Patents

Literature

94results about How to "Achieve the purpose of screening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

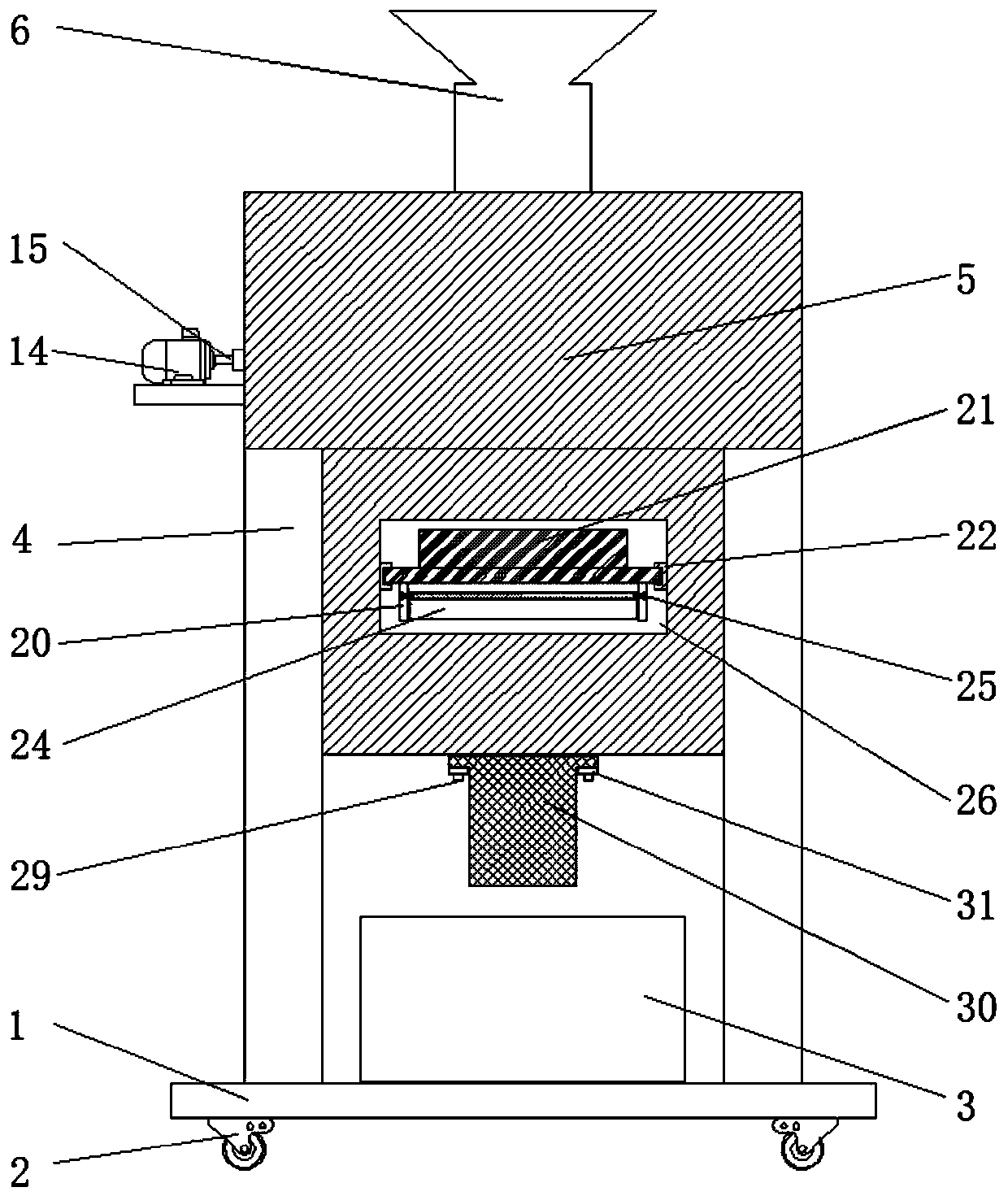

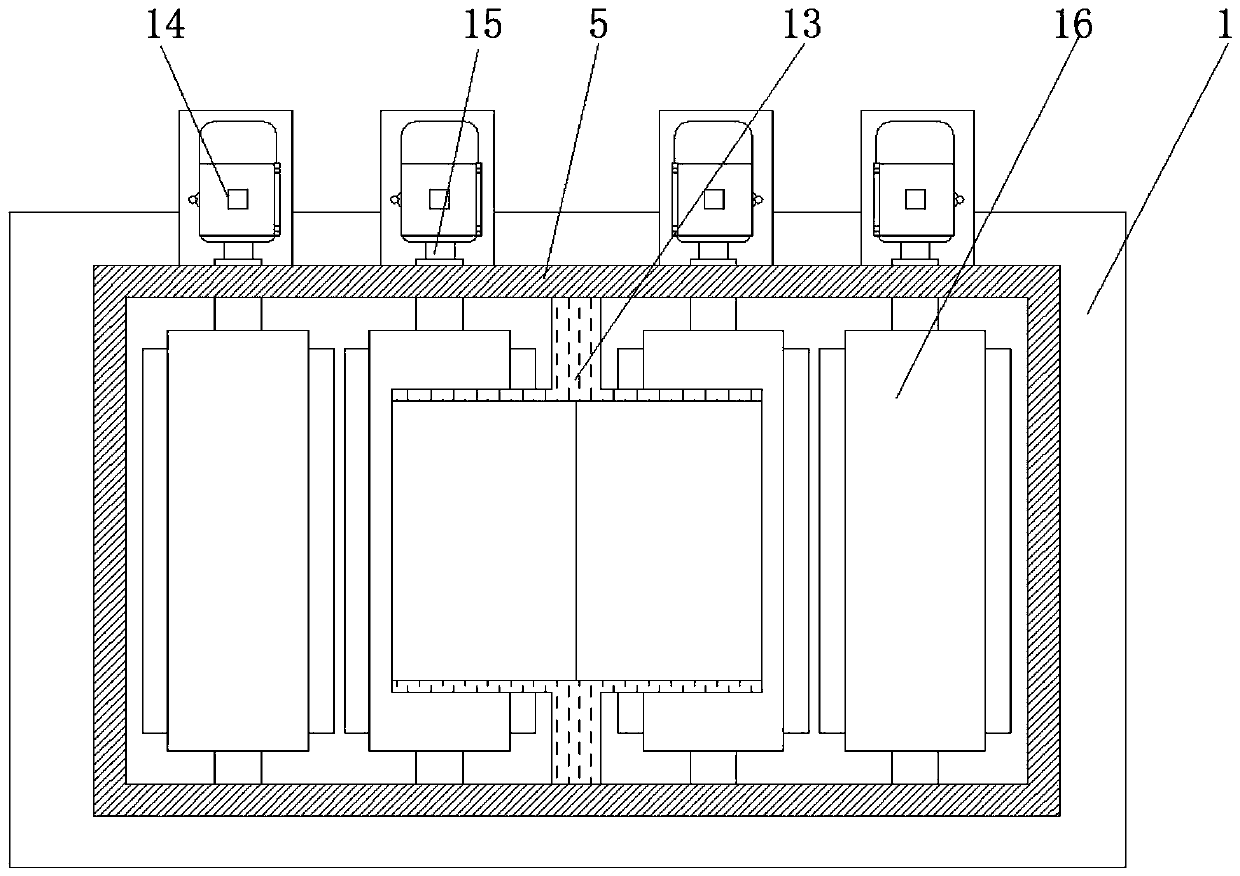

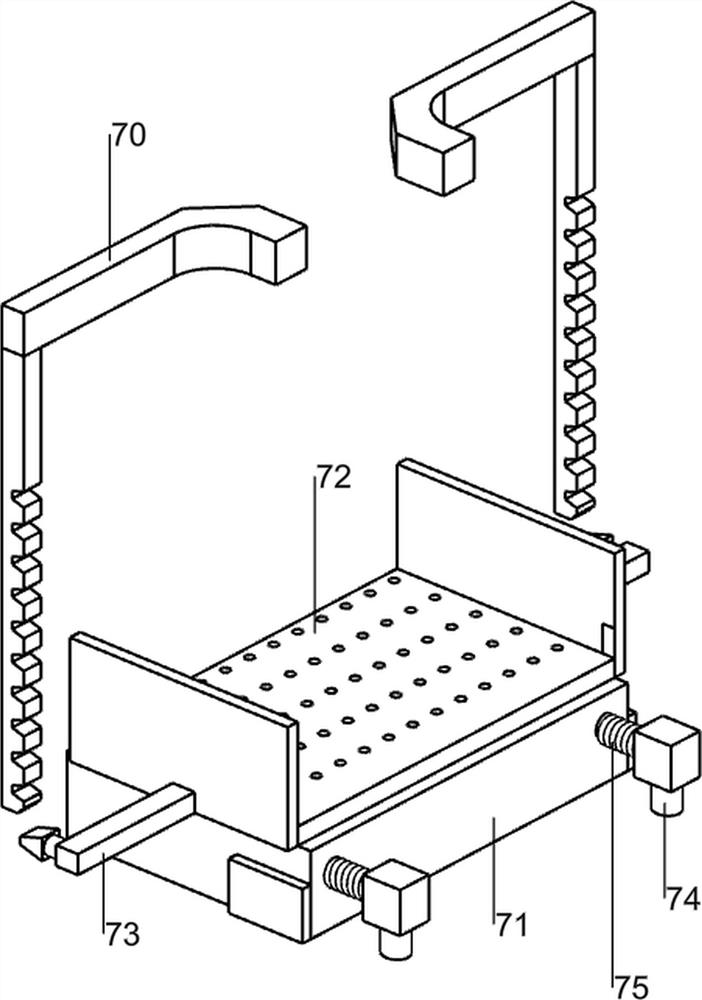

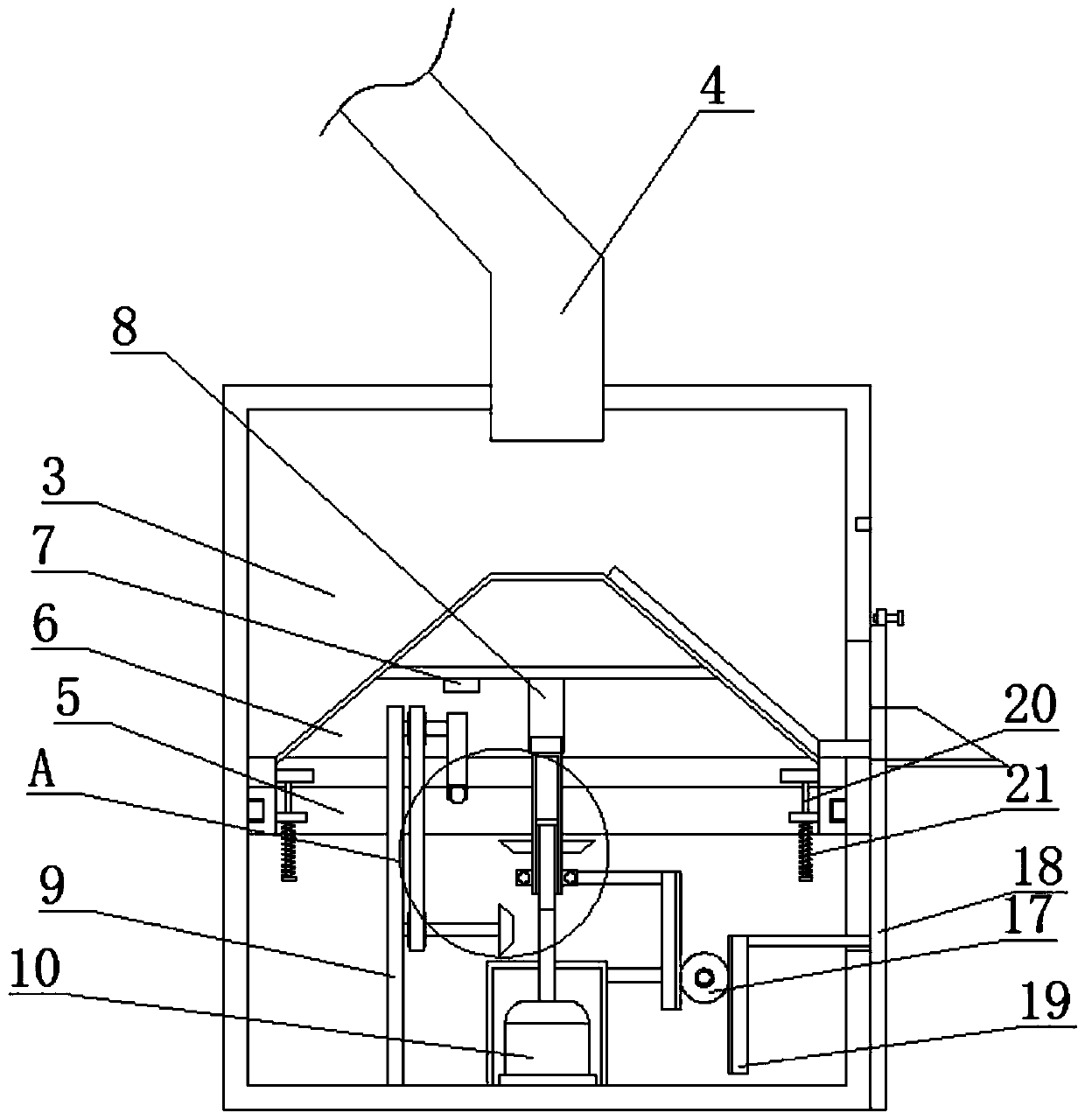

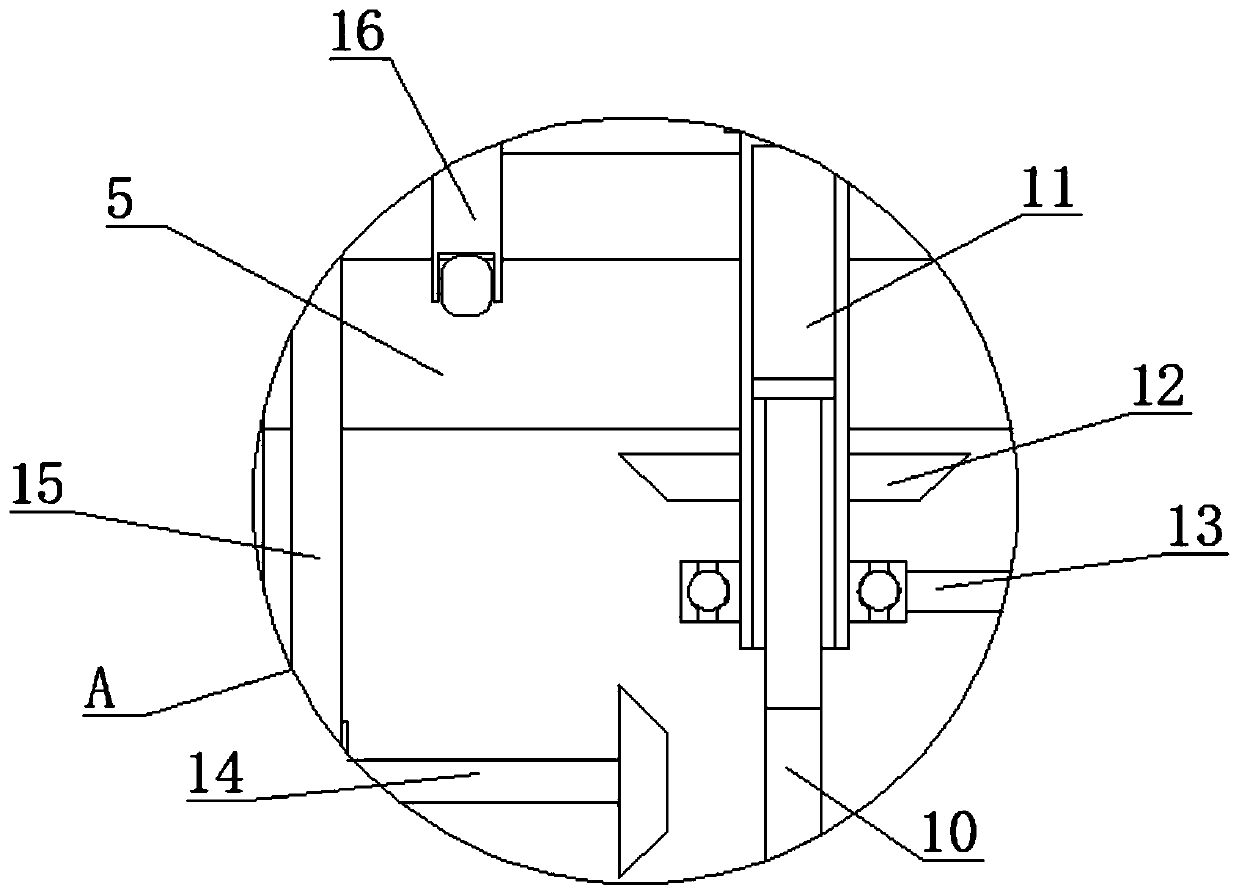

Rare earth gravel screening device for rare earth waste recycling

ActiveCN107739853AAvoid getting wetImpact screeningProcess efficiency improvementRare earthMaterials science

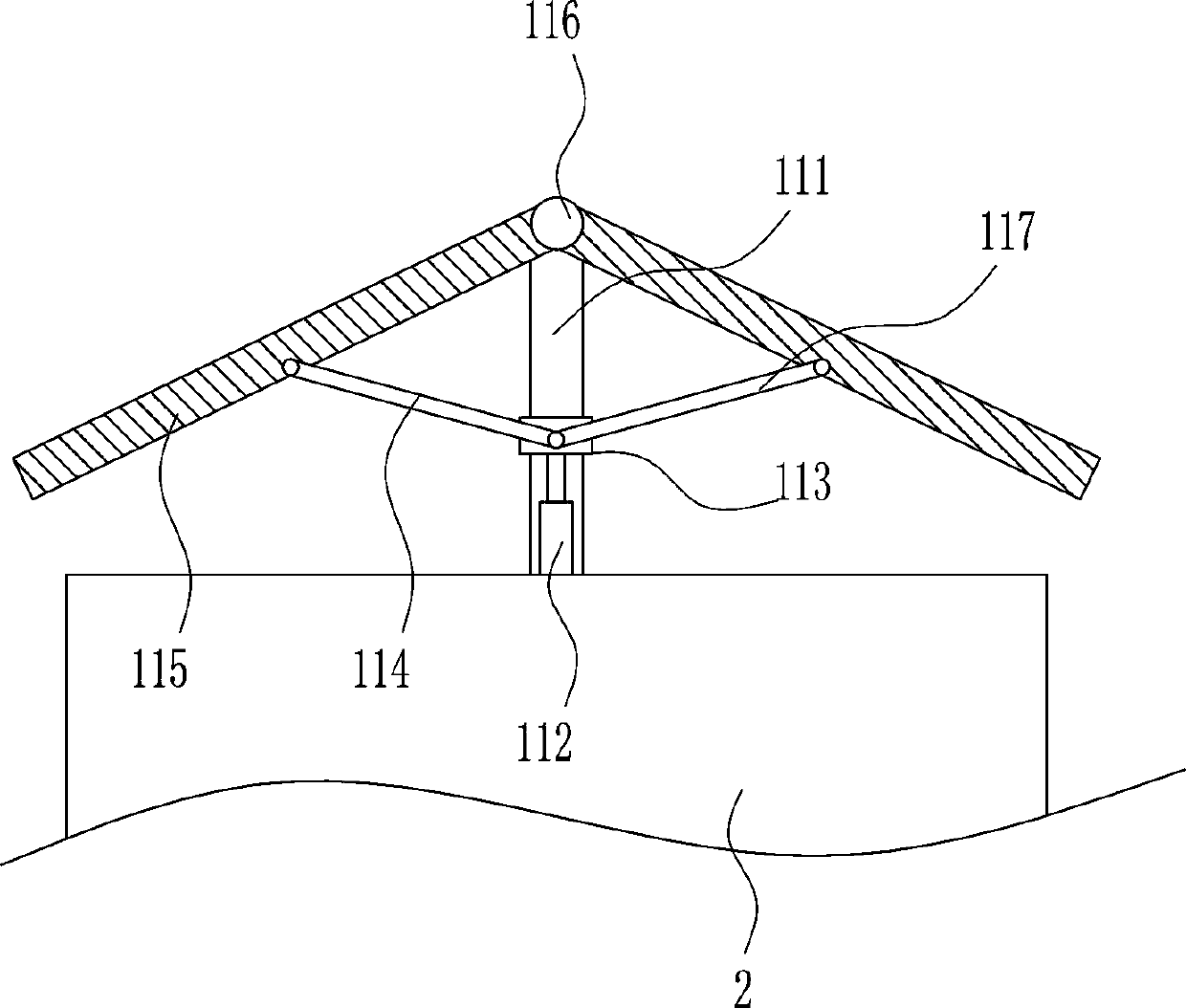

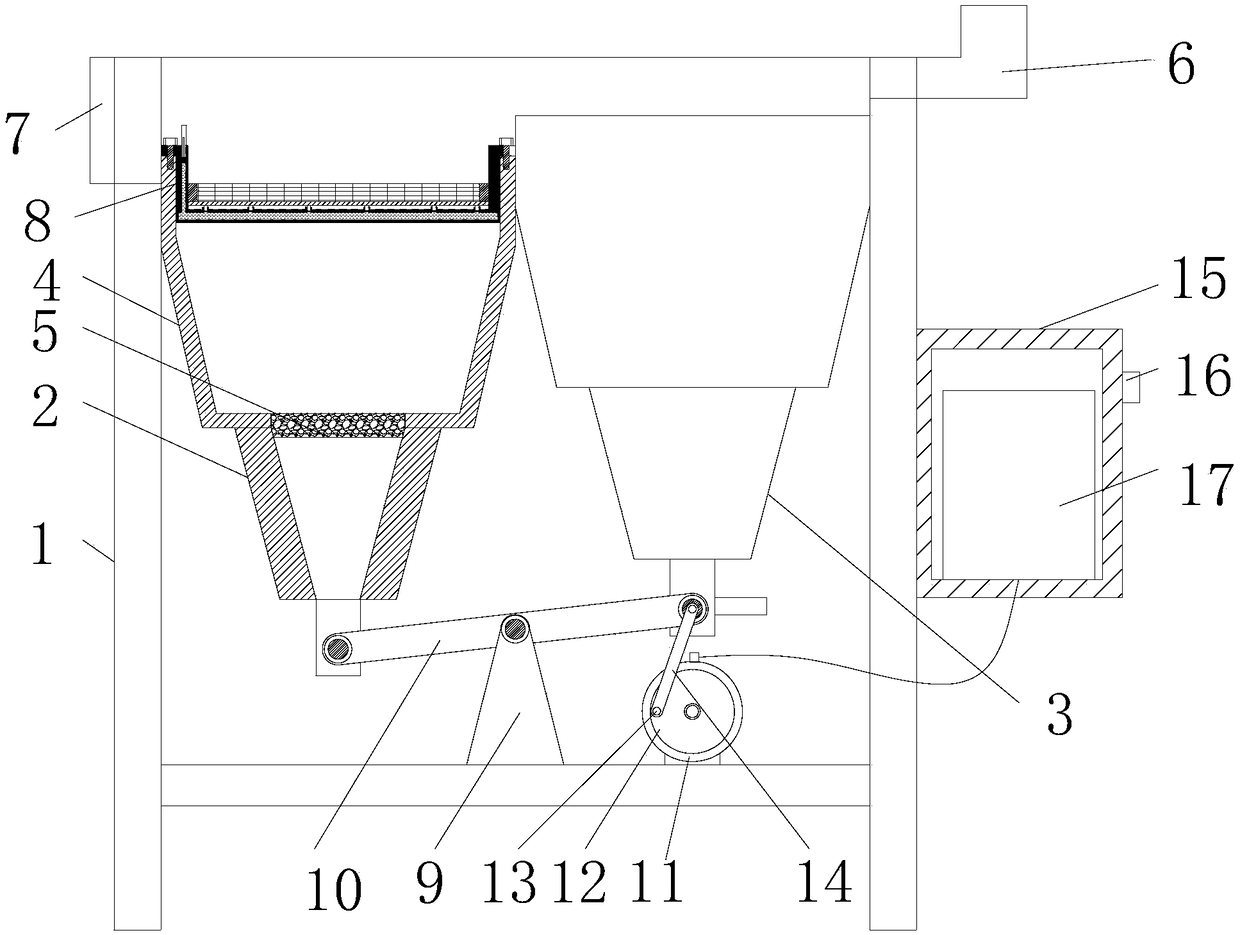

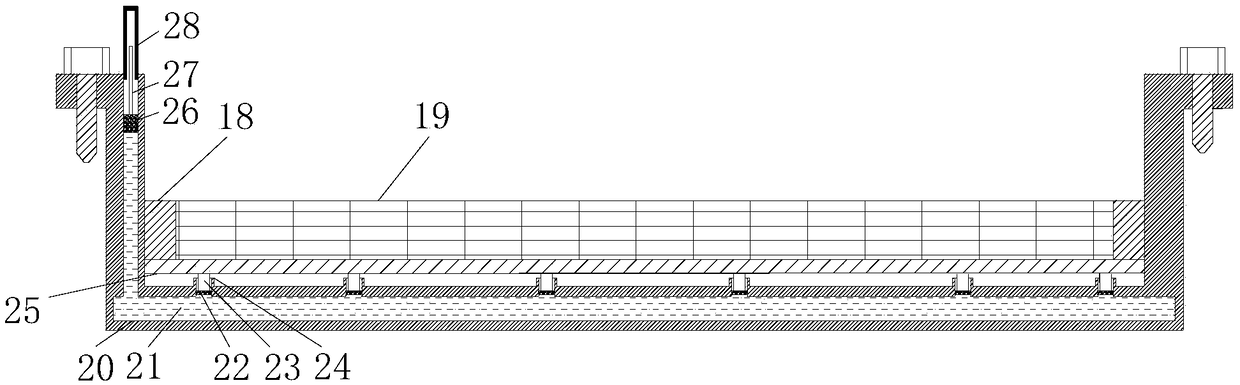

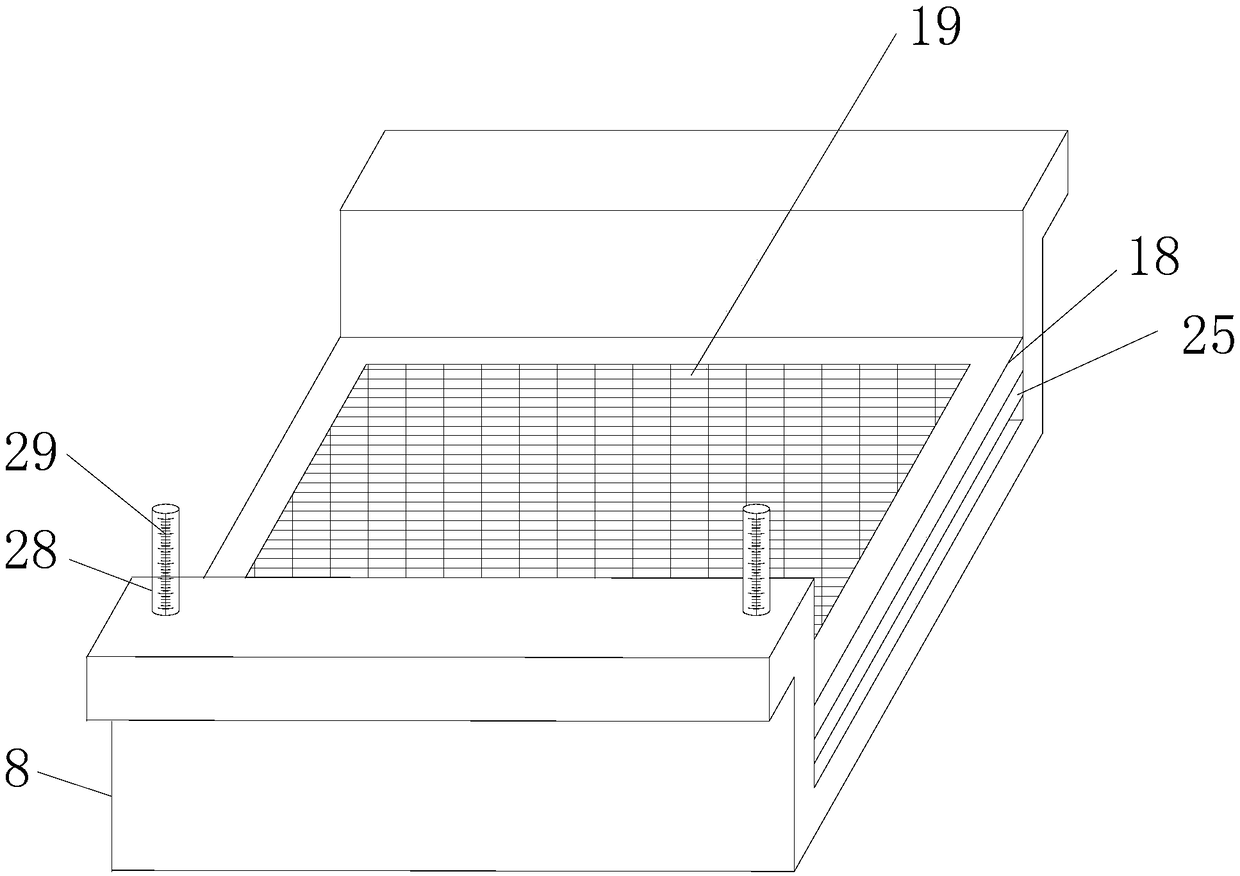

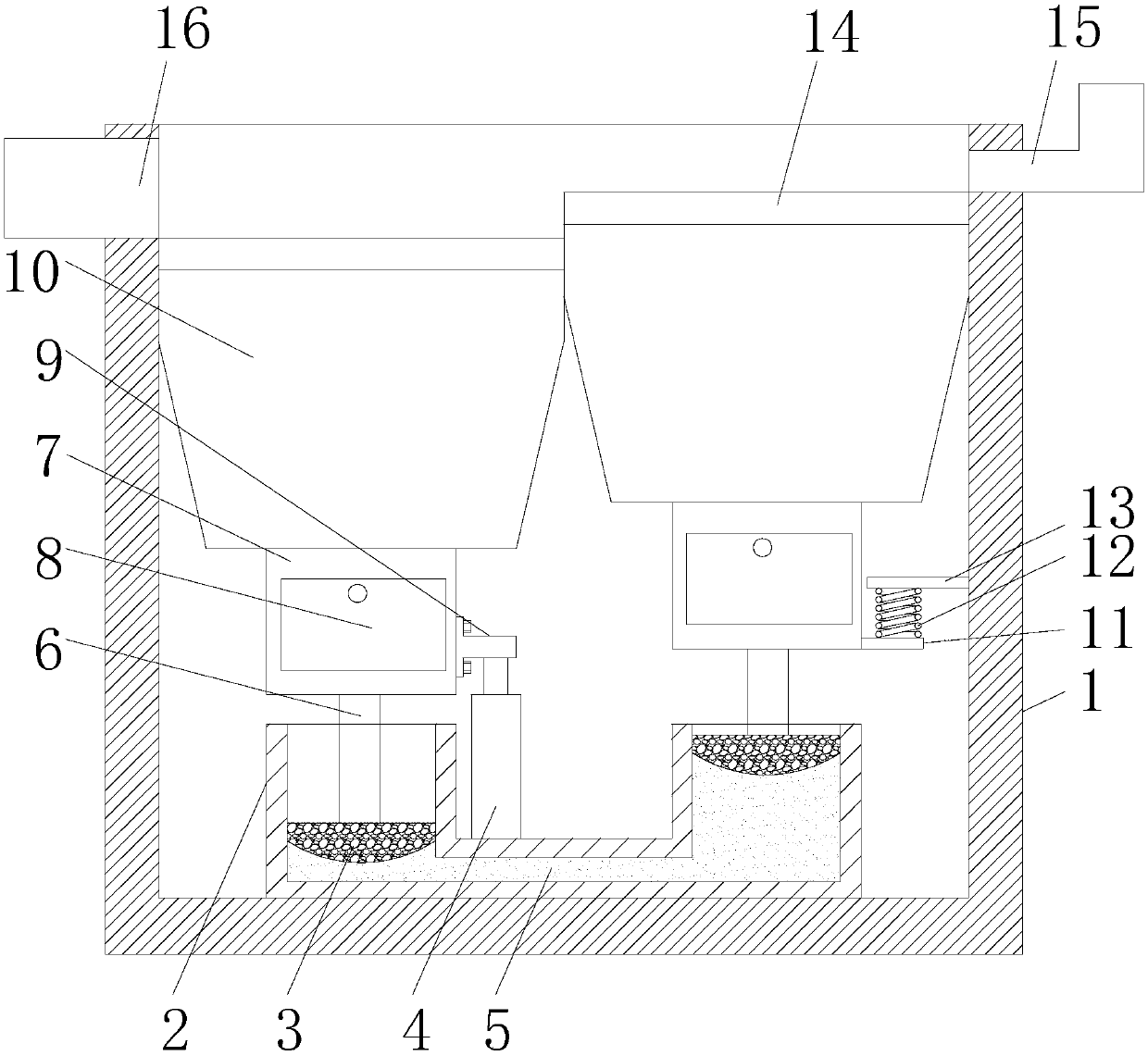

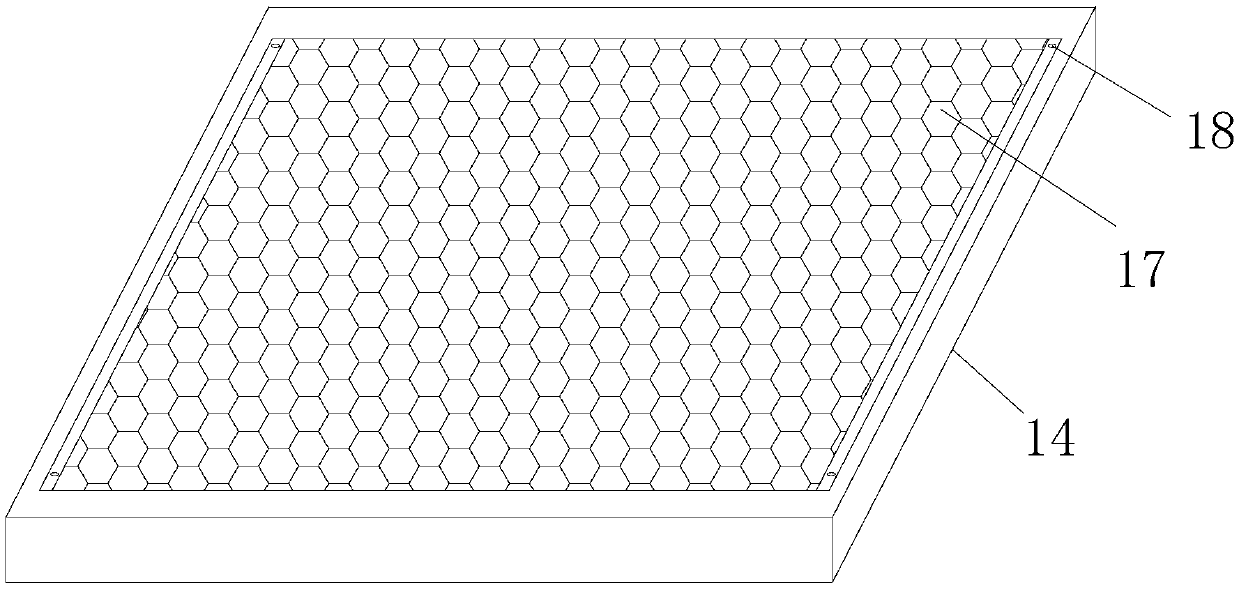

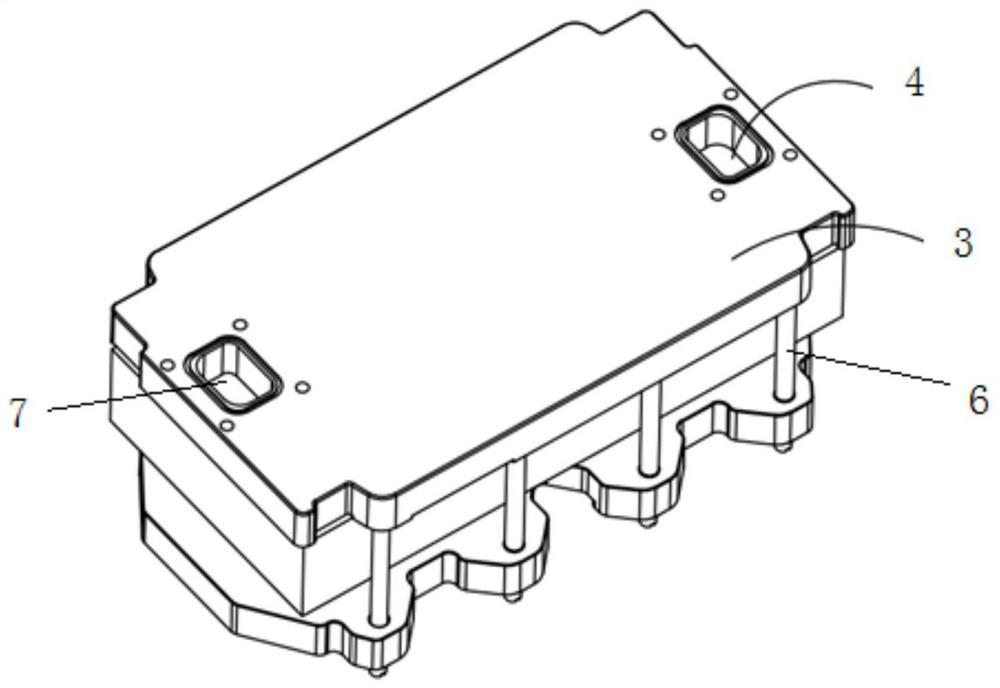

The invention relates to a rare earth gravel screening device, in particular to the rare earth gravel screening device for rare earth waste recycling. The invention aims to solve the technical problemof providing a rare earth gravel screening device for rare earth waste recycling convenient to screen rare earth gravel, fast in screening speed, high in screening efficiency and convenient to move.The rare earth gravel screening device for rare earth waste recycling includes a base plate, a left supporting plate, a right supporting plate, a collecting box, a first supporting rod, a collecting hopper and the like. The left side of the top of the base plate is provided with the left supporting plate and the right side of the top of the base plate is provided with the right supporting plate. The middle of the top of the base plate is provided with the collecting box. The middle of the right side surface of the left supporting plate is provided with the first supporting rod and the right end of the first supporting rod is connected with the collecting hopper. According to the rare earth gravel screening device for rare earth waste recycling, the effects that rare earth gravel screeningis convenient, the screening speed is rapid, screening efficiency is high and movement is convenient are achieved.

Owner:南通海睿知新信息科技有限公司

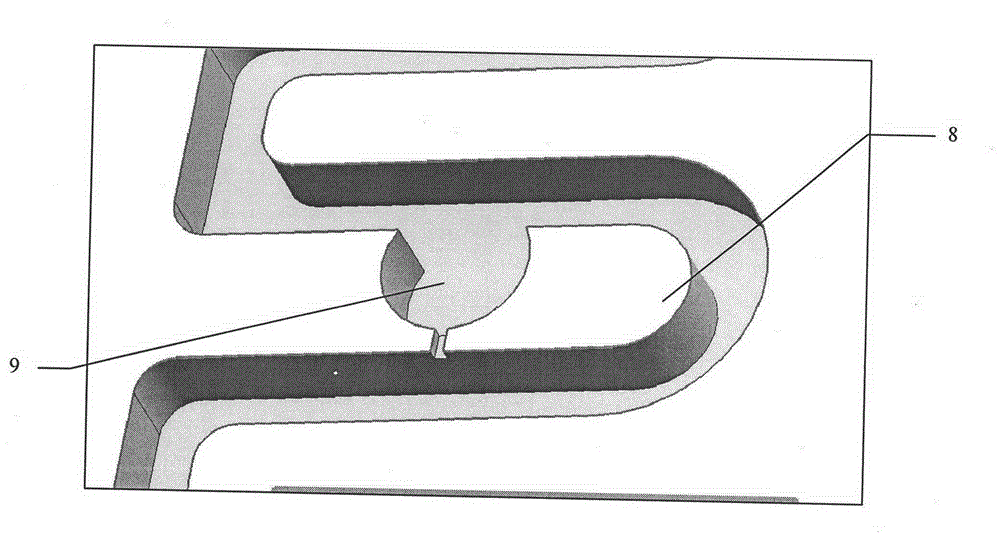

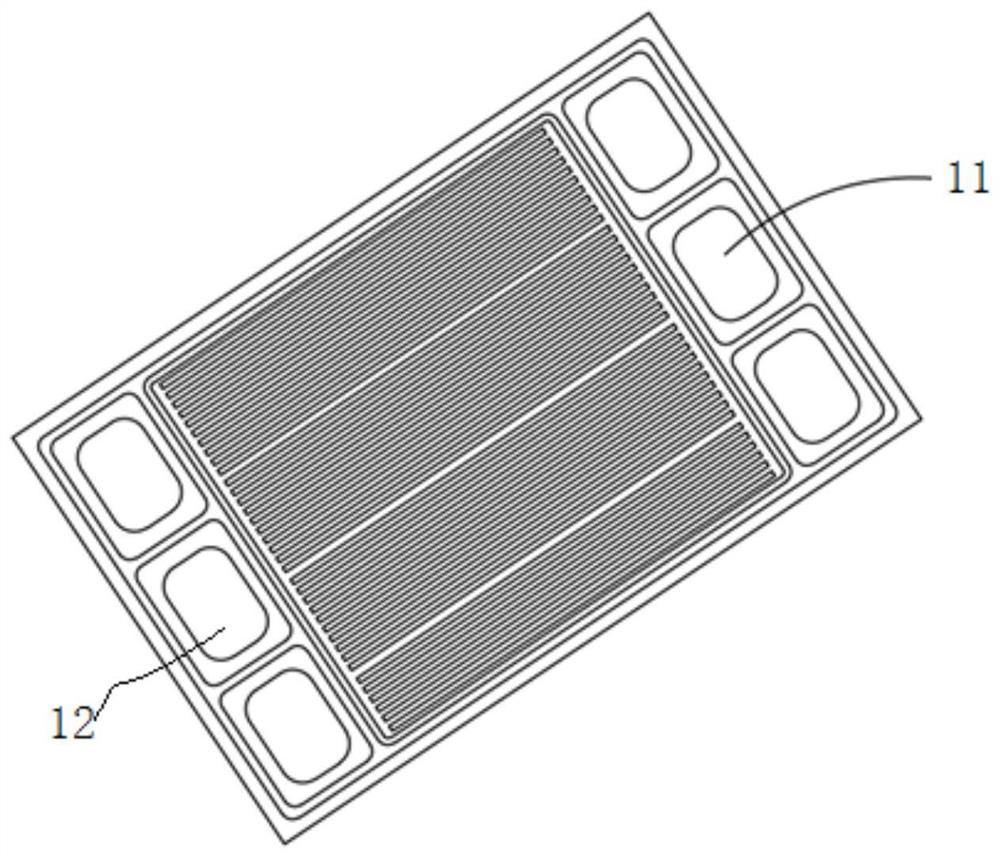

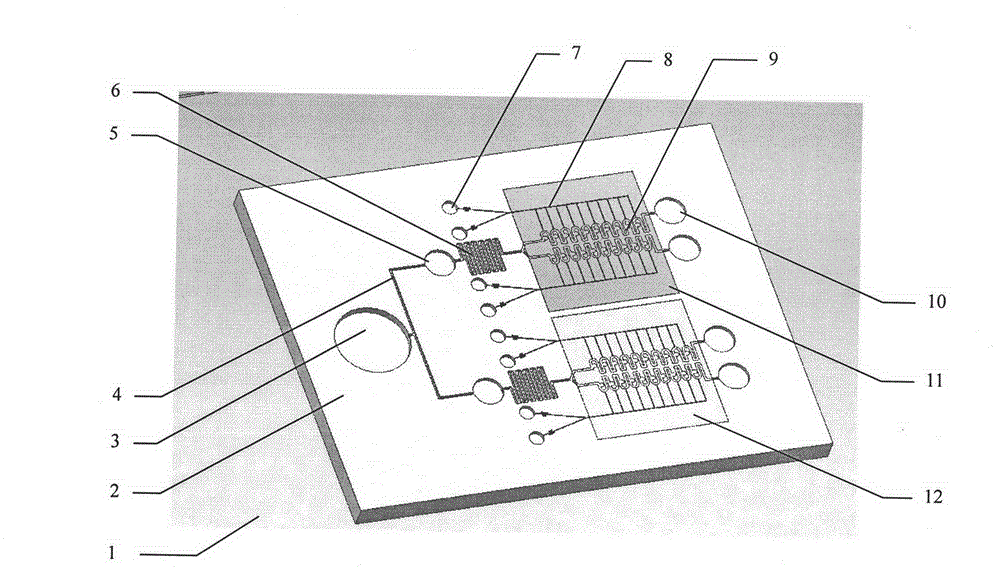

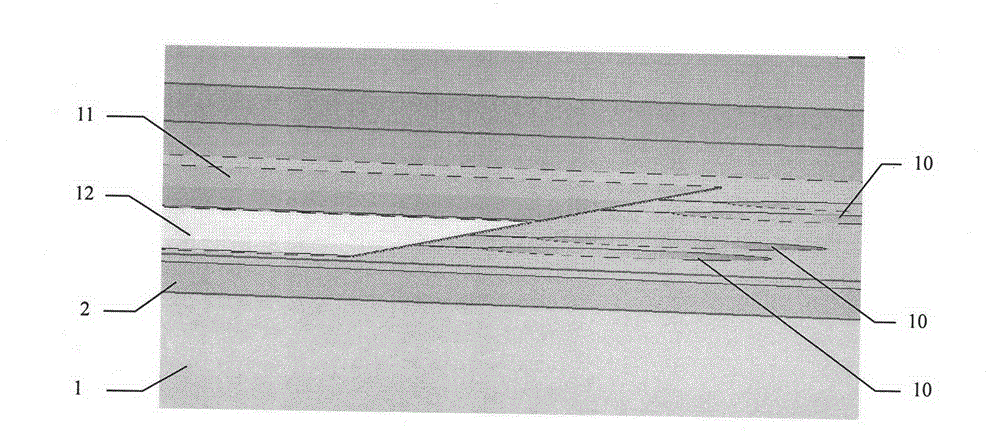

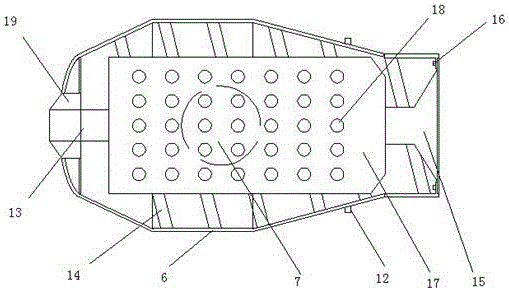

High-flux drug screening microfluidic chip

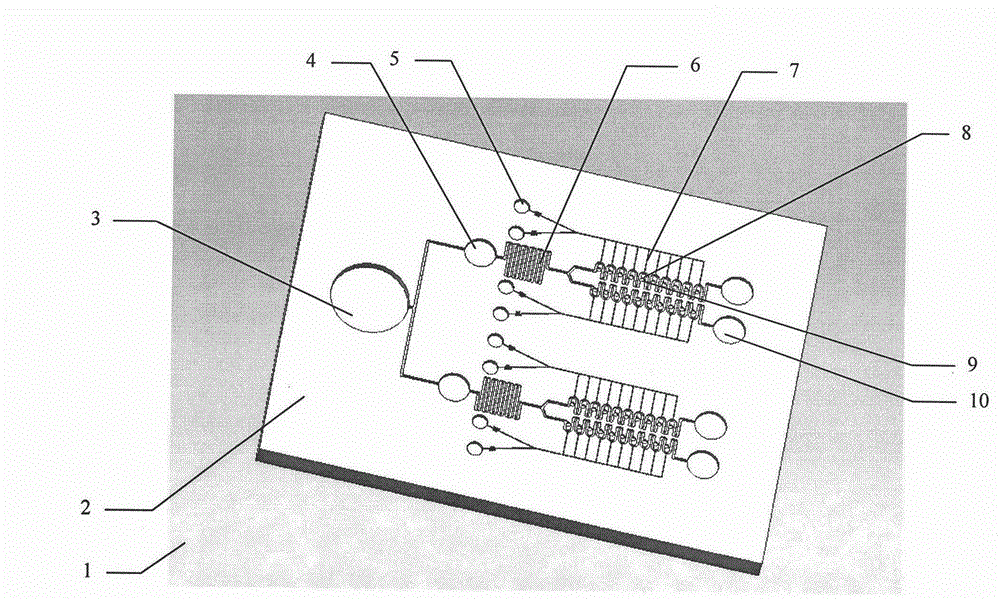

InactiveCN102876570AReflect real-time effectsReal-time control of functions and effectsBioreactor/fermenter combinationsBiological substance pretreatmentsHigh fluxDrug action

The invention provides a high-flux drug screening microfluidic chip which is composed of a cell sample introduction element, a buffer pool, a one-way drive micro-valve, a disk-like bent channel, a drug loading element, a plasmid transfection element, a liquid receiving pool and the like. The elements for cell sample introduction, transfection, cell capture, drug loading and the like are assembled on one chip, so that the invention can simultaneously detect cell integral shape and intracellular labeled protein activity variation under different drug actions on one chip in the detection process, and monitor the action effect of the drug on the actual cells, thereby greatly lowering the detection cost, enhancing the detection accuracy and detection efficiency, and achieving the goal of drug screening.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

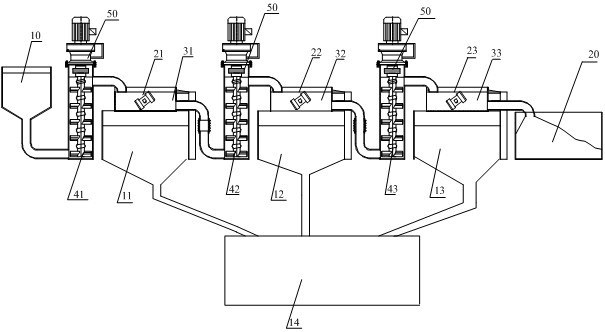

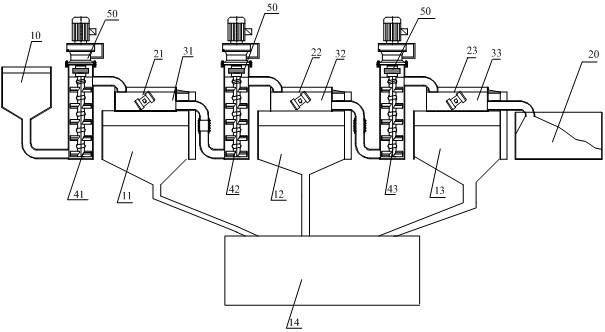

Equipment used for crushing fluorite tailings, crushing method and fluorite flotation method

InactiveCN102580836AHigh recovery rateGood quality concentrateFlotationGrain treatmentsEngineeringAgitator

The invention provides equipment used for crushing fluorite tailings and a crushing method. The equipment comprises a tailing receiver and a first stirrer, wherein a first vibrating screen is connected above the first stirrer, a fist collector is arranged below the first vibrating screen, the first vibrating screen is connected with a second stirrer which is connected with a second vibrating screen, a second collector is arranged below the second vibrating screen, the second vibrating screen is connected with a third stirrer which is connected with a third vibrating screen, and a third collector is arranged below the third vibrating screen; the third vibrating screen is also connected with a material collector; the first collector, the second collector and the third collector are all connected with a fourth collector. The invention also provides the method for using the equipment and a fluorite flotation method. The invention has the beneficial effects that the fluorite concentrate obtained by flotation has good quality, is high in recovery and low in cost, and is suitable for being applied in various fluorite flotation factories.

Owner:SHENZHEN SUNXING LIGHT ALLOYS MATERIALS CO LTD +1

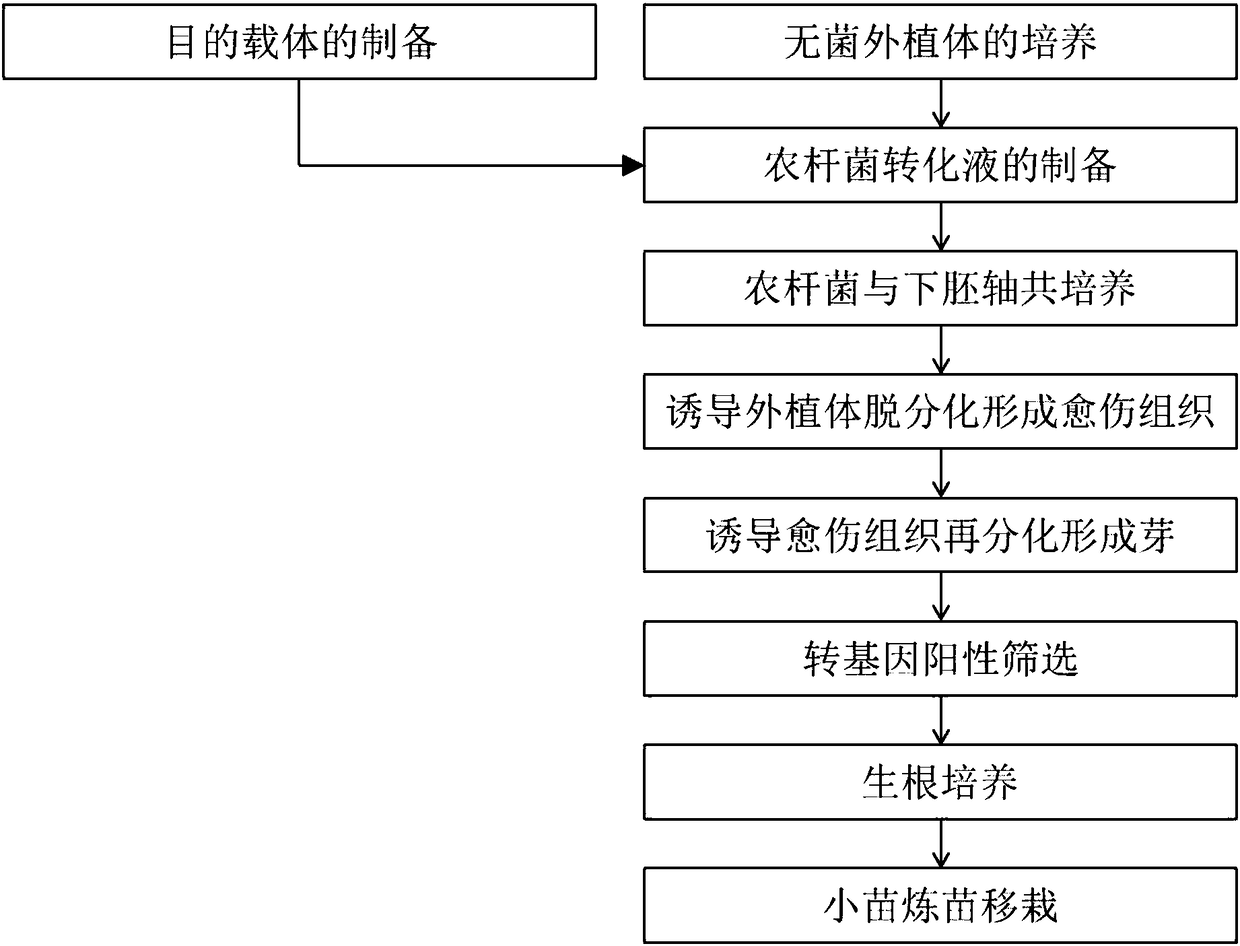

Efficient genetic transformation and rapid identification method for cabbage type rapes

ActiveCN108456690AReduce adverse effectsAdd lessPlant tissue cultureHorticulture methodsHypocotylRapid identification

The invention discloses an efficient genetic transformation and rapid identification method for cabbage type rapes. The genetic transformation method for cabbage type rapes comprises the following steps: (1) cultivation of sterile explant; (2) preparation of a target carrier; (3) preparation of agrobacterium conversion liquid; (4) co-cultivation of agrobacterium and hypocotyledonary axis; (5) induction of explant dedifferentiation to form callus; (6) induction of callus dedifferentiation to form buds; (7) transgenic positive selecting; (8) rooting culture; and (9) plantlet hardening-off and transplanting. Integral process settings of the genetic transformation method, parameter conditions of key steps, and the like are improved and are further preferably selected, so that cabbage type rapetransgenic seedlings can be efficiently and quickly obtained through effective selecting means in comparison with the prior art. A DsRed gene is inserted into a carrier containing a target gene, so that the target carrier with DsRed is transferred into agrobacterium strain, and therefore, transgenic positive screening can be quickly and efficiently performed by observing color of the hypocotyledonary axis.

Owner:HUAZHONG UNIV OF SCI & TECH

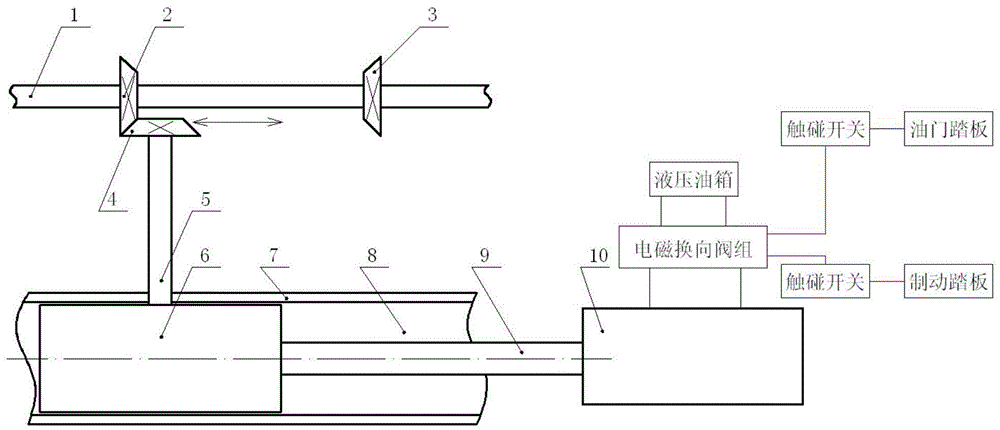

Automobile brake energy reutilizing device based on volute spiral spring

InactiveCN104802774ATimely switchReduce outputAuxillary drivesBraking element arrangementsDrive shaftMirror image

The invention relates to an automobile brake energy reutilizing device based on a volute spiral spring. The automobile brake energy reutilizing device comprises a transmission unit and a movement unit, wherein the transmission unit comprises a brake bevel gear, an acceleration bevel gear and a matching bevel gear; the brake bevel gear and the acceleration bevel gear are coaxially and symmetrically arranged on a driving shaft of an automobile wheel in a mirror image way; the conical parts of the brake bevel gear and the acceleration bevel gear are oppositely arranged; a gap is formed between the brake bevel gear and the acceleration bevel gear; the matching bevel gear is arranged in the gap and is respectively engaged with the brake bevel gear and the acceleration bevel gear; the matching bevel gear can do reciprocating movement between the brake bevel gear and the acceleration bevel gear through the movement unit. The automobile brake energy reutilizing device based on the volute spiral spring has the advantage that by utilizing the close coordination of the volute spiral spring and the bevel gear, the recovery and release of kinetic energy can be switched at proper time.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

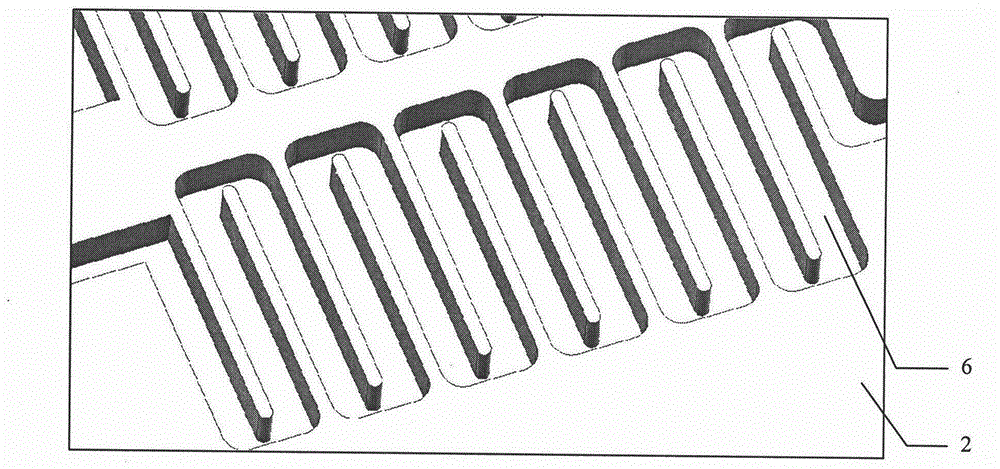

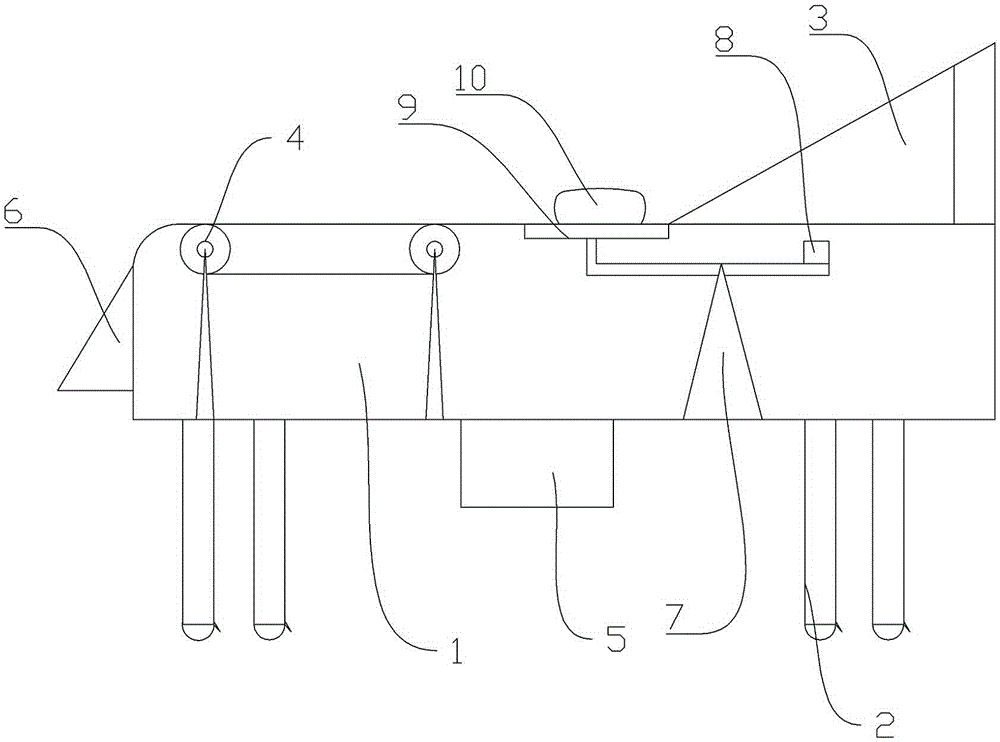

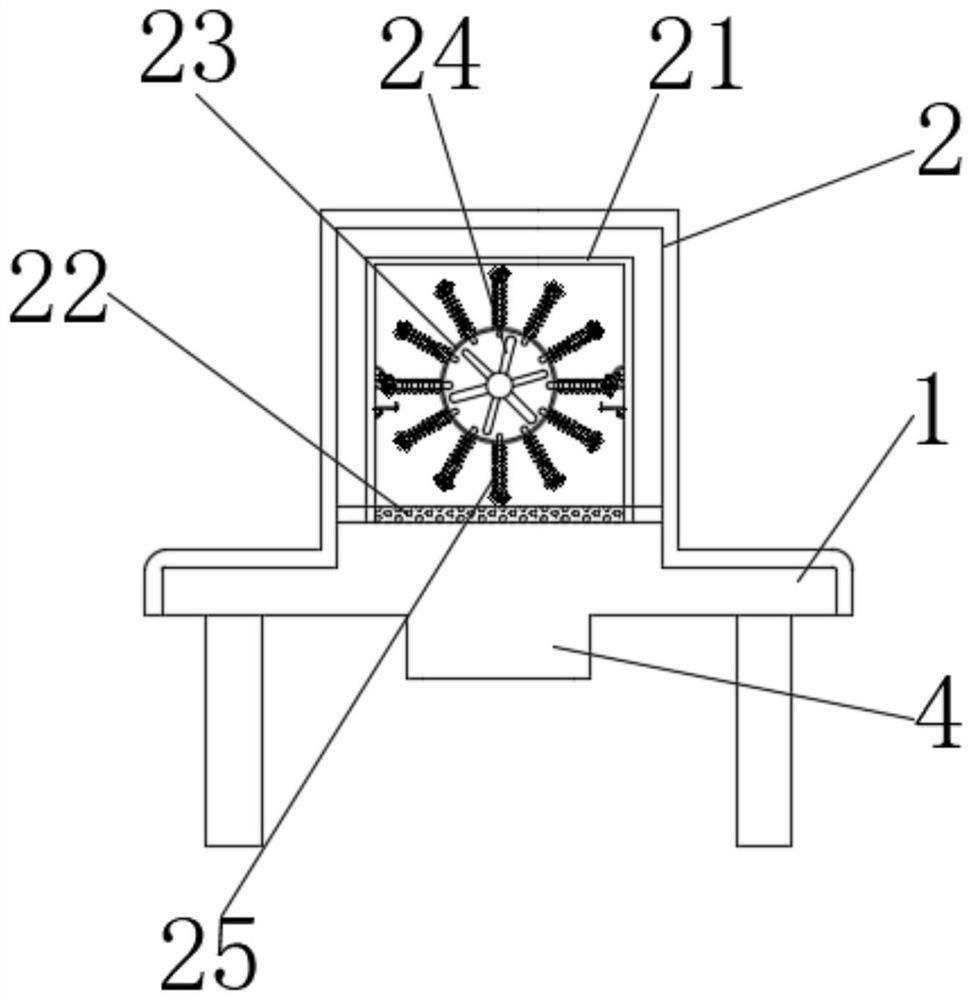

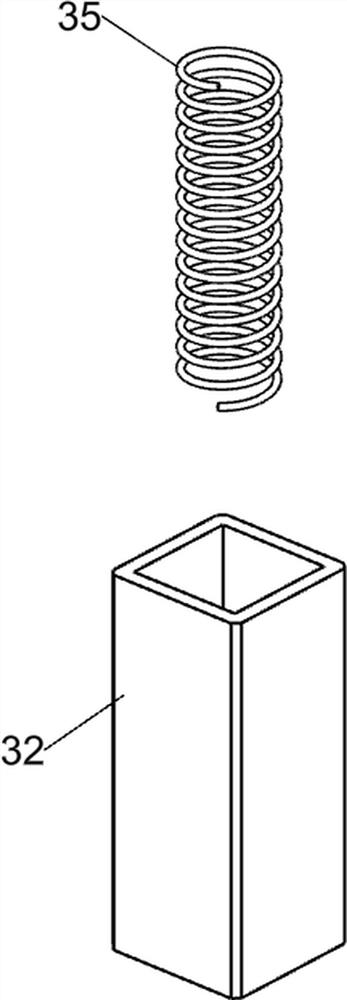

Novel mineral separation washbox

InactiveCN108654825AEasy to judge the degree of deformationAchieve the purpose of screeningWet separationEngineering

Owner:江西金石宝矿山机械制造有限公司

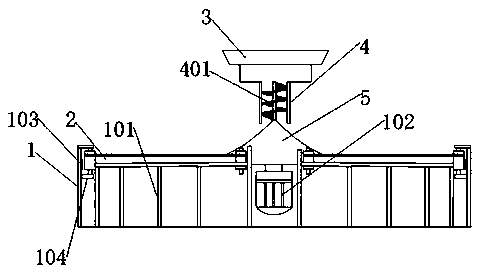

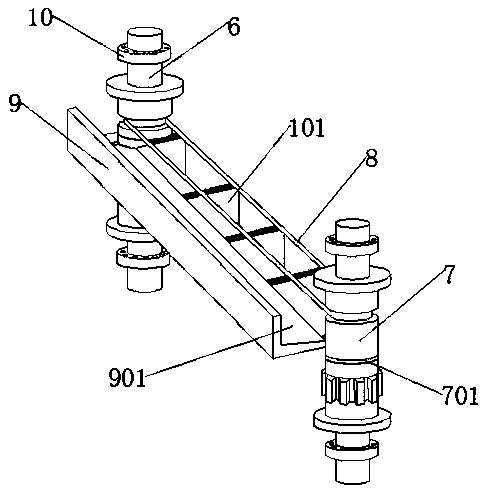

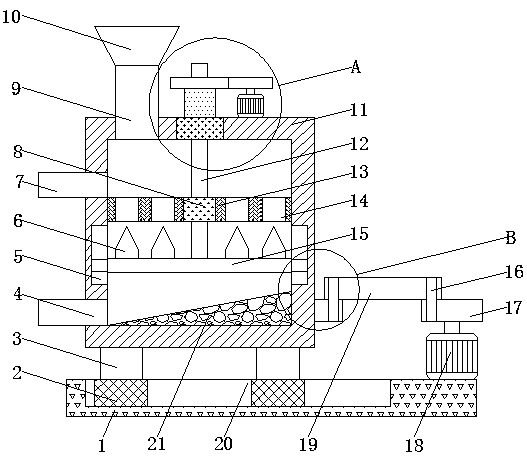

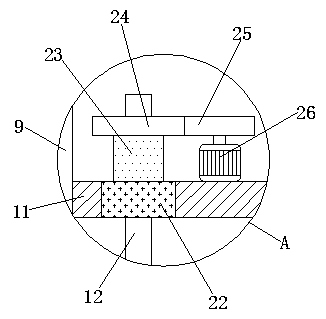

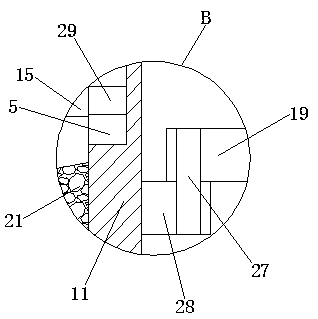

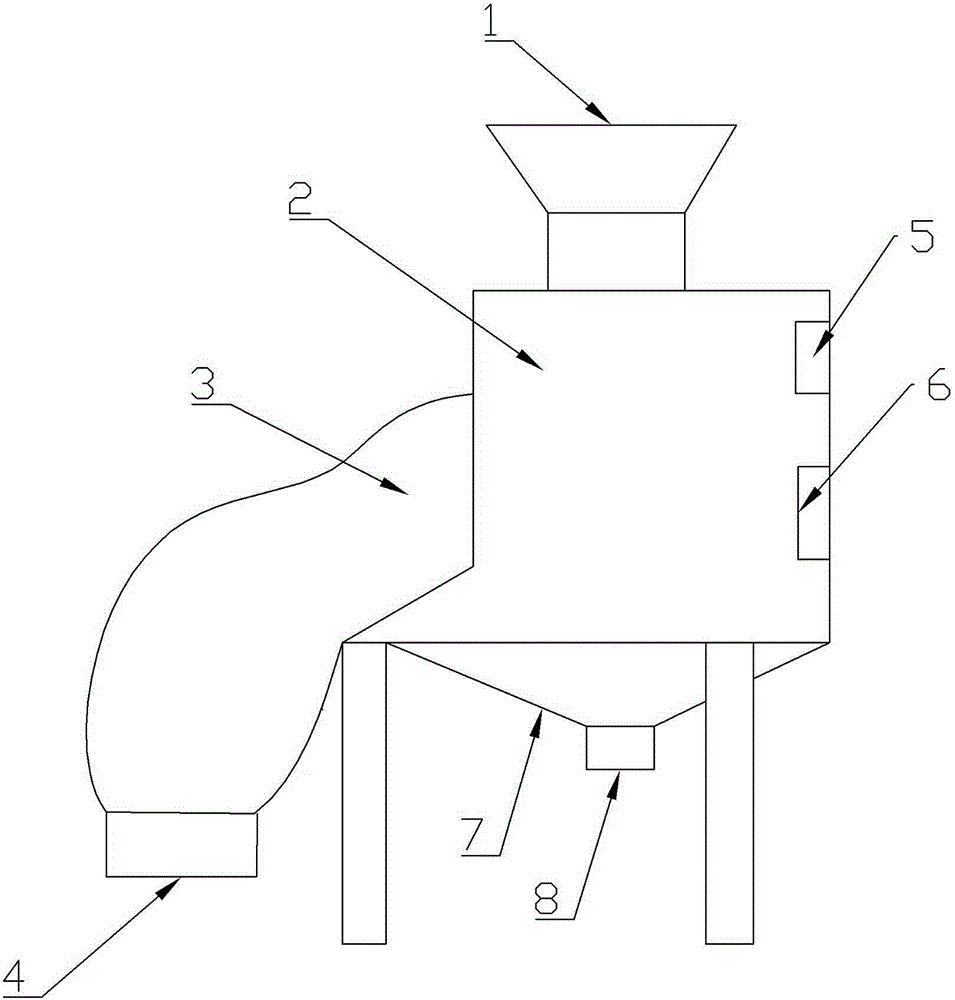

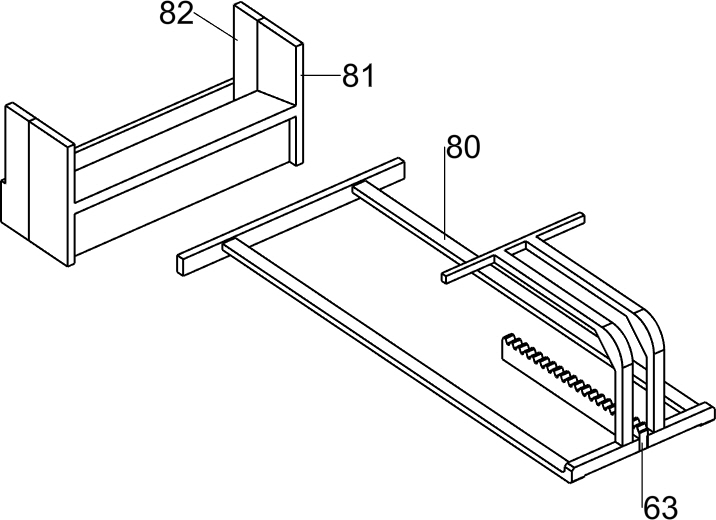

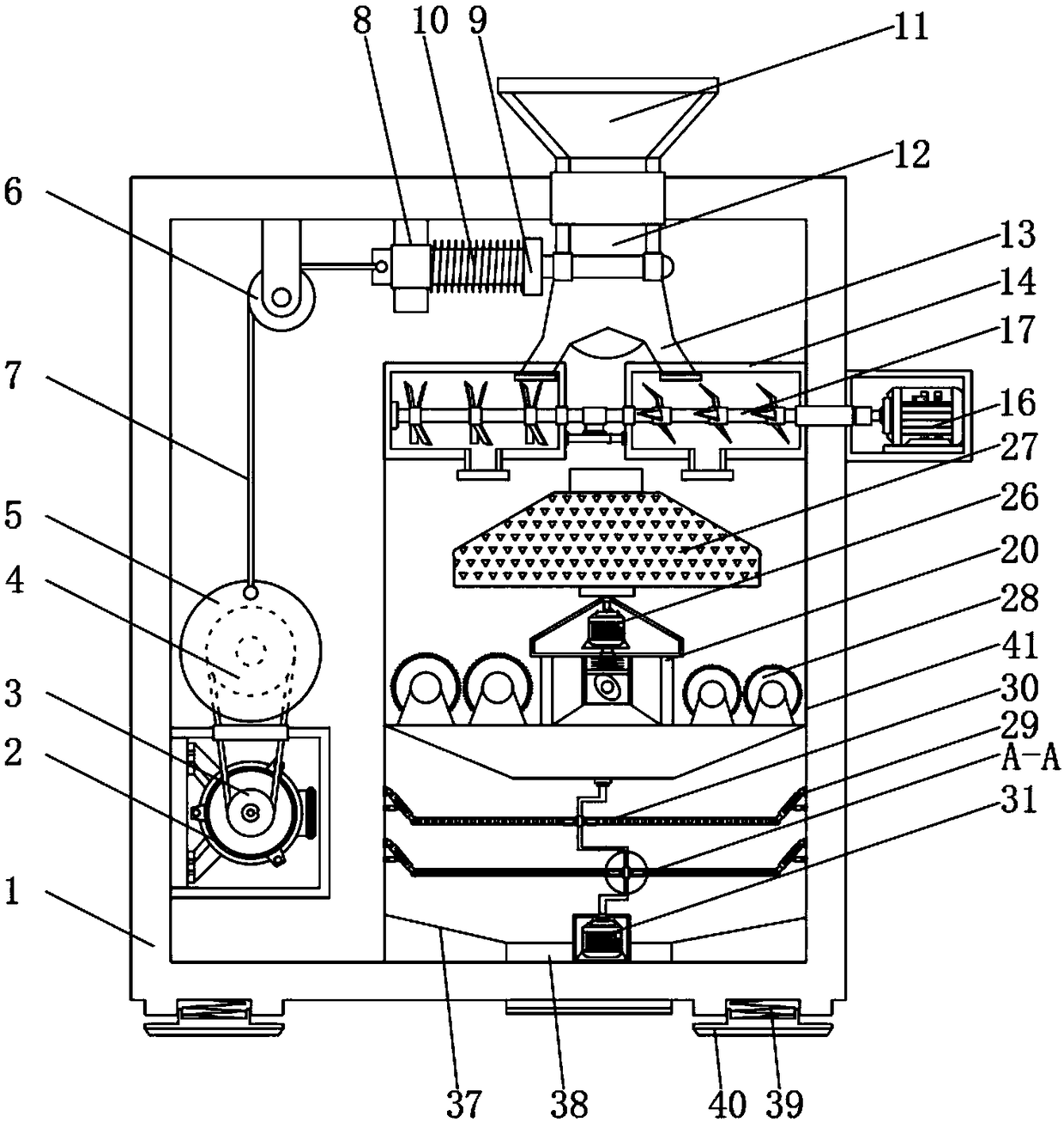

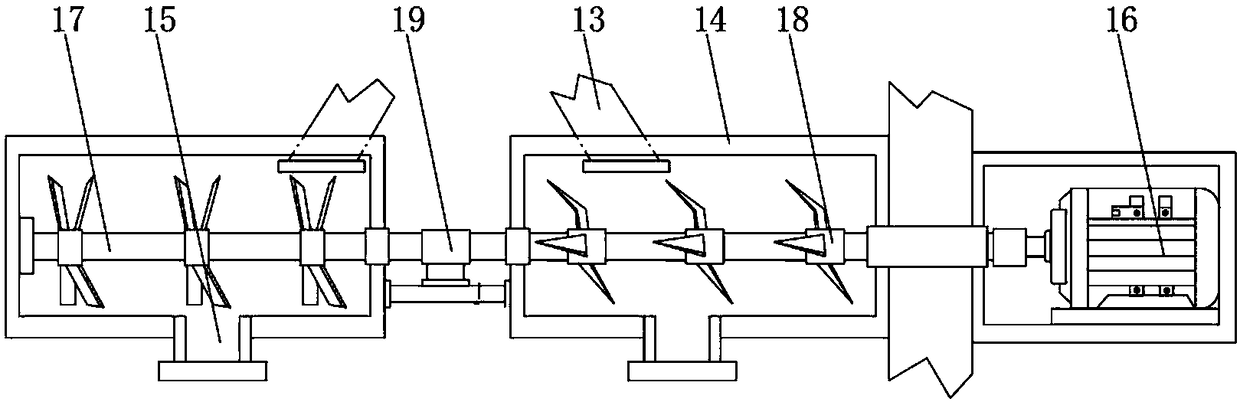

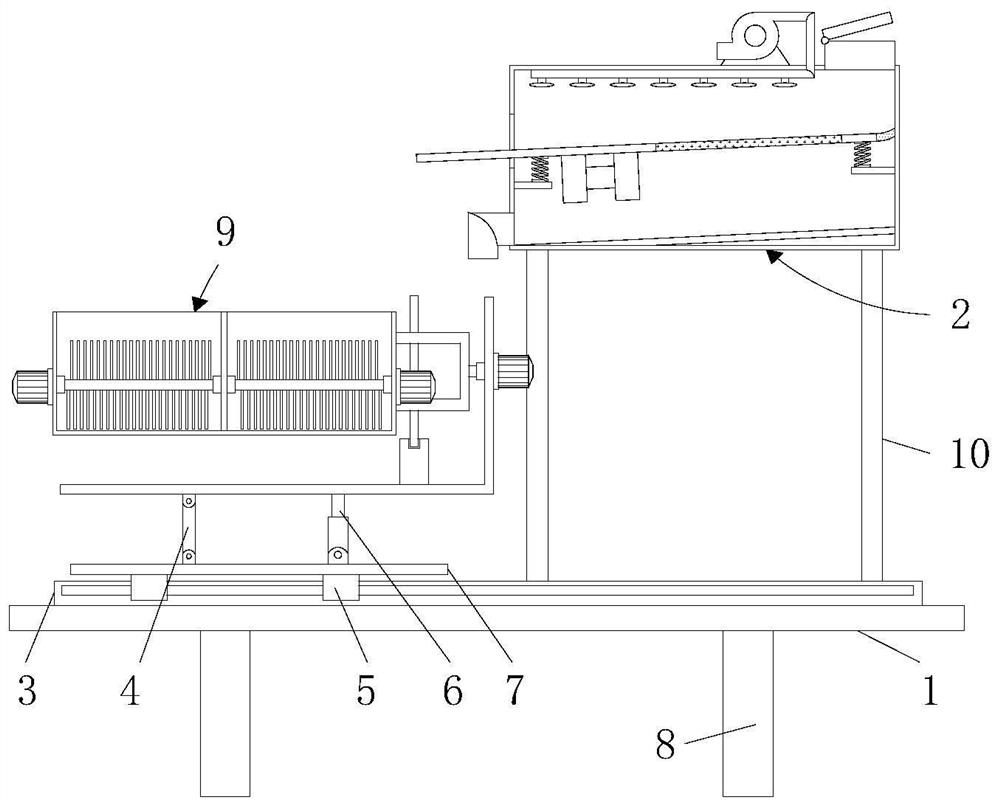

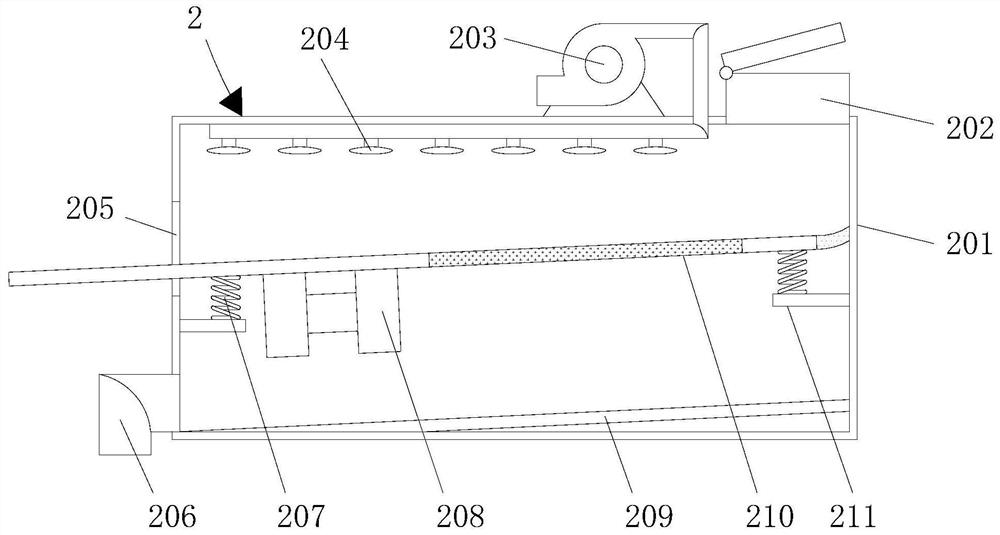

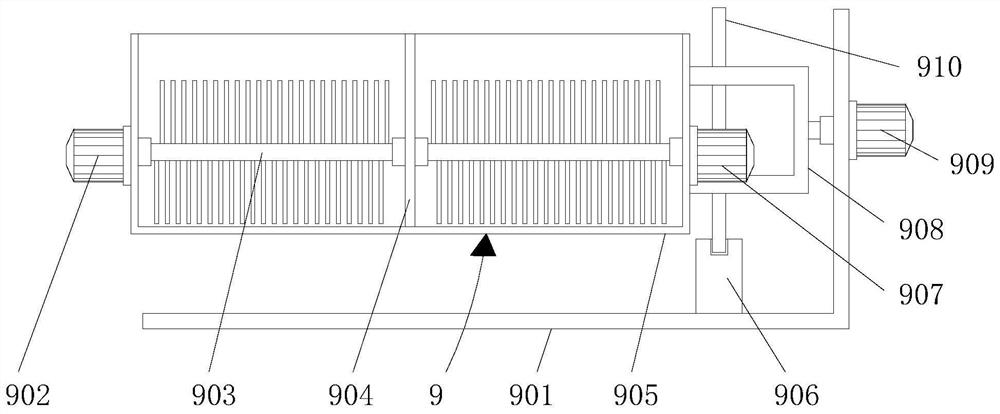

Multi-wheel type silicon material pulverizer

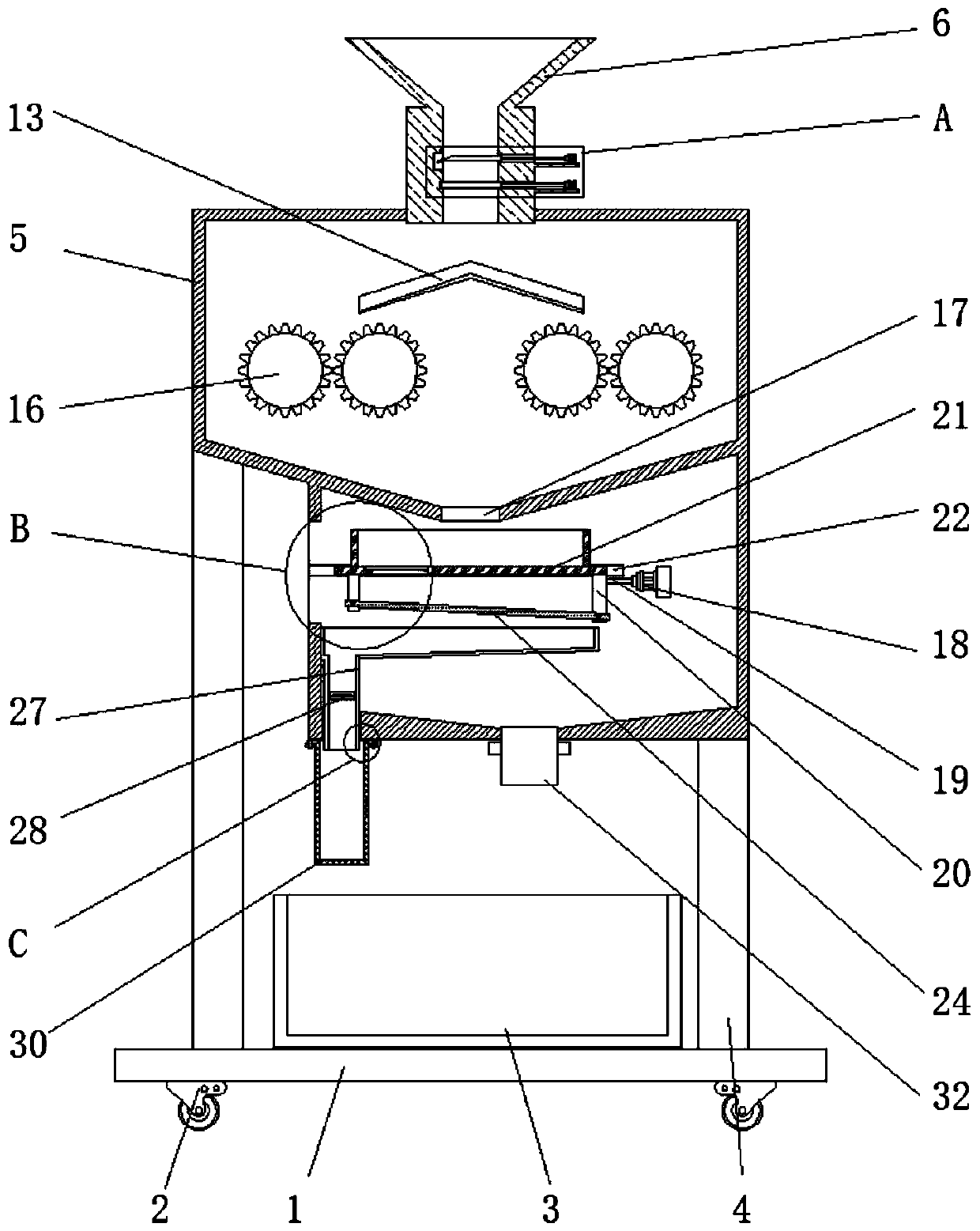

The invention discloses a multi-wheel type silicon material pulverizer. A base and a feeding device are included. Self-locking wheels are arranged on the left side and the right side of the bottom ofthe base. A motor is arranged on the rear side of the feeding device. A discharging port is formed in the lower sides of pulverizing barrels. A vibration motor is arranged in a pulverizing box, a sieve frame is arranged on the lower side of the discharging port, a rotation door is rotationally connected in the bottom of the sieve frame, and a sieve plate is fixed to the bottom of a bearing rod through second bolts. A discharging pipeline is arranged on the lower side of the sieve plate. A threaded column is fixed to the bottom of the pulverizing box. A material collecting frame is arranged onthe lower side of the discharging pipeline. A collecting box is arranged on the lower side of the material collecting frame. An electric valve is arranged at the bottom of the pulverizing box. According to the multi-wheel type silicon material pulverizer, after silicon materials fall between the left set of pulverizing barrels and the right set of pulverizing barrels, the pulverizing barrels can rotate under the action of a motor and a motor shaft, the silicon materials are pulverized, the two pulverizing barrels work at the same time, and the work efficiency can be improved.

Owner:江苏众鑫磁电有限公司

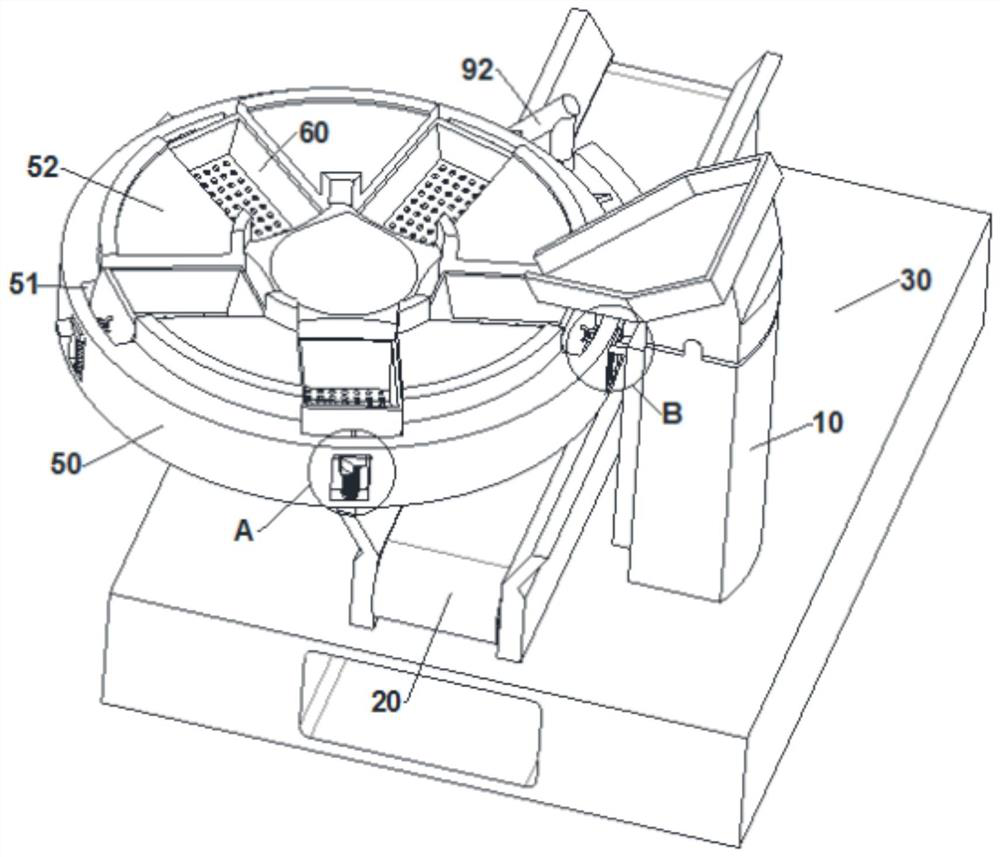

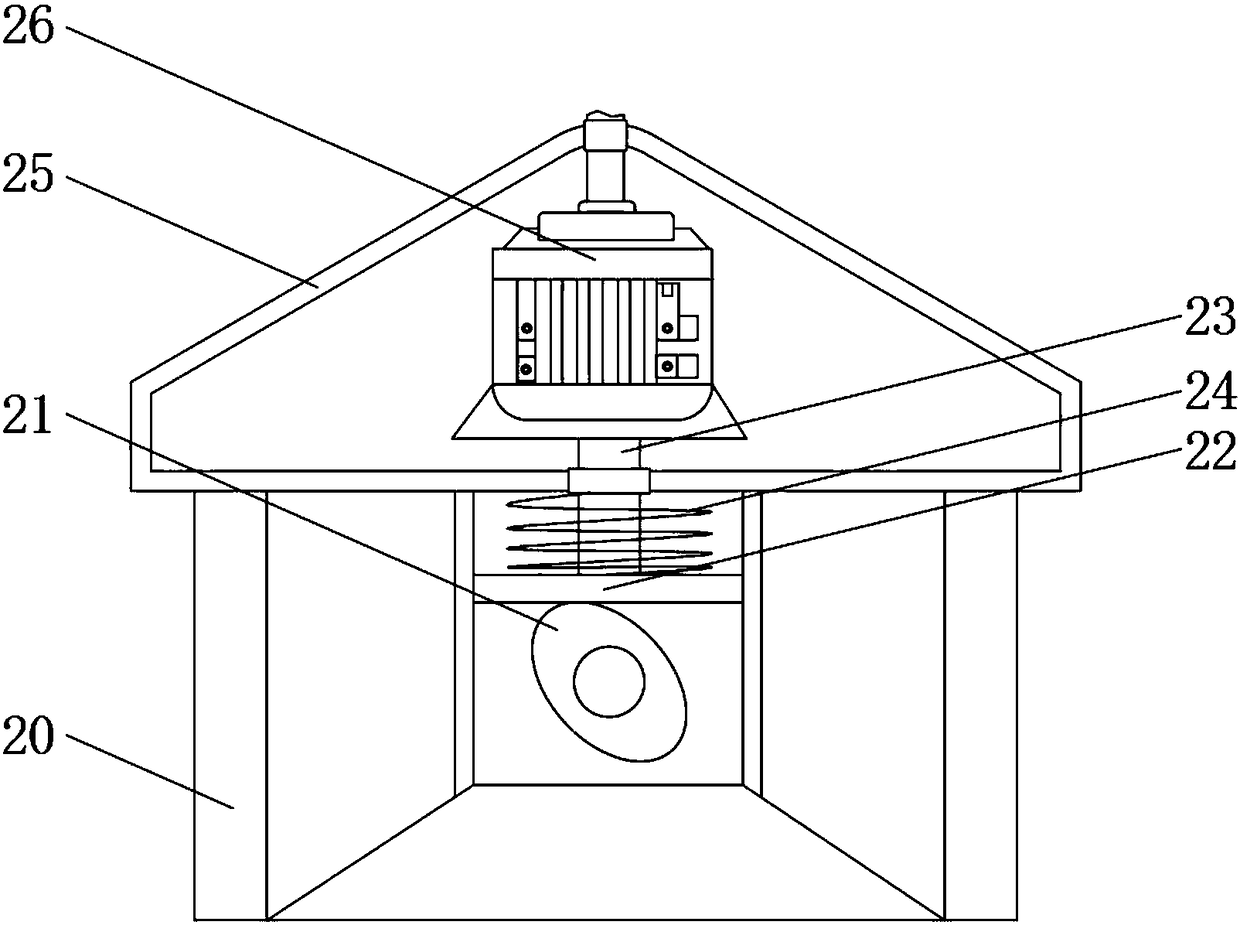

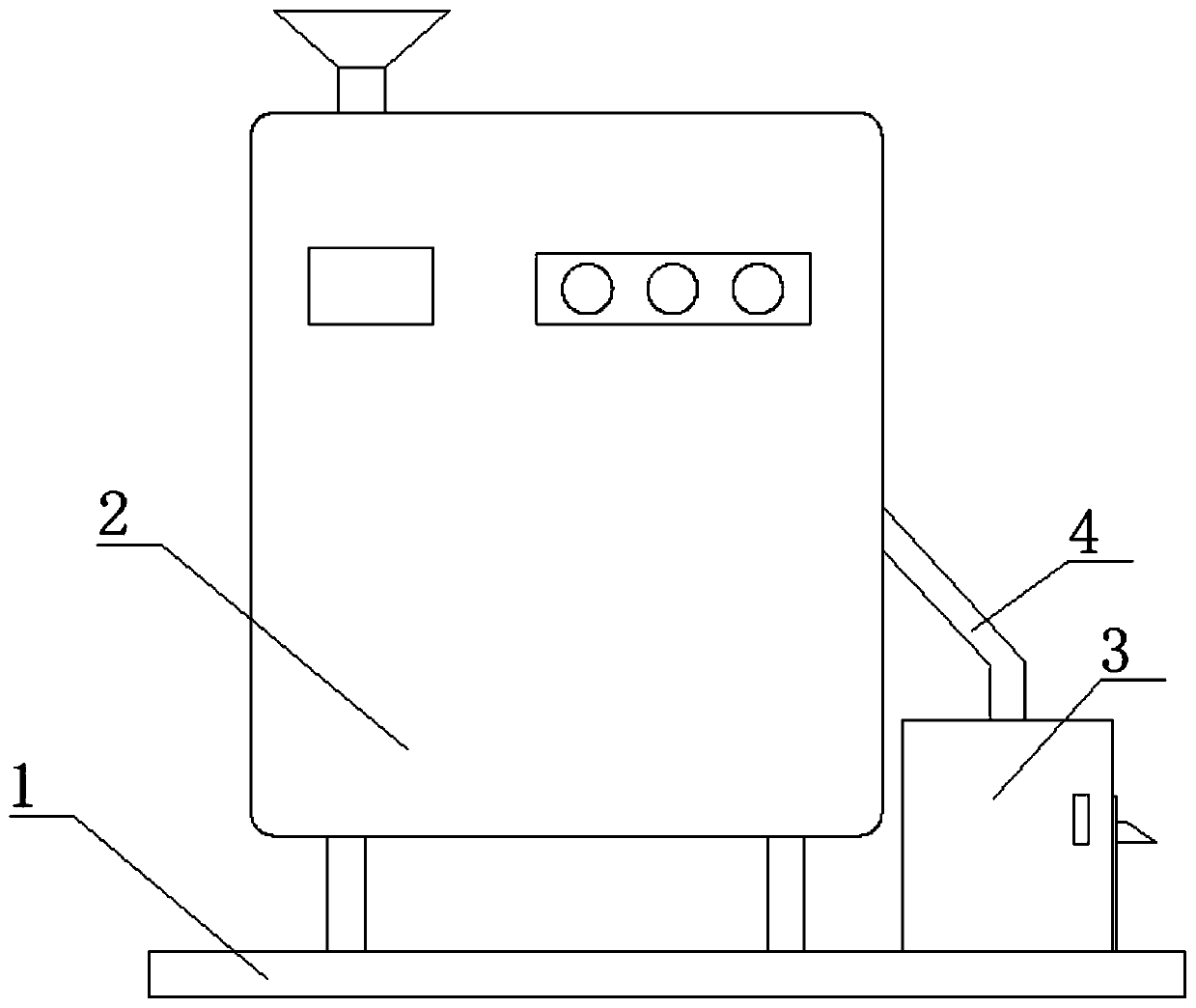

Intelligent screening equipment

The invention provides intelligent screening equipment which comprises a device bottom plate, a sorting mechanism, a feeding trough, a conveying pipe, a flow guide conic plate, partition plates, a servo motor, driving teeth, locating buckle plates and flow guide troughs. The partition plates are integrally arranged on the left side and the right side in the device bottom plate. The servo motor isfixedly connected to the middle in the device bottom plate. The locating buckle plates are arranged on the device bottom plate along the periphery in an embedded manner. The driving teeth are integrally arranged on the inner walls of the locating buckle plates. The upper portion of the servo motor is in transmission connected with the flow guide conic plate. The flow guide troughs are arranged onthe surface of the flow guide conic plate in an embedded manner. In the screening arrangement, centrifugal force is utilized, the device screening precision is high, the speed is high, operation is more intelligent, reliability is higher, and control is more convenient; meanwhile, the stability and fluency of a device are improved, and the device can be more suitable for screening irregular dates;and the classification interval can be adjusted according to different article kinds, and the action range of the device can be wider during use.

Owner:汤泓

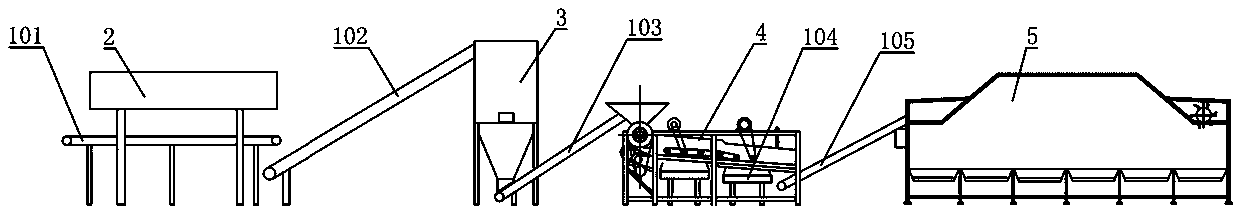

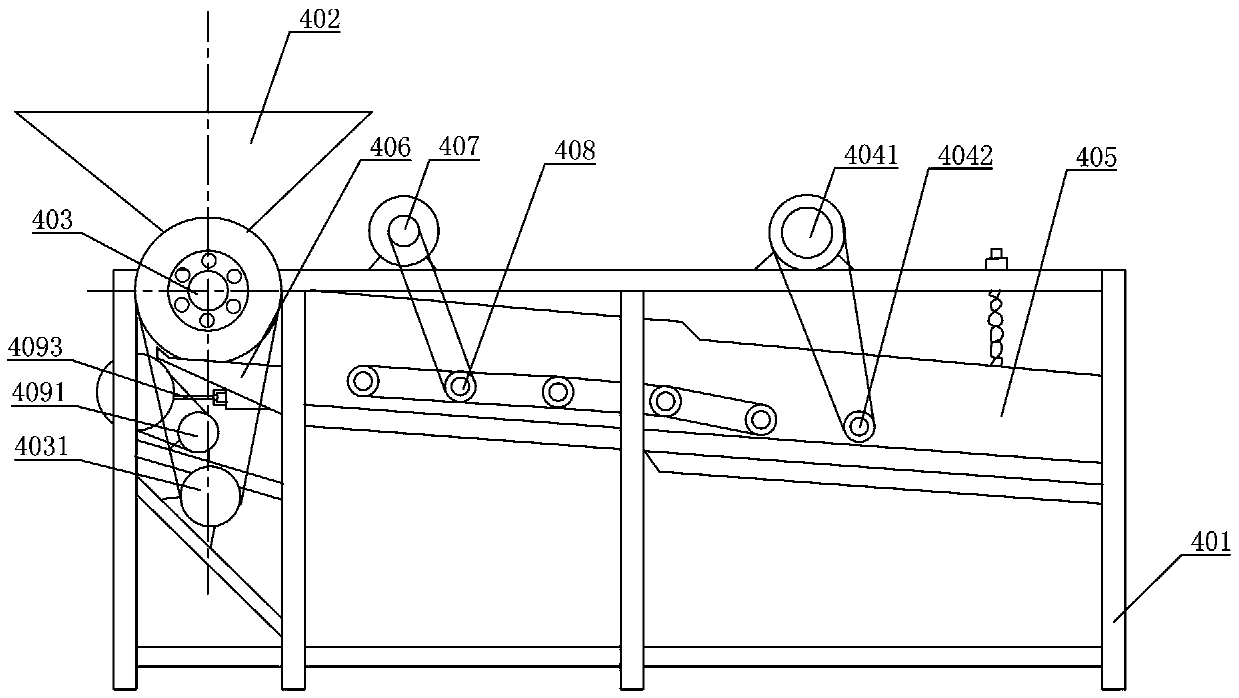

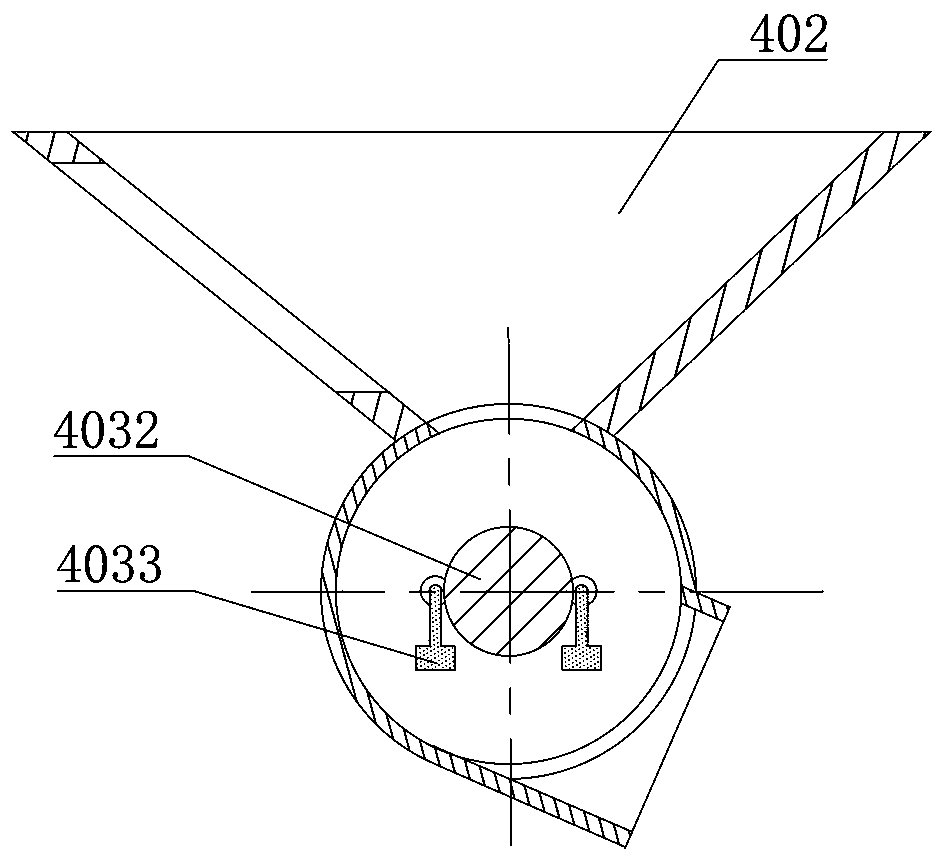

Garbage classification system and process

PendingCN110152798ADetailed classificationAchieve the purpose of screeningSievingGas current separationMagnetic separatorElectric machinery

The invention relates to a garbage classification system and process. The garbage classification system involves conveyors, a magnetic separator and a stock bin, wherein the magnetic separator is arranged above the first conveyor, the stock bin is arranged at one end of the second conveyor, a bag breaking motor and a bag breaking roller are arranged below the stock bin, the third conveyor is arranged below the stock bin, the third conveyor conveys garbage to a crushing and screening machine, a screening plate is arranged in the crushing and screening machine, the plurality of fourth conveyorsare arranged below the screening plate, and one end of the crushing and screening machine is used for conveying the garbage to an air separator through the fifth conveyor. According to the garbage classification system and process, the garbage can be subjected to classification treatment, the garbage with a large volume can be crushed in the classification process, and the mixed garbage is screened, so that the garbage, with light weight and generated in the sorting and classifying process, is easy to collect, then treatment or recycle is facilitated, the structure is simple, and the manufacturing cost is low.

Owner:李长征

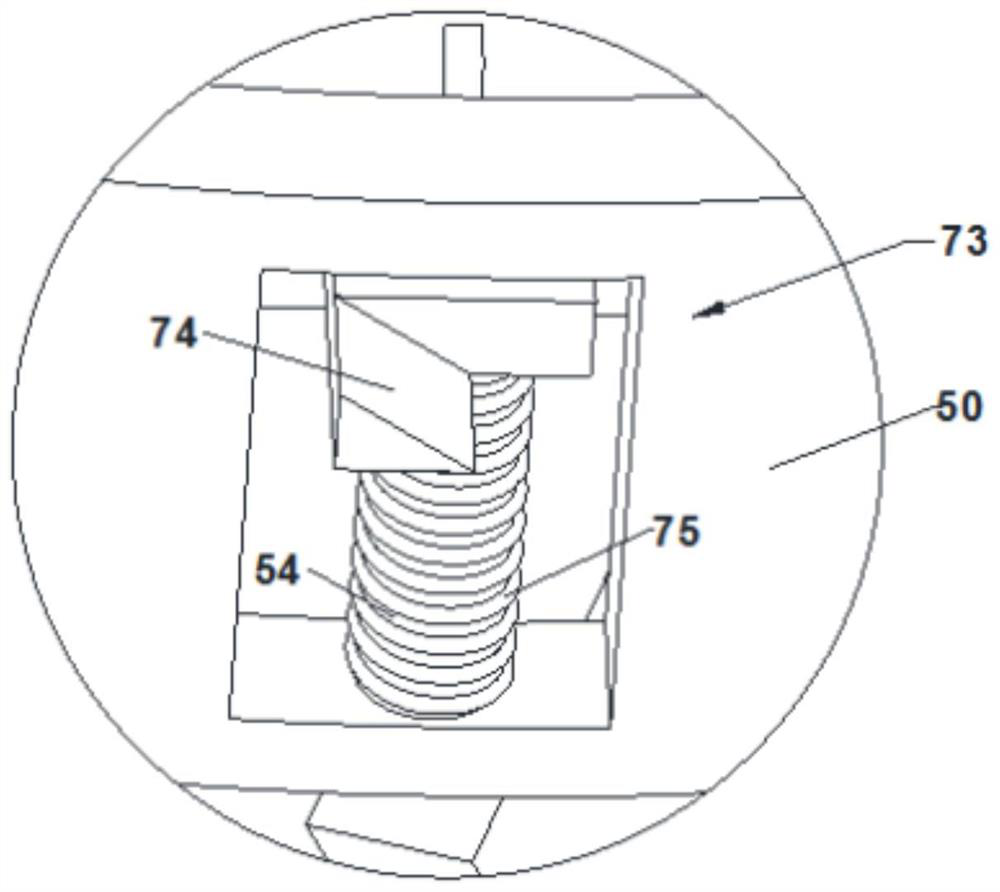

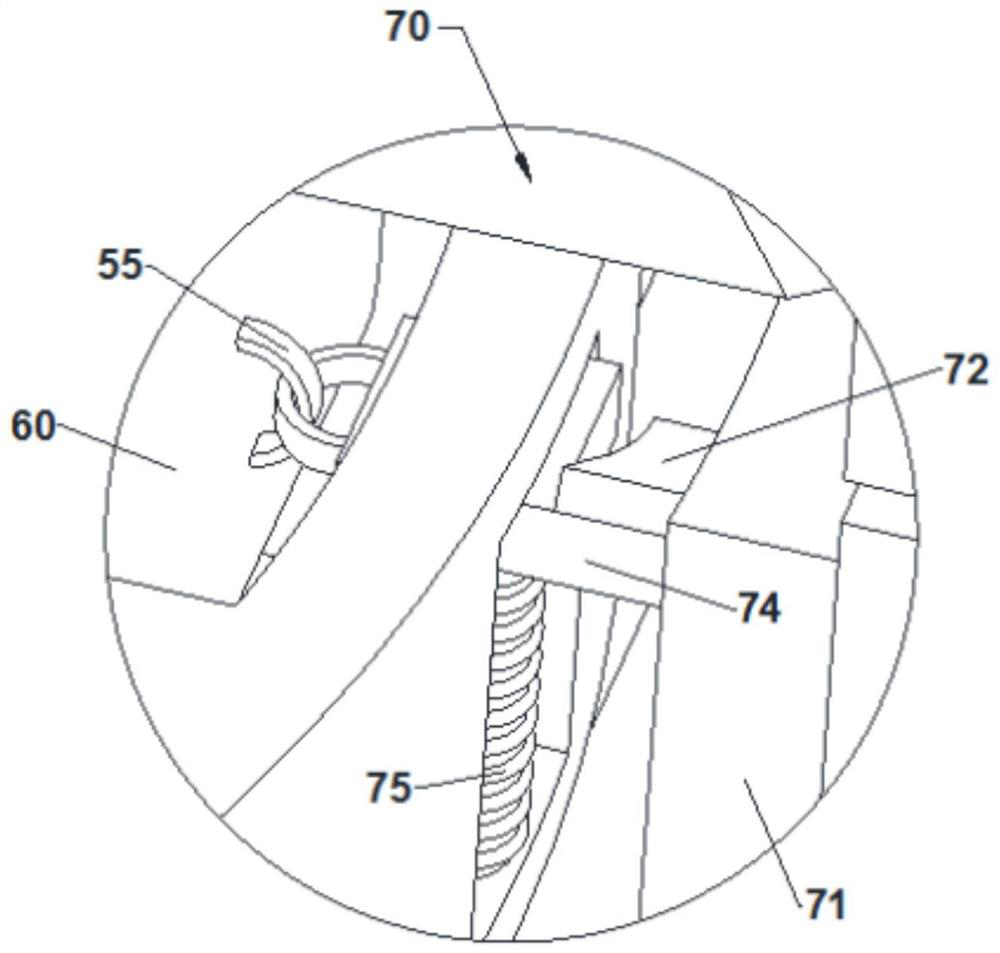

Mineral separation washbox

InactiveCN108672077AEasy to collectAchieve the purpose of screeningWet separationPush pullEngineering

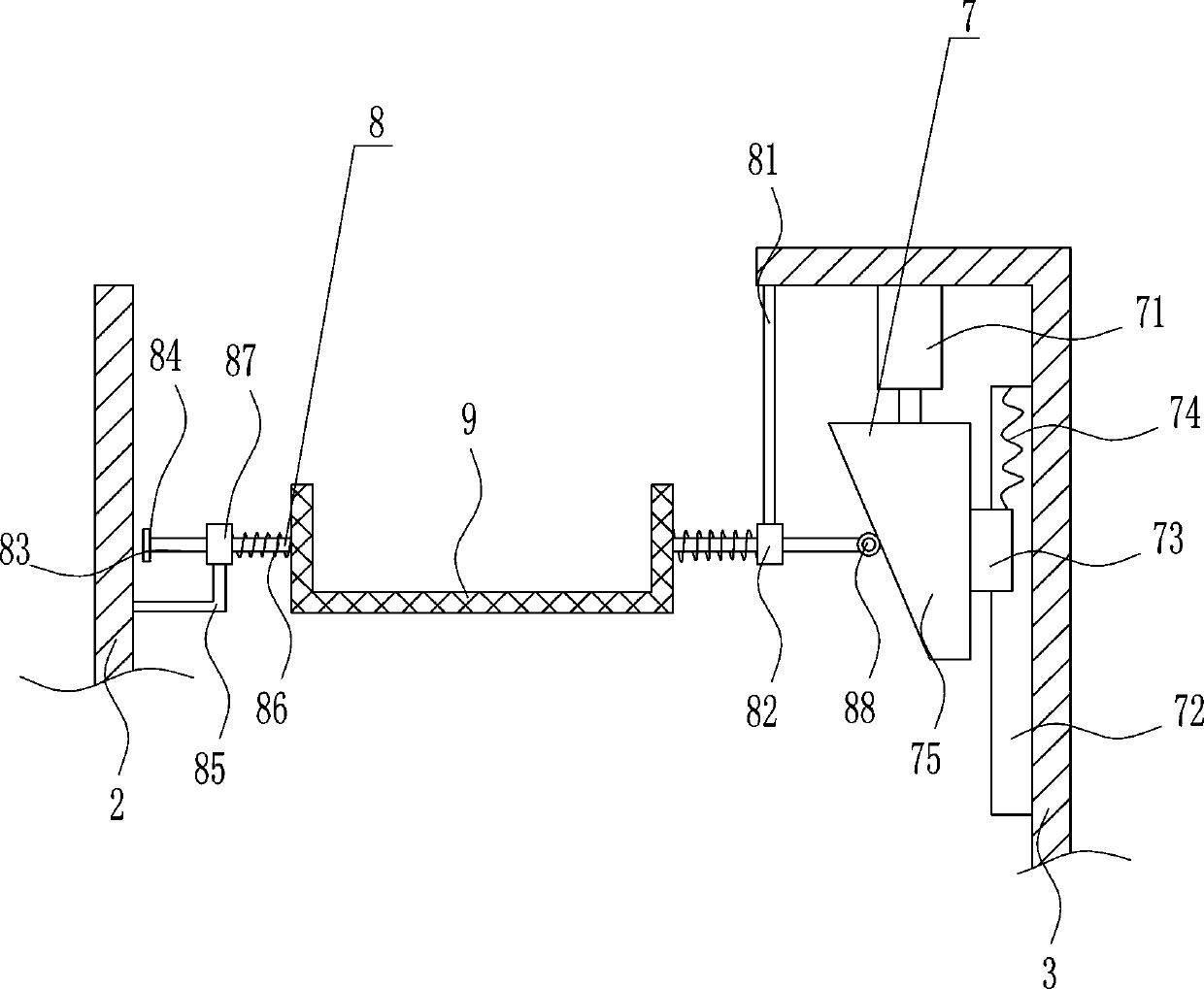

The invention discloses a mineral separation washbox. The mineral separation washbox comprises a box body, a U-shaped pipe is arranged on the bottom wall of the interior of the box body, pistons are in sliding connection into interiors of pipe openings in the two ends of the U-shaped pipe, the interior of the U-shaped pipe is filled with hydraulic oil, a hydraulic rod is arranged on the U-shaped pipe, the top end face of the piston is fixedly connected with the bottom end of a supporting rod, the top end of the supporting rod is fixedly connected with a discharging box, the top of the discharging box is in through connection with a feeding box, the front side wall of the discharging box is movably provided with a push-pull type drawer, the position, close to the left side wall of the interior of the box body, of the right side wall of the discharging box is fixedly connected with one end of a partition board, the top end of the piston rod of the hydraulic rod is fixedly connected withthe center of the bottom end face of the partition board, the position, close to the right side wall of the interior of the box body, of the right side wall of the discharging box is fixedly connectedwith one end of a first baffle, a second baffle is fixedly welded to the right side wall of the interior of the box body, and a spring is fixedly connected between the first baffle and the second baffle. The mineral separation washbox is compact in structure and convenient to use.

Owner:江西金石宝矿山机械制造有限公司

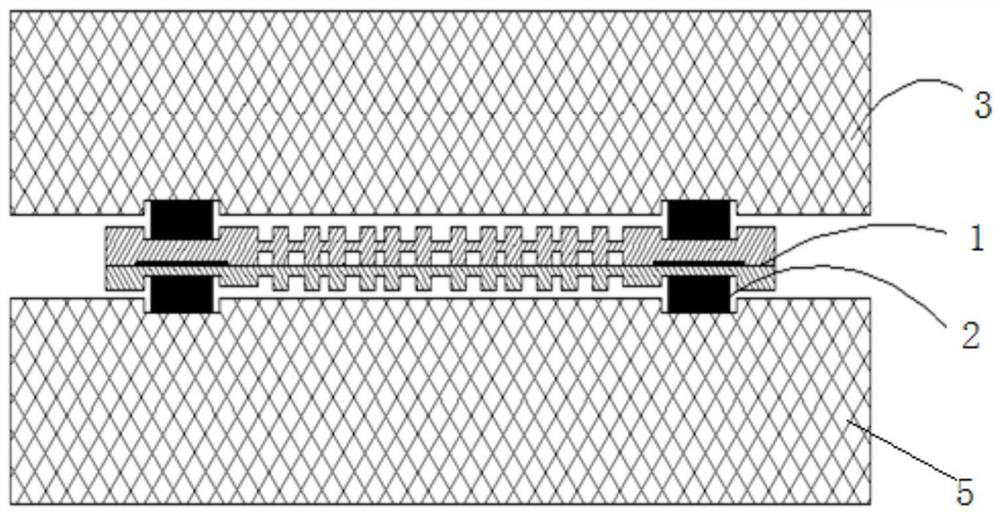

Fuel cell pole bipolar plate leakage detection method

PendingCN112414629AIncrease pressureAchieve the purpose of screeningDetection of fluid at leakage pointFuel cellsPhysical chemistry

The invention relates to a fuel cell pole bipolar plate leakage detection method, which comprises the following steps of sealing a bipolar plate (1) to be detected in a detection tool, arranging a detection liquid inlet and outlet on the detection tool, communicating the detection liquid inlet and outlet with a cooling cavity of the bipolar plate (1), inputting a detection liquid containing a fluorescent agent into the cooling cavity through the detection liquid inlet and outlet, pressurizing to 20-200kPa, and standing for 0.5-7 days, and disassembling the bipolar plate, and placing the disassembled bipolar plate under an ultraviolet lamp, wherein the area with fluorescence reaction is the leakage point area of the bipolar plate. Compared with the prior art, the method has the advantages of sensitive detection, simplicity, convenience and the like.

Owner:SHANGHAI SHENLI TECH CO LTD

Solid separation device facilitating adjusting of size of filter net

The invention discloses a solid separation device facilitating adjusting of size of a filter net. The device comprises a base, the upper surface of the base is provided with a first sliding groove, the right side of the upper surface of the base is fixedly connected with a first electric motor, the output end of the first electric motor is fixedly connected with a disc, the edge of the disc is fixedly hinged to a first connecting rod through a first pin shaft, according to the solid separation device facilitating adjusting of the size of the filter net, a second electric motor is fixedly connected to the upper surface of a box body, the output end of the second electric motor is fixedly connected with a driving gear, the driving gear can be driven to rotate, through engaging of the drivinggear and a driven gear, the driven gear and a thread pipe can be driven to rotate, a thread rod can move up and down, the thread rod and a transverse rod are fixedly connected, the upper surface of the transverse rod is fixedly connected with a fixed block, the fixed block can move up and down, the top end of the fixed block is in a conical shape, the size of particles separated in a second through hole can be adjusted, and solid separation is more convenient.

Owner:陈斌武

High-flux biomaterial-screening microfluidic chip

InactiveCN102876564AAchieve the purpose of screeningMonitoring role and effectBioreactor/fermenter combinationsBiological substance pretreatmentsHigh fluxProtein activity

The invention provides a high-flux biomaterial screening microfluidic chip which is characterized in that a microfluidic detection device is attached to a substrate, wherein the microfluidic detection device is provided with a cell sample introduction element from which more than 2 channels are led out; each channel is communicated with a plasmid transfection element, and the outlet of the plasmid transfection element is communicated with a serpentine tube; the outlet of each serpentine tube is divided into more than 2 channels; each channel is communicated with a cell capture element; and each cell capture element is communicated with a biochemical reagent and growth factor loading element. The invention can simultaneously detect cell integral shape and intracellular labeled protein activity variation under different biomaterial actions on one chip, and monitor the action effect of the biomaterial on the actual cells, thereby greatly lowering the detection cost, enhancing the detection accuracy and detection efficiency, and achieving the goal of biomaterial screening.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Sorting device for packaging bag food

The invention relates to the field of solid separation, in particular to a sorting device for packaging bag food. The sorting device comprises a frame body, wherein the bottom of the frame body is provided with a foot stool; the top of the frame body is provided with an inclined plate; the inclined plate is a first conveying section; a balance is arranged in the frame body; one side of the balance is provided with heavy stuff; the other side of the balance is provided with a supporting plate; the supporting plate is communicated with an inclined bottom end of the inclined plate; the supporting plate is a second conveying section; a conveyor belt is further arranged on the frame body; an inlet end of the conveyor belt is communicated with the supporting plate; the conveyor belt is a third conveying section; an outlet end of the conveyor belt is provided with a second outlet; and the bottom of the supporting plate is provided with a first outlet. According to the sorting device, by virtue of the balance principle, packaging bags with up-to-standard mass and packaging bags with less mass are separated to achieve a screening purpose, so that the problem that trouble is brought to manufacturers and venders because of fewer products in the packaging bags is avoided; meanwhile, the sorting device is very convenient in operation; and the packaging bags are only needed to sequentially place into the inclined upper end of the inclined plate, so that one worker can operate the sorting device.

Owner:CHONGQING CHUANGLONG IND

Process for producing environmental-friendly and odorless regenerated rubber by using tread rubber powder prepared from waste/used tires

InactiveCN104004246ASolve pollutionAvoid secondary pollutionPlastic recyclingMechanical material recoveryAsphaltNational standard

The invention discloses a process for producing environmental-friendly and odorless regenerated rubber by using tread rubber powder prepared from waste / used tires. The process comprises the steps of crushing and magnetic separation and chemical desulfurization, wherein the step of crushing and magnetic separation comprises the processes of crushing lumpy tires by a coarse crusher, sieving, so as to obtain coarse granules, carrying out first-time magnetic separation and second-time magnetic separation, so as to obtain pure coarse rubber granules and recovered steel wires, crushing the pure coarse rubber granules by a crushing machine, and then, sieving, thereby obtaining rubber powder; the step of chemical desulfurization comprises the processes of adding the tread rubber powder and auxiliaries, wherein a formula comprises the following ingredients in parts by weight: 1,200-2,000 parts of tread rubber powder, 120-200 parts of vegetable oil asphalt, 2-10 parts of activator, 10-40 parts of carbonate and 100-400 parts of water. According to the process, iron wires can be effectively separated, so that the wear to equipment is reduced, and the quality of the prepared tread rubber powder is good; the existing softener is replaced with the vegetable oil asphalt, and meanwhile, carbonate is added, so that the prepared product reaches the class-A recycled rubber standard of the national standard, is environmental-friendly and odorless and is not subjected to bluing.

Owner:CHONGQING JUYI RUBBER PROD

Highly-throwing rice sieving machine

InactiveCN105214945AAchieve the purpose of screeningScreen thoroughlyGas current separationAgricultural engineeringMechanical equipment

The invention belongs to the technical field of agricultural mechanical equipment, and specifically discloses a highly-throwing rice sieving machine. The highly-throwing rice sieving machine comprises a highly-throwing frame, wherein a charge port is formed in the top end of the highly-throwing frame, a discharge port is formed in the bottom end of the highly-throwing frame, an opening used for discharging vacant shells is formed in one sidewall of the highly-throwing frame, a vertical slide way is formed in a sidewall opposite to the opening, of the highly-throwing frame, a fan is installed on the slide way, and the fan is slidably connected with the highly-throwing frame; and the distance between the top end and the bottom end of the highly-throwing frame is 1-3m. Compared with the traditional fan sieving, the equipment is capable of throwing and dispersing rice, capable of greatly achieving a sieving purpose by matching with a position design for a fan, thorough in sieving, capable of sieving according to the proportions of impurities contained in rice to meet different sieving needs, and high in practicability.

Owner:CHONGQING ZHIRUIDE TECH

Steel ball screener for bearing production

InactiveCN106269492AAchieve the purpose of screeningImprove screening efficiencySievingScreeningArchitectural engineeringSteel ball

The invention discloses a steel ball screener for bearing production. The steel ball screener comprises a base, a support, a vibrating screen fixing plate, vibrating filtering screen plates and a screening chamber. The base is installed at the bottom of the support, a bottom plate is arranged above the support, spring struts are installed at the bottoms of the two ends of the vibrating filtering screen plates, vibrating motors are installed at the positions, on the inner sides of the spring struts, of the bottom plate, four downward discharge ports are formed in the ends, away from the vibrating screen fixing plate, of the vibrating filtering screen plates side by side, the bottom of a feeding chamber is provided with a discharge port extending into the screening chamber, and a telescopic plate is installed at the bottom of the discharging port. The inclined vibrating filtering screen plates are arranged and can automatically classify and screen steel balls, and screening efficiency is high; the three vibrating filtering screen plates of different hole diameters are arranged, under vibration of the vibrating motors, the steel balls can be screened into four different specifications, the screened steel balls are discharged through the different discharge ports, and the purpose of screening the steel balls is achieved.

Owner:湖南天天特训教育咨询有限公司

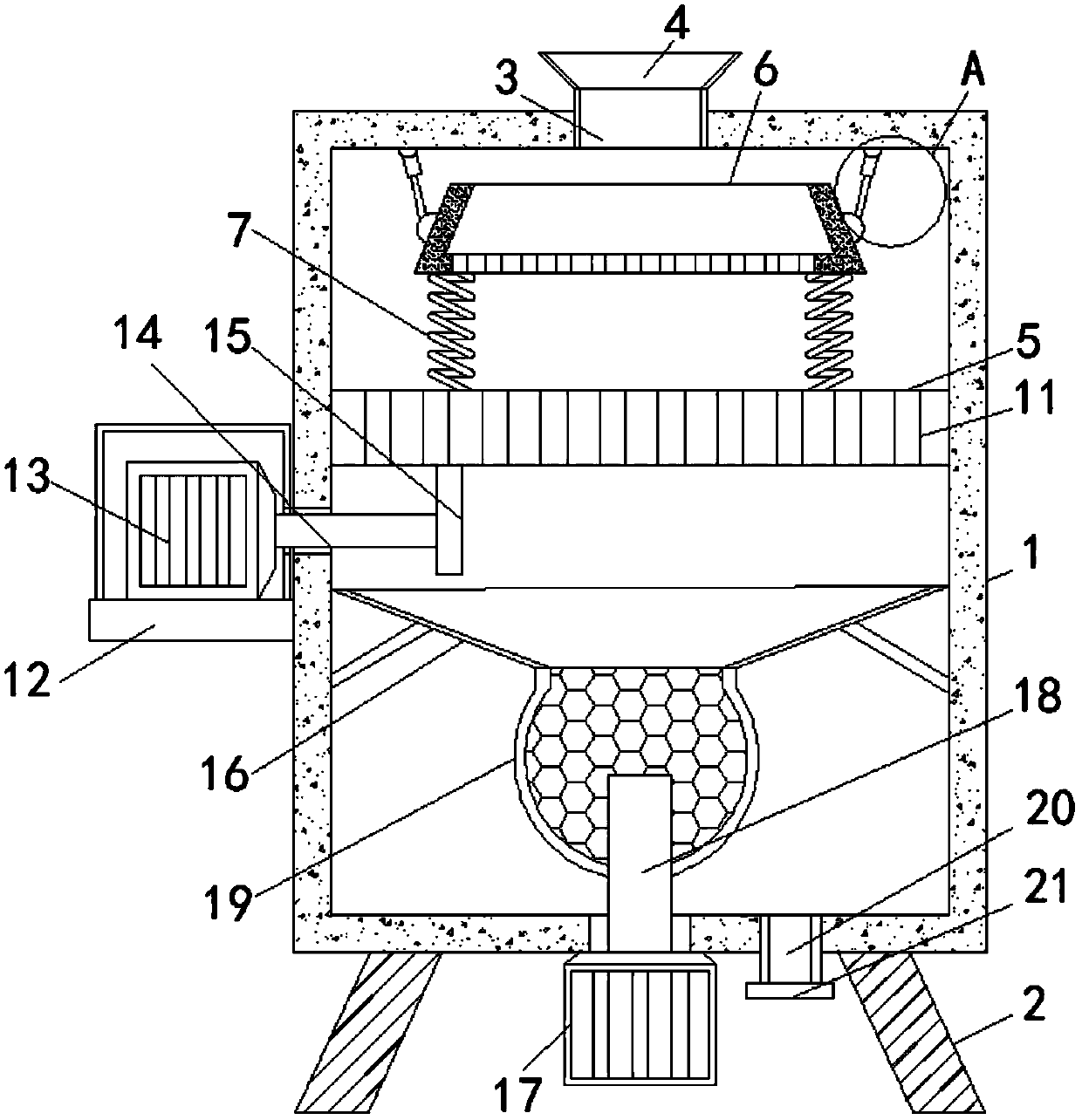

Fodder screening device for animal husbandry

InactiveCN107552389AAchieve the purpose of screeningImprove screening effectSievingScreeningEngineeringDrive motor

The invention relates to the technical field of animal husbandry, and discloses a feed screening device for animal husbandry, which includes a screening box, the four corners of the bottom of the screening box are fixedly installed with fixing feet, and the top of the screening box is connected with a A feed pipe, the top of the feed pipe is provided with a feed hopper, the inside of the screening box is provided with a horizontal plate, and the horizontal plate is provided with leak holes arranged at equal distances, and the outer sides of the horizontal plate are It is fixedly connected with the inner wall of the screening box. In this invention, the feed can be put into the screening box through the feed pipe, and the opening screening bucket will filter the feed in the first step, and the opening and screening can be better achieved by extending and shortening the hydraulic telescopic rod. The bucket is tilted left and right, so as to achieve the purpose of screening more effectively. The feed screened in the first step will be screened for the second time through the screening holes on the horizontal plate. When the first drive motor is turned on, the eccentric block will make the horizontal plate Vibration can better improve the screening effect.

Owner:王莉莉

Iron ore screening device

InactiveCN113117884AAffect magnetismAchieve the purpose of shakingMagnetic separationIronstoneMining engineering

The invention belongs to the technical field of ore production equipment, and discloses an iron ore screening device which comprises a base, a screening box is fixedly installed at the top of the base, an ore discharging pipe is arranged on the outer surface of the side face of the screening box, a slag outlet is formed in the side, away from the screening box, of the base, a feeding channel is fixedly installed on the side, away from the ore discharging pipe, of the screening box, and a control panel is fixedly installed over the ore discharging pipe. According to the iron ore screening device, when a collision driving rod moves, a collision conduction rotating support is squeezed; when the collision conduction rotating support is squeezed to deform, an arc-shaped rotating rod is pushed to rotate; and after the arc-shaped rotating rod rotates, a memory elastic piece deforms; when the memory elastic piece deforms, an impact ball is pushed to impact an iron attraction block; and therefore, the purpose of shaking off dust on the surface of the iron attraction block is achieved, and the situation that the magnetism of the iron attraction block is affected due to excessive dust accumulation is prevented.

Owner:韩庆磊

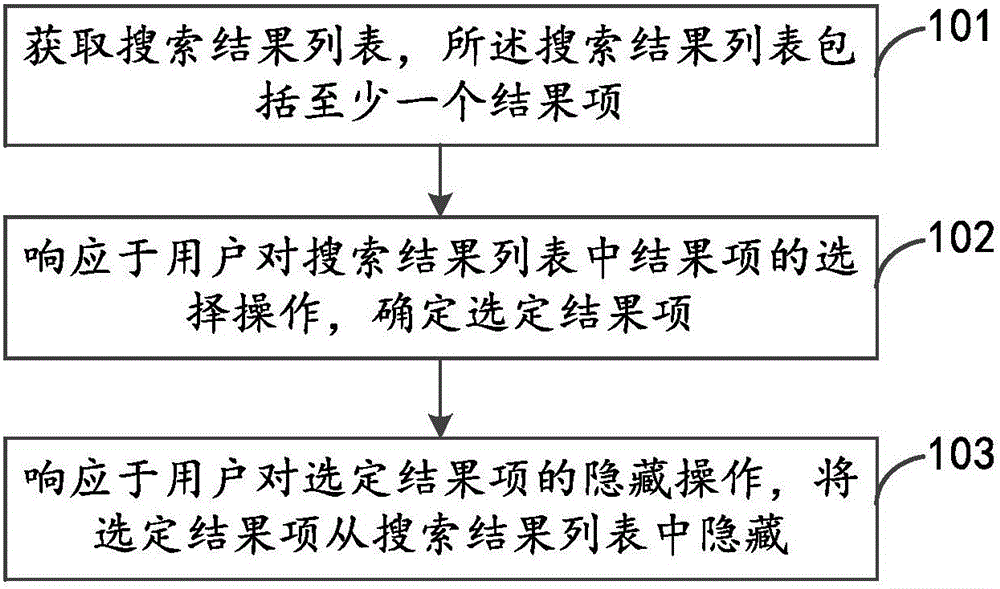

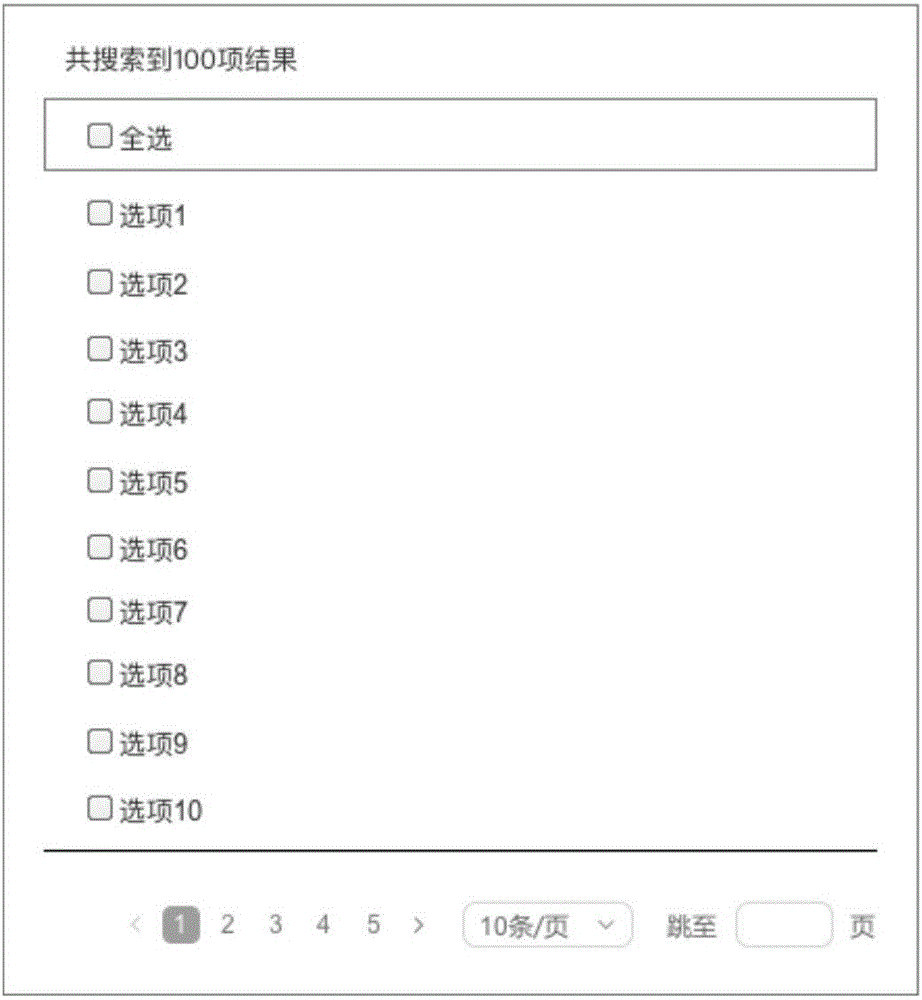

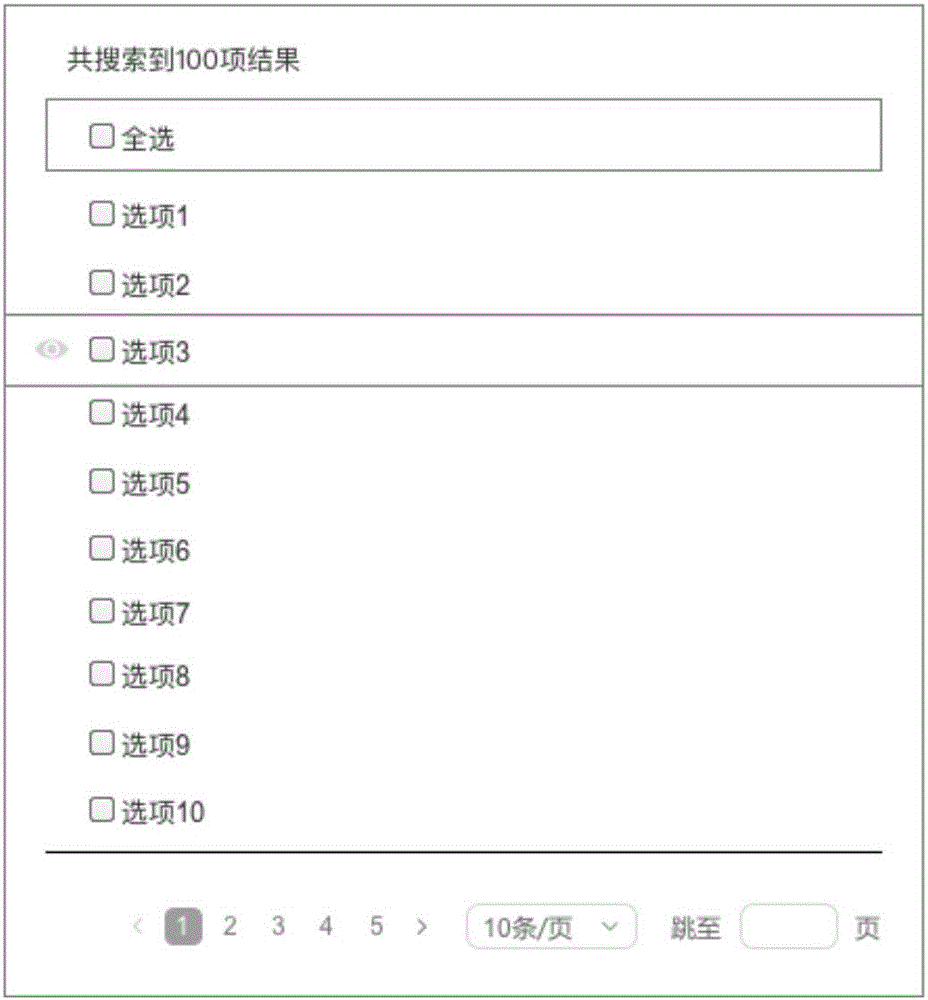

Method and device for processing search results

InactiveCN107436868AReduce screening burdenReduce misuseSpecial data processing applicationsBatch processingResult list

The application discloses a method and device for processing search results. The method comprises following steps: obtaining a search result list, wherein the search result list comprises at least one result item; determining a selected result item in response to the selection operation on the result items in the search result list by a user; hiding the selected result item from the search result list in response to the hiding operation on the selected result item by the user. By means of the application, search results can be filtered, the probability of mis-operation is reduced, and the batch processing of search results is facilitated.

Owner:ALIBABA GRP HLDG LTD

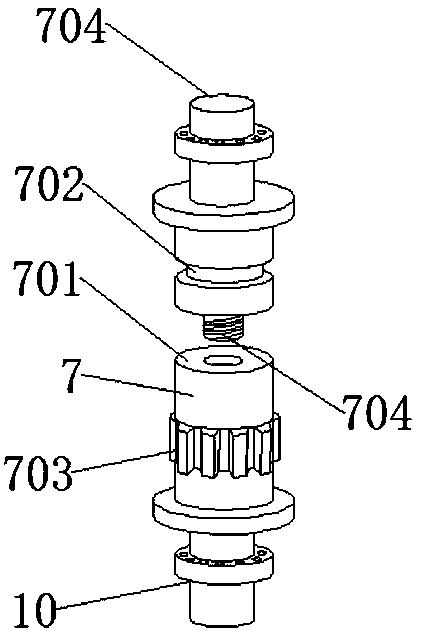

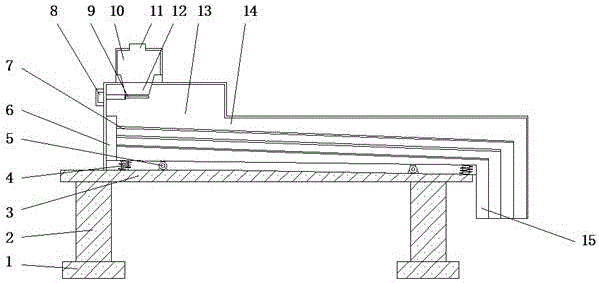

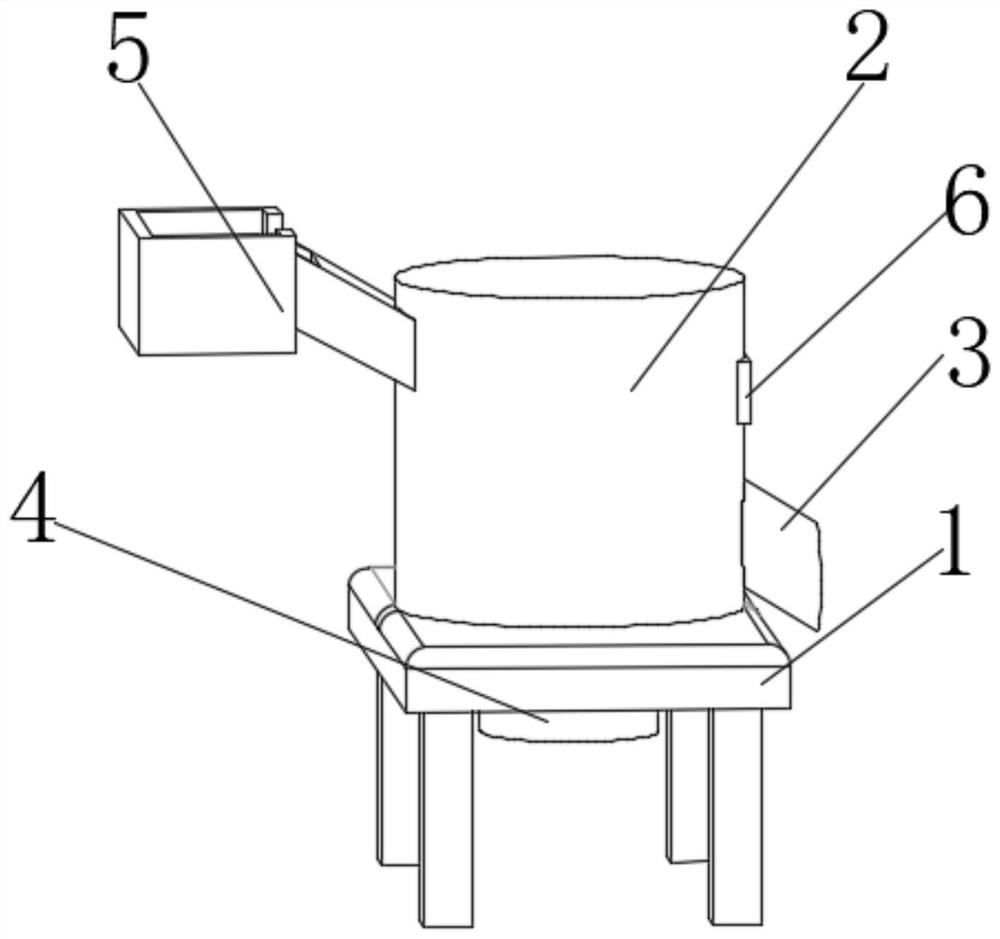

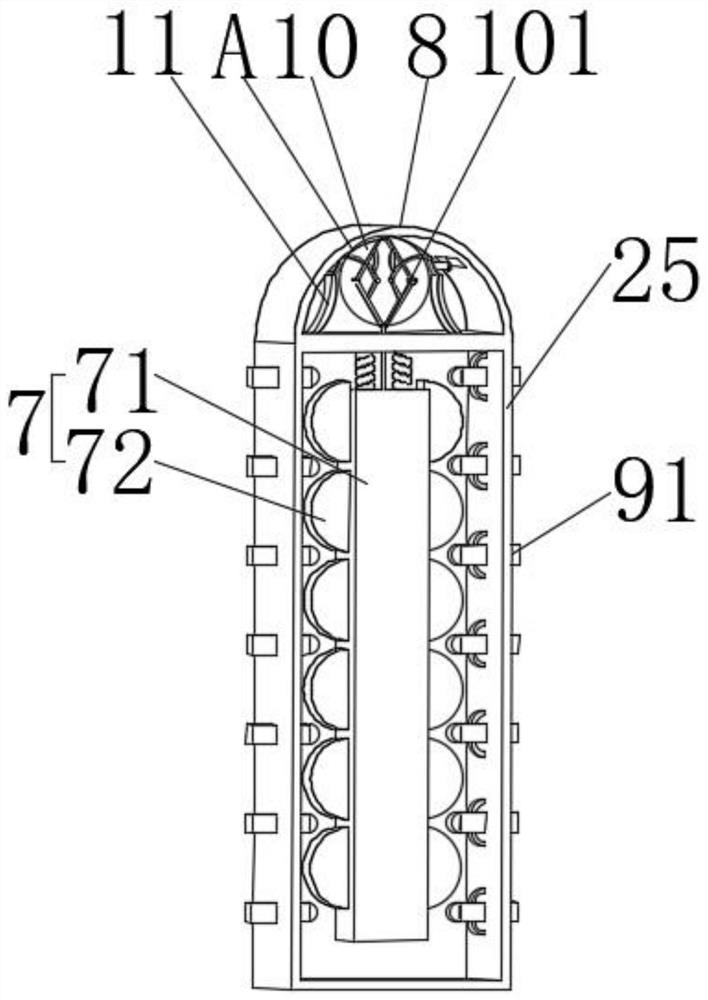

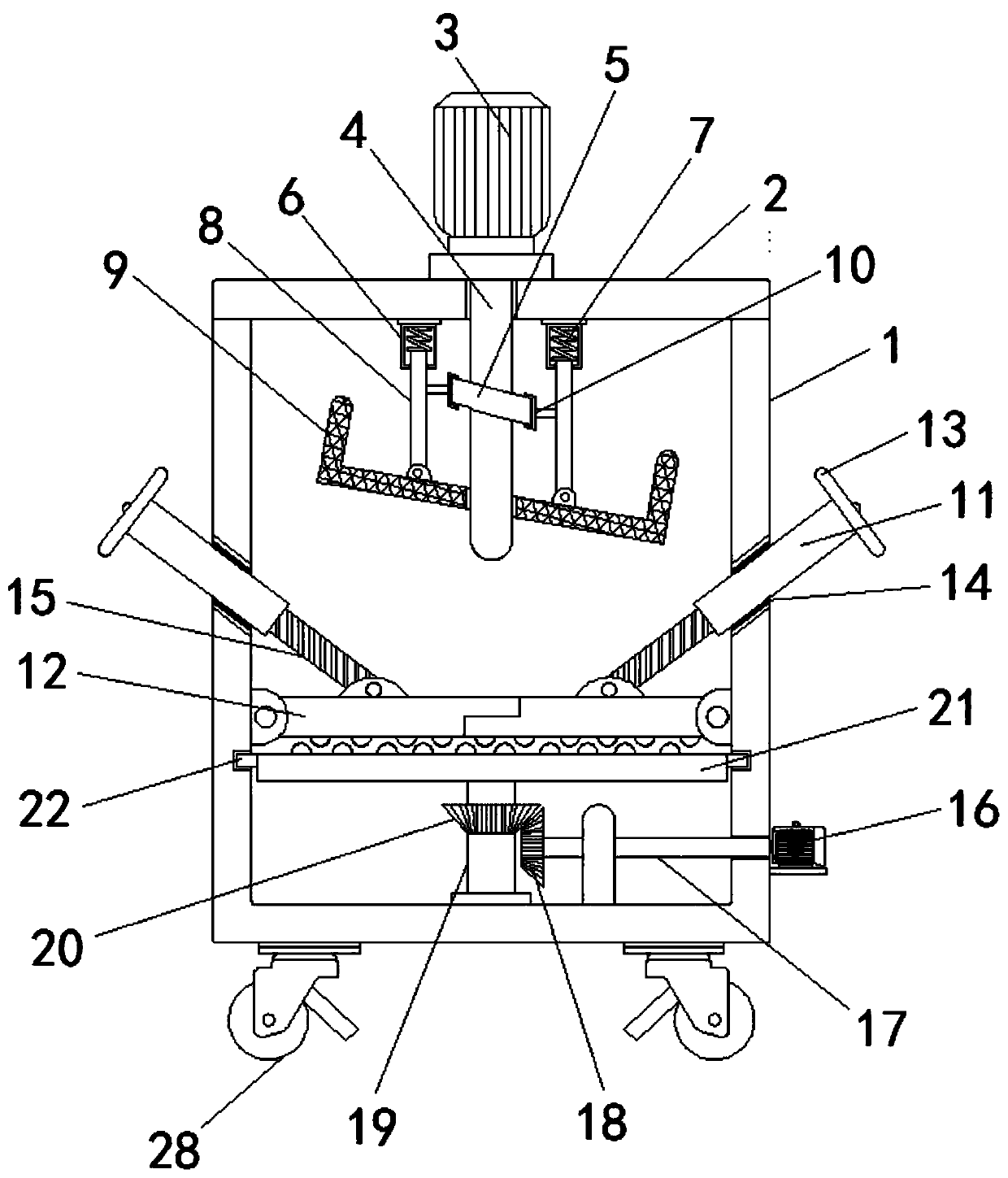

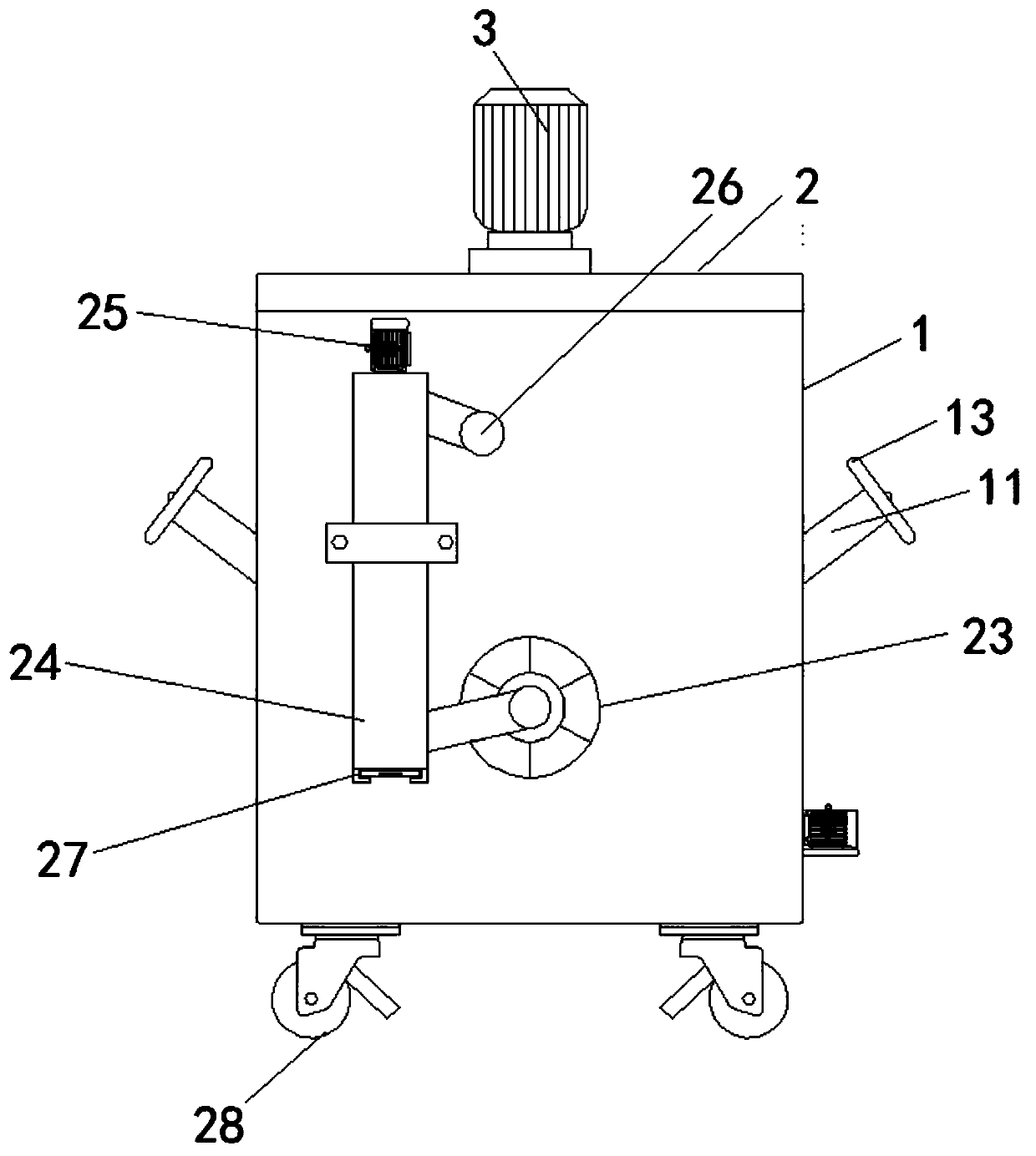

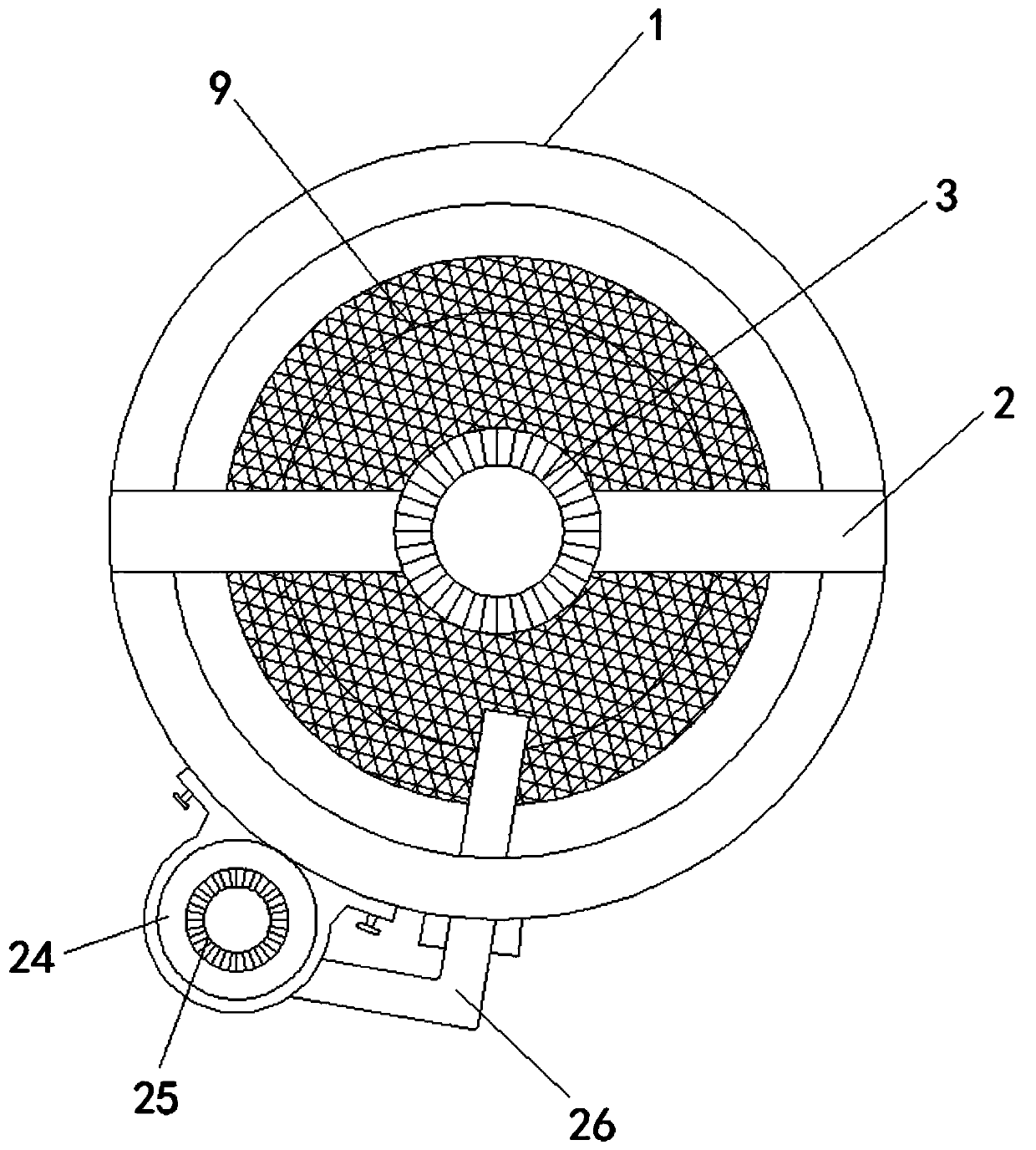

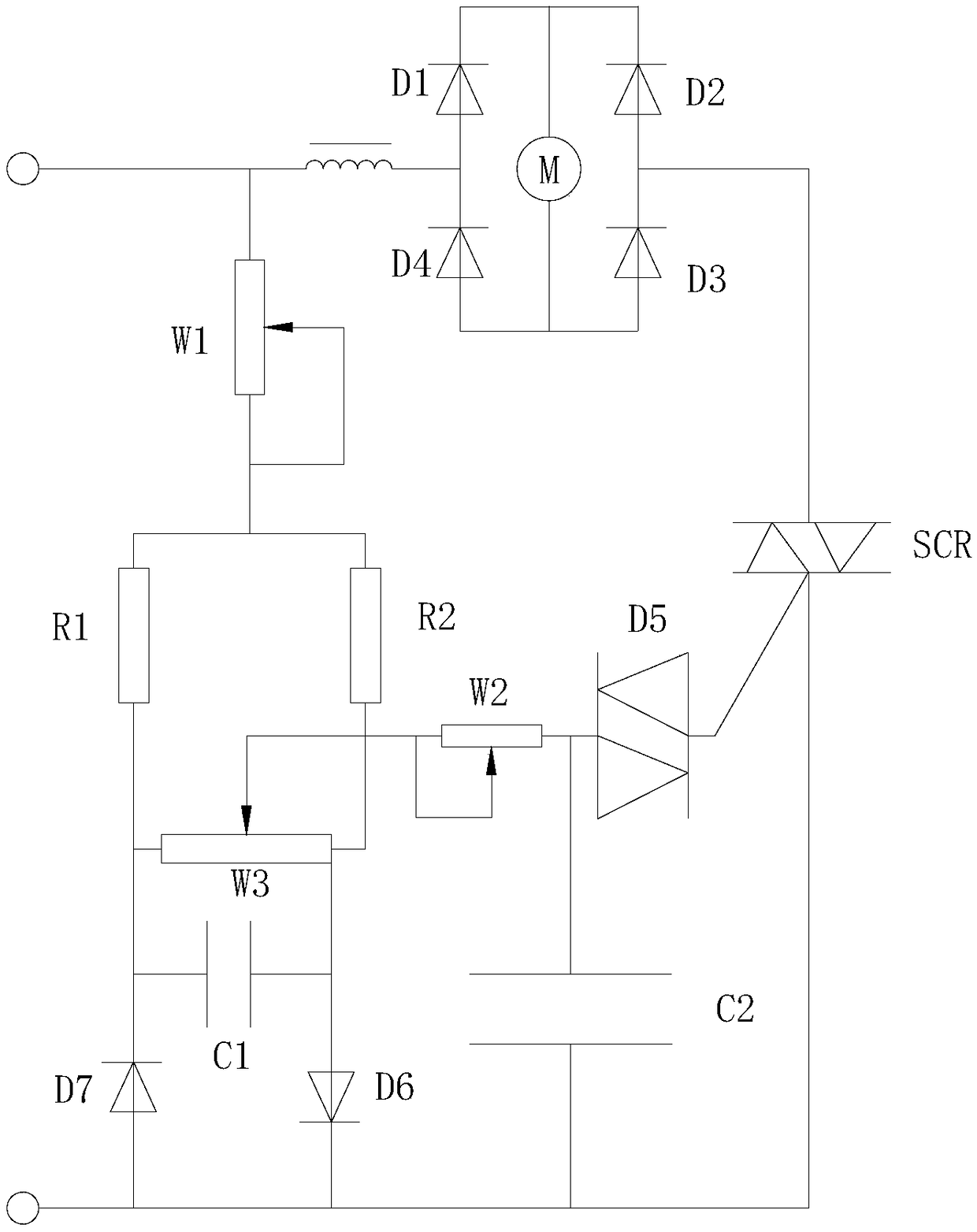

Rolling device for producing tea leaves and application method of rolling device

PendingCN110915955ASwing up and down stableEasy to usePre-extraction tea treatmentElectric machineryAgricultural engineering

The invention relates to the technical field of tea production rolling, and discloses a rolling device for producing tea leaves. The rolling device comprises a rolling box, wherein a propping rod is fixedly connected to the top of the rolling box; a first driving motor is fixedly connected to the top of the propping rod; a rotating rod is fixedly connected to an output shaft of the first driving motor; an oblique wheel is fixedly connected to the external surface of the rotating rod; sleeves are fixedly connected to the left end and the right end of the bottom of the propping rod; a spring isfixedly connected to the top of an inner cavity of each sleeve; a sliding rod is fixedly connected to the bottom of each spring; and a sieving cylinder is fixedly connected to the bottoms of the sliding rods. According to the rolling device for producing tea leaves and the application method of the rolling device disclosed by the invention, the rotating force of the first driving motor is converted into the swinging force of the sieving cylinder, so that the purpose of sieving is achieved, and minced tea leaves and tea leaf pieces are convenient to separate by workers quickly, and reprocessingon the tea leaf pieces is convenient to perform; and manual sorting is not needed, so that the rolling device for producing tea leaves is time-saving and labor-saving, and convenient to use and is suitable for all kinds of situations.

Owner:贵州润盛潭茶业有限公司

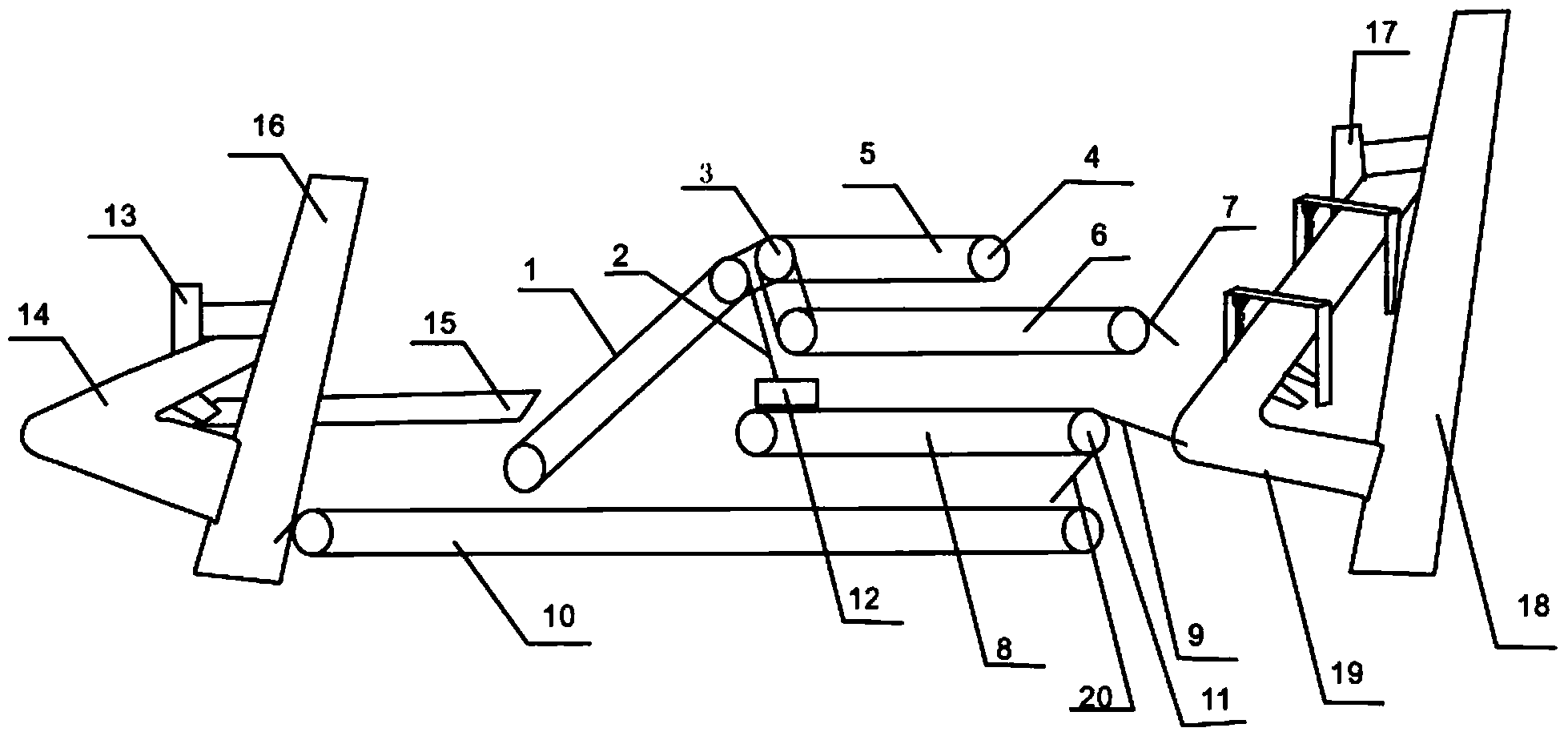

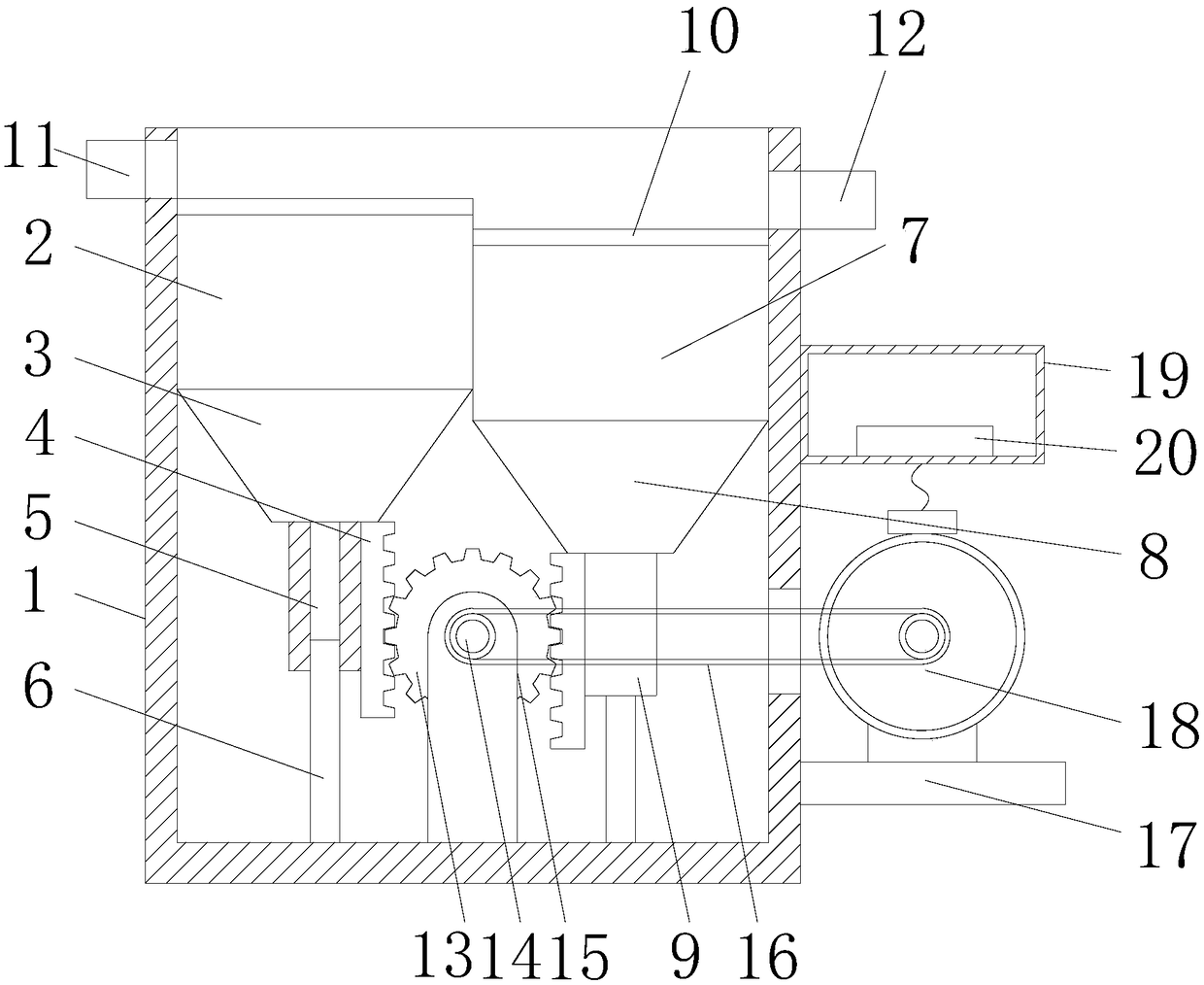

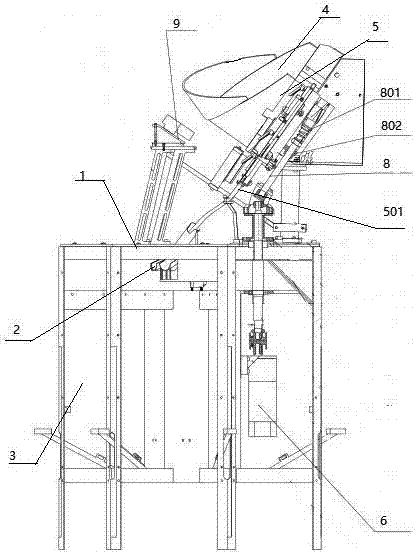

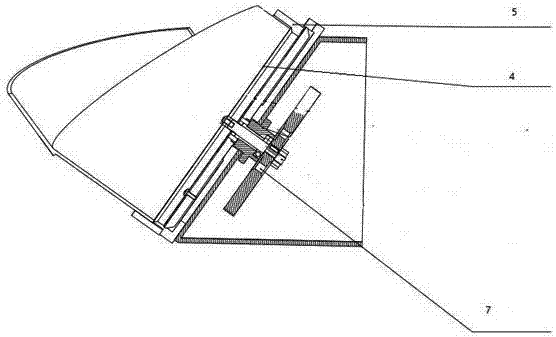

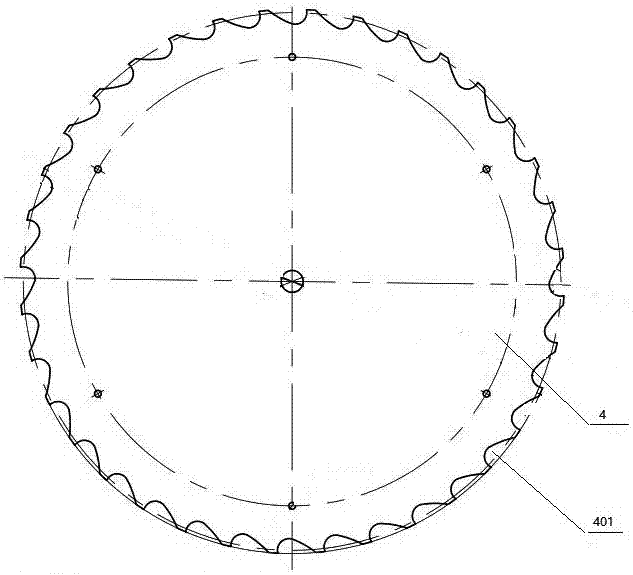

Lateral-moving screening and jigging machine

InactiveCN108772184AAchieve the purpose of screeningWet separationArchitectural engineeringLateral move

The invention discloses a lateral-moving screening and jigging machine, comprising a box body. A support frame is installed at the bottom of the interior of the box body, a rotating shaft is movably connected to the support frame, a gear is installed on the rotating shaft, and cylinder columns are separately and symmetrically installed on the two sides of the support frame. A first cylinder is slidably connected on the cylinder column positioned on the left side of the support frame in a sleeving mode, a second cylinder is slidably connected on the cylinder column positioned on the right sideof the support frame in a sleeving mode, the top end of the first cylinder is fixedly welded at the center position of the bottom end of a first discharge hopper, a first feed hopper is welded at thetop end of the first discharge hopper in a penetrating mode, the top end of the second cylinder is fixedly welded at the center position of the bottom end of a second discharge hopper, and a second feed hopper is welded at the top end of the second discharge hopper in a penetrating mode. Screening plates are separately installed at the top end opening positions of the first feed hopper and the second feed hopper, a feed inlet is formed in the top of the left side wall of the box body, and a discharge outlet is formed in the top of the right side wall of the box body. The screening and jiggingmachine is compact in structure and convenient to use.

Owner:江西金石宝矿山机械制造有限公司

Plate-shaped pear syrup candy crushing equipment

ActiveCN112619750AAchieve the purpose of breakingTo achieve the purpose of automatic receivingGrain treatmentsConveyor partsEngineeringMechanical engineering

The invention relates to crushing equipment, in particular to plate-shaped pear syrup candy crushing equipment. The plate-shaped pear syrup candy crushing equipment is convenient for crushing plate-shaped pear syrup candies and is convenient for people to eat. According to the technical scheme, the plate-shaped pear syrup candy crushing equipment is characterized by comprising supporting columns, a crushing mechanism and limiting mechanisms, wherein the two sides of the top of a base are both connected with the supporting columns; the top side of the base is connected with the crushing mechanism; and the limiting mechanisms are connected to the two sides of the crushing mechanism, and the supporting columns are connected with the limiting mechanisms. Through cooperation of an air cylinder, a mounting square pipe, a crusher and a second spring, the purpose of crushing the plate-shaped pear syrup candies is achieved.

Owner:安徽龙润堂生物科技有限公司

Button color separating machine

InactiveCN107377414ASolve color separation difficultiesFree laborSortingImage sensorElectrical and Electronics engineering

The invention relates to a button color separating machine which consists of a mechanical part, an image sensor and a control center. The mechanical part consists of a rack, a transmission device, a feeding device and a discharging device; the feeding device is connected with the discharging device; the transmission device is used for driving the discharging device; the transmission device enables the feeding device to feed buttons into the discharging device one by one; the feeding device or the discharging device is connected with the image sensor; the discharging device is provided with a plurality of discharging ports, and each discharging port is connected with a different storage cavity; the image sensor is connected with the control center and used for collecting color information and outputting signals; and the control center processes the signals output by the image sensor, the colors of the measured buttons are displayed, then signals are output, and the buttons fall into corresponding discharging pipes accordingly. According to the button color separating machine, the problem that color separation of the buttons is difficult is solved, the labor force is liberated, and the production efficiency is high.

Owner:WENZHOU POLYTECHNIC

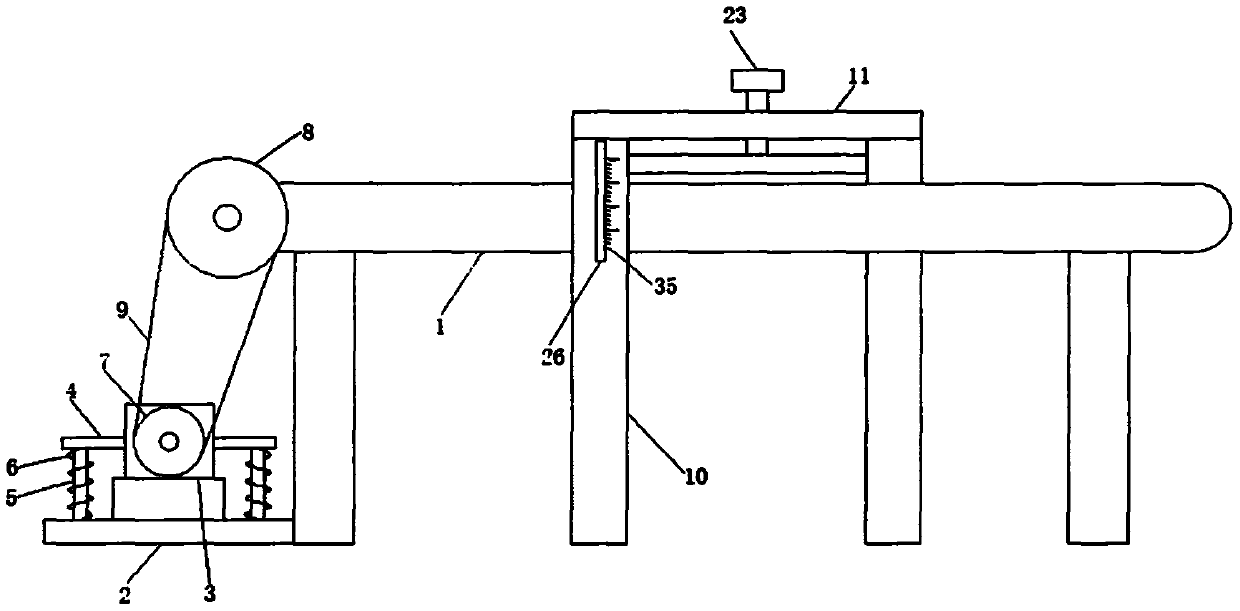

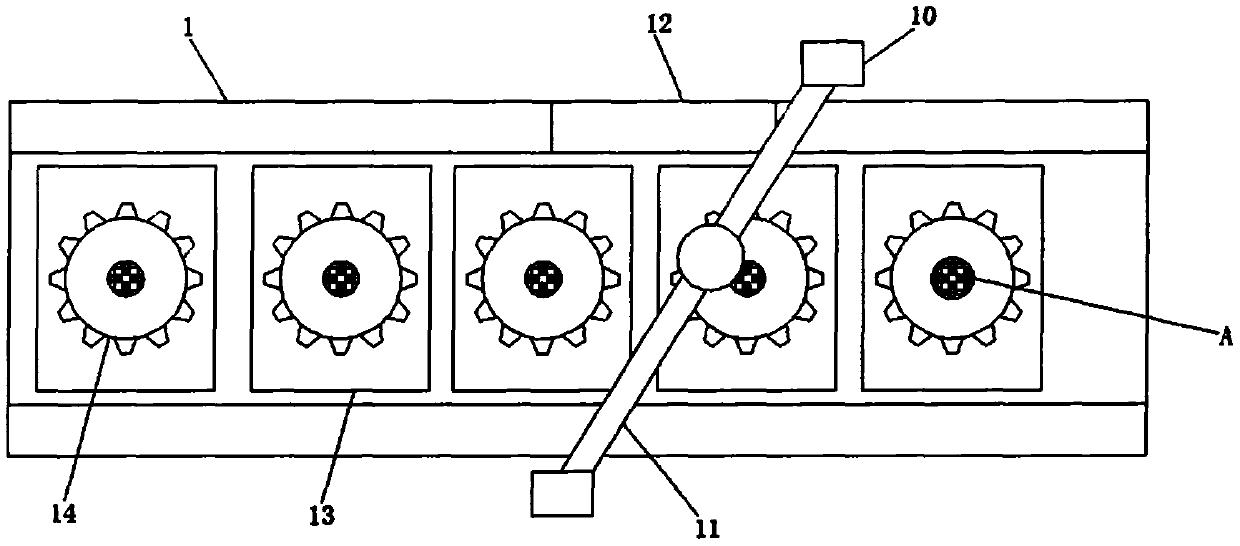

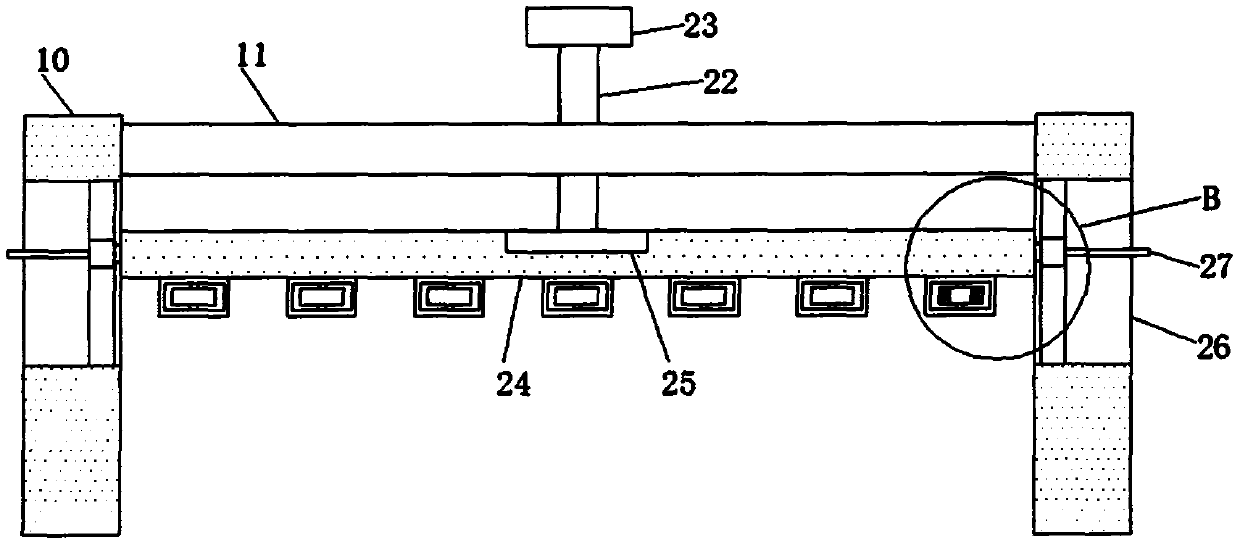

Automatic detection device for automobile gearbox gear production

ActiveCN110201890ASolve the problem of low detection efficiency and poor effectAchieve the purpose of screeningNon-rotating vibration suppressionMechanical thickness measurementsGear wheelTransmission belt

Owner:徐州玉伟机械设备有限公司

A material sorting device based on computer control

ActiveCN111871755BImprove work efficiencyAchieve the purpose of screeningSievingConveyorsMechanical engineeringControl material

The invention relates to the technical field of material sorting, and provides a material sorting device based on computer control, which includes a base, and further includes: an electric turntable, the electric turntable is arranged on the base, and the first end is connected to the base in rotation; Sorting tray, the sorting tray is set on the second end of the electric turntable, and a plurality of inwardly extending accommodating grooves are opened on the end surface of the sorting tray, and a plurality of material guide plates are also arranged on the end surface of the sorting tray; the screening frame, The number of screening frames is the same as that of the storage tank, and they are set in the storage tank in one-to-one correspondence. The screening frame is rotatably connected with the tank wall of the storage tank. The screening frame is used to receive and screen the materials unloaded from the unloading equipment; the drive The mechanism is used to drive the screening frame to rotate in the accommodating tank; and the computer control box is arranged in the sorting tray and is electrically connected with the electric turntable and the driving mechanism. The invention provides a material sorting device based on computer control, which can continuously sort bulk materials and has high working efficiency.

Owner:CHONGQING COLLEGE OF ELECTRONICS ENG

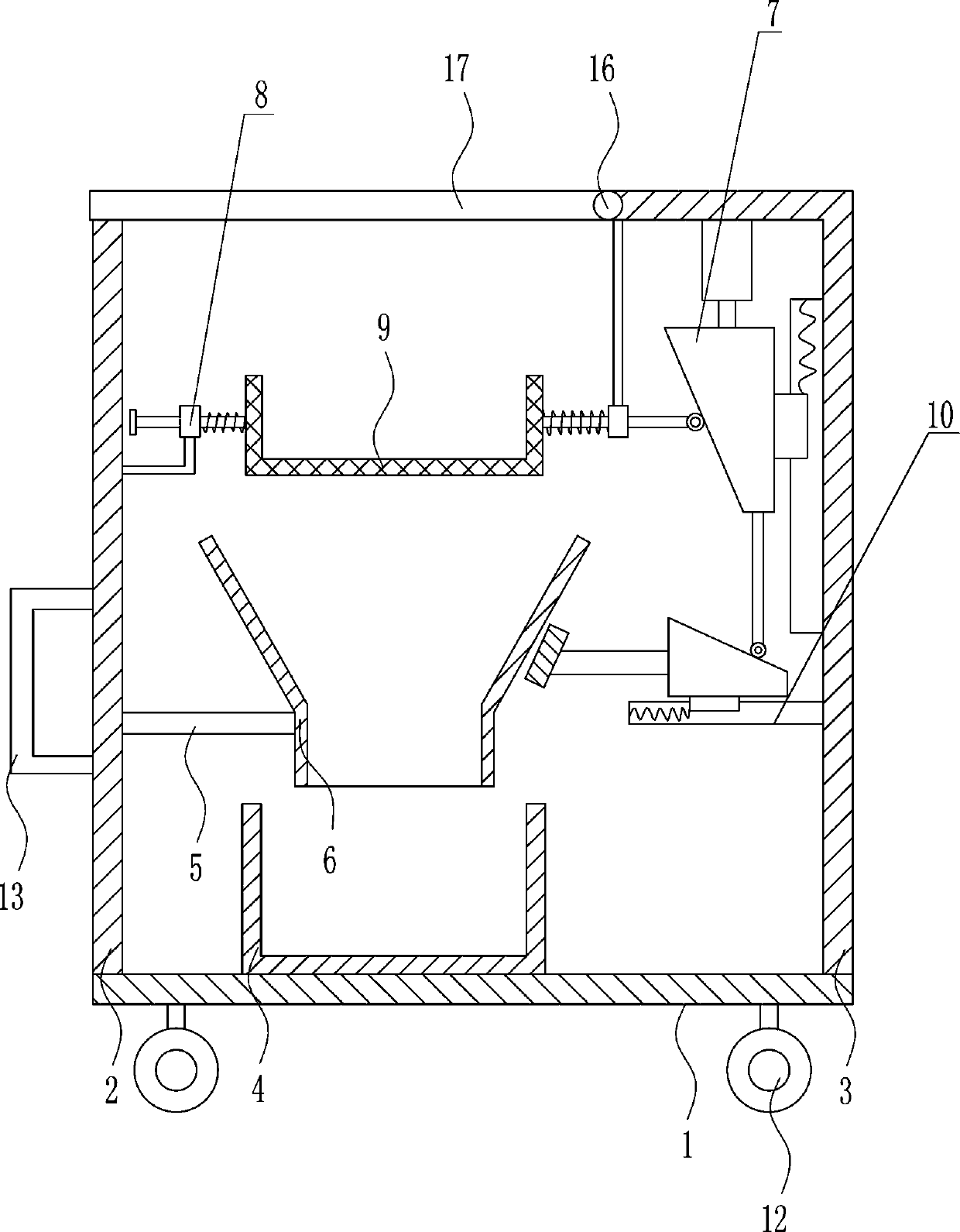

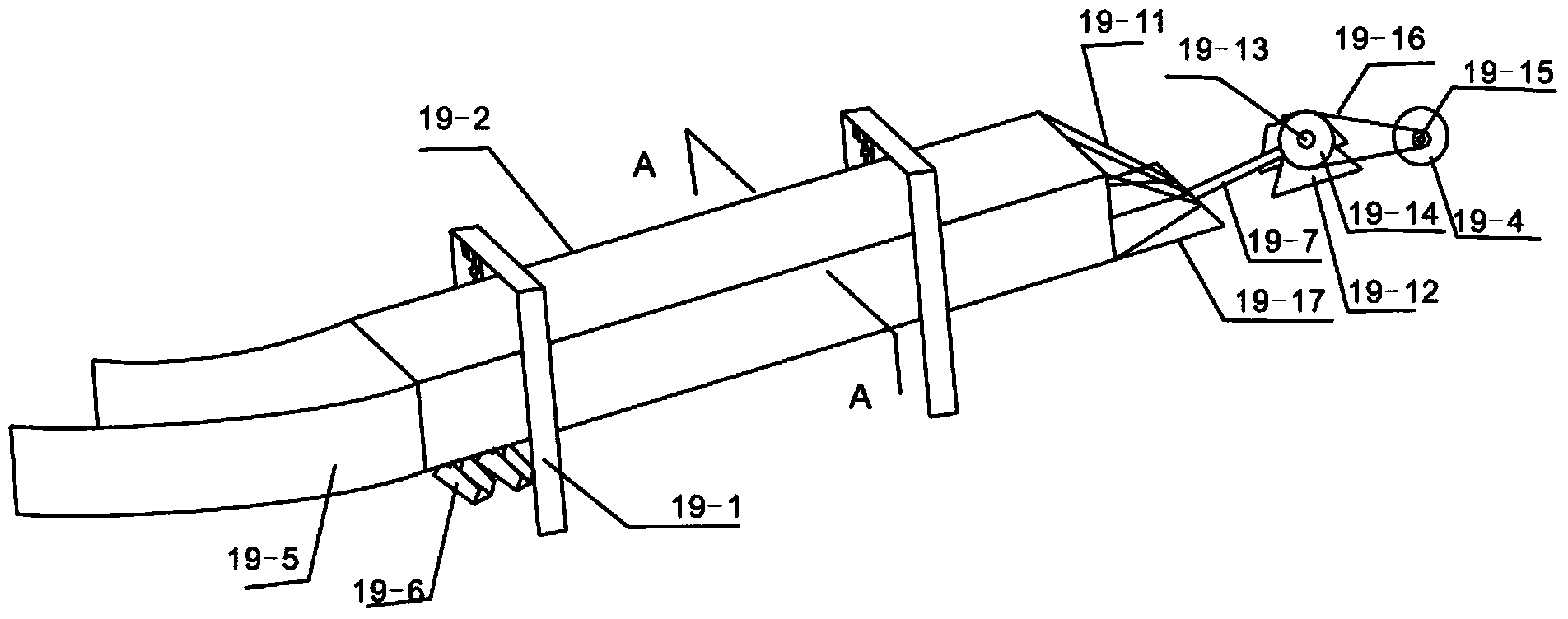

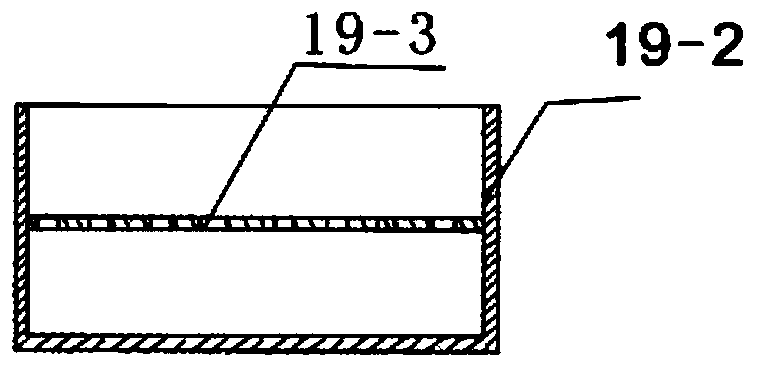

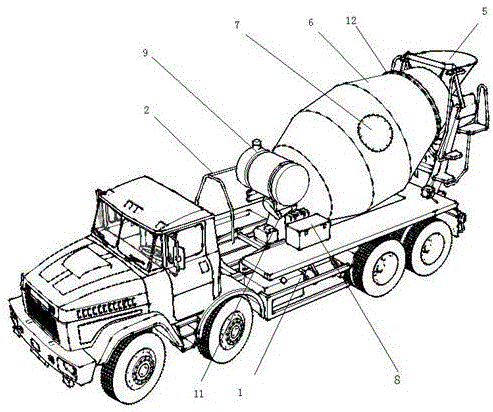

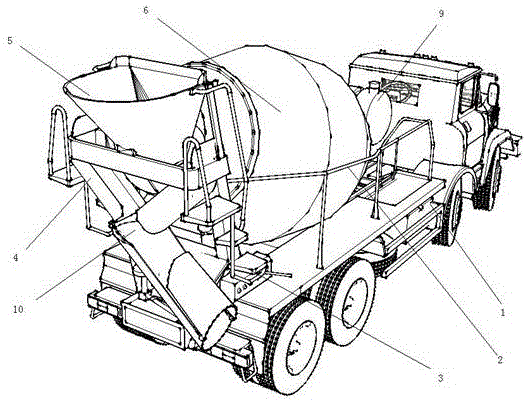

Gravel screening vehicle

InactiveCN106378872ARealize automatic dischargeAchieve the purpose of screeningCement mixing apparatusSpiral bladeEngineering

The invention discloses a gravel screening vehicle. A stirring barrel is arranged on a body of a vehicle body; the upper side of the stirring barrel is connected with the upper part of the body of the vehicle body; the lower end of one side of the stirring barrel is connected with a rotating shaft of a rotating mechanism; a hydraulic device is mounted above the rotating mechanism; a storage battery box is arranged on one side of the rotating mechanism; the other side of the stirring barrel is connected with a feeding hopper; a discharging mechanism is arranged below the feeding hopper; a movable discharging pipeline is arranged below the discharging mechanism and is fixed at the back of the body of the vehicle body; stairs are arranged on one side of the discharging mechanism; a spiral blade is arranged on the inner wall of the discharging mechanism; a screening barrel is arranged in the stirring barrel; a feeding port is inserted in the upper end of the screening barrel; at least two sleeve barrels are arranged in an outer barrel of the screening barrel; and screening holes are formed in walls of the sleeve barrels and the wall of the outer barrel. The vehicle body of the vehicle adopts the design of a special truck like a concrete mixer, the stirring barrel is arranged at the upper part, the gravel screening barrel is arranged in the stirring barrel, and gravel can be screened through rotation in the transportation process, so that the gravel is screened in the transportation process.

Owner:JINLING INST OF TECH

Silicon micro-powder crushing and grinding screening machine

The invention discloses a silicon micro-powder crushing and grinding screening machine, and relates to the technical field of silicon micro-powder. The silicon micro-powder crushing and grinding screening machine comprises a machine box. One side of the inner wall of the machine box is fixedly connected with a switch motor through a motor frame. The switch motor is rotationally connected with a first belt pulley through an output shaft. The first belt pulley is rotationally connected with a second belt pulley through a belt. The outer side of the second belt pulley is rotationally connected with a control rotating disc. The top of the inner wall of the machine box is rotationally connected with a pulley through a pulley frame. A steel cable is connected to the position between the controlrotating disc and the pulley. A movable sleeve ring frame is fixedly connected to the position, located on the right side of the pulley, of the top of the inner wall of the machine box. According to the silicon micro-powder crushing and grinding screening machine, the problems that the silicon micro-powder crushing and grinding working efficiency is low, and large impurities after crushing is conducted cannot be removed are solved, the crushing process can also be smoother without using a tool with precision, the working efficiency is improved, a screening net can be dismantled and replaced automatically, and the situation that the screening efficiency is reduced due to plugging of screening holes cannot occur.

Owner:甘肃中科凯越硅材料科技有限公司

Coal washing device for coal mining

InactiveCN112139022ATo achieve the purpose of air washingAchieve the purpose of screeningSievingGas current separationElectric machineMechanical engineering

The invention discloses a coal washing device for coal mining. The coal washing device comprises a supporting base, supporting legs are fixedly connected to the periphery of the bottom of the supporting base, the right end of the top of the supporting base is fixedly connected with a wind washing mechanism comprising a wind washing box, a draught fan, a spraying head, springs, a vibration motor, ascreen and second supporting plates through four supporting frames distributed at equal intervals. According to the coal washing device, the wind washing mechanism is arranged, so that the purpose ofconducting wind washing on coal at the top of the screen can be achieved; meanwhile, the vibration motor can drive the screen to vibrate under the action of the springs, so that the purpose of screening the coal is achieved; sliding bases and sliding devices are arranged, so that the purpose of driving the water washing mechanism to horizontally move is achieved; supporting rods, rotating shaftsand electric telescopic rods are arranged so that the coal can conveniently slide down along a third supporting plate; a water washing mechanism is arranged, so that the purpose of conducting water washing on the coal falling from a first discharging port and / or a second discharging port can be achieved; and meanwhile, a third motor can drive a water washing box to rotate, so that the coal in thewashing box is poured out.

Owner:ANHUI HUITENG INTELLIGENT TRANSPORTATION TECH CO LTD

Discharging structure of plastic extruder

InactiveCN111331752AQuick filterAchieve the purpose of screeningSievingScreeningElectric machineryEngineering

The invention belongs to the field of plastic processing, and particularly relates to a discharging structure of a plastic extruder. For solving the problem that a corresponding screening device is not arranged at a discharging port of an existing extruder, so that the sizes of produced plastic particles are prone to being different, the following scheme is proposed: the discharging structure of the plastic extruder comprises a base, wherein the extruder and a screening box are respectively fixedly installed on the top of the base, a discharging pipe is arranged on the extruder, the bottom endof the discharging pipe extends into the screening box, a rotating ring is rotationally connected to the inner wall of the screening box, and a conical screen is connected to the rotating ring in a sliding mode. According to the discharging structure of the plastic extruder, a moving plate moves longitudinally, when a driving motor is started, the plastic particles can be screened, and the particles which do not pass through the conical screen can be discharged, and therefore, a purpose of screening the plastic can be achieved, the sizes of the produced plastic particles can be basically consistent, and the production quality can be effectively improved.

Owner:YANCHENG INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com