Method for efficiently recovering and reselecting steel slag

A high-efficiency technology for steel slag, applied in the field of high-efficiency recycling and re-selection of steel slag, can solve the problems of insufficient economic benefits of comprehensive utilization of steel slag, environmental pollution, waste of resources, etc., to ensure product quality indicators and protect the ecological environment. , the effect of reducing production costs and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

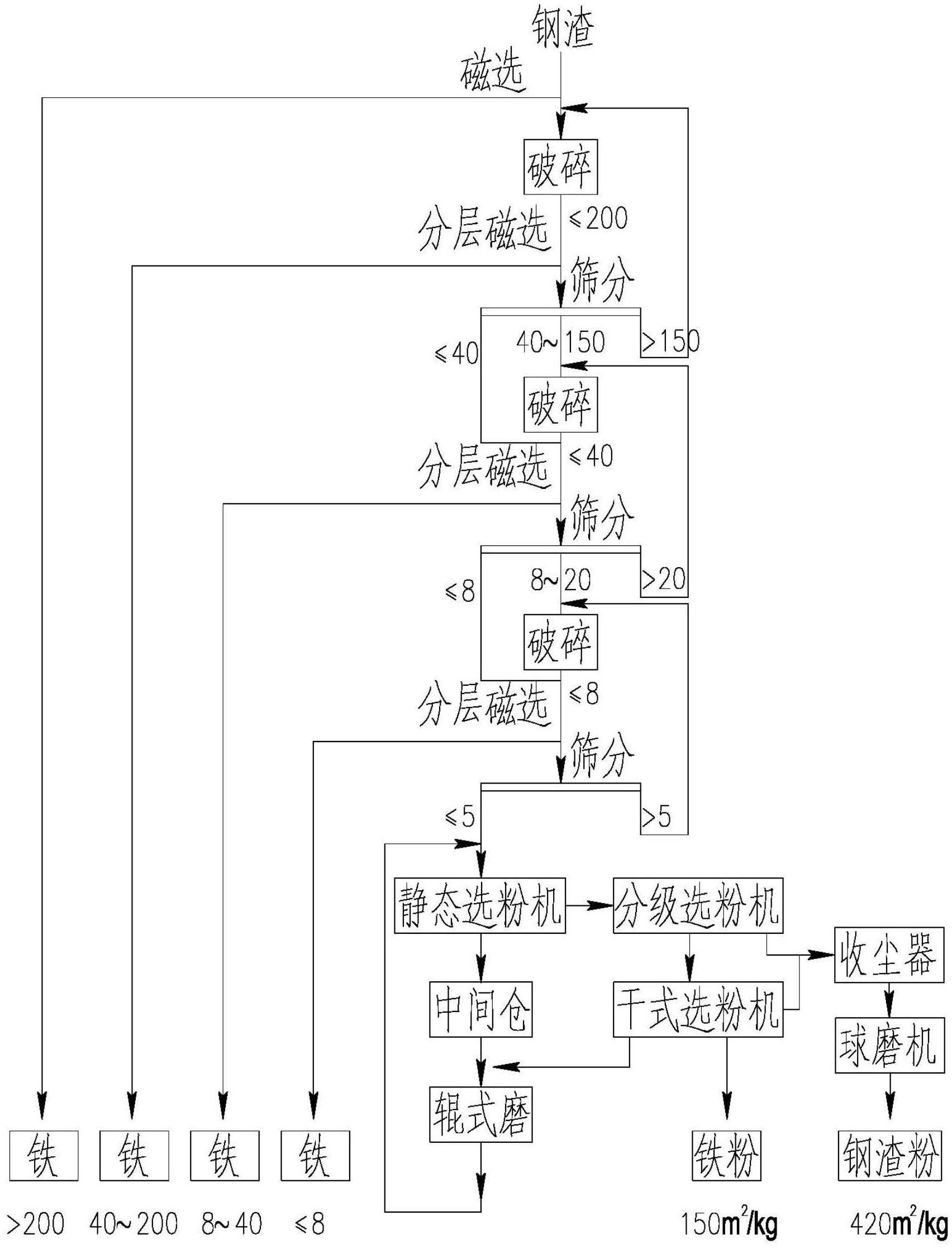

[0027] A method for efficient recovery and reselection of steel slag, the steps are:

[0028] The following describes the technical solutions in the embodiments of the present invention clearly and completely in conjunction with the accompanying drawings of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative work shall fall within the protection scope of the present invention.

[0029] A method for efficient recovery and reselection of steel slag, the specific process is:

[0030] Step A, crush the magnetic separation, and use a lifting electromagnet to separate the iron from the steel slag in the yard. Other steel slag directly enters the crusher for crushing. The crushed steel slag is subjected to layered magnetic separation through a belt convey...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com