Method for producing aluminum oxide based on calcification-carbonization transformation

A low-grade bauxite, carbonization transformation technology, applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, alumina/aluminum hydroxide, alkaline earth metal silicate, etc. The increase in lime consumption and the increase in unit consumption of bauxite have achieved the effect of solving land occupation and polluting the environment, reducing the amount of CO2 gas, and improving environmental protection standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

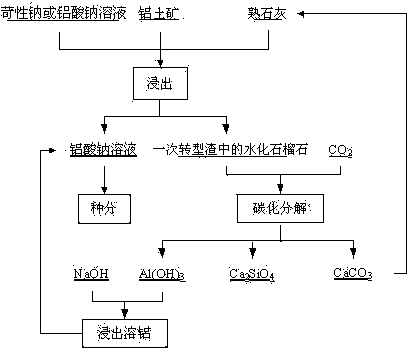

Method used

Image

Examples

Embodiment 1

[0046] Crush the low-grade bauxite to -500μm, then mix the burned slaked lime and bauxite at a mass ratio of 0.5:1, and put them in 260g / L caustic soda under the conditions of transformation temperature of 130℃ and transformation time of 15min Calcification transformation in the solution, the liquid-solid mass ratio is 7:1, part of the alumina in the mineral enters the eluate (the eluate can be recycled during the transformation process), and the other alumina and slaked lime and all the silicon in the mineral are converted into hydration Garnet enters the slag phase and obtains a transformation slag;

[0047] After mixing the primary transformation slag and clean water in a closed container under the condition of liquid-solid ratio (15:1) mL / g, in CO 2 The partial pressure of the gas is 1.8MPa, and the carbonization temperature is 150°C for 10 minutes, and the hydrated garnet of the primary transformation slag is transformed into the secondary transformation slag whose main c...

Embodiment 2

[0050] Crush the low-grade bauxite to -500μm, then mix the burned slaked lime and bauxite at a mass ratio of 0.5:1, and put in 140g / L caustic soda under the conditions of transformation temperature of 260℃ and transformation time of 60min Medium calcification transformation, the liquid-solid mass ratio is 2.5:1, part of the alumina in the mineral enters the eluate (the eluate can be recycled during the transformation process), and other alumina, slaked lime and all the silicon in the mineral are transformed into hydrated pomegranate The stone enters the slag phase and obtains a transformation slag;

[0051] After mixing the primary transformation slag and clean water in a closed container under the condition of a liquid-solid ratio of 3:1, the CO 2 The partial pressure of the gas is 0.8MPa, and the carbonization temperature is 90°C for 30 minutes, and the hydrated garnet of the primary transformation slag is transformed into the secondary transformation slag whose main compone...

Embodiment 3

[0054] Crush the low-grade bauxite to -500μm, then mix the burned slaked lime and bauxite at a mass ratio of 0.3:1. The transformation temperature is 180°C, the transformation time is 40min, the concentration of sodium hydroxide is 200g / L, hydrogen Calcification transformation in sodium aluminate solution with a molar ratio of sodium oxide to alumina of 3.5:1, the mass ratio of liquid to solid is 4:1, part of the alumina in the mineral enters the eluate (the eluate can be recycled), and the other alumina and slaked lime And all the silicon in the mineral is converted into hydrated garnet and enters the slag phase to obtain a transformation slag;

[0055] After mixing the primary transformation slag and the low-concentration sodium aluminate solution with a sodium hydroxide mass content of 30g / L in a closed container under the condition of liquid-solid ratio (4:1) mL / g, the CO 2 The partial pressure of the gas is 1.2MPa, and the carbonization temperature is 120°C for 20 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com