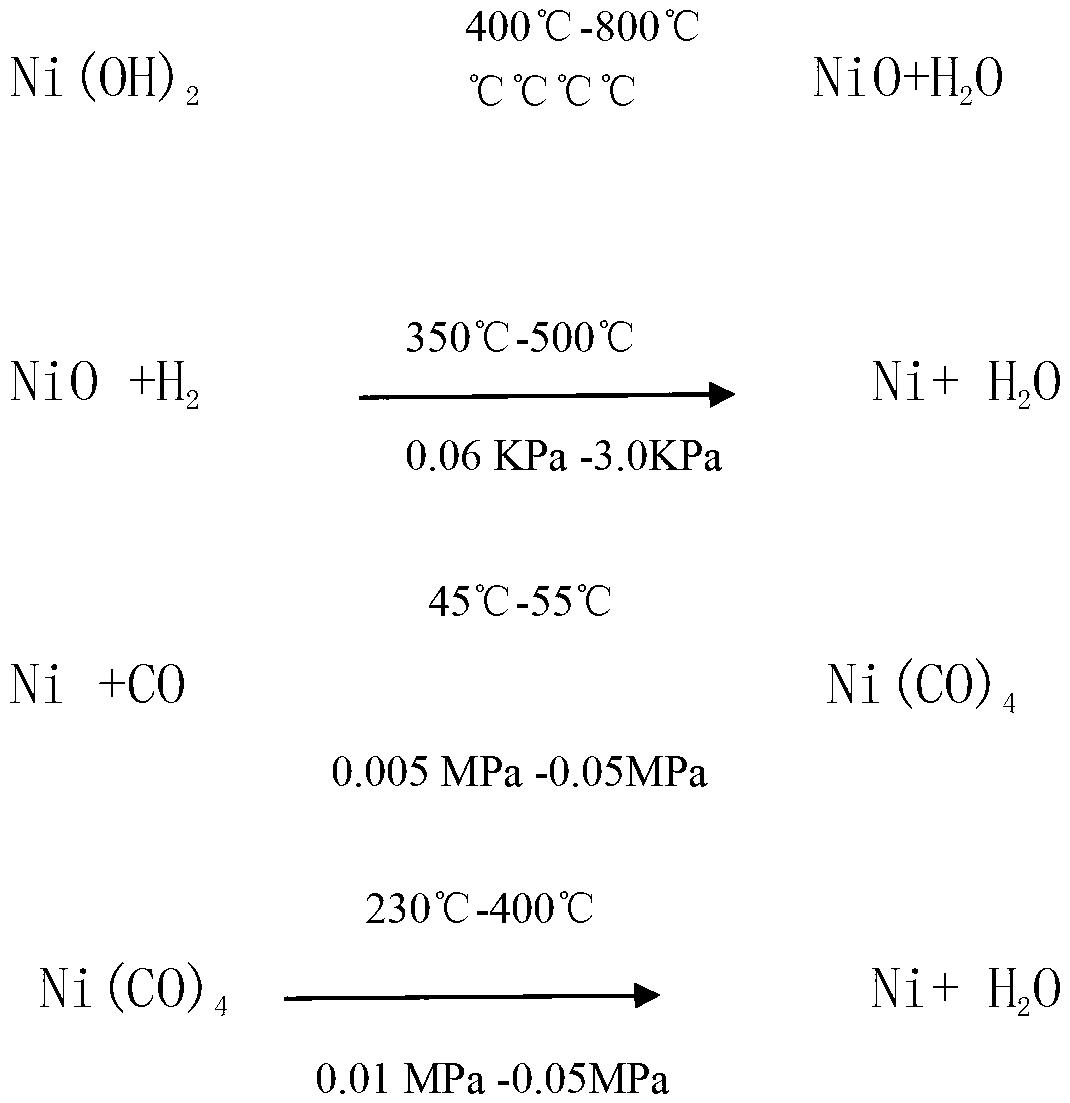

Method for producing nickel carbonyl powder from nickel hydroxide

ActiveCN103130284AMild reaction conditionsSimple processNickel carbonylsDecomposerNickel oxide hydroxide

The invention relates to a method for producing nickel carbonyl powder from nickel hydroxide, belonging to the technical field of powder metallurgy. The method comprises the following steps: adding nickel hydroxide into a rotary roasting furnace, removing water at high temperature, and roasting to obtain nickel oxide; adding the oxide into a hydrogen reducing furnace to perform reduction, thereby generating simple substance active nickel; adding the simple substance active nickel into a nickel carbonyl synthesis reactor to make counterflow contact with CO, and reacting to generate nickel carbonyl gas; delivering the nickel carbonyl gas to a nickel carbonyl decomposer by a blower, and delivering generated nickel carbonyl residues into a nickel carbonyl treater to perform passivating treatment; and decomposing the nickel carbonyl gas in the nickel carbonyl decomposer to produce the nickel carbonyl powder. The invention does not need to perform extra treatment on the raw material, and has the advantages of mild reaction conditions, simple technique, high production safety, low cost, high synthesis efficiency and the like.

Owner:吉林卓创新材料有限公司

Method for producing high-iron low-sulfur iron ore concentrate from pyrite cinder

The invention relates to a method for producing high-iron low-sulfur iron ore concentrate from pyrite cinder, comprising the steps of controlling a calcination temperature of pyrite to be 900-950 DEG C and an excess air ratio to be 1.15-1.25 to produce red low-sulfur cinder with Fe2O3 as a principal component in a furnace in fluid bed; then adding 2-6% of biomass with an average particle size of 0.5-2mm containing 70-90% of fixed carbon, 5-25% of volatile matter and 5-20% of ash content in the cinder for magnetizing roasting by the own temperature of the cinder so as to reduce hematite in the cinder into magnetite; and finally implementing processes of ore grinding and magnetic separation to obtain the high-iron low-sulfur iron ore concentrate with an iron grade of more than 63%, the sulfur content of lower than 0.2%, and the iron recovery rate of higher than 80%.

Owner:CENT SOUTH UNIV

Sintering prevention vanadium-containing stone coal microwave roasting method

The invention relates to a sintering prevention vanadium-containing stone coal microwave roasting method. According to the technical scheme, the method includes: crushing vanadium-containing stone coal into coarse-grained vanadium-containing stone coal with the grain size less than 6mm and greater than 1mm and fine-grained vanadium-containing stone coal with the grain size less than 1mm; adding water to the fine-grained vanadium-containing stone coal to be mixed according to the mass ratio of the fine-grained vanadium-containing stone coal to the water of 1:0.06-0.09 to produce small balls 3-8mm in grain size and drying the small balls; placing the dried small balls in an industrial microwave roasting device as bedding materials, placing the coarse-grained vanadium-containing stone coal on the bedding materials prior to microwave roasting, and cooling to indoor temperature to obtain vanadium-containing stone coal roasting materials, wherein the microwave roasting is characterized in that the temperature rate ranging from 25 DEG C / min to 55 DEG C / min is increased rapidly to the temperature rate ranging from 750 DEG C to 850 DEG C, 25-40 min constant-temperature microwave roasting is performed, and the industrial microwave roasting device is 2400 to 2500 MHz (megahertz) in frequency. With the method, sintering during microwave roasting of the vanadium-containing stone coal is obviously reduced, and the effect of microwave roasting is good.

Owner:WUHAN UNIV OF SCI & TECH

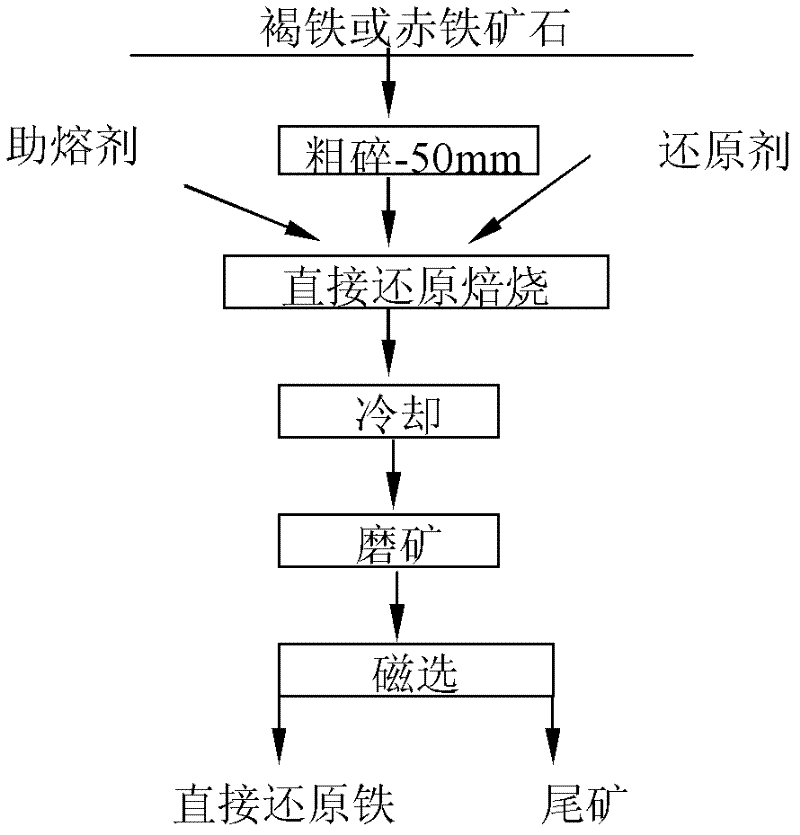

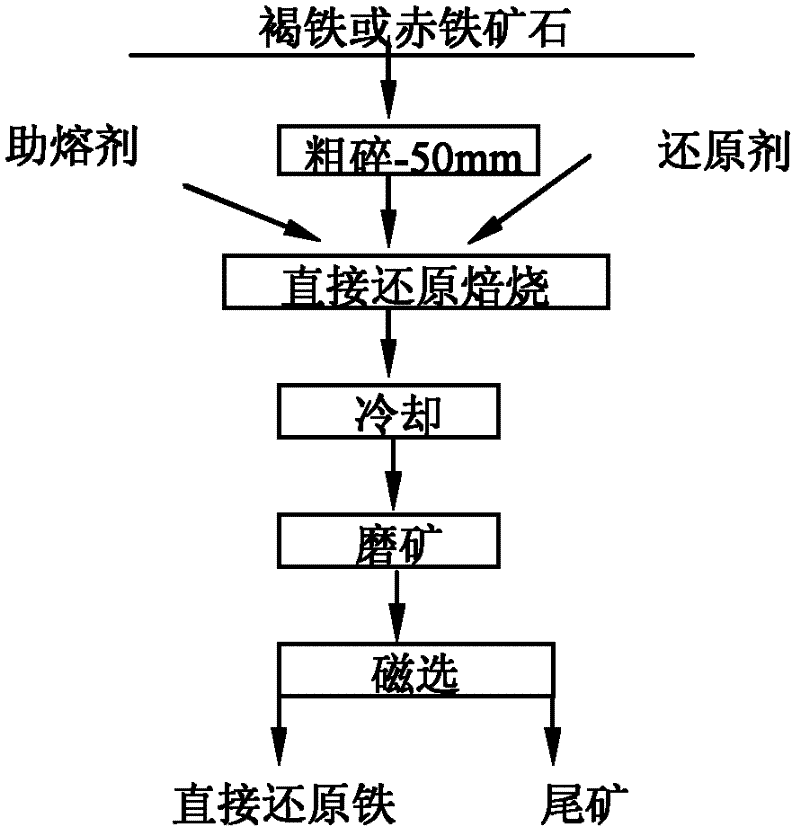

A process for producing direct reduced iron from large-grained limonite and hematite ores

InactiveCN102268503AHigh recovery rateSimplify the crushing processFluidised-bed furnacesIronstoneRoasting

The invention belongs to the field of ferrous metallurgy and relates to a process method for producing reduced iron in a roasting shaft furnace by using a direct reduction roasting method, wherein used iron are iron ores which mainly exist in forms of limonite and hematite. The method is characterized in that roughly smashing raw ore till particle size is 100%(-50mm), and then fully mixing the pulverized ore with a tailor-made reducing agent and a fluxing agent in a proportion; carrying out direct reduction roasting in the roasting shaft furnace; and obtaining the directly reduced iron product with an iron grade of 90% and iron recovery of more than 80% by using an ore grinding magnetic method. In the process, the reduction temperature is 1100 DEG C-1250 DEG C, wherein the specific temperature is determined according to the property of the ore; the reduction time is 120-240 minutes; and according to the properties of different ores, different amounts of reducing agent and fluxing agent can be added in the process.

Owner:UNIV OF SCI & TECH BEIJING +1

Efficient roasting device for rare earth waste

InactiveCN106482504AReasonable useEasy to passCharge composition/stateCharge treatment typeRare earthEngineering

The invention relates to a roasting device, in particular to an efficient roasting device for rare earth waste. The efficient roasting device for rare earth waste achieves the technical aims of being easy to operate, low in equipment cost and low in energy consumption and comprises a bottom plate, a roasting furnace, a support, a bearing pedestal, a reel, a rotating shaft, a rotating rod, shifting pieces, a first connecting rod, an exhaust fan, a second connecting rod, a baffle and the like; the top of the bottom plate is connected with the support in a welded manner, the support is located on the right of the roasting furnace, the upper portion and the lower portion of the right wall in the support are connected with the first connecting rod in a welded manner, and the left end of the first connecting rod is connected with a roasting box in a bolt connection manner. The effects of being rapid in heating, uniform in heating, low in energy consumption, simple in structure and capable of reasonably utilizing labor resources are achieved, and a groove is formed in the bottom of the roasting box.

Owner:明光智慧天顺技术转移服务有限公司

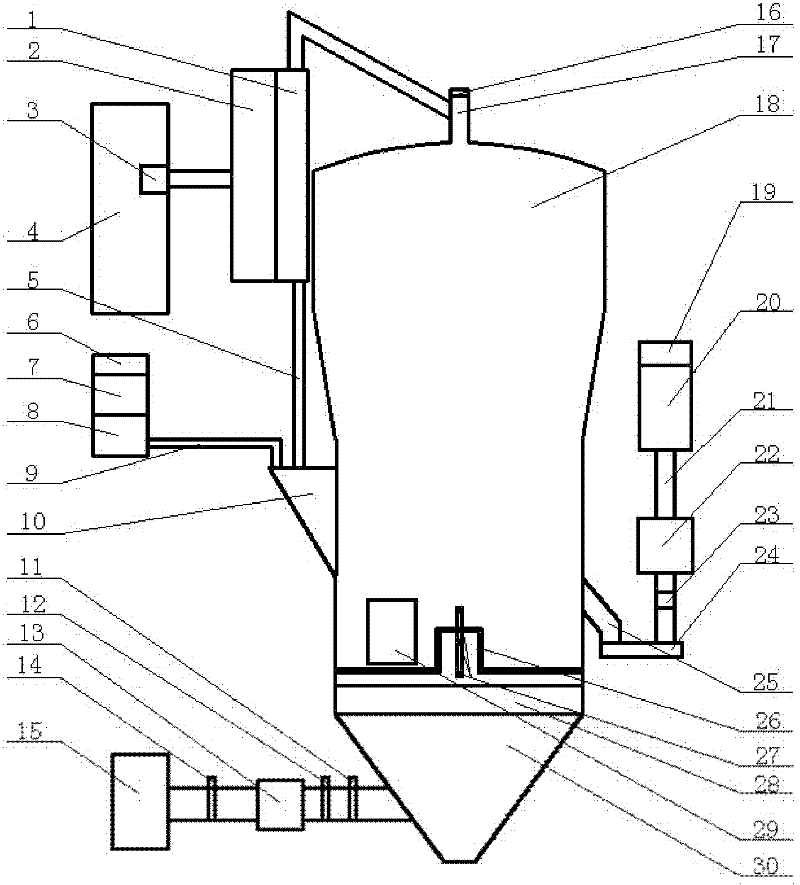

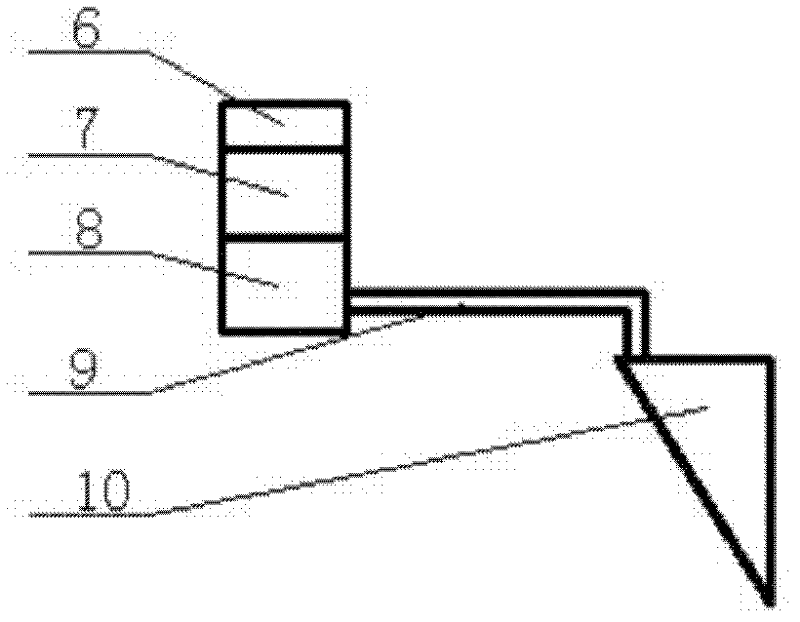

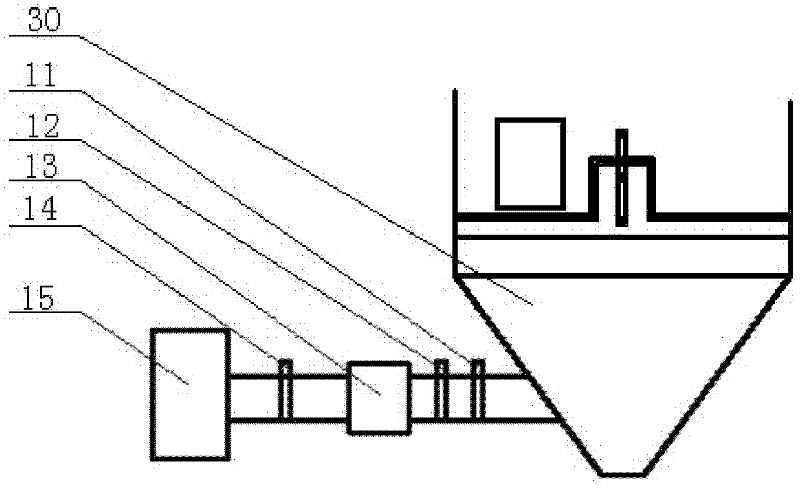

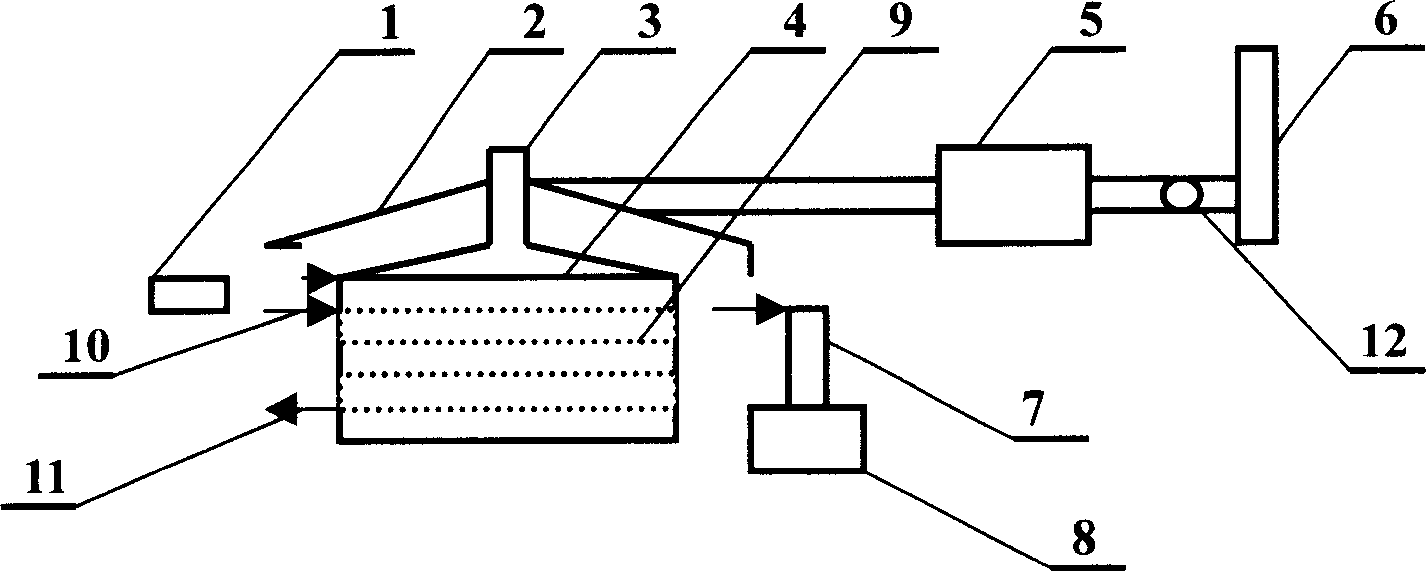

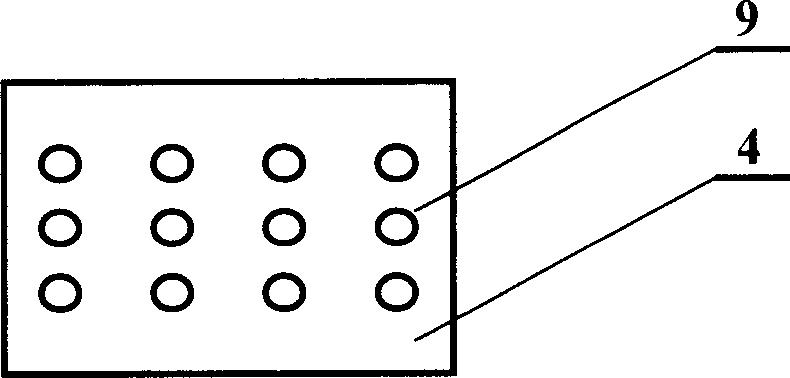

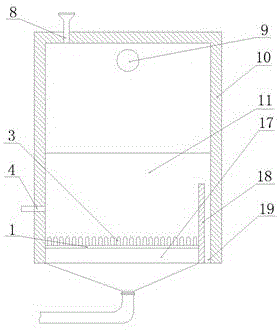

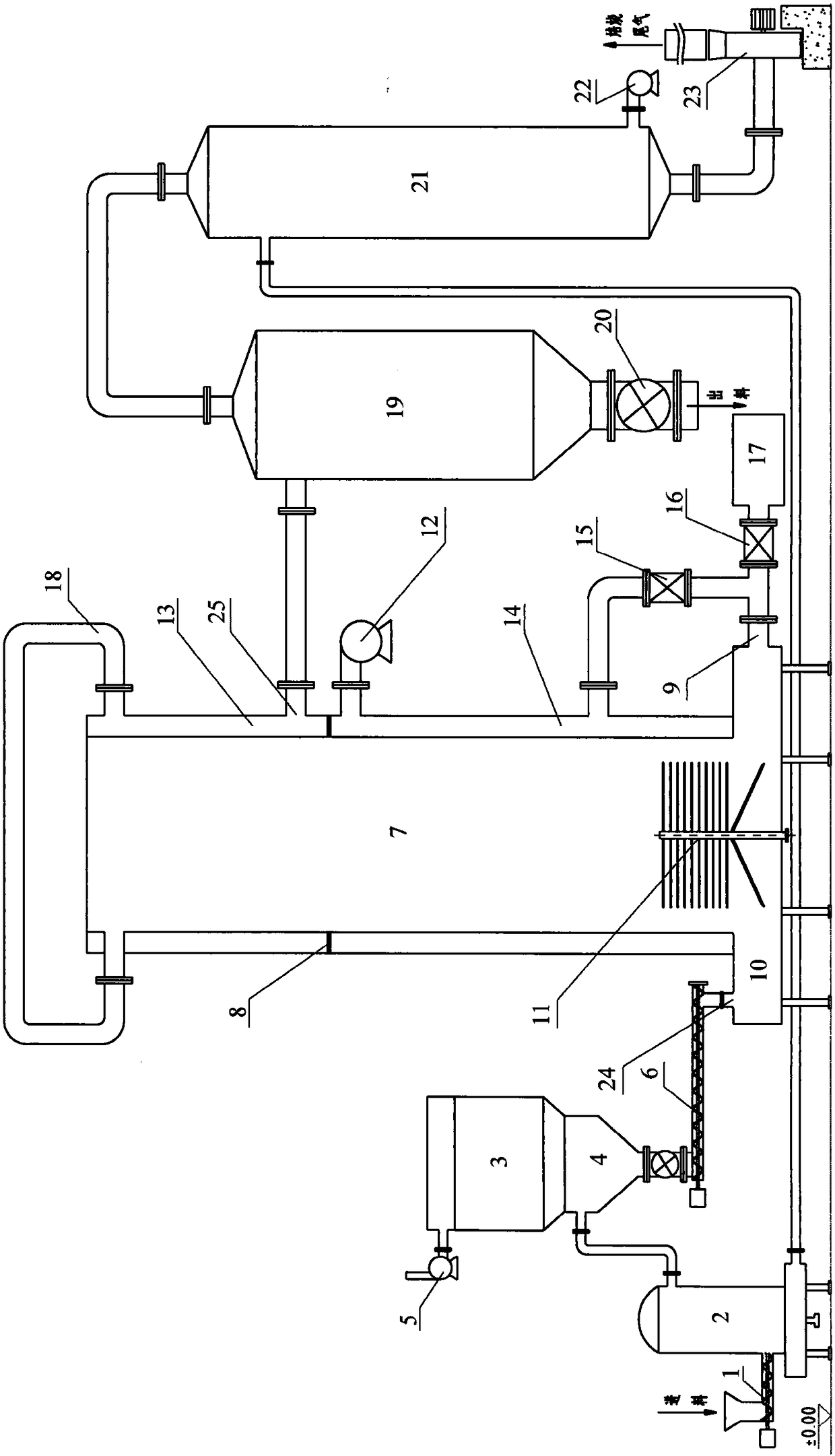

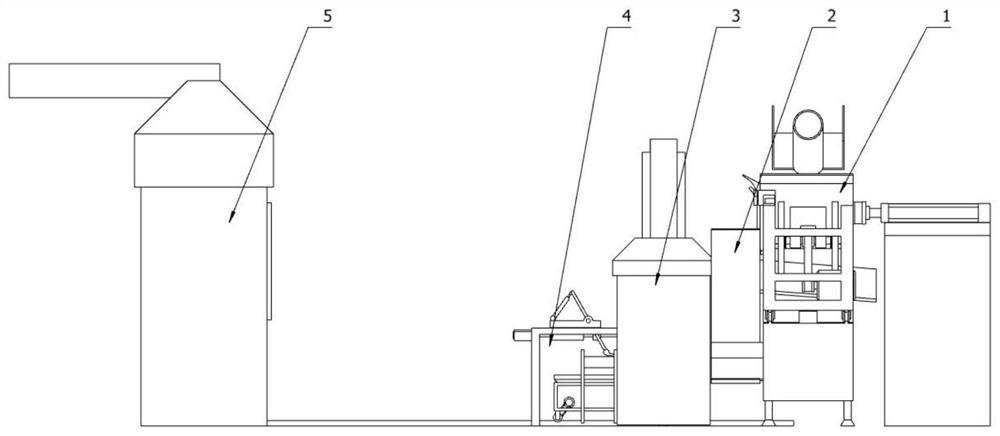

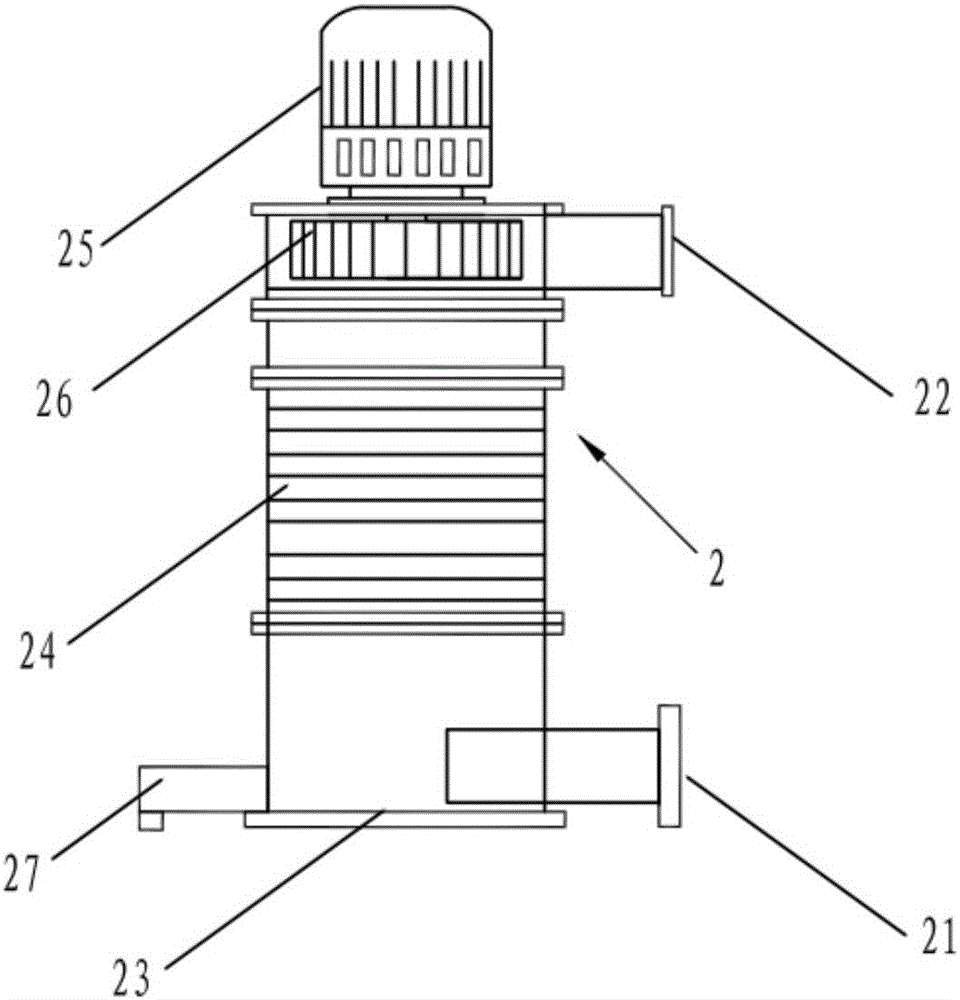

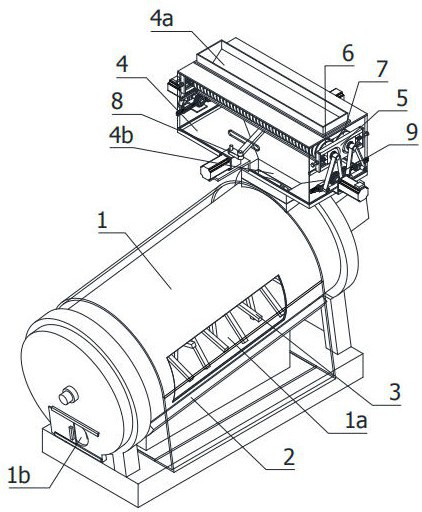

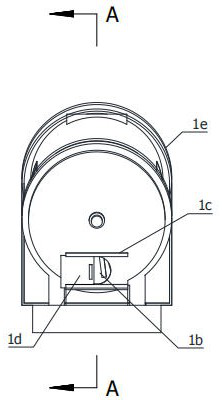

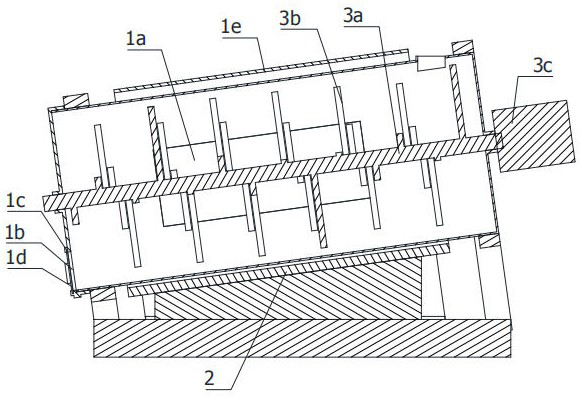

Fluidized bed furnace device for circularly roasting molybdenum concentrates and method for using same

InactiveCN102653821AFully roasted oxidation reactionIncrease heat productionFluidised-bed furnacesFluidized bedFlue gas

The invention discloses a fluidized bed furnace device for circularly roasting molybdenum concentrates, which comprises a fluidized bed furnace, a dust collection system, a flue gas recycling system, an air supply system, a feeding system and a discharged-material packing automation system, wherein the discharged-material packing automation system is connected to a discharge outlet of the fluidized bed furnace; the dust collection system and the feeding system are both connected to a feed inlet of the fluidized bed furnace; the air supply system is connected to an air chamber of the fluidized bed furnace, and is composed of a Roots blower, a heating facility and a facility capable of indicating and controlling the pressure and air inflow volume in the air chamber; and the feeding system can uniformly and continuously feed molybdenum concentrates with sizes of 20-200 meshes into the fluidized bed furnace according to a given amount. The invention also discloses a method for using the fluidized bed furnace device for circularly roasting molybdenum concentrates, through which molybdenum concentrates are in full contact with enough oxygen, so that an effect of supplying heat without using an external heat source in the roasting process of molybdenum concentrates is achieved, and high-dissolubility molybdenum oxides of which the soluble molybdenum content is greater than 98% can be efficiently produced, therefore, the method is storing in production capacity; and the concentration of SO2 in roasting in flue gas can reach 4%.

Owner:CHINA MOLYBDENUM

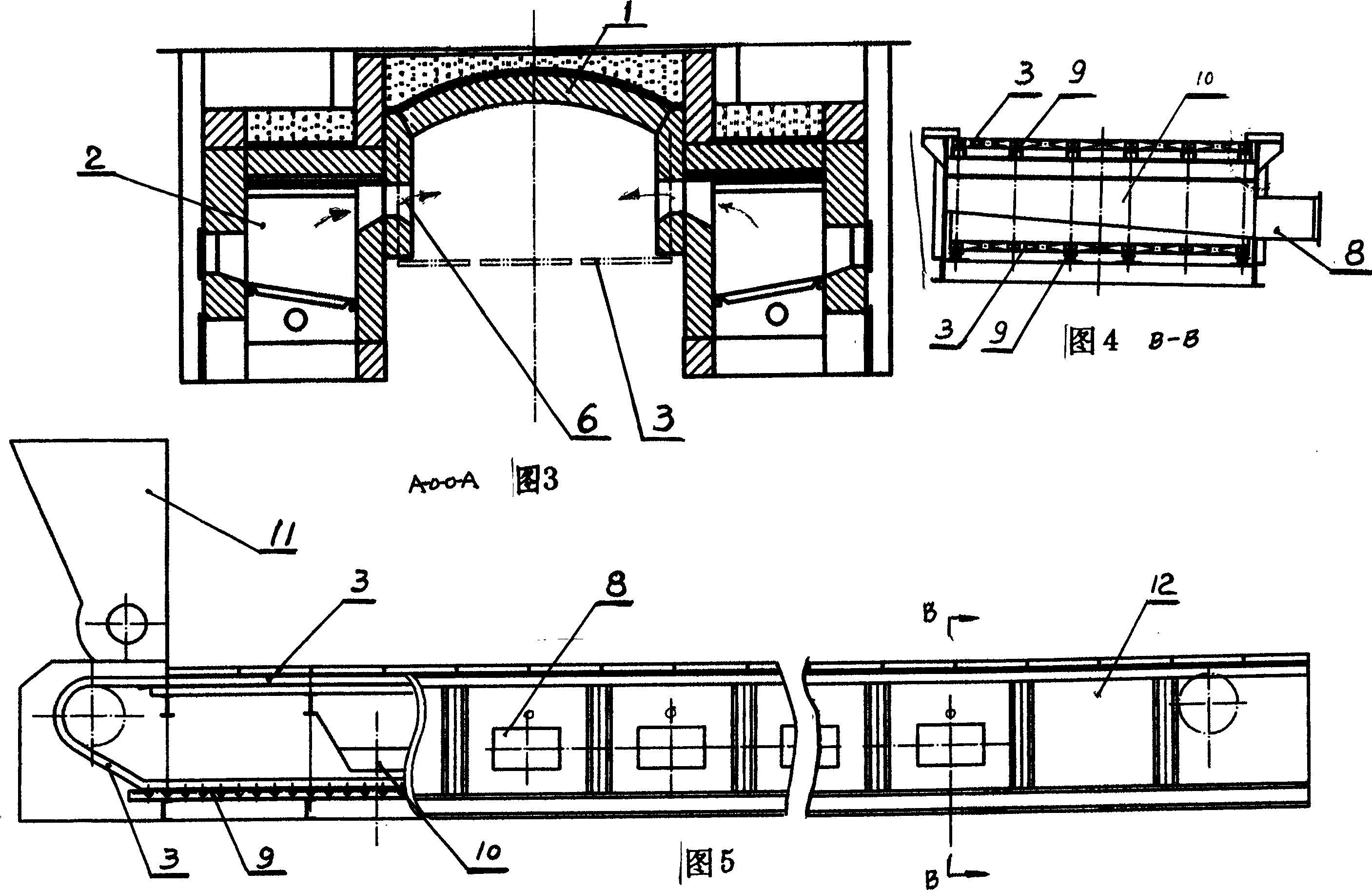

Method and apparatus for calcining mineral materials difficult to be treated

The invention opened a roasting method of the intractable mineral. The mineral is put into the roasting pipe of the roasting furnace to roast for 1.0-5.0h, and then heated by the coal, the gas or the residual heat. The temperature of the pipe is 400-1150 DEG C. It mixes the mineral by turning the pipe continuously or intermittently. The roasting furnace includes the dispenser, the petticoat pipe collector, the flue, the rectangular parallelepiped furnace body, bag-type dust collector, the eluting gas wash tower, the receiver bin, the fueling equipment, the fuel discharge device and the draught fan. The ratio of the long to the diameter of the roasting pipe is 2-15:1. the method has the low cost and high production.

Owner:ZIJIN MINING GROUP

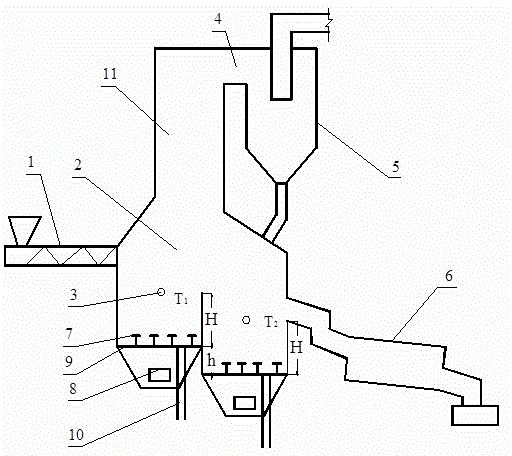

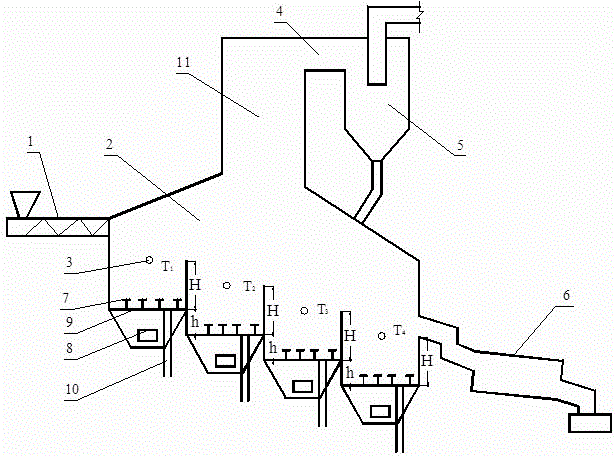

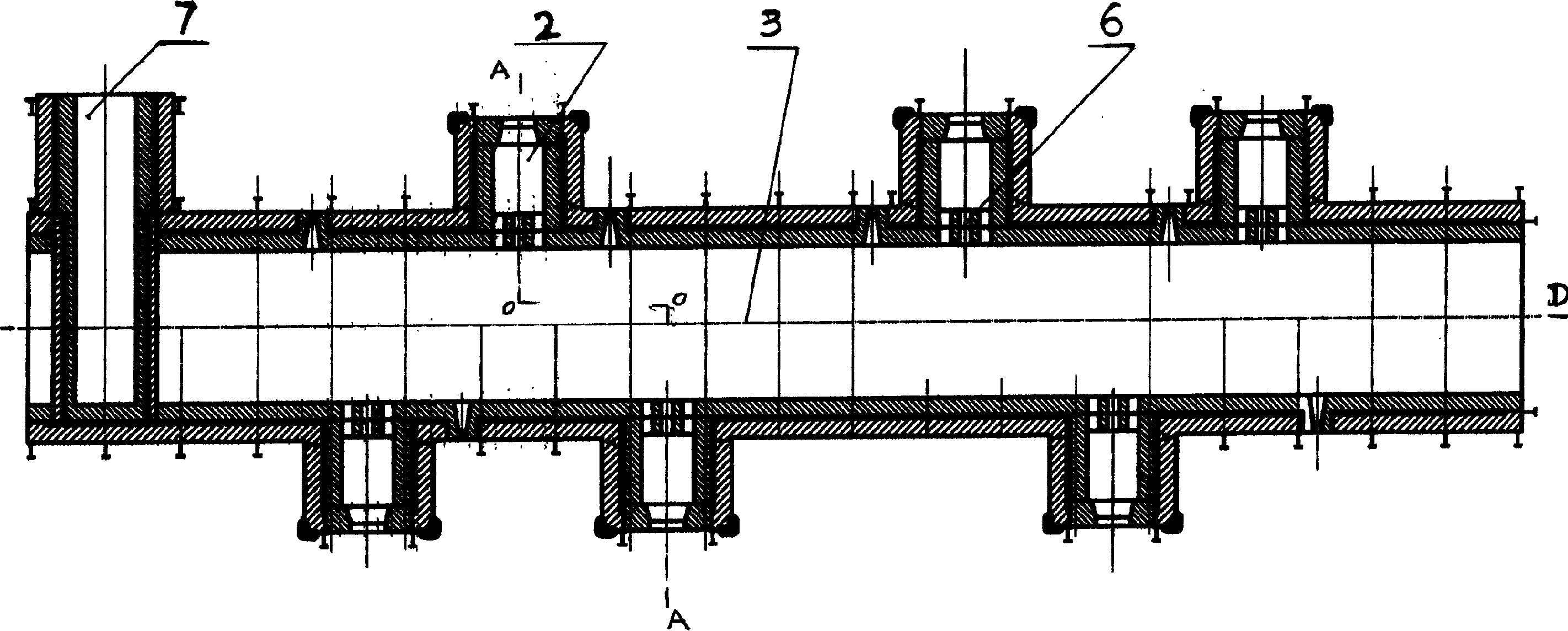

Multi-bed linkage fluidized bed roasting furnace

A multi-bed linkage fluidized bed roasting furnace comprises a feeding device, a combustion chamber, a top passing flue arranged at the top of the combustion chamber, a cold slag device and a cyclone separator connected behind the top passing flue. Roasting beds at two or more levels are arranged under the combustion chamber, each roasting bed at the previous level and the corresponding roasting bed at the next level are arranged in a stepped mode, each roasting bed comprises an air chamber, an air distributing plate, air caps arranged on the air distributing plate and a slag discharging pipe on the bed, and an additive opening for adding calcium-based additives or combustion-supporting coal is formed in the upper portion of each roasting bed; the cold slag device is arranged behind the roasting bed at the last level. The height difference h between each roasting bed at the previous level and the corresponding roasting bed at the next level is 100-300 mm, wherein the roasting beds are arranged in the stepped mode. The multi-bed linkage fluidized bed roasting furnace has the advantages of being high in roasting efficiency and treating roasting flue gas well.

Owner:BEIJING SIWEI TIANTUO TECH CO LTD

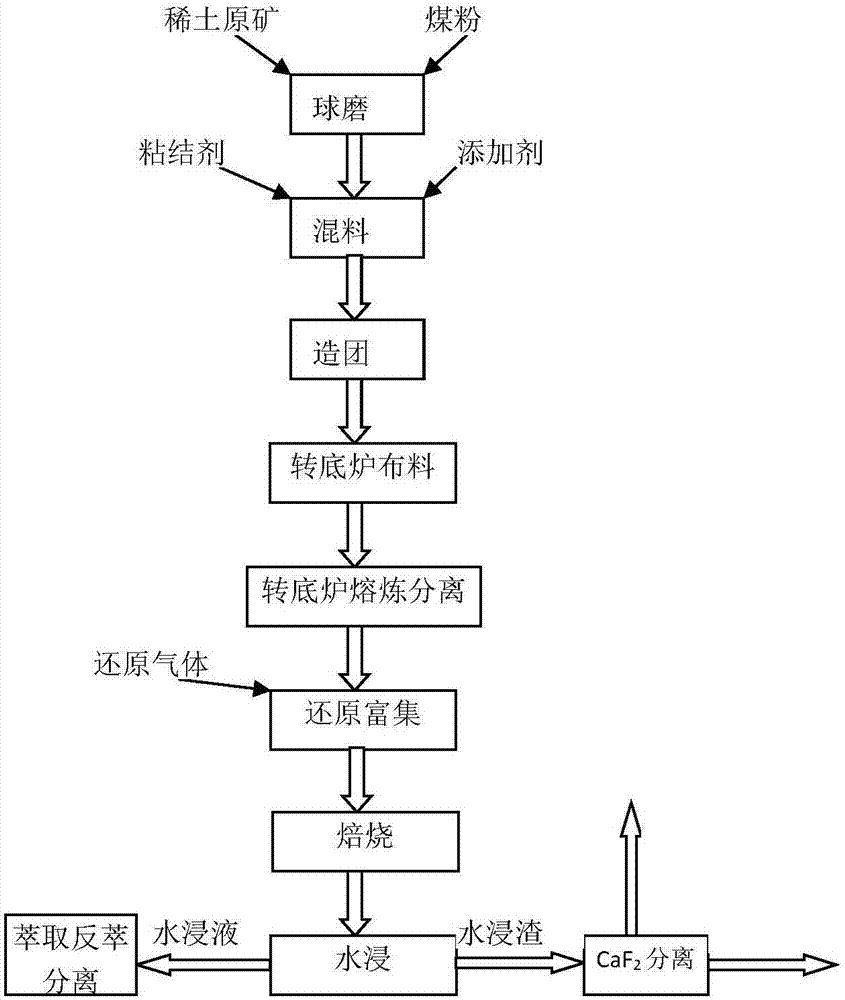

Method for separating and producing rare earth from iron-containing rare earth raw ore

The invention belongs to the field of firing and wet comprehensive smelting of rare earth ore and particularly relates to a method for separating and producing rare earth from iron-containing rare earth raw ore. An iron bead product and a rare earth product are obtained through steps as follows: grinding, mixing, agglomerating, distribution in a rotary hearth furnace, smelting separation in the rotary hearth furnace, roasting, water leaching and the like. Under the condition of relatively lower cost, production efficiency and rare earth leaching rate are greatly increased.

Owner:UNIV OF SCI & TECH BEIJING

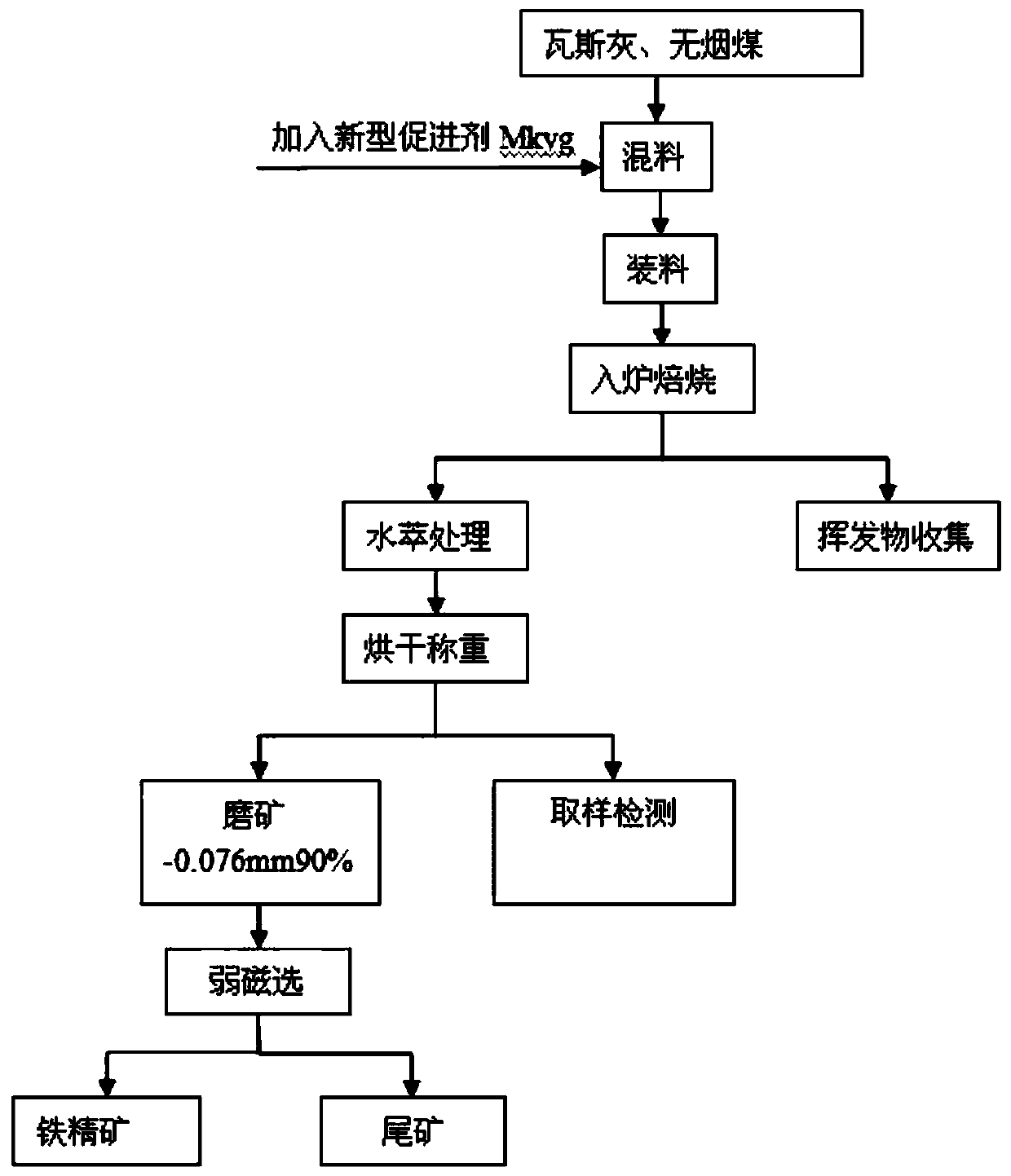

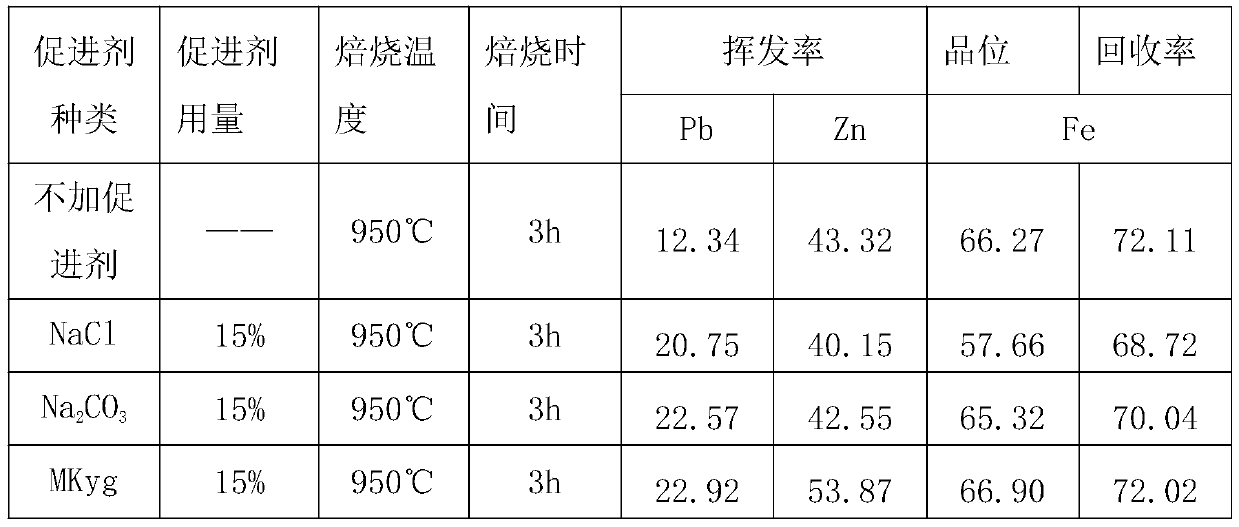

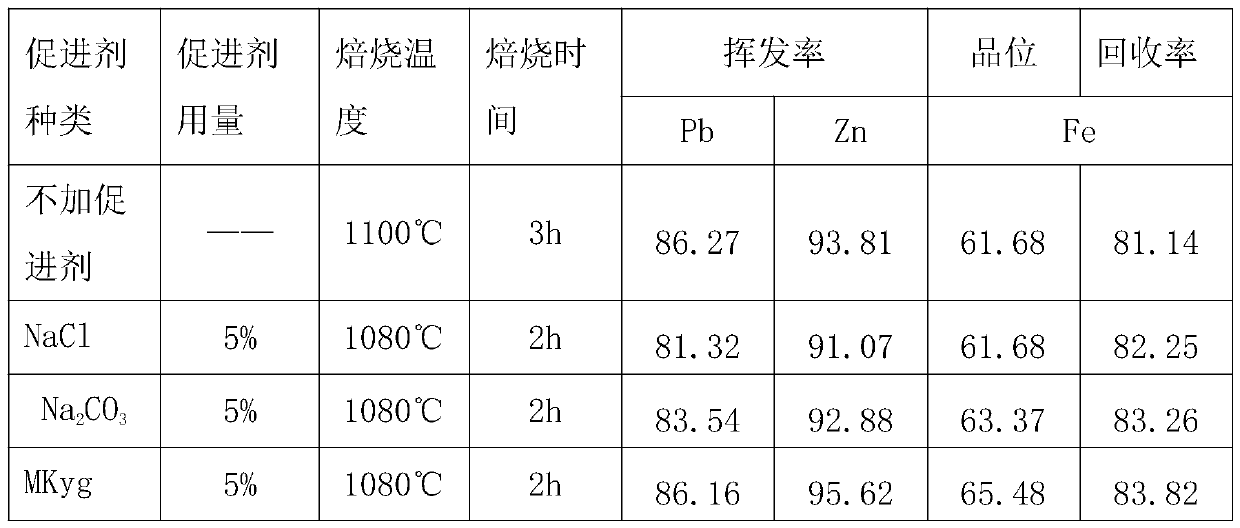

Method for comprehensively recovering lead, zinc and iron in gas ash of blast furnace

ActiveCN110564969AIncrease relative volatilityEfficient evaporationProcess efficiency improvementProduction rateAnthracite

The invention discloses a method for comprehensively recovering lead, zinc and iron in gas ash of a blast furnace. Anthracites of 20-30% of the total mass of blast furnace gas mud are fed in the blastfurnace gas mud containing lead, zinc and iron, and roasting accelerants of 4.0-6.0% of the total mass of the blast furnace gas mud and compounded by Na2CO3 and CaCO3 are fed; the materials are uniformly mixed and fed in a rotary kiln or a rotary hearth furnace, with a smoke recovery system, for reduction roasting; gas is extracted to feed in the smoke recovery system for treatment; mud settlingproducts containing lead and zinc are collected; roasting ores discharged from the rotary kiln or the rotary hearth furnace are quenched by water; and the water-quenched materials are fed in an ore grinding-weak magnetic separation recovery system to obtain iron concentrate powder. The method can synchronously realize the zinc volatilization rate of above 95% and the lead volatilization rate of above 86%, obtains iron concentrates with the grade of above 65.00%, not only can effectively recover lead, zinc and iron resources in the gas ash, but also can reduce the energy consumption, and improves the productivity.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

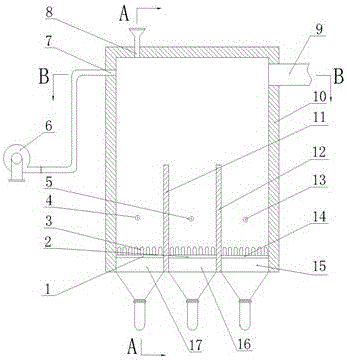

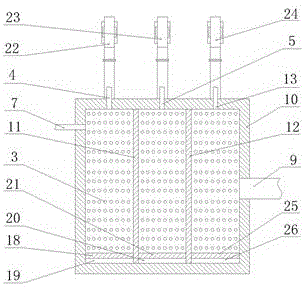

Method for fluidized roasting of stone coal in one step

ActiveCN106244796AOne-step gradingAvoid screening operations outside the furnaceFluidized bedHigh energy

The invention relates to a method for fluidized roasting of stone coal in one step. According to the technical scheme, a fluidized-bed roaster for roasting the stone coal in one step is adopted for roasting; stone coal crushing materials are fed into a roaster body (10) from a feeding inlet (8); the feeding amount and the wind speed of an air port (7) are regulated so that the stone coal crushing materials are distributed in a first fluidized bed (1), a second fluidized bed (2) and a third fluidized bed (14) according to different size fractions; the blast volumes of a first fan (19), a second fan (20) and a third fan (21) are adjusted to regulate the height of a material layer; the coal gas volumes of a first coal gas burner (4), a second coal gas burner (5) and a third coal gas burner (13) are adjusted to regulate a roasting system; after roasting finishes, roasted materials in the first fluidized bed (1), the second fluidized bed (2) and the third fluidized bed (14) are respectively discharged from a first discharge port (19), a second discharge port (20) and a third discharge port (26) and are combined to obtain the stone coal roasted materials. The method has the characteristics of strong material adaptability, simple operation, high yield of the roasted material, high roasting efficiency and high energy utilization rate.

Owner:WUHAN UNIV OF SCI & TECH

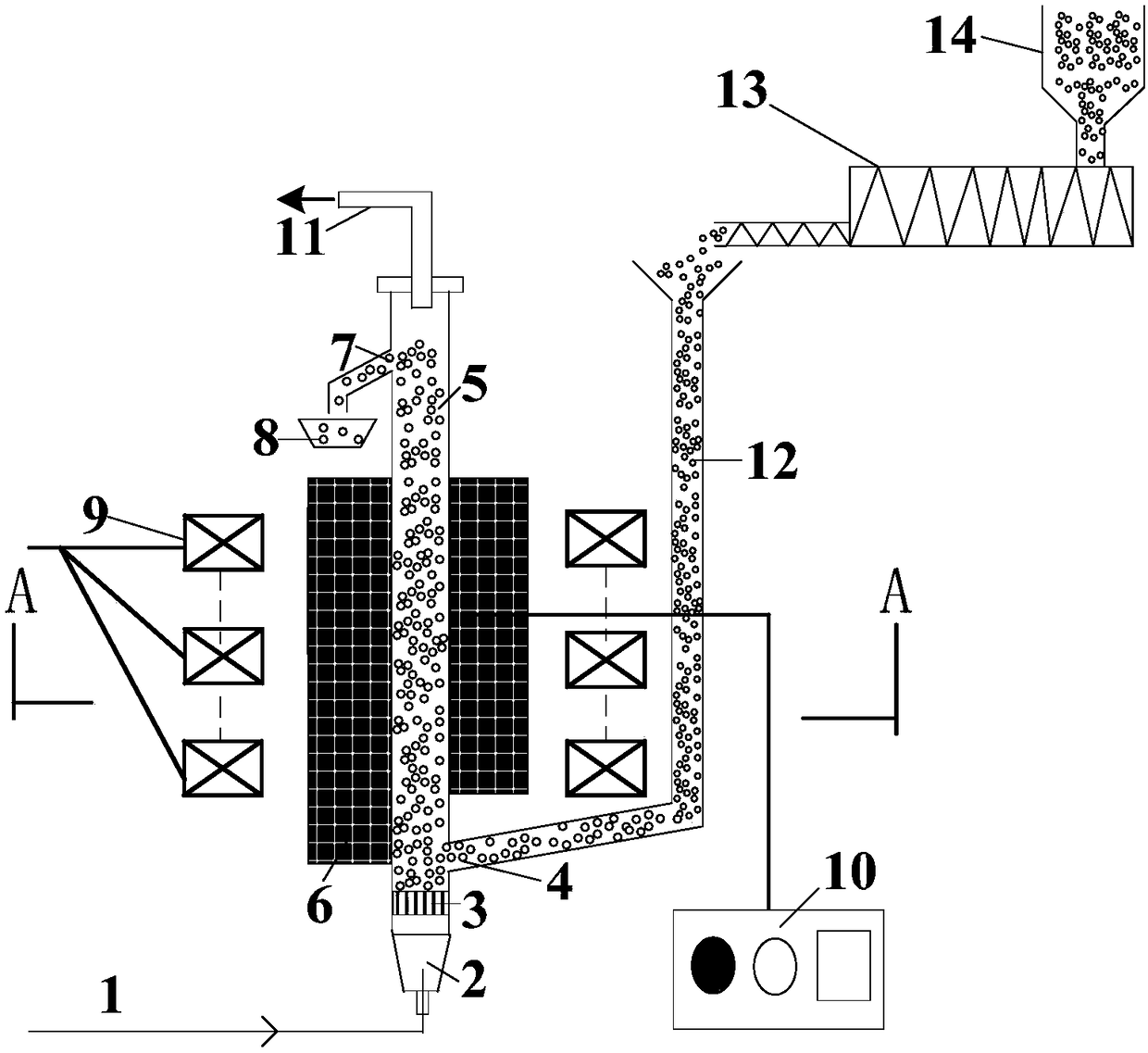

Bright molybdenum concentrate self-heating type rotational flow roasting technology and equipment

ActiveCN108149006AFully roasted oxidation reactionComplete desulfurizationMolybdenum oxides/hydroxidesWaste heat treatmentComing outGas solid

The invention relates to a bright molybdenum concentrate self-heating type rotational flow roasting technology and equipment. A rotational flow roasting furnace provided with a furnace body heat exchanging device is utilized to roast bright molybdenum concentrate so as to produce industrial molybdenum oxide. The heat emitted by a roasting reaction of the bright molybdenum concentrate is utilized to preheat air entering from an interlayer heat exchanging device of a lower furnace body in the roasting process, the preheated air is supplied into the rotational flow roasting furnace from the furnace bottom, a rotational flow wind distributing device makes the bright molybdenum concentrate be subjected to a roasting reaction under a rotational eddy state, a material coming out from the rotational flow roasting furnace enters an upper interlayer heat exchanging device of the rotational flow roasting furnace along with roasting eddy under the effect of negative pressure, a desulfurization reaction is completed in the interlayer heat exchanging device in the rotational advancing process, and a reacted gas-solid mixture enters a gas-solid separation discharging device to be subjected to gas-solid separation so that a solid roasted product and roasted smoke can be separated. The roasted smoke is sent to a SO2 recycling processing system under a draft effect of an induced draft fan afterentering a heat exchanger to exchange heat with the air, and the air after being subjected to heat exchanging is sent to a flash evaporation drying machine to dry the bright molybdenum concentrate.

Owner:NORTHEASTERN UNIV

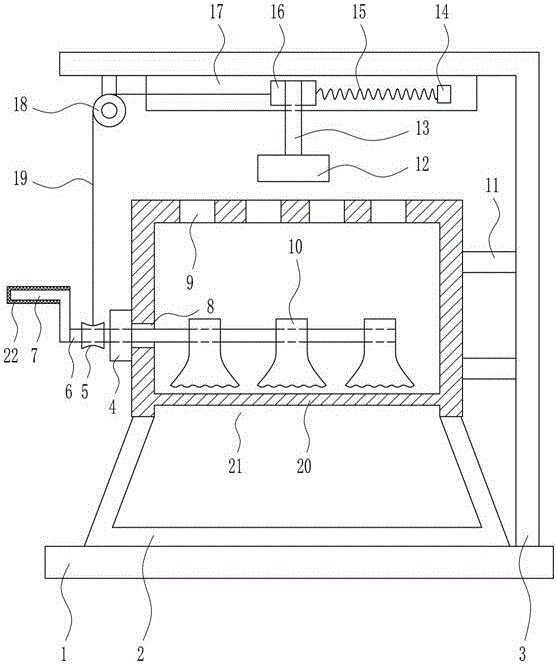

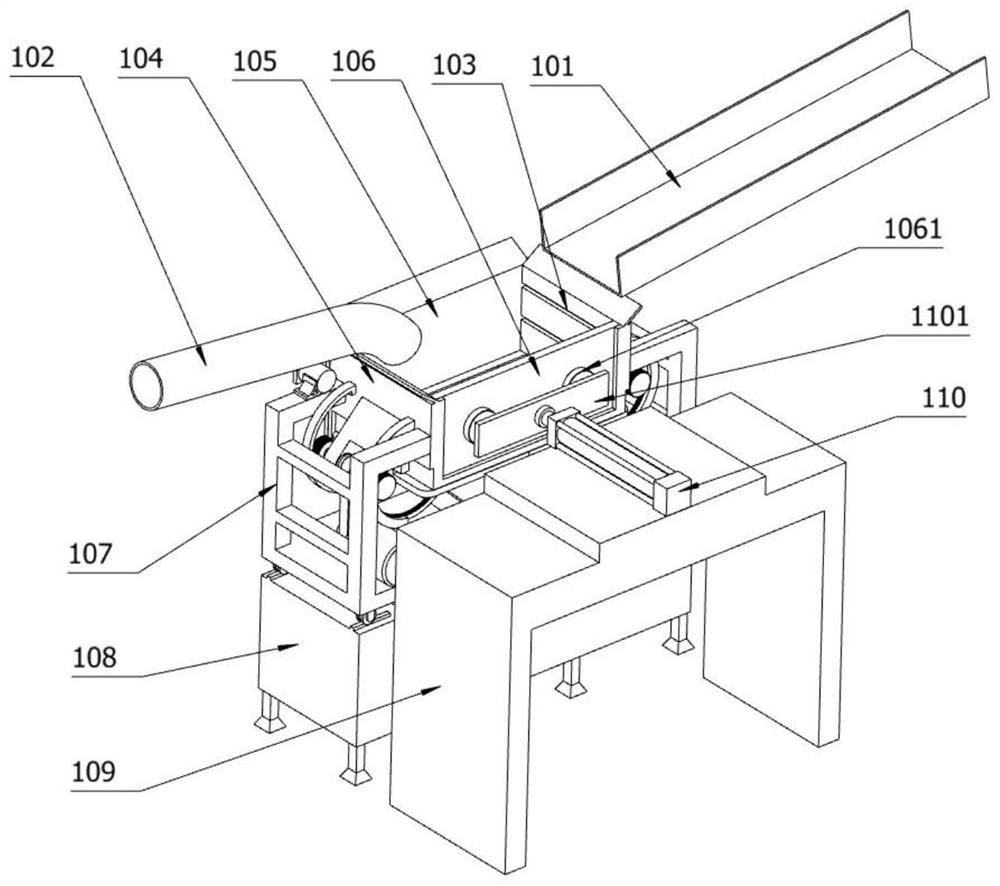

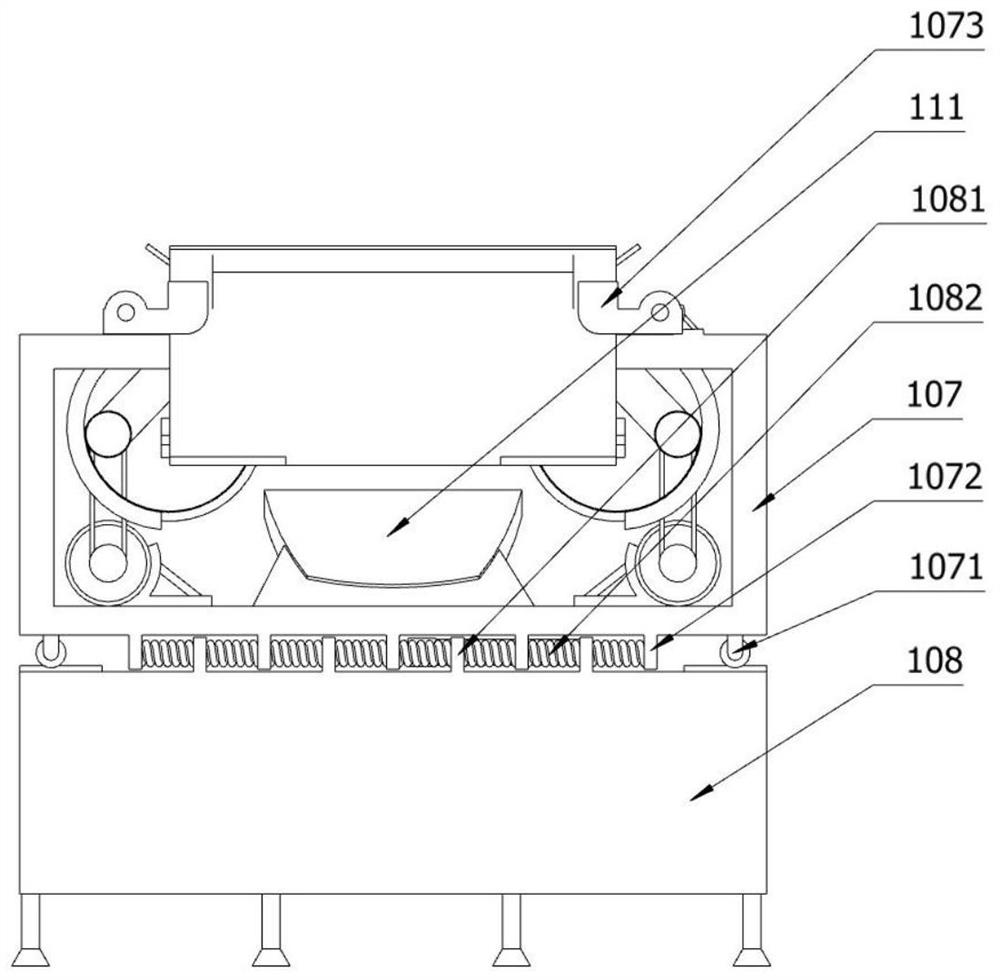

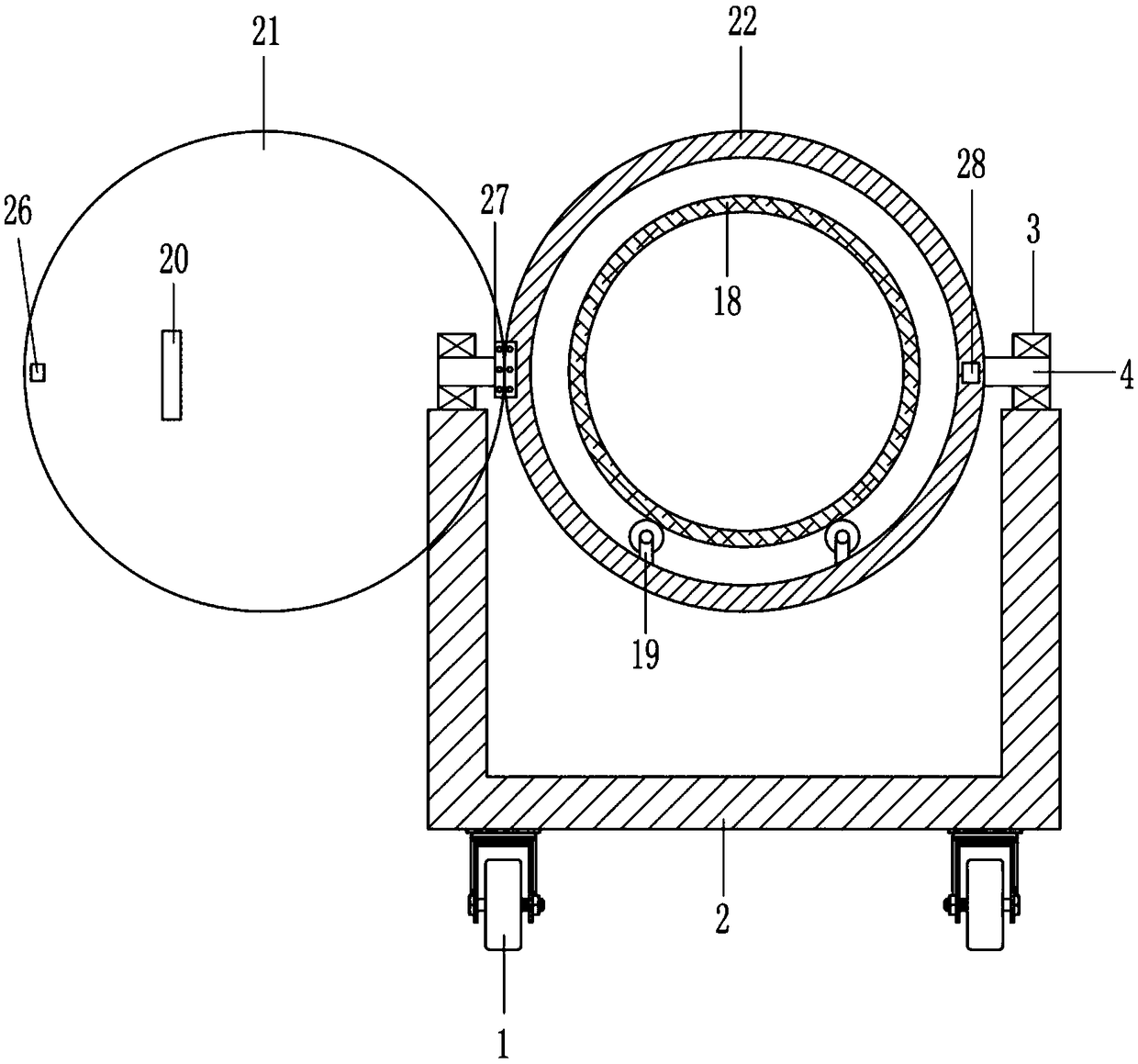

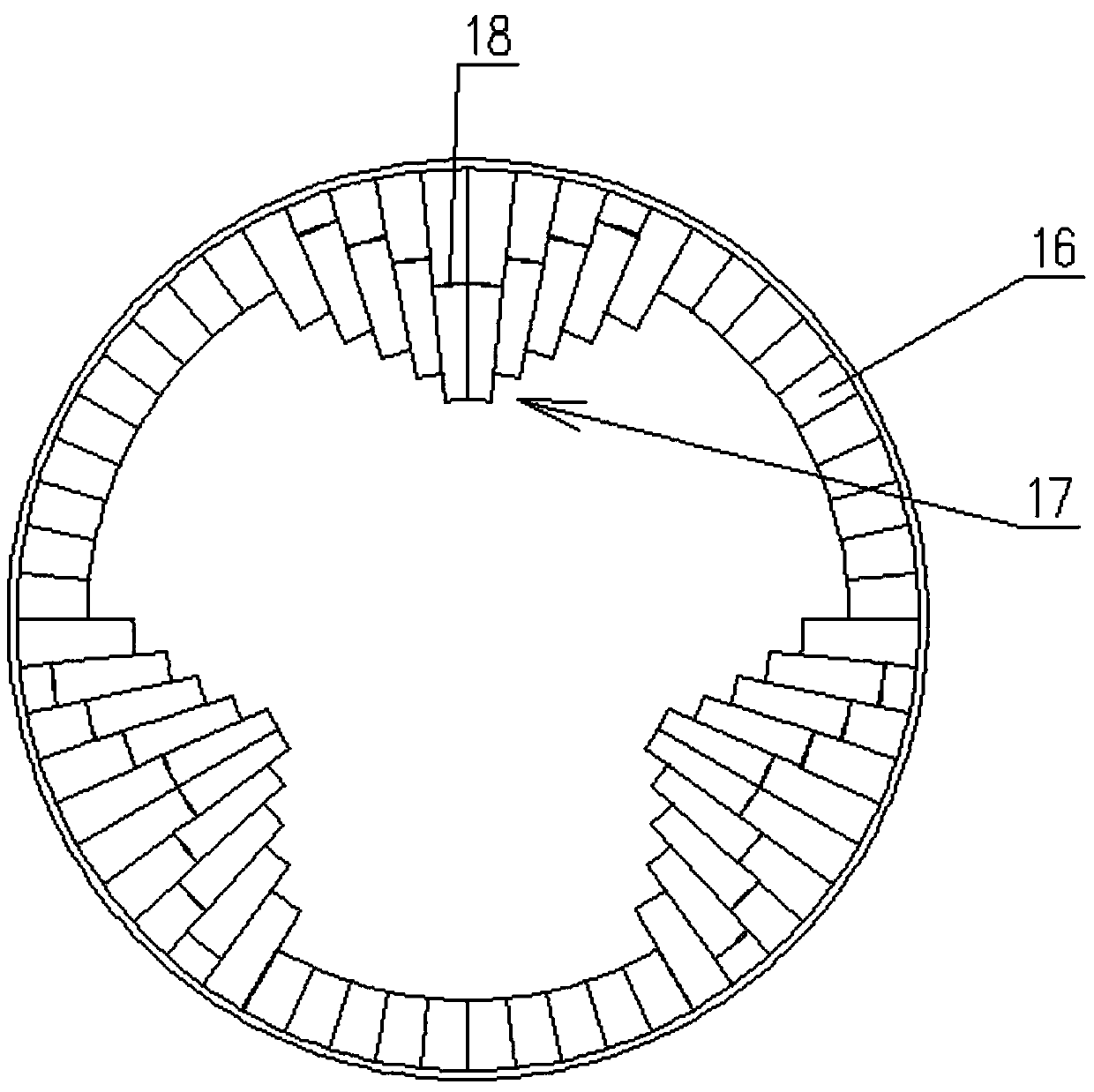

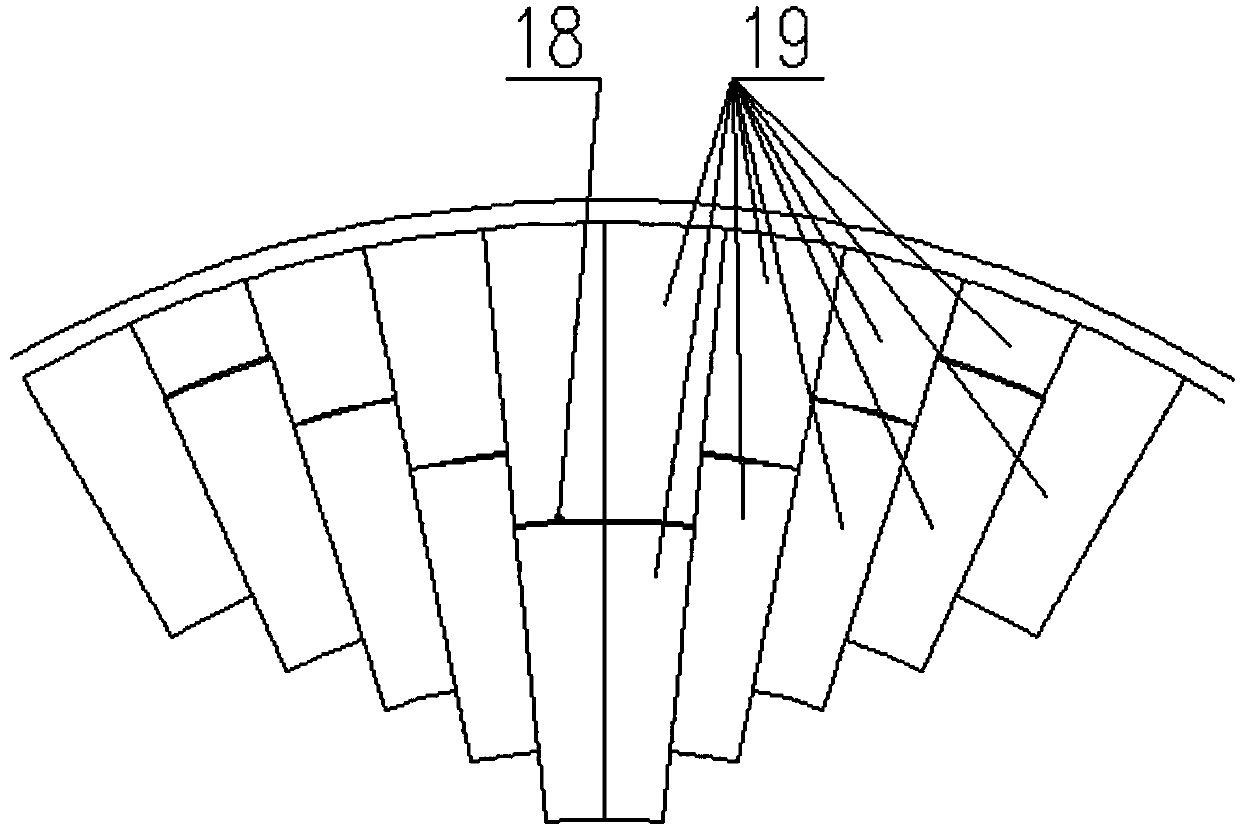

Preprocessing device for neodymium, iron and boron waste materials before roasting

PendingCN111607695AFully roastedImprove roasting efficiencyProcess efficiency improvementEngineeringReamer

The invention discloses a preprocessing device for neodymium, iron and boron waste materials before roasting, and mainly solves the problem that existing neodymium, iron and boron waste materials cannot be fully roasted and roasting efficiency is affected. The preprocessing device comprises a washing device, a breaking device, a centering device and a roasting device, wherein the washing device is provided with a left baffle plate, a right baffle plate, a front plate, a rear plate and a bottom plate; the right baffle plate is arranged on the right of the left baffle plate; the front plate isarranged in front of the left baffle plate and the right baffle plate; the rear plate is arranged behind the left baffle plate and the right baffle plate; the bottom plate is arranged on the bottom ofthe left baffle plate, the right baffle plate, the front plate and the rear plate; the breaking device is arranged in front of the washing device and is provided with a breaking box and a breaking reamer, wherein the breaking reamer is arranged in the breaking box and is used for breaking neodymium, iron and boron; the centering device is arranged between the breaking device and the washing device and is provided with a material blocking plate; the material blocking plate is arranged between the breaking box and the front plate; and the roasting device is arranged in front of the breaking device. The processing device has the advantages of being sufficient in roasting and high in roasting efficiency.

Owner:XINFENG BAOGANG XINLI RARE EARTH

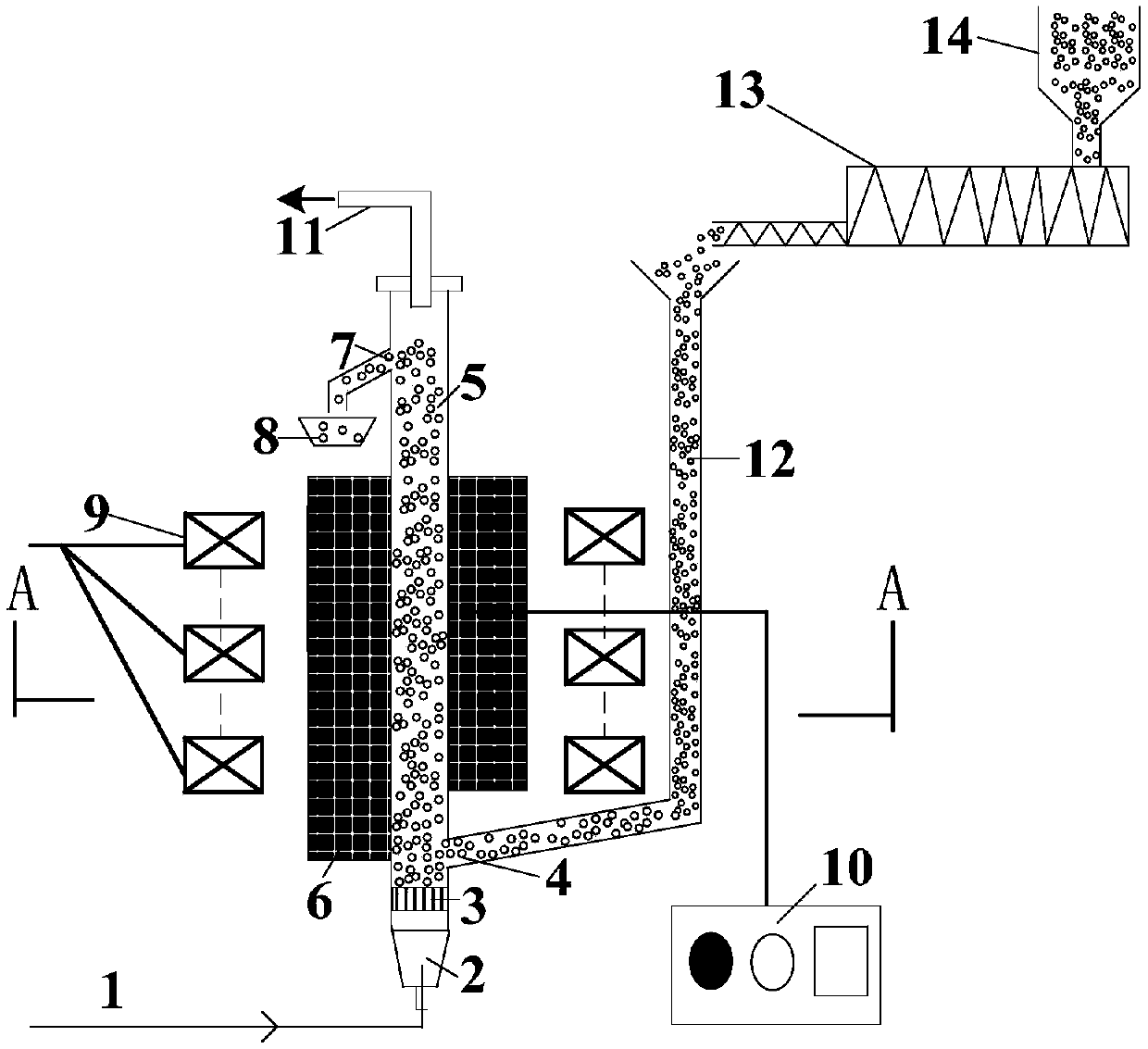

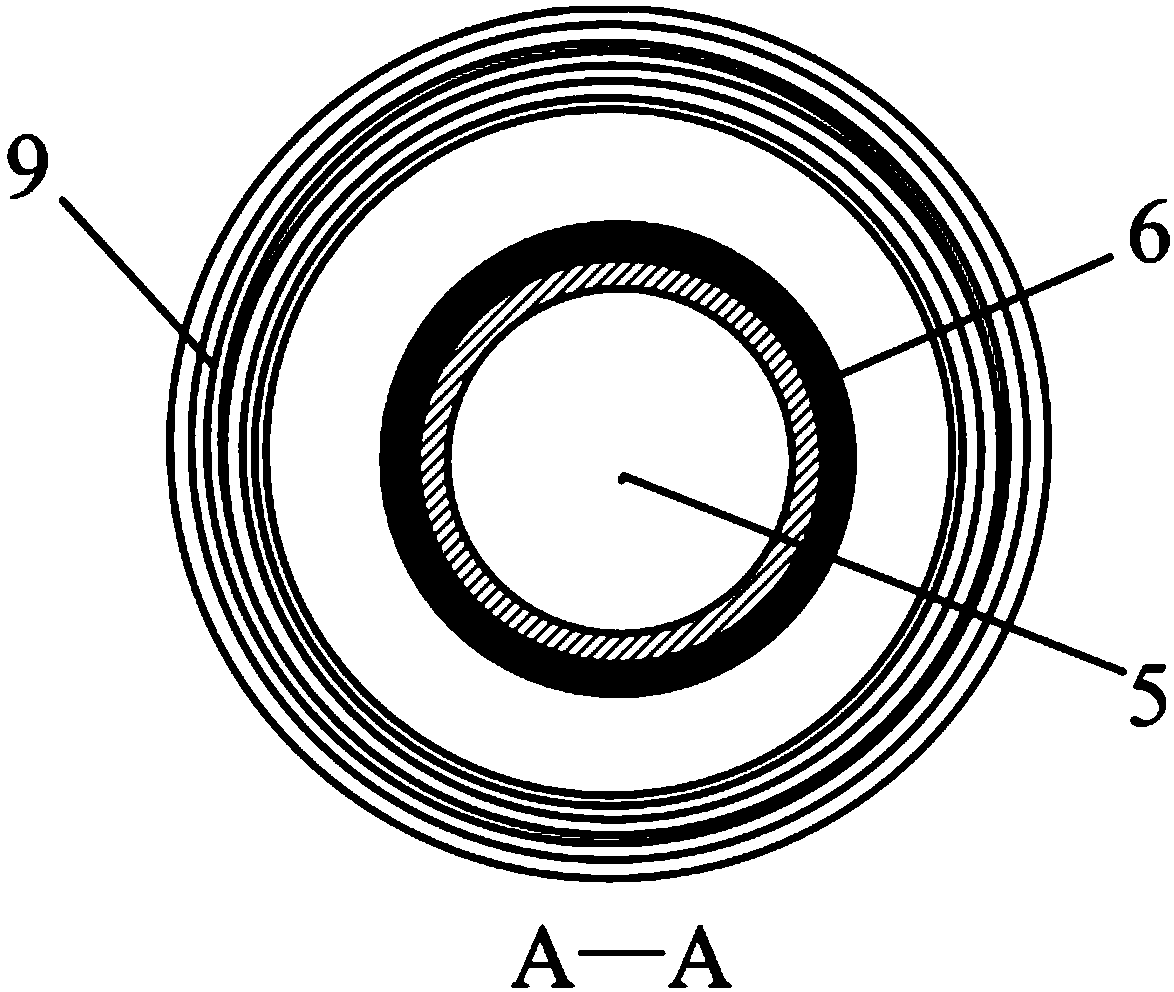

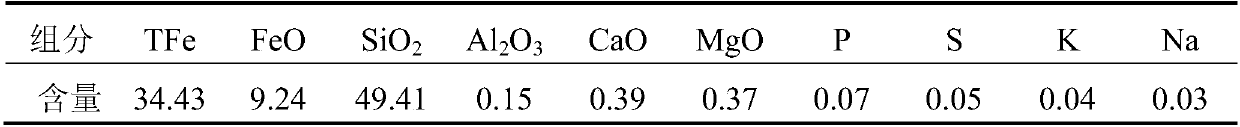

Fluidization roasting technology for processing iron ores

The invention relates to a fluidization roasting technology for processing iron ores and belongs to the technical field of mineral processing. The fluidization roasting technology for processing the iron ores is characterized in that iron ore particles are continuously fed into a reduction reactor from the lower portion of the reduction reactor, reductive mixed gas flow entering the reduction reactor from the bottom of the reduction reactor is used for carrying the iron ore particles to move upward, and roasting is conducted on the iron ore particles at 500-600 DEG C; after roasting, the obtained solid material is continuously discharged out of the reactor via a material outlet on the upper portion of the reactor, a magnetic field is exerted to the reduction reactor at the same time, the intensity of the magnetic field is 40-60 kA / m, and the direction of the magnetic field is vertically upward. According to the fluidization roasting technology for processing the iron ores, the stable magnetic field is exerted around the reduction reactor, the flowing behavior of magnetic particles in the reactor is reasonably controlled, the gaseous-solid two-phase flow in the reactor is more stable, the gas is fully reacted with the iron ores, and the roasting efficiency is improved.

Owner:NORTHEASTERN UNIV

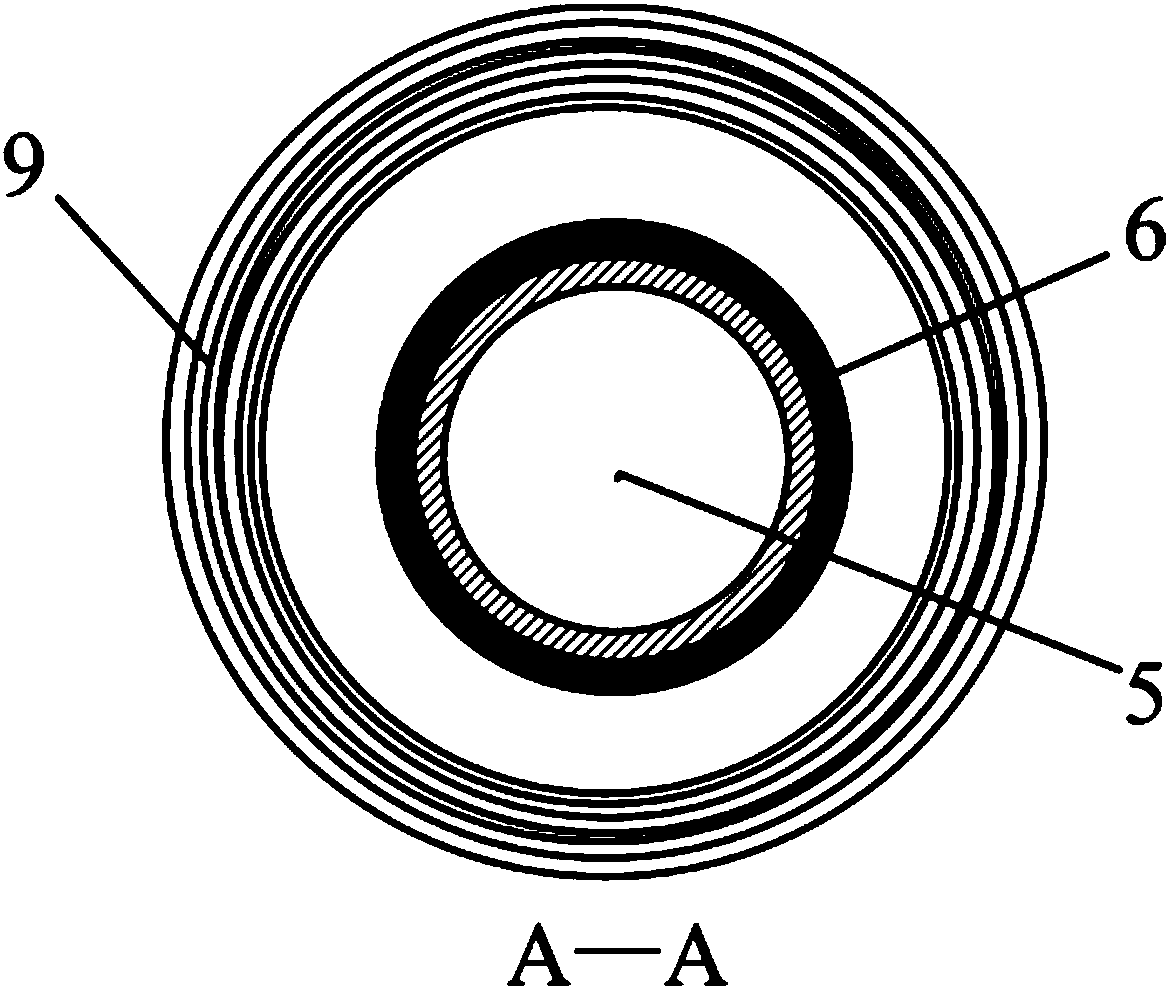

Continuous parching equipment

The invention relates to continuous parching equipment which comprises a rack, a feeding mechanism, a parching mechanism, a discharging mechanism and an oil stain separation and collection device. The parching mechanism is mounted above the rack, the feeding mechanism and the discharging mechanism are arranged at the feeding end and the discharging end of the parching mechanism respectively and communicated with the parching mechanism, and the parching mechanism comprises a roller and a heating element. The roller comprises an inner barrel and an outer barrel arranged outside the inner barrel in a sleeving mode, a closed air channel is formed between the inner barrel and the outer barrel, and the heating element is arranged in the air channel. An air inlet of the oil stain separation and collection device is communicated with the interior of the roller, an air outlet of the oil stain separation and collection device is communicated with the air channel, and high-temperature smoke generated in the roller is purified through the oil stain separation and collection device and then is subjected to secondary heating through the air channel to be guided back to the roller. In the seed parching process, cyclic utilization of heat is achieved, it is guaranteed that the equipment is free of emissions, the production environment can be clean, and the aims of saving energy and reducing emissions are achieved.

Owner:浙江宇清热工科技股份有限公司

Method for paving roasting medium in aluminum electrolysis cell and method for roasting lining

The invention discloses a method for paving a roasting medium in an aluminum electrolysis cell and a method for roasting a lining of the aluminum electrolysis cell. The method for paving a roasting medium in an aluminum electrolysis cell comprises the following steps of: placing a fence frame in an anode orthographic projection area of the aluminum electrolysis cell; filling the fence frame with a roasting medium, wherein the roasting medium contains scorched particles and graphite; and after leveling the surface of the roasting medium, removing the fence frame. Through the invention, the roasting medium can be effectively paved in the aluminum electrolysis cell.

Owner:YUNNAN YONGXIN ALUMINUM +1

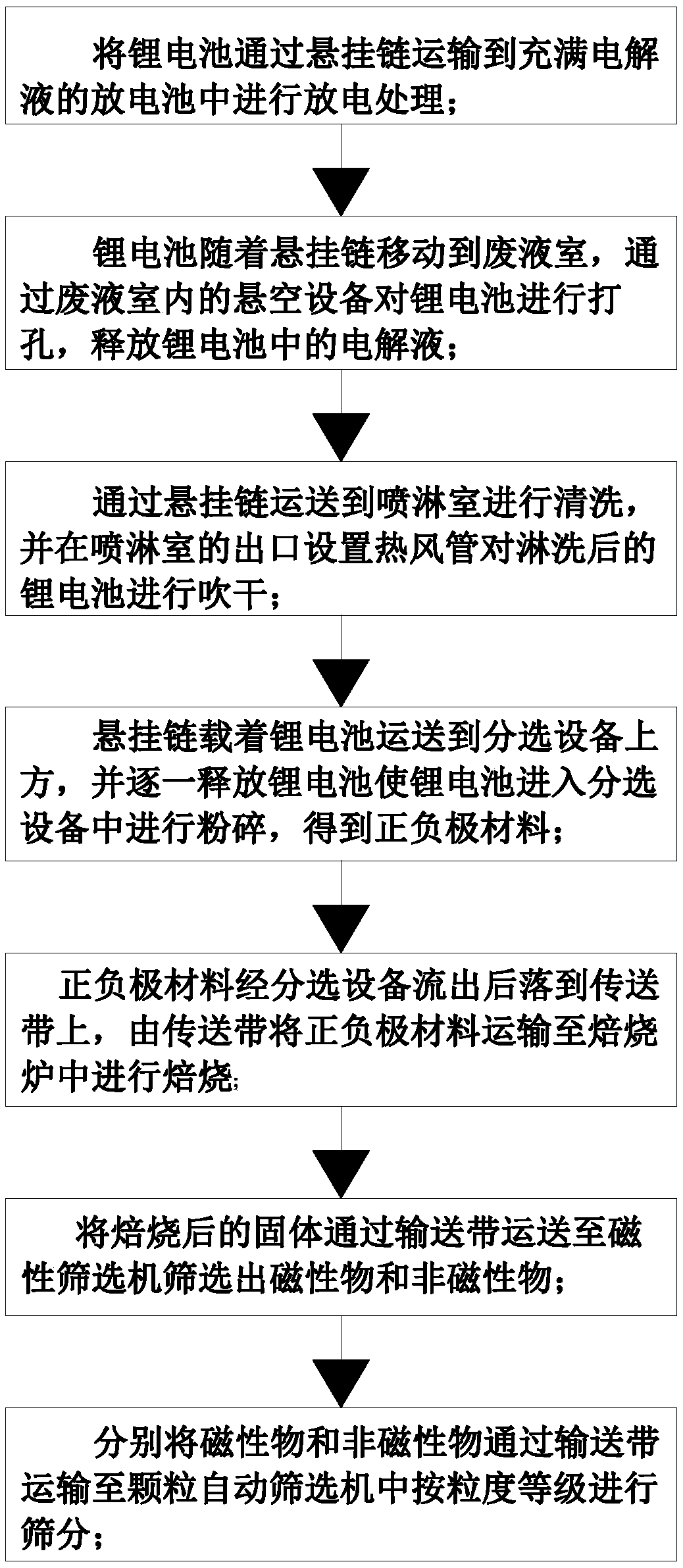

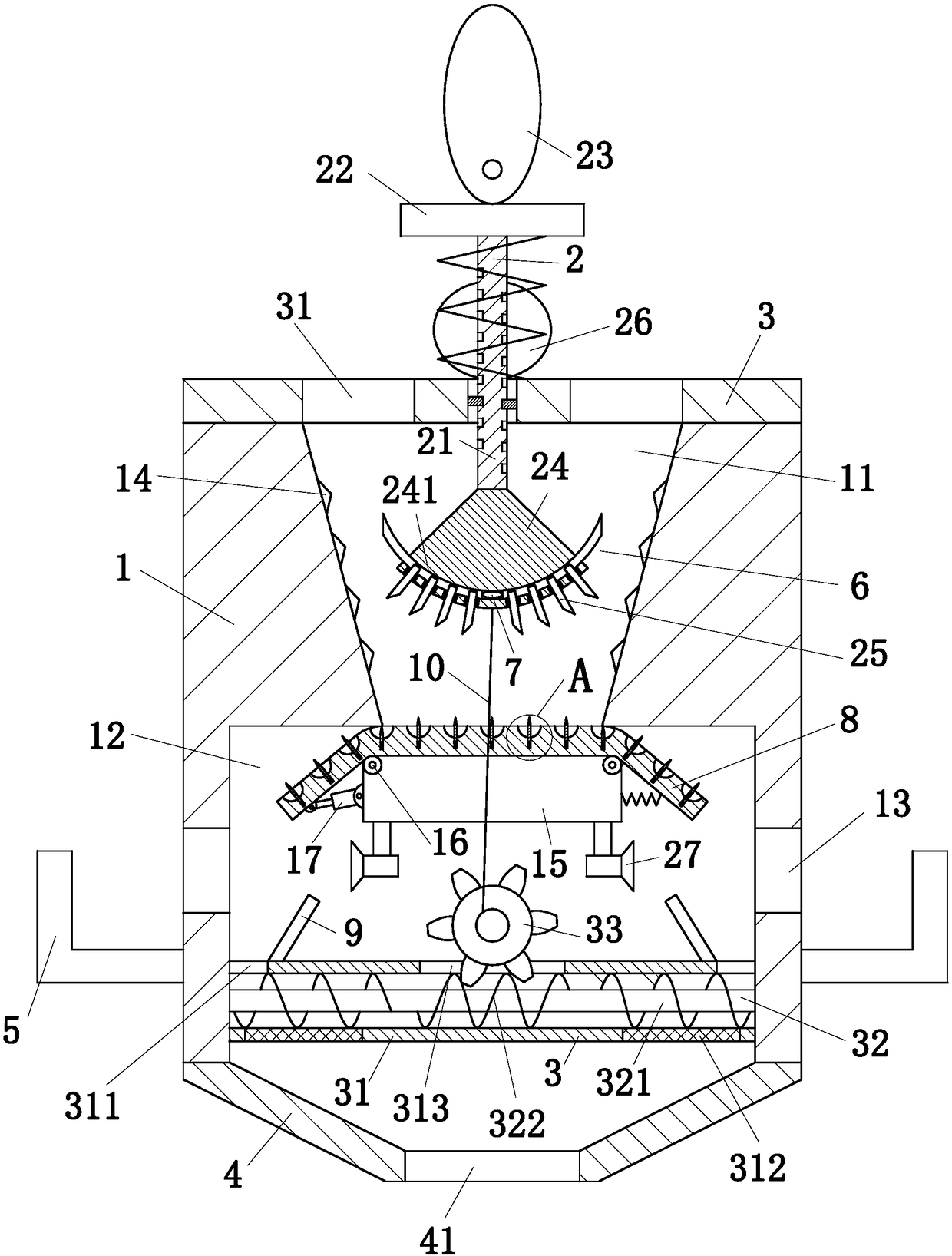

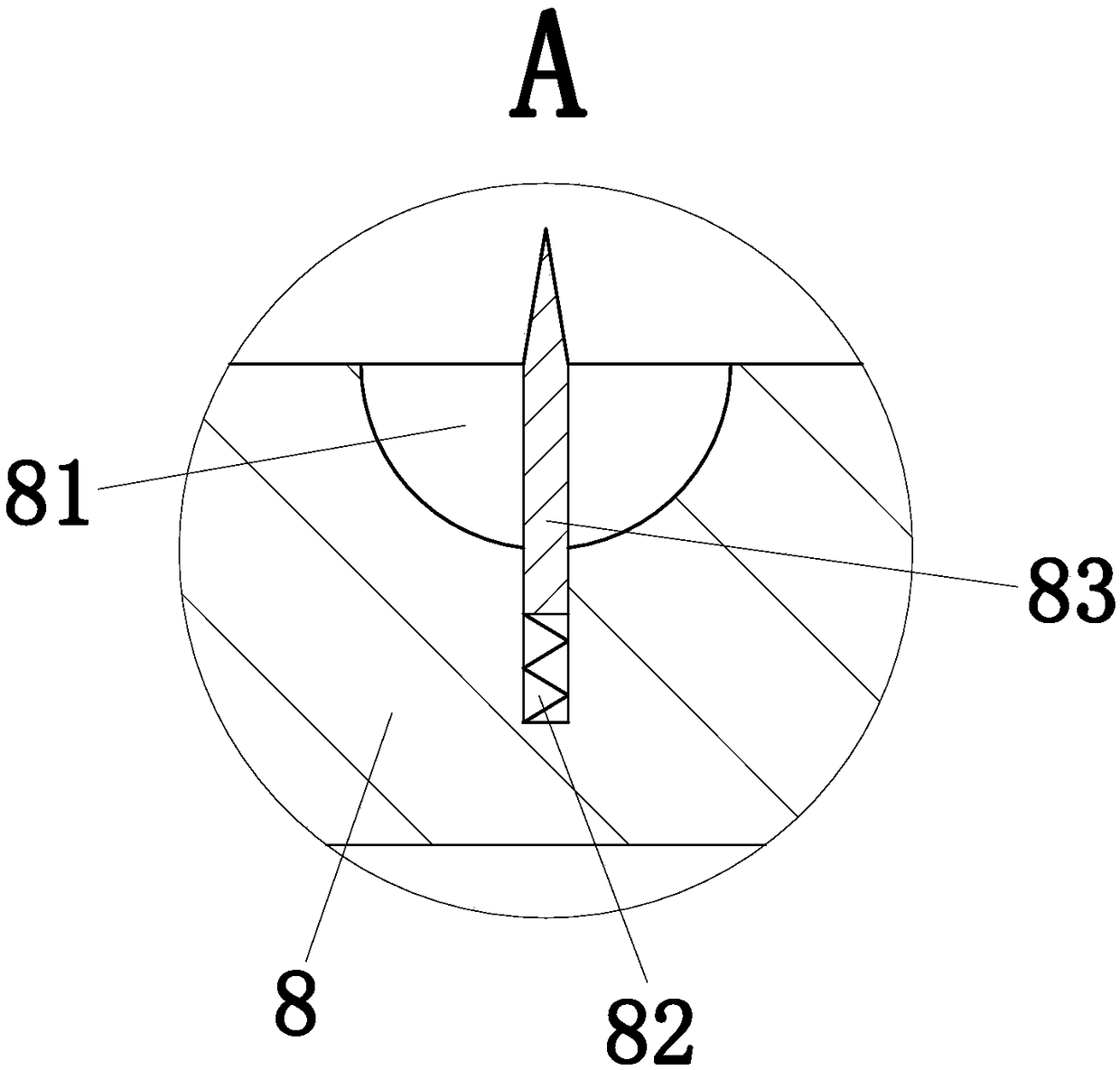

A method for recovering valuable metal from waste lithium battery

ActiveCN109244578AImprove crushing effectEasy to separateWaste accumulators reclaimingProcess efficiency improvementRecovery methodEngineering

The invention belongs to the technical field of lithium battery recovery, in particular to a method for recovering valuable metal from a waste lithium battery. The method comprises the following steps: transporting the lithium battery to a discharge battery filled with electrolyte through a hanging chain for discharge treatment; As the suspension chain moves to the waste liquid chamber, the lithium battery is perforated through the suspension equipment in the waste liquid chamber; conveying the lithium battery to the shower room for cleaning through a suspension chain; A suspension chain carries lithium batteries above that sorting equipment and releases the lithium batteries one by one so that the lithium battery enters the sorting equipment for crushing; The positive and negative electrode materials are transported to a baking furnace by a conveyor belt for baking; Transporting the calcined solid to a magnetic screening machine through a conveyor belt to screen out magnetic and non-magnetic substances; magnetic and non-magnetic materials are transported to an automatic particle sieving machine through a conveyor belt for sieving according to particle size grades. The invention realizes the classified recovery of valuable metals such as cobalt, copper and nickel good iron in lithium battery, and has the advantages of simple process and high recovery rate.

Owner:JIANGXI RUIDA NEW ENERGY TECH CO LTD

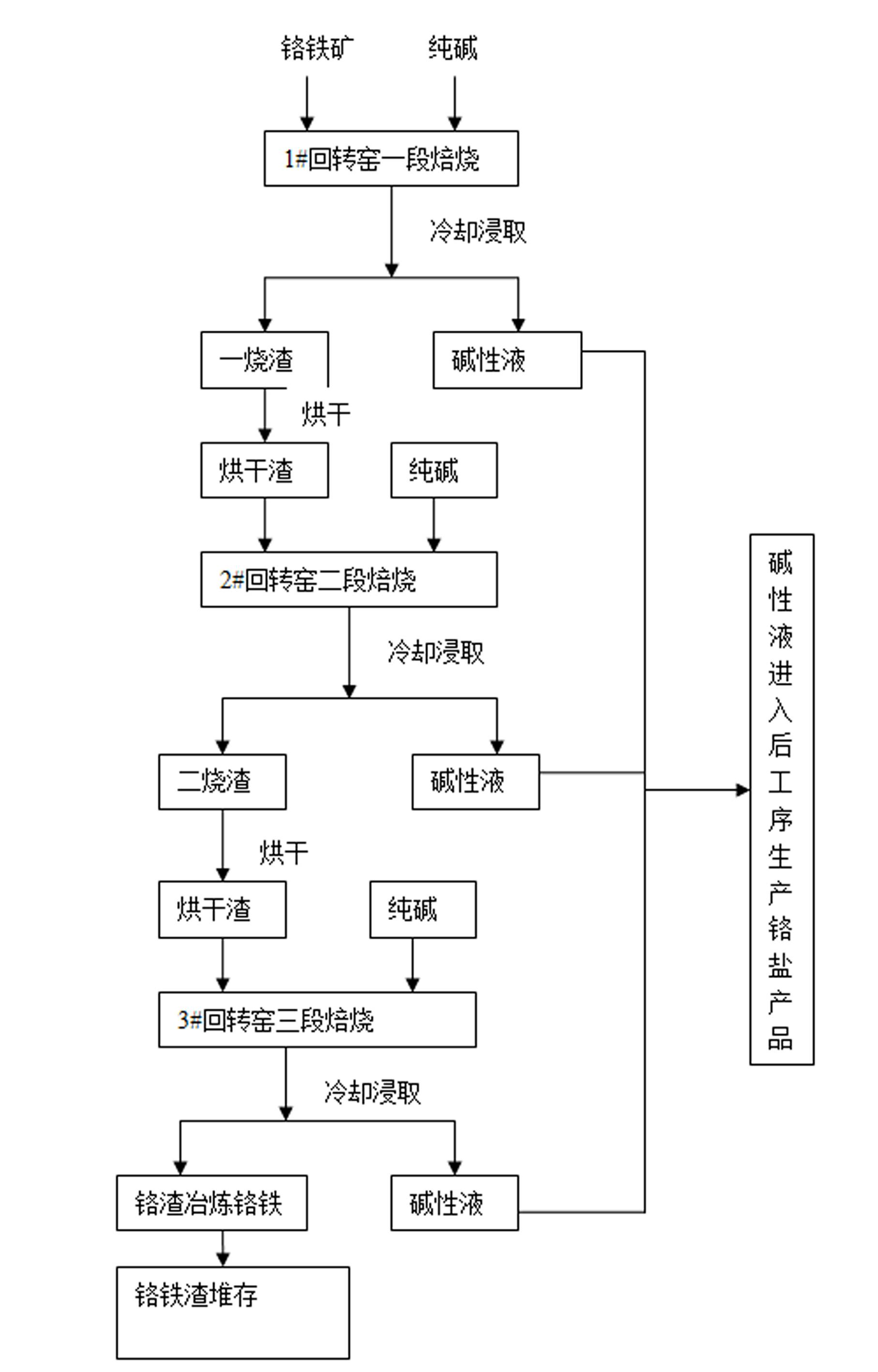

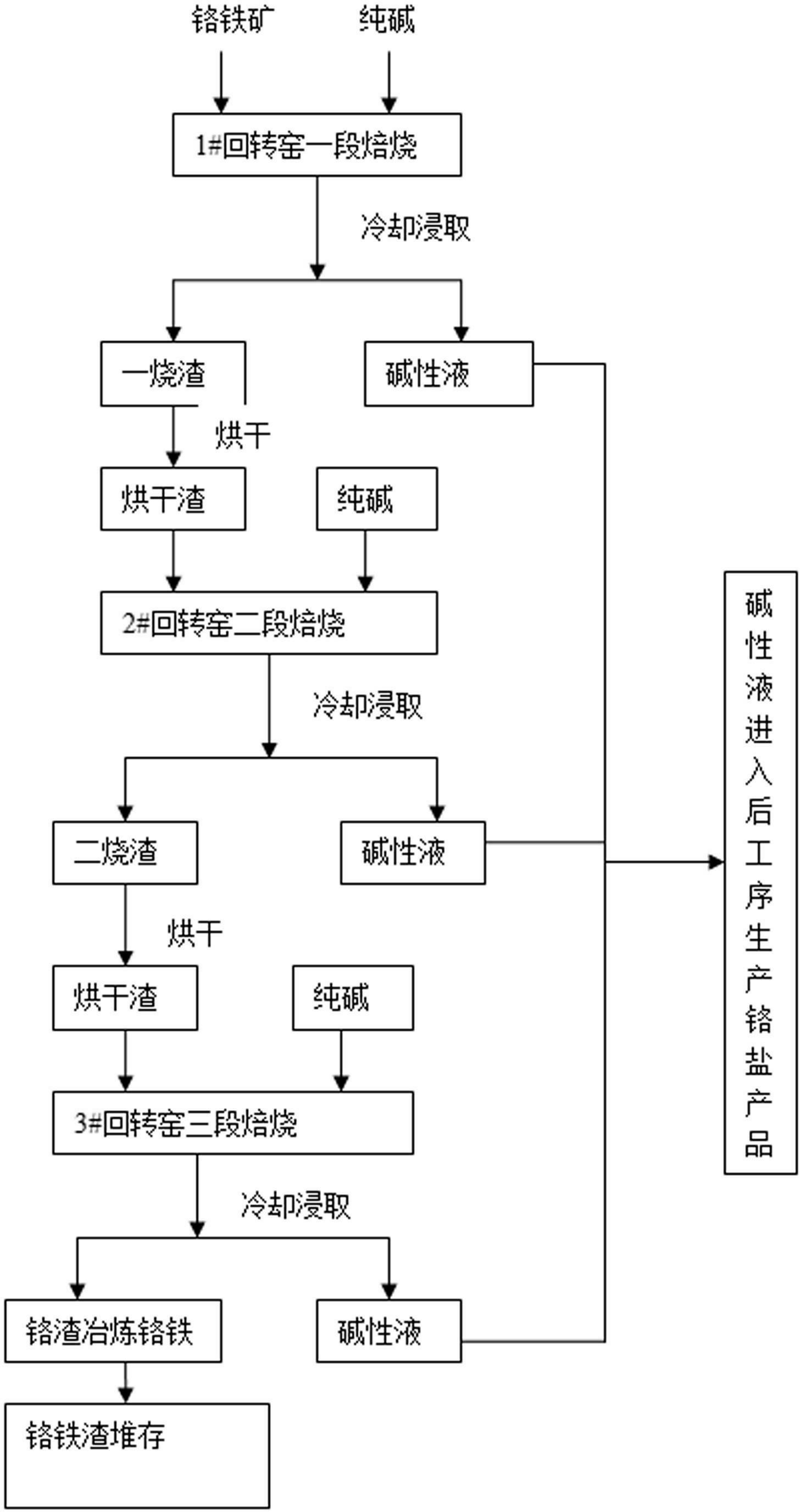

Method for producing sodium chromate and co-producing chrome-containing cast iron by three-stage process through un-calcium roasting

InactiveCN102557137AMine consumption reductionReduce alkali consumptionChromates/bichromatesSlagMixed materials

The invention discloses a method for producing sodium chromate and co-producing chrome cast iron by a three-stage process through un-calcium roasting, aiming at solving the problems of low roasting efficiency and high energy consumption in the existing method for producing chromic salt by un-calcium roasting. The method for producing sodium chromate by the three-stage process through un-calcium roasting comprises the following steps of: A, mixing roasting material in a first stage, mixing chromite and sodium carbonate in proportion; B, roasting in the first stage, putting the mixed material in the first stage into a rotary kiln and performing oxidizing roasting; C, leaching and filtering in the first stage; D, performing second-stage roasting technology; and E, performing third-stage roasting technology. The leaching of clinker after roasting for three times is same as the roasting leaching in the first time and the second time, the grinding leaching is performed to the clinker by a wet grinding ball mill, the clinker is filtered by a belt type filter and the filtered chromium slag by three-stage roasting is obtained by filtering of the belt type filter, the filter liquor is sodium chromate alkali solution. Compared with the traditional un-calcium roasting technology, the method in the invention adopts the three-stage process un-calcium roasting technology and effectively reduces the mine consumption and the alkali consumption and has the energy-saving and emission-reducing effect.

Owner:INNER MONGOLIA CHROMIUM

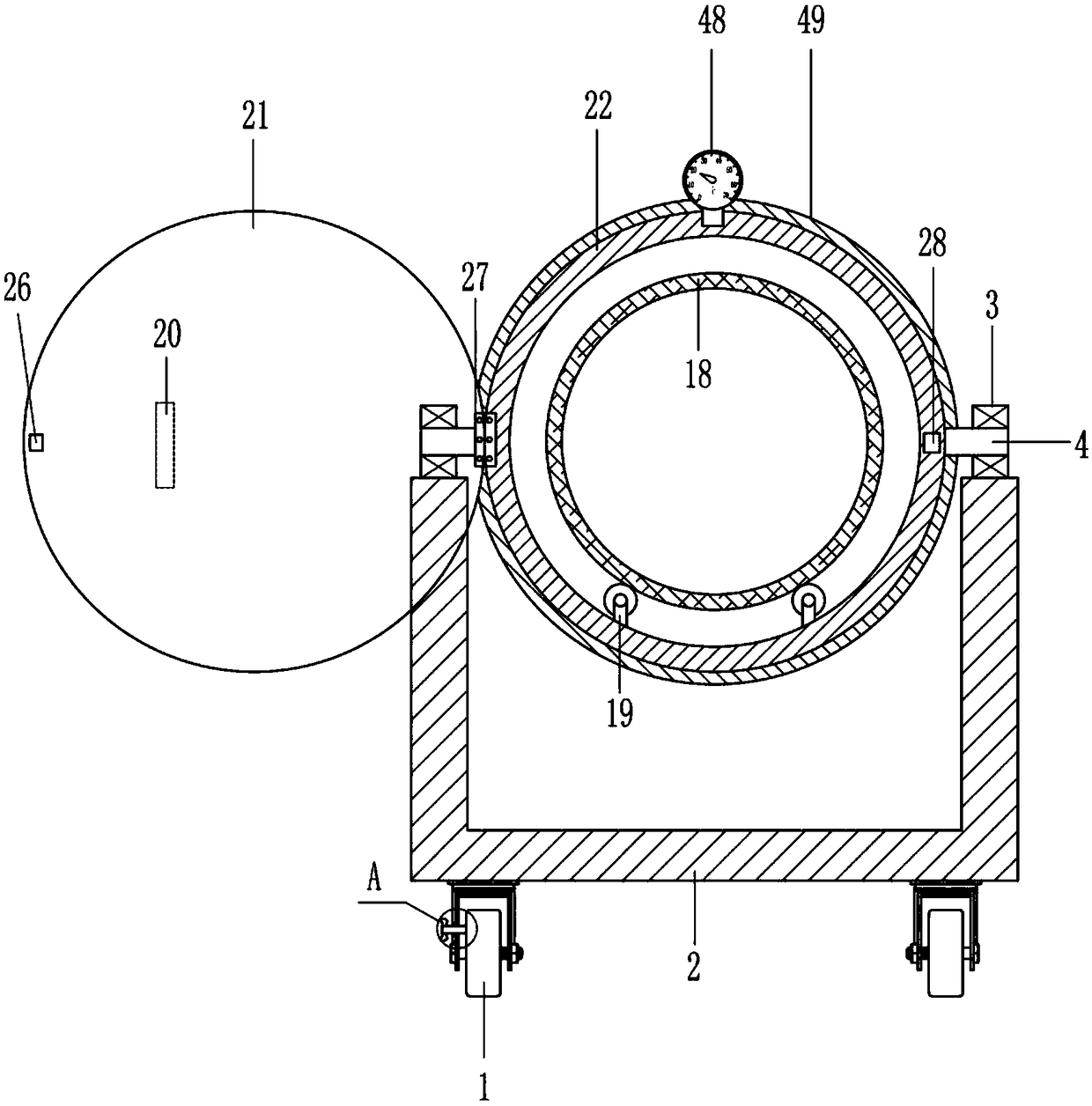

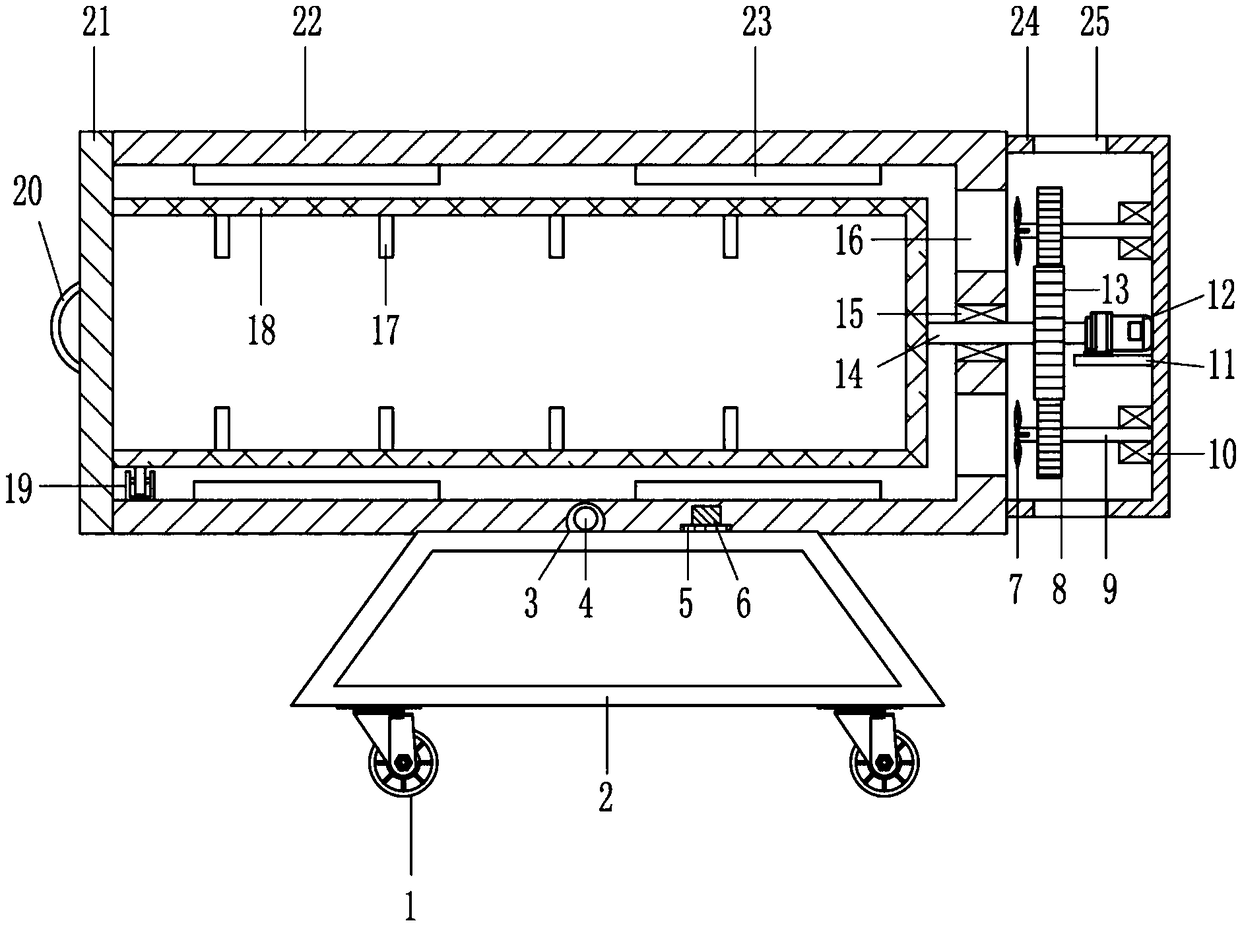

A Chinese medicinal parch device for processing Chinese medicinal material

ActiveCN109157413AReduce labor intensityStir fry evenlyPharmaceutical product form changeDomestic articlesTraditional medicineFan blade

The invention belongs to the field of traditional Chinese medicine processing, in particular to a parching device for traditional Chinese medicine processing. The technical problem to be solved by theinvention is to provide a parching device for processing traditional Chinese medicine, which can reduce labor intensity of workers, increase parching efficiency, parch the traditional Chinese medicine evenly, and is not easy to parch the traditional Chinese medicine. A Chinese medicinal parch device for processing Chinese medicinal material comprises a universal wheel, a support seat, a first bearing seat, a first rotating shaft, a sponge pad, a support block, a fan blade, a first gear, a second rotating shaft, a second bearing seat, a mounting plate, an electric motor, a second gear, a thirdrotating shaft, a third bearing seat, a stirring bar, a mesh drum, a guide wheel, a first pull ring, a cover plate, a drum, a heating plate, a mounting frame, a clamping block, a hinge, a handle anda rubber pad. The invention achieves the effects of lightening labor intensity of workers, increasing baking and frying efficiency, uniformly frying traditional Chinese medicine, and not easily fryingand scorching.

Owner:广东颂春南药产业园科技有限公司

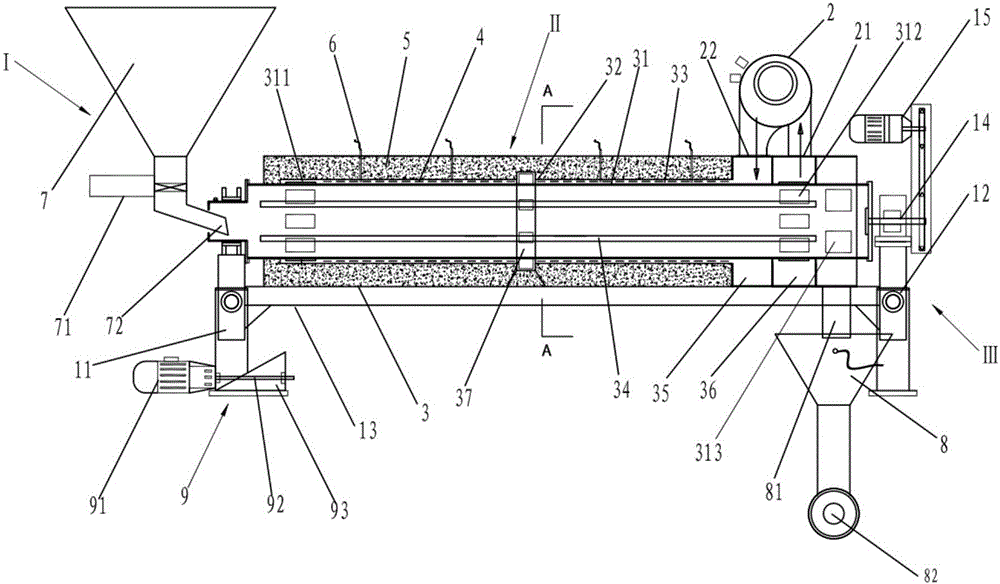

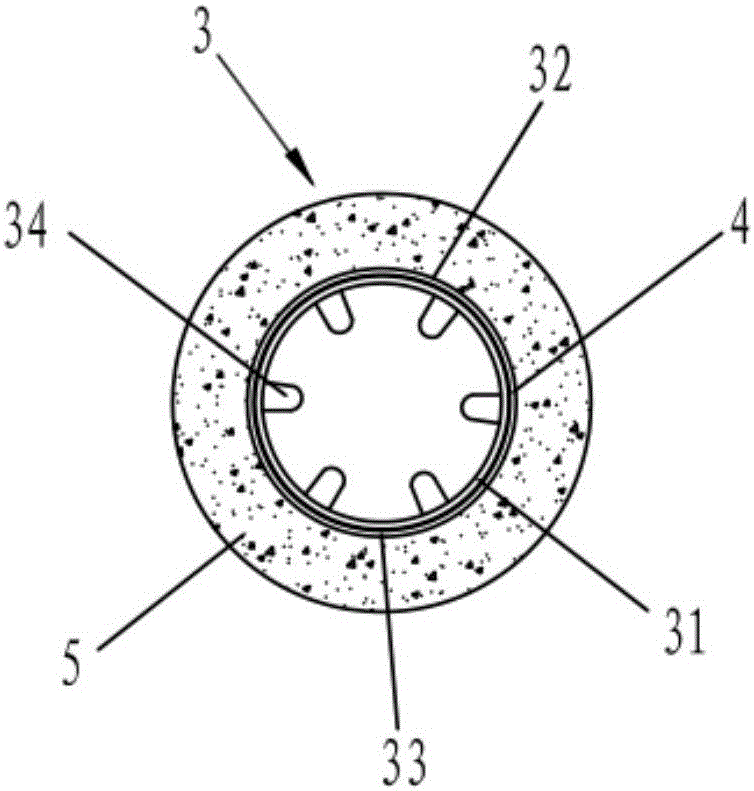

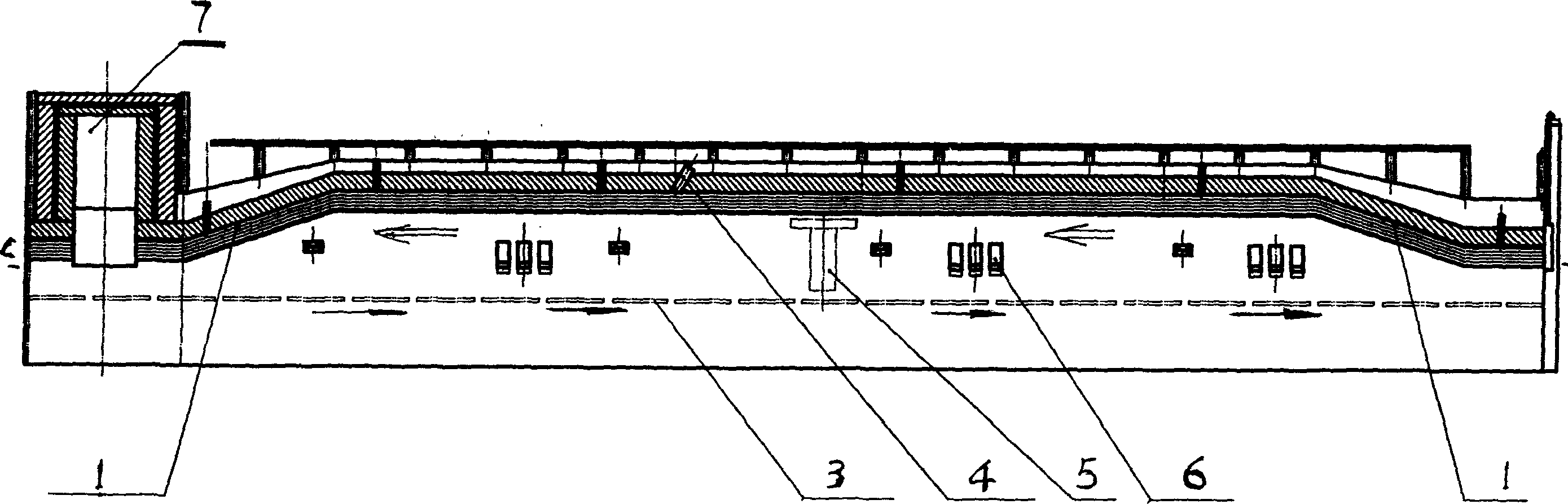

Continuous roasting furnace for vanadium pentoxide

InactiveCN1844819AFully roastedImprove roasting efficiencyFurnace typesAutomatic controlNonferrous metal

The invention discloses an ore continuous bake furnace, which can solve the defects of hearth-furnace and revolution furnace that short bake time and lower weight when continuously baking colorful metallic ore, as vanadic anhydride. Wherein, the hearth comprises a material feeder 12; two sides of bake furnace are distributed with burning furnace 2; the middle of bake furnace is mounted with a material mixer 5; the arc top of furnace 1 has an incline oxygen ejector 4. The invention can realize bath and automatic production, with high baking efficiency, while it can bake vanadic anhydride and other metallic ores.

Owner:胡熙友 +1

Folium mori tea preparation equipment

InactiveCN111802494AImprove roasting efficiencyImprove qualityTea substituesDrying chambers/containersMechanical engineeringMorus Alba Root

The invention relates to the technical field of agricultural machinery, in particular to folium mori tea preparation equipment. The folium mori tea preparation equipment comprises a drum type stir-frying machine and an adjustable folium mori cutting machine, wherein the adjustable folium mori cutting machine comprises a stir-frying furnace, an arc-shaped heating plate, a spiral stirrer, a cuttingbox, duplex horizontal distance regulation devices, a first cutting disk component, a second cutting disk component, a reciprocating type blade cutter and a meshing transmission element, wherein the stir-frying furnace is aslant arranged on a bottom plate, is provided with an observation window and is also provided with a material outlet; the arc-shaped heating plate is coaxially arranged on the bottom side of the stir-frying furnace; the working end of the spiral stirrer is coaxially rotatably arranged in the stir-frying furnace; the upper end and the lower end of the cutting box are independent provided with a material inlet and a material falling hole, and the cutting box is arranged on the top of one end, with a horizontal plane, of the stir-frying furnace; the duplex horizontal distance regulation devices are arranged on two sides of the cutting box; the first cutting disk component and the second cutting disk component are arranged on the duplex working ends of the horizontal distance regulation devices; the incision of the reciprocating type blade cutter is horizontally arranged on the bottom of the cutting disk component; and the meshing transmission element and two ends ofthe cutting disk are coaxially fixedly connected. According to the device, Morus alba L. leaves can be automatically cut and stir-fried, and efficiency is high.

Owner:姚俊鹏

Rotary kiln

PendingCN109539777AHigh strengthShorten the lengthFurnace componentsRotary drum furnacesCombustorBrick

The invention discloses a rotary kiln. The rotary kiln comprises an inclined rotary kiln barrel, a kiln head arranged at the head portion of the rotary kiln barrel, a kiln tail arranged at the tail portion of the rotary kiln barrel, and a transmission device driving the rotary kiln barrel to rotate, wherein the kiln tail is higher than the kiln head, a burner is arranged inside the kiln head, anda feeding inlet and a smoke outlet are formed in the kiln tail. The rotary kiln is characterized in that refractory brick layers are piled on the inner wall of the rotary kiln barrel and at least comprise material flying structures formed by arch-shaped protrusions which protrude to the inner wall of the barrel in the axial direction of the barrel; and the arch-shaped protrusions of the material flying structures protrude out of the surfaces of the refractory brick layers on the side face. Materials inside the kiln are evenly roasted, the breakage rate of products can be reduced, the product performance is greatly improved, the heat exchange area between the products and hot airflow inside the rotary kiln barrel is increased, and the roasting efficiency of the haycite products is effectively improved.

Owner:SHANDONG CHAMBROAD EQUIP MFG INSTALLATION CO LTD

Pellet roasting system and method based on sintering machine

The invention discloses a pellet roasting system based on a sintering machine. The system comprises the sintering machine, a circular cooler, a circulating air flow unit and a flue gas treatment unit. A discharge port of the sintering machine is connected with a feed port of the circular cooler. The circulating air flow unit is arranged among the sintering machine, the circular cooler and the flue gas treatment unit. A smoke hood is arranged above the sintering machine, and an air bellow is arranged below the sintering machine. According to the trend of materials, the smoke hood located above the sintering machine is sequentially divided into a preheating section, a combustion section and a roasting section. The sintering machine is adopted for pellet roasting, meanwhile, an air flow system is improved, the flue gas circulation heat utilization rate is increased, energy consumption is reduced, meanwhile, the roasting effect is improved, meanwhile, the good cooling effect can be achieved, generation of nitric oxide is reduced through gradient heat compensation, the desulfurization and denitrification cost is reduced, and the environment is protected.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Fluidized baking device

The invention relates to a fluidized baking device, and belongs to the technical field of mineral processing. The fluidized baking device comprises a reduction reactor perpendicular to the ground, anda magnetic field generation device acting on the reduction reactor, wherein a magnetic field generated by the magnetic field generation device is perpendicular to an upward uniform magnetic field; the main body of the reduction reactor is a columnar cavity container; a gas inlet is formed in the bottom of the container; a gas distribution plate with the edge fixed on the side wall of the bottom of the container is arranged in a cavity; the cavity between the gas distribution plate and the gas inlet is a gas distribution chamber; a material inlet is formed in the side wall above the gas distribution plate; a gas outlet is formed in the top of the reduction reactor container; and a material outlet is formed in the side wall of the upper part of the reaction reactor container. By adding a stable magnetic field on the periphery of the reaction reactor and reasonably controlling the flow behavior of magnetic particles in the reactor, the gas-solid two-phase flow in the fluidized baking device is relatively stable, gas and iron ores are fully reacted, and the baking efficiency is improved.

Owner:NORTHEASTERN UNIV

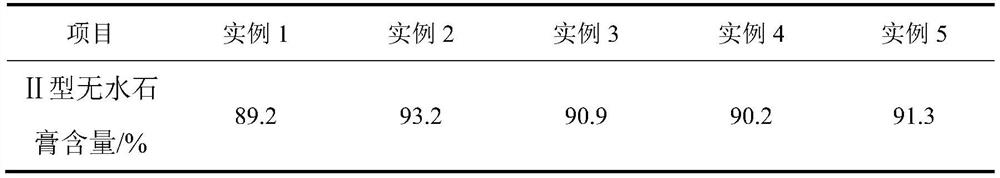

Method for preparing type II anhydrous gypsum by fluidizing and roasting beta-semi-hydrated gypsum

The invention discloses a method for preparing type II anhydrous gypsum by fluidizing and roasting beta-semi-hydrated gypsum, which comprises the following steps: step 1, fluidizing and roasting beta-semi-hydrated gypsum powder in a small fluidized bed, keeping the gas-solid ratio at 0.2320-0.2680 L.( g.min)-1, and controlling the heating rate at 5-15 DEG C / min; 2, when the temperature of a roasting furnace is increased to 700-900 DEG C, carrying out heat preservation for 100-200 min; 3, after the heat preservation stage is finished, naturally cooling to normal temperature, and taking out the gypsum. According to the method, efficient mass transfer and heat transfer of the fluidized bed are utilized, the roasting efficiency is improved, and the content of the II-type anhydrous gypsum can reach 85% or above; impurities can be removed through high-temperature fluidized roasting, and the quality of the II-type anhydrous phosphogypsum subjected to high-temperature roasting is slightly influenced by the impurities.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com