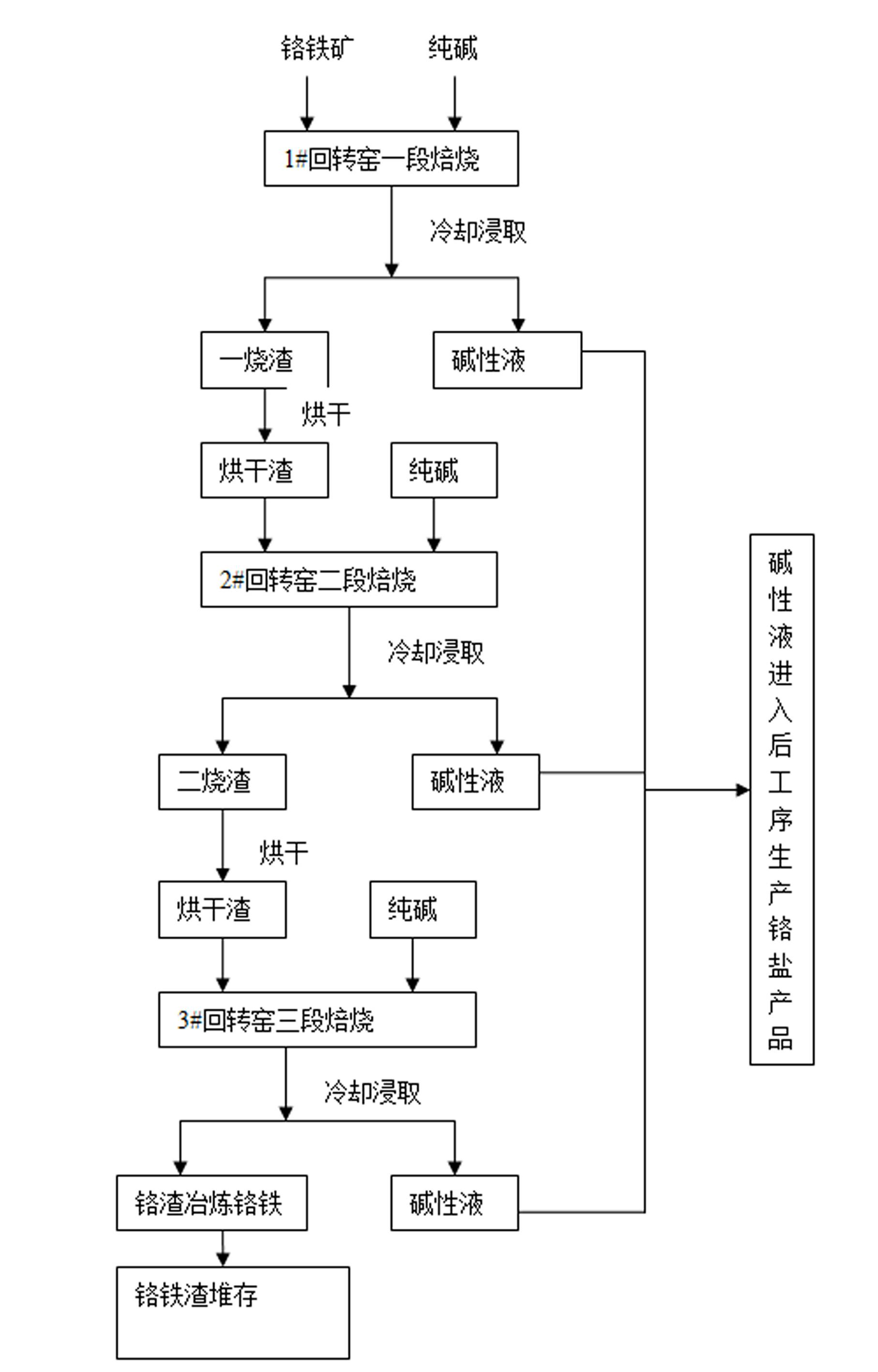

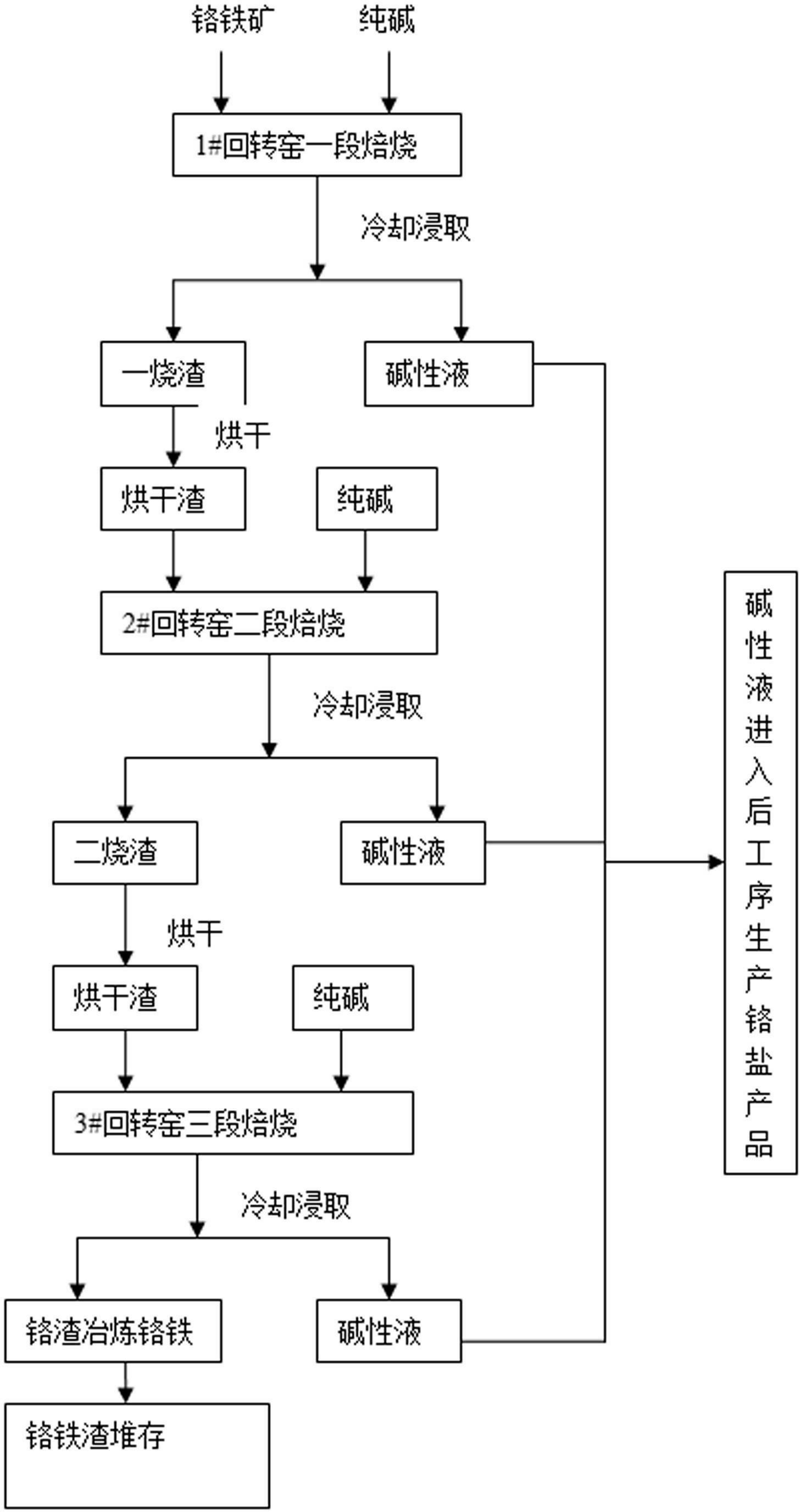

Method for producing sodium chromate and co-producing chrome-containing cast iron by three-stage process through un-calcium roasting

A technology of calcium-free roasting and sodium chromate, applied in the direction of chromate/dichromate, etc., can solve the problems of low roasting efficiency and large energy loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A, a roasting process: 1000 tons of South African chromite (the main chemical composition is: Cr 2 o 3 42.8%, Fe 2 o 3 26.57%, MgO 8.22%, Al 2 o 3 18.62%, SiO 2 3.46%, V 2 o 5 0.33%) ground to 200 mesh, the pass rate is greater than 95%, and 250 tons of Jinchang soda ash (Na 2 CO 3 Content: 98.62%) mixed evenly, the mixing accuracy is 99%,

[0019] B. Put the material into the rotary kiln at a rate of 5 tons per hour and roast at a temperature of 1100 ° C. The residence time of the material in the kiln for roasting is 120 minutes, and the material does not form a wall. The chromium conversion rate of one-stage roasting is 42.3%,

[0020] C. When the clinker obtained by roasting is cooled to 300°C, it enters the wet ball mill for grinding, and the liquid-solid ratio is controlled to be 65:35. The leached slurry is directly filtered through a belt filter, and the filtrate is a section of sodium chromate. Liquid, obtain the sodium chromate alkaline liquid 1...

Embodiment 2

[0026]After storing and drying the filtered chromium slag of the three-stage roasting in step E of Example 1, after mixing according to the ratio of chromium slag: silica: lime: coke=68:10:5:17, pass through a high-temperature electric arc furnace according to the existing process Smelted into chromium-containing cast iron, the quality of chromium-containing cast iron is qualified. No hexavalent chromium was detected in the smelted ferrochrome slag, and the ferrochrome slag was piled up.

Embodiment 3

[0028] A, a roasting process: 1000 tons of South African chromite (the main chemical composition is: Cr 2 o 3 42.8%, Fe 2 o 3 26.57%, MgO 8.22%, Al 2 o 3 18.62%, SiO 2 3.46%, V 2 o 5 0.33%) ground to 200 mesh, the pass rate is greater than 95%, and 266 tons of Jinchang soda ash (Na 2 CO 3 Content: 98.62%) mixed evenly, the mixing accuracy is 99%.

[0029] B. Put the material into the rotary kiln at a rate of 5 tons per hour and roast at a temperature of 1250 ° C. The residence time of the material in the kiln for roasting is 120 minutes, and the material does not form a wall. The chromium conversion rate of one-stage roasting is 42.93%,

[0030] C. When the clinker obtained by roasting is cooled to 400°C, it enters the wet ball mill for grinding, and the liquid-solid ratio is controlled to be 65:35. The leached slurry is directly filtered through a belt filter, and the filtrate is a section of sodium chromate. Alkaline liquid, obtain 1192m sodium chromate alkal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com