Method for producing gypsum building products by using expressing technique

An extrusion process, gypsum technology, applied in the direction of manufacturing tools, sustainable waste treatment, solid waste management, etc., can solve the problems of reducing the strength of products, restricting the application field, prolonging the production cycle, etc., to reduce production energy consumption, good application Prospects, the effect of a short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] 1. Preparation of gypsum extrusion material

[0035] Gypsum extrudates were formulated in the following weight percents:

[0036] Gypsum powder (the content of hemihydrate gypsum in the plaster powder should be more than 60%, and the fineness should be controlled at particle size ≤ 1mm) 63%;

[0037] Fly ash (fineness controlled at particle size ≤ 3mm) 7%;

[0038] Fine sand (fineness controlled at particle size ≤ 3mm) 8%;

[0039] Wood fiber (fiber diameter controlled at Φ500~1μm, chopped length at 50-5mm) 2%;

[0040] The admixture is dissolved in water to make 20% of mixing water.

[0041] The composition of mixing water is formulated by following weight %:

[0042] Carboxymethylcellulose 1%, citric acid 0.3%; water 98.7%.

[0043] 2. Structural design of the extruder for the production of gypsum products

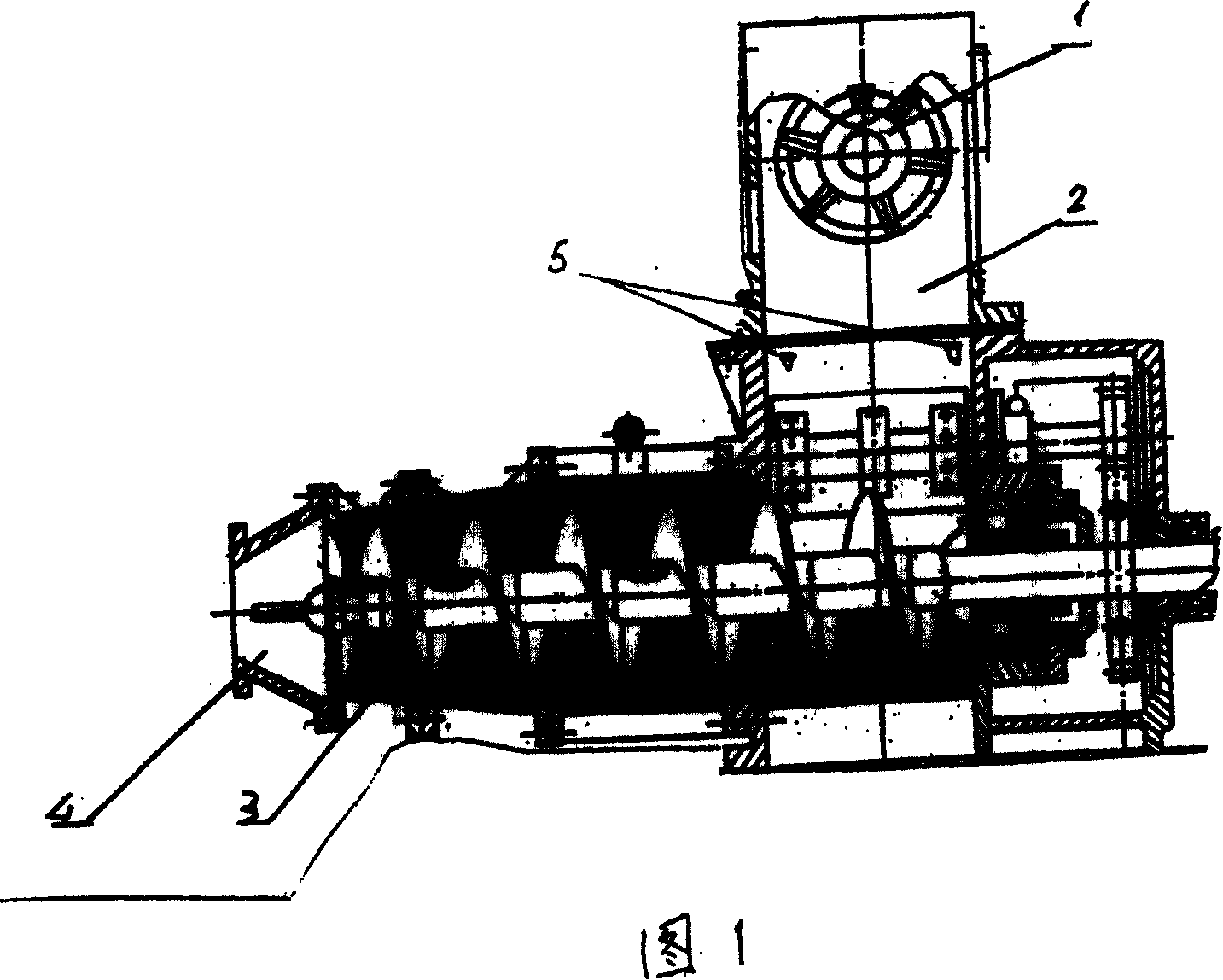

[0044] The structure of the extruder for producing gypsum products is mainly composed of four parts: mixing section 1, buffer section 2, extrusion section 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com