Patents

Literature

69results about How to "Achieve the purpose of breaking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

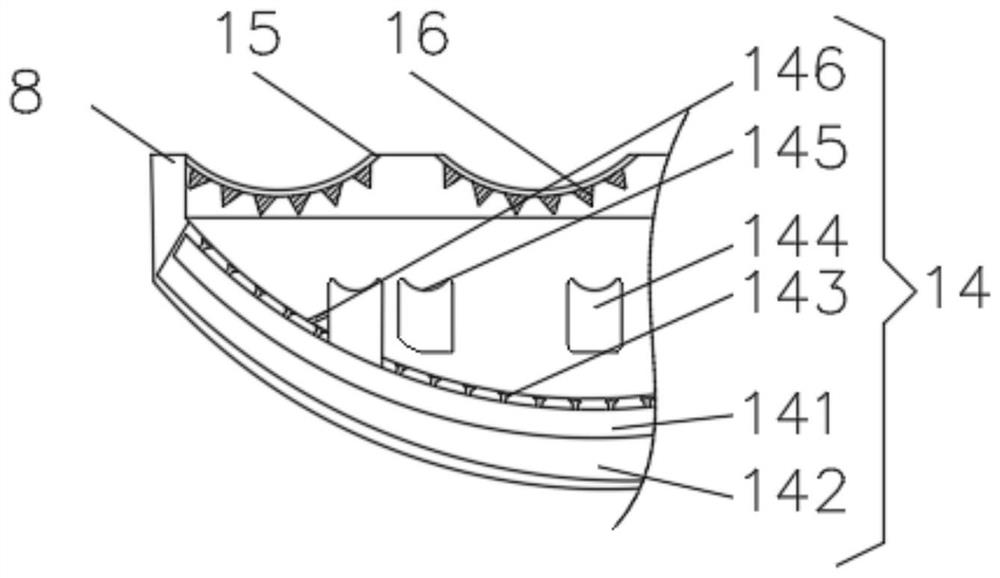

Efficient crushing plant for blocky cement for building

InactiveCN106362844AGuaranteed to workImprove grinding efficiencyCement productionGrain treatmentsEngineeringPulley

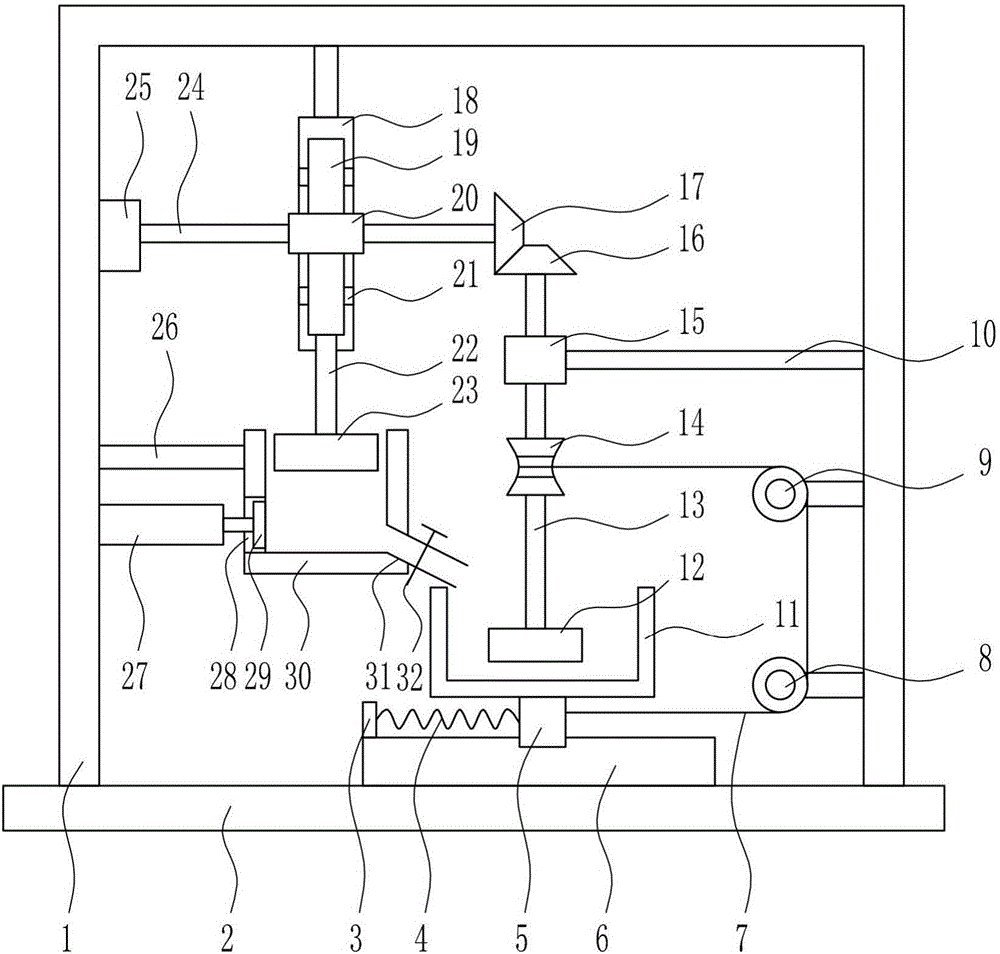

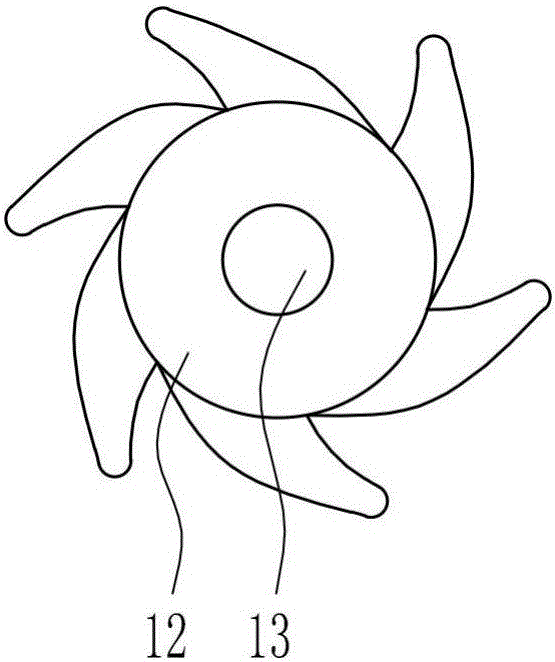

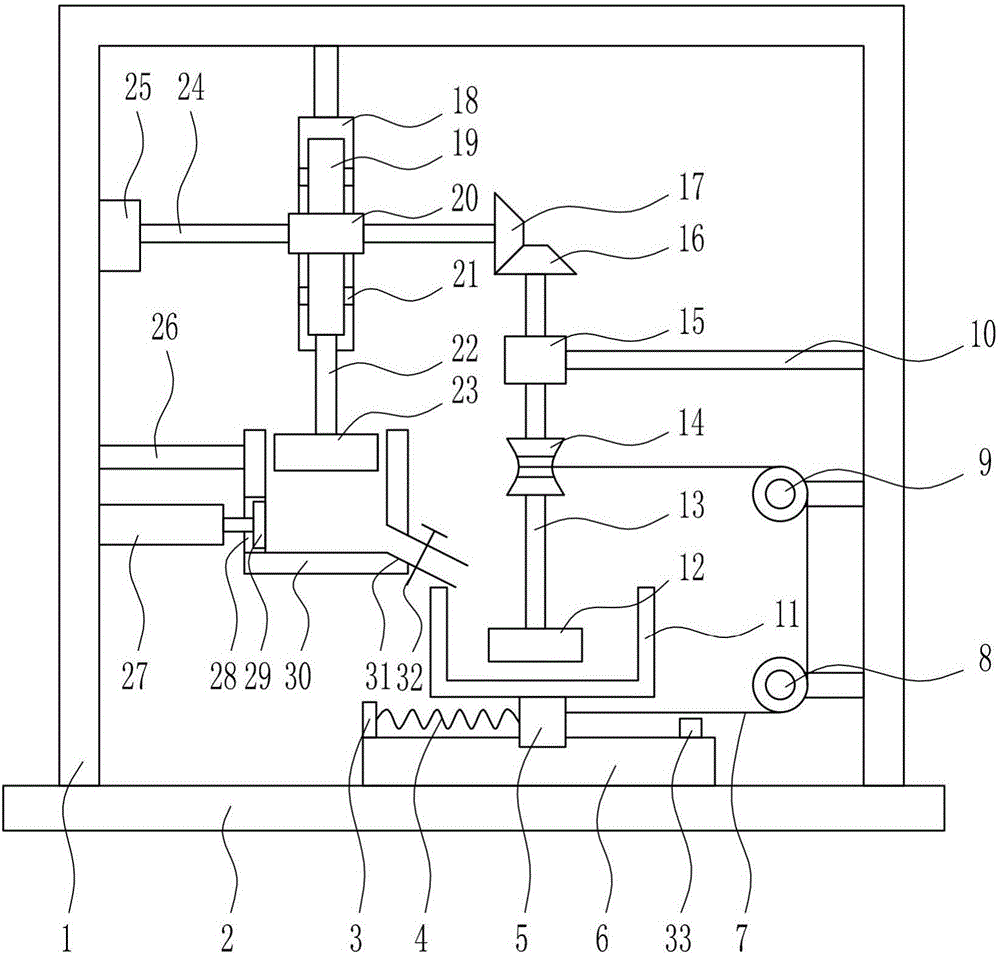

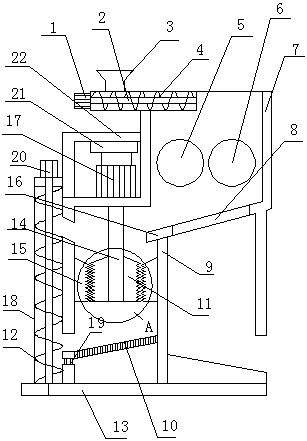

The invention relates to a crushing device, in particular to an efficient crushing plant for blocky cement for building. According to the efficient crushing plant for blocky cement for building, the technical aim of being high in crushing efficiency is achieved. In order to achieve the above technical aim, the efficient crushing plant for blocky cement for building is provided and comprises a support, a base plate, a fixing plate, an elastic element, a second sliding block, a second sliding rail, a pull line, a first fixed pulley, a second fixed pulley, a first strut, a crushing box and the like; and the second sliding rail is arranged at the position, in the support, at the top of the base plate, the second sliding block is arranged on the second sliding rail, the crushing box is arranged at the top of the second sliding block, and the fixing plate is arranged at the left end of the top of the second sliding rail. By means of the efficient crushing plant, the aim of crushing the blocky cement is achieved; and meanwhile, a grinding block and a grinding box are used for crushing the blocky cement, and therefore the problems that during manual blocky cement crushing, time and labor are wasted, and efficiency is low are solved.

Owner:广东森濠建设有限公司

Environmental self-lubricating wear-resistant copper alloy and preparation method thereof

The invention discloses environmental self-lubricating wear-resistant copper alloy, comprising the following components by mass percent: 5-13% of Sn, 2-9% of Ni and / or Co, 2-11% of Bi, 0.05-0.3% of Zr, 0.05-0.5% of RE, the balance of Cu and inevitable impurities, wherein the content of the impurity is smaller than or equal to 0.3%, the RE is Ce-La misch metal. Meanwhile, the preparation method of the environmental self-lubricating wear-resistant copper alloy is disclosed. The environmental self-lubricating wear-resistant copper alloy has the advantages that the conventional wear-resistant copper alloy containing lead is replaced, and the environmental self-lubricating wear-resistant copper alloy is the wear-resistant copper alloy material with environment-friendly and self-lubricating effects. The alloy solidification molding process is interfered by adopting a strong pulsed electromagnetic physical field in the manufacturing process, the as-cast segregation and loosening of the obtained environmental self-lubricating wear-resistant copper alloy are significantly reduced, the alloy is fine and even in as-cast structure, and high in density, the hardness of the molded casting is greater than 70HB, the tensile strength is greater than 230MPa, and the alloy density is greater than 8.7g / cm<3>. The environmental self-lubricating wear-resistant copper alloy has good overall performance, the preparation method is good in stability, and low in cost, the preparation process is green and free of pollution, and industrialization is easily achieved.

Owner:镇江金鑫有色合金有限公司 +2

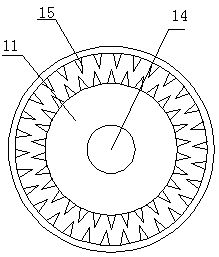

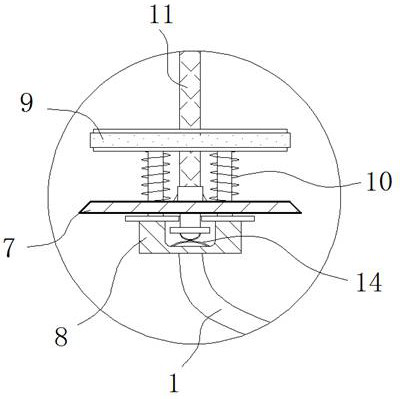

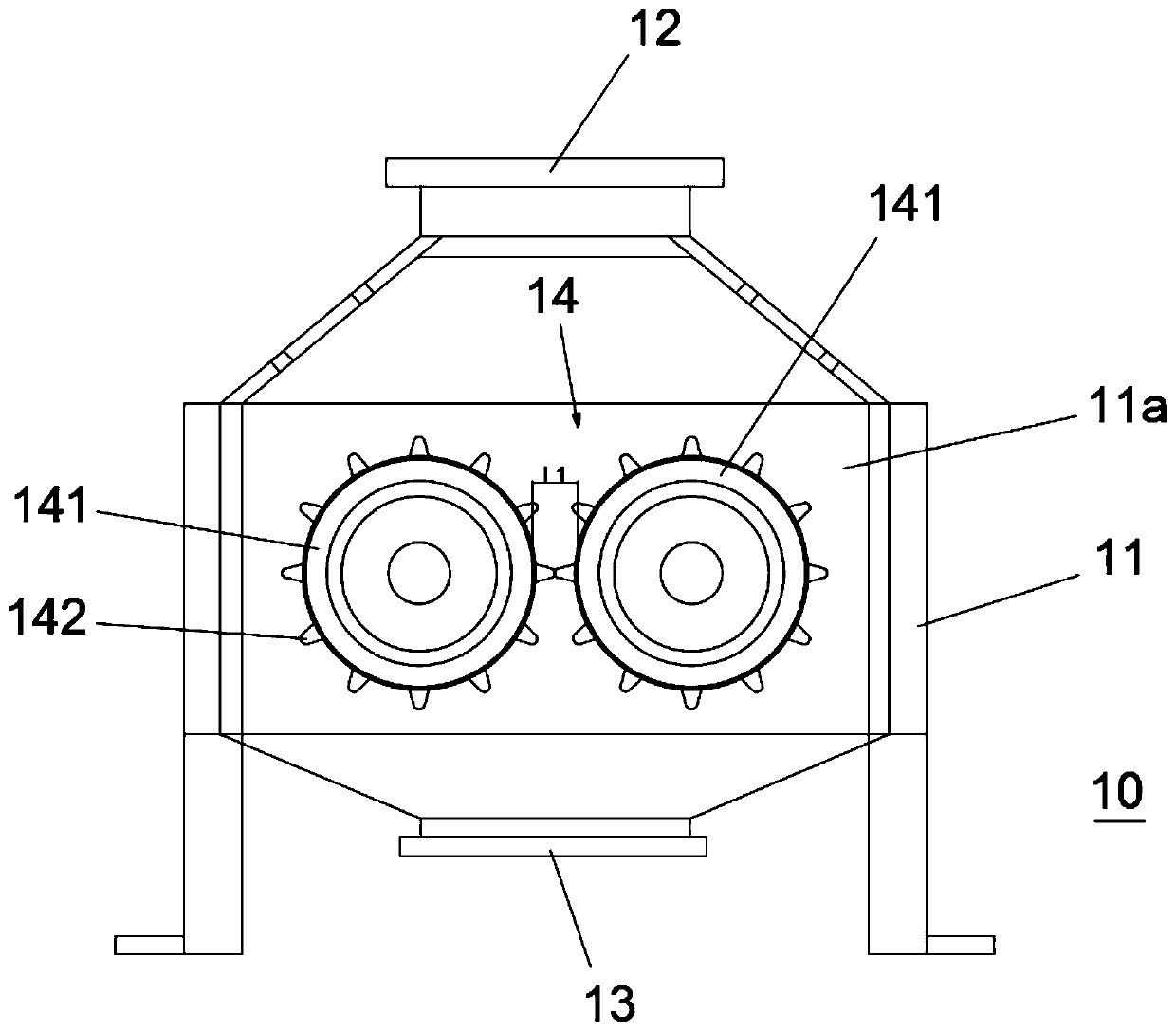

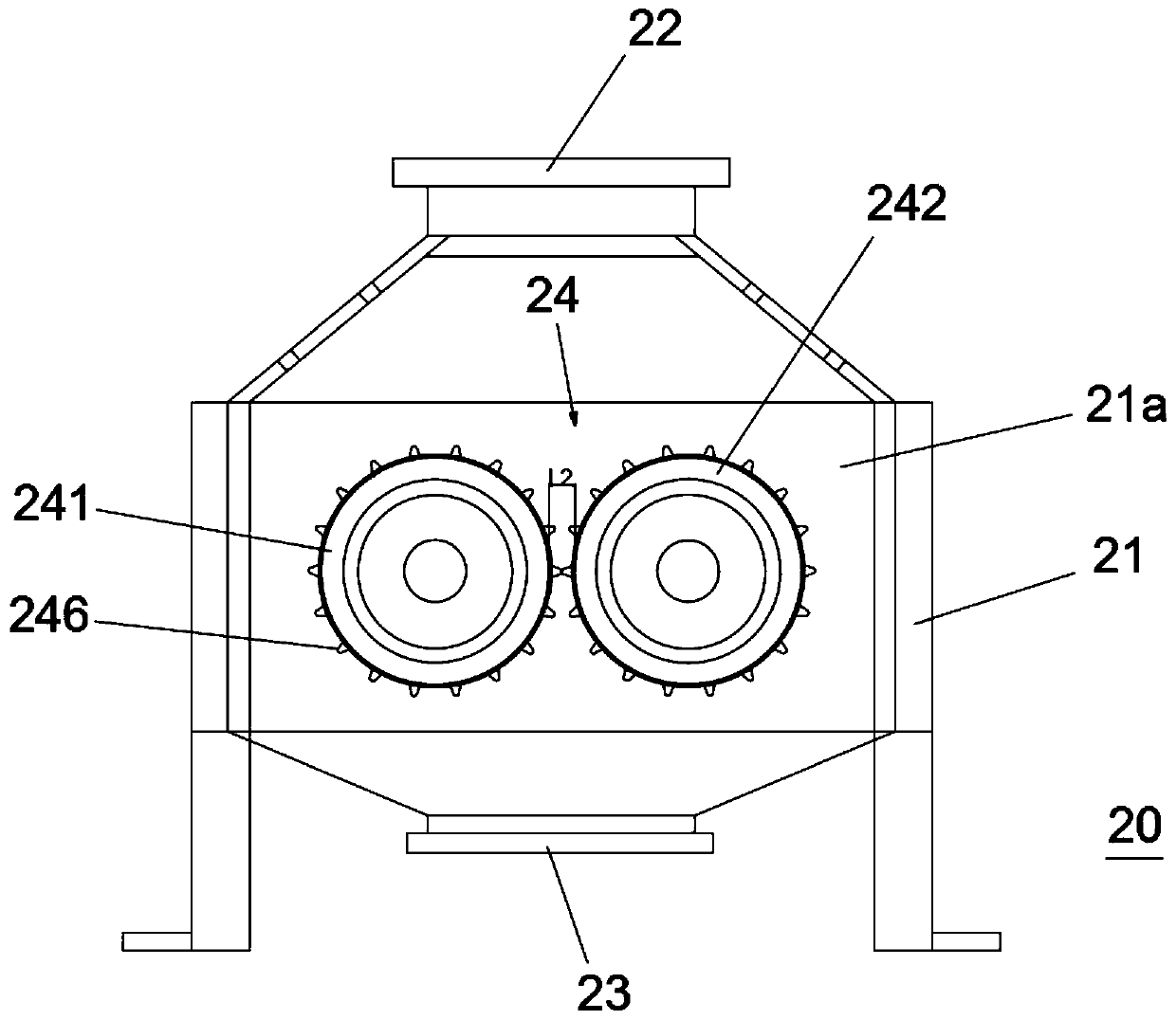

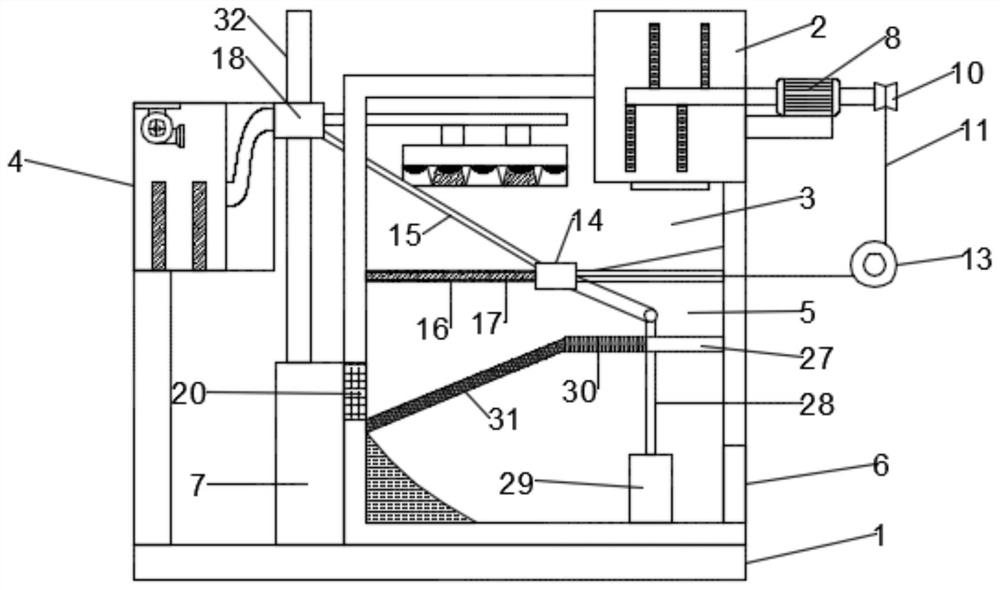

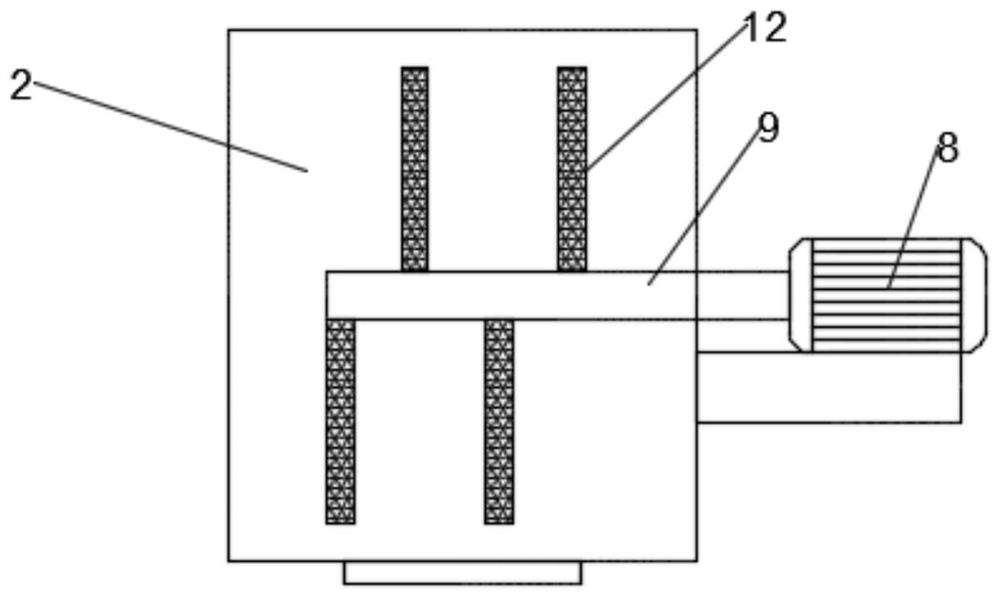

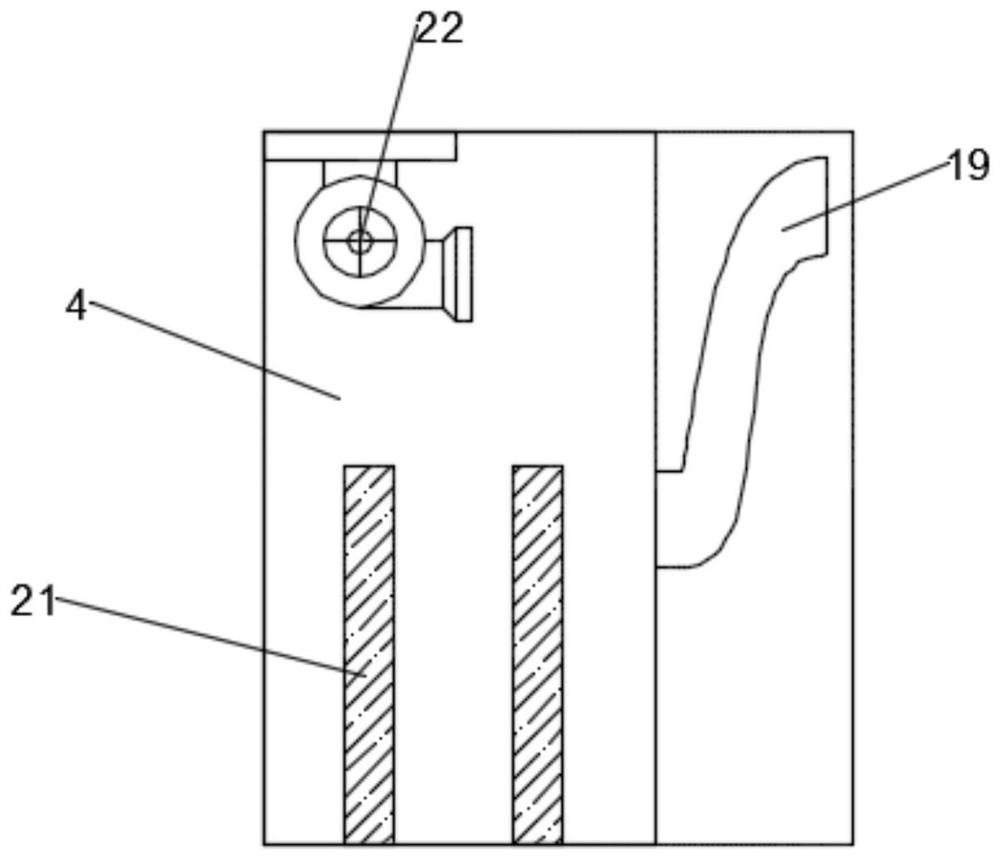

Adjustable particle size circulation stone crushing device

The invention discloses an adjustable particle size circulation stone crushing device. The adjustable particle size circulation stone crushing device comprises a machine body, a feeding barrel, a driving crushing roller and a driven crushing roller. A crushing cavity is formed in the machine body. The feeding barrel is arranged at the top end of the machine body, and the part, below the feeding barrel, of the crushing cavity is internally provided with the driving crushing roller and the driven crushing roller. One end of the driving crushing roller is connected with a motor A through a speedreducer. A discharging port A is formed below the driving crushing roller and the driven crushing roller. A filter sieve is arranged at the upper end of the discharging port A. A supporting frame is arranged on the left side of the machine body and provided with a lifting device. A motor B is connected to the lower end of the lifting device. The output end of the motor B is connected with a rotation shaft through a connector. A crushing tooth disc is arranged on the rotation shaft, a fixing crushing tooth ring is fixed to the part, on the outer side of the crushing tooth disc, of the machine body, and the inner diameter of the fixing crushing tooth ring is in an inverted cone shape with the large upper part and the small lower part. A support is arranged below the crushing tooth disc, a vibration plate is arranged on the support, a spring is arranged between the vibration plate and the support, and an elevating device is arranged on one side of the vibration plate.

Owner:成都人人揭网络科技有限公司

Refractory material powder making equipment

The invention discloses refractory material powder making equipment, and belongs to the technical field of refractory material production. The refractory material powder making equipment comprises a crushing box, a crushing assembly, a filtering plate, a material scraping assembly, a containing box, a grinding box, a grinding assembly, a screening box, a supporting assembly, a screening assembly and a material conveying assembly, wherein the crushing box and the grinding box are sequentially arranged on the ground, the supporting assembly is arranged beside the grinding box, the screening boxis arranged on the supporting assembly, a feeding opening is formed in the top end of the crushing box, the crushing assembly is arranged in the crushing box, the filtering plate is fixedly connectedwith the inner wall of the crushing box, the filtering plate is provided with a plurality of filtering holes, the material scraping assembly is arranged in the crushing box, the grinding assembly is arranged in the grinding box, the screening assembly is arranged in the screening box, and the material conveying assembly is arranged between the grinding box and the screening box. According to the refractory material powder making equipment, the problems that after the raw materials are ground into powder, the size of the particles is different, the powder cannot be classified according to the size of the particles, and later use is influenced are solved.

Owner:杨腾跃

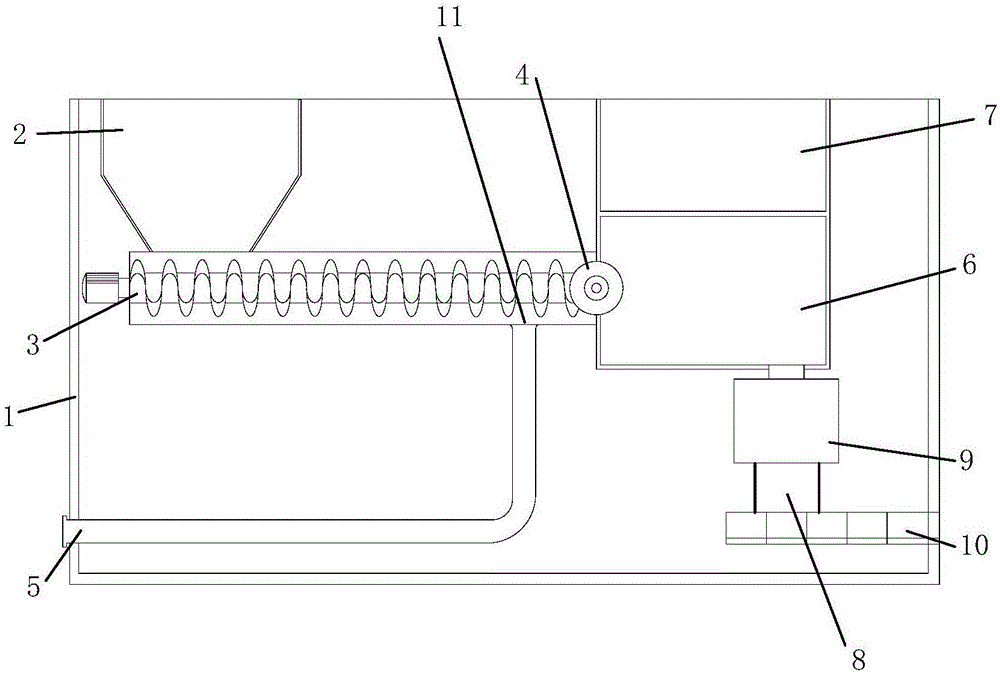

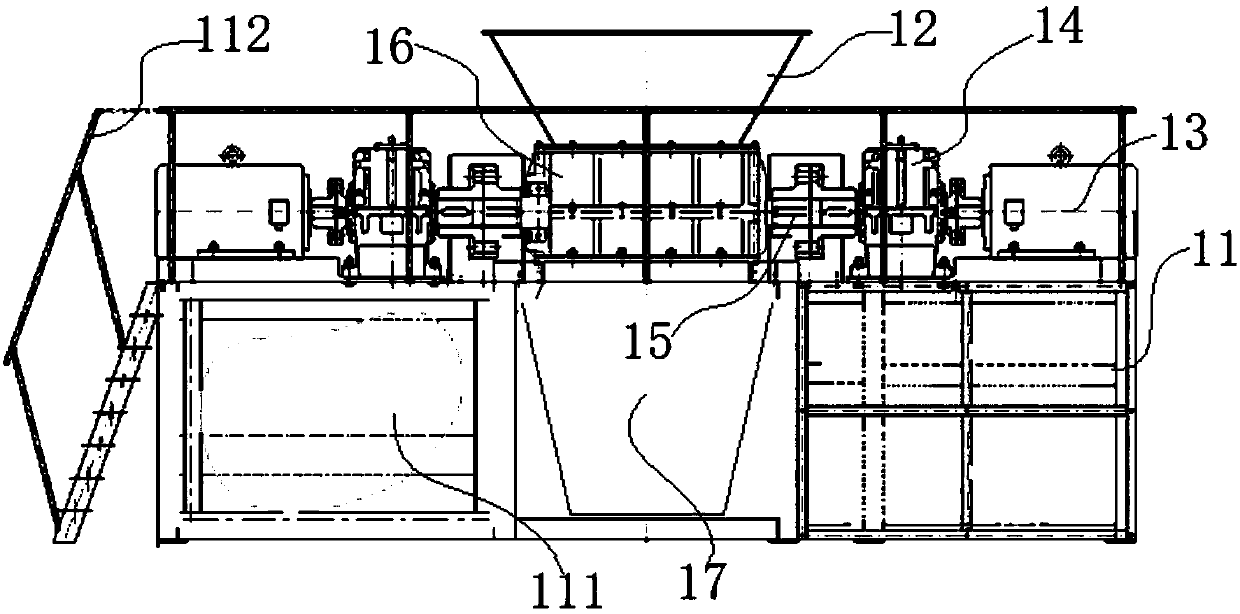

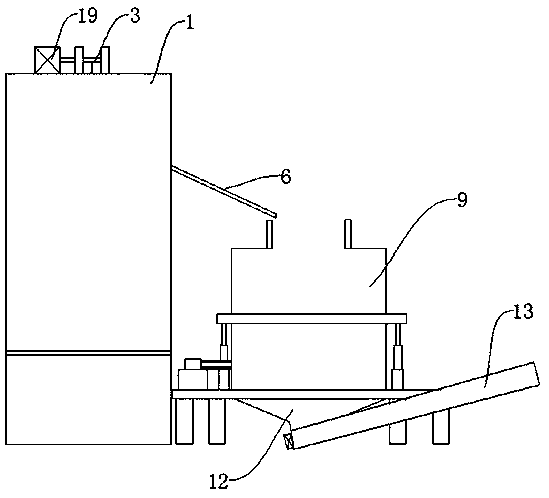

Kitchen waste treatment device and kitchen waste treatment method

InactiveCN105689368AAchieve the purpose of breakingTimely processingSolid waste disposalSewageWaste treatment

The invention discloses a kitchen waste treatment device and a kitchen waste treatment method. The kitchen waste treatment device comprises a feeding hopper, a screw conveyor, a stirring and mixing chamber, an EM storage box and a filling and sealing machine. The feeding hopper, the screw conveyor, the stirring and mixing chamber and the filling and sealing machine are sequentially connected. A valve is arranged on a discharging opening of the screw conveyor. A drain outlet is formed in the pipe wall, below the feeding opening side of the valve, of the screw conveyor. The drain outlet is connected with a sewage draining pipeline. A screen is mounted on the drain outlet. The EM storage box communicating with the stirring and mixing chamber is arranged on the stirring and mixing chamber. By the adoption of the kitchen waste treatment method, kitchen waste can be treated in time, the storage life of the kitchen waste is greatly prolonged, and the storage safety of the kitchen waste is greatly improved; and the treated kitchen waste can be stored and transported conveniently, meanwhile anaerobic fermentation can continue in the storage and transportation processes, and the subsequent treatment time of the kitchen waste is shortened greatly.

Owner:GUANGDONG INST OF APPLIED BIOLOGICAL RESOURCES

Waste and old plastic pulverizing and grinding device

The invention discloses a waste and old plastic pulverizing and grinding device. The device comprises a supporting bottom plate. The top of the supporting bottom plate is fixedly connected to a conveying box. The top of the conveying box is fixedly connected to a pulverizing box through symmetric first supporting legs. The center of the bottom of the pulverizing box is communicated with the top ofthe conveying box. The center of the top of the pulverizing box is communicated with a feeding channel. The top of the feeding channel is communicated with a waste feeding hopper. The two sides of the inner wall of the feeding channel are fixedly connected to symmetric anti-pinch splash-proof devices. The middles of the two sides of the inner wall of the pulverizing box are fixedly connected to symmetric supporting material falling plates. The invention relates to the technical field of plastic processing machinery and equipment. The waste and old plastic pulverizing and grinding device solves the problem that the existing plastic pulverizing device has high energy consumption and poor pulverizing effects and produces secondary pollution, realizes uniform and thorough plastic pulverizing,effectively improves the plastic recovery efficiency and protects the environment.

Owner:湖州南浔博逸金属材料经营部

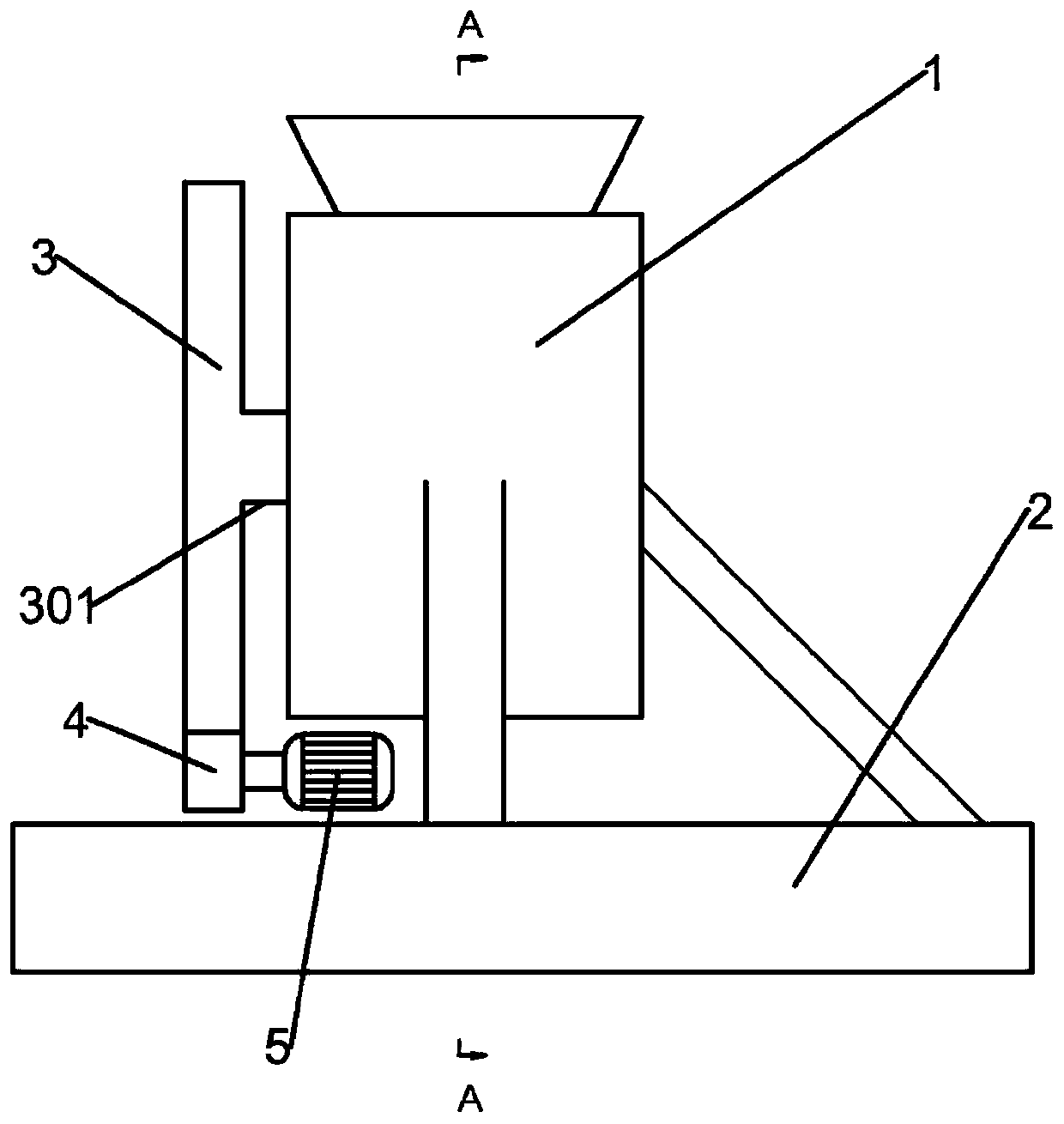

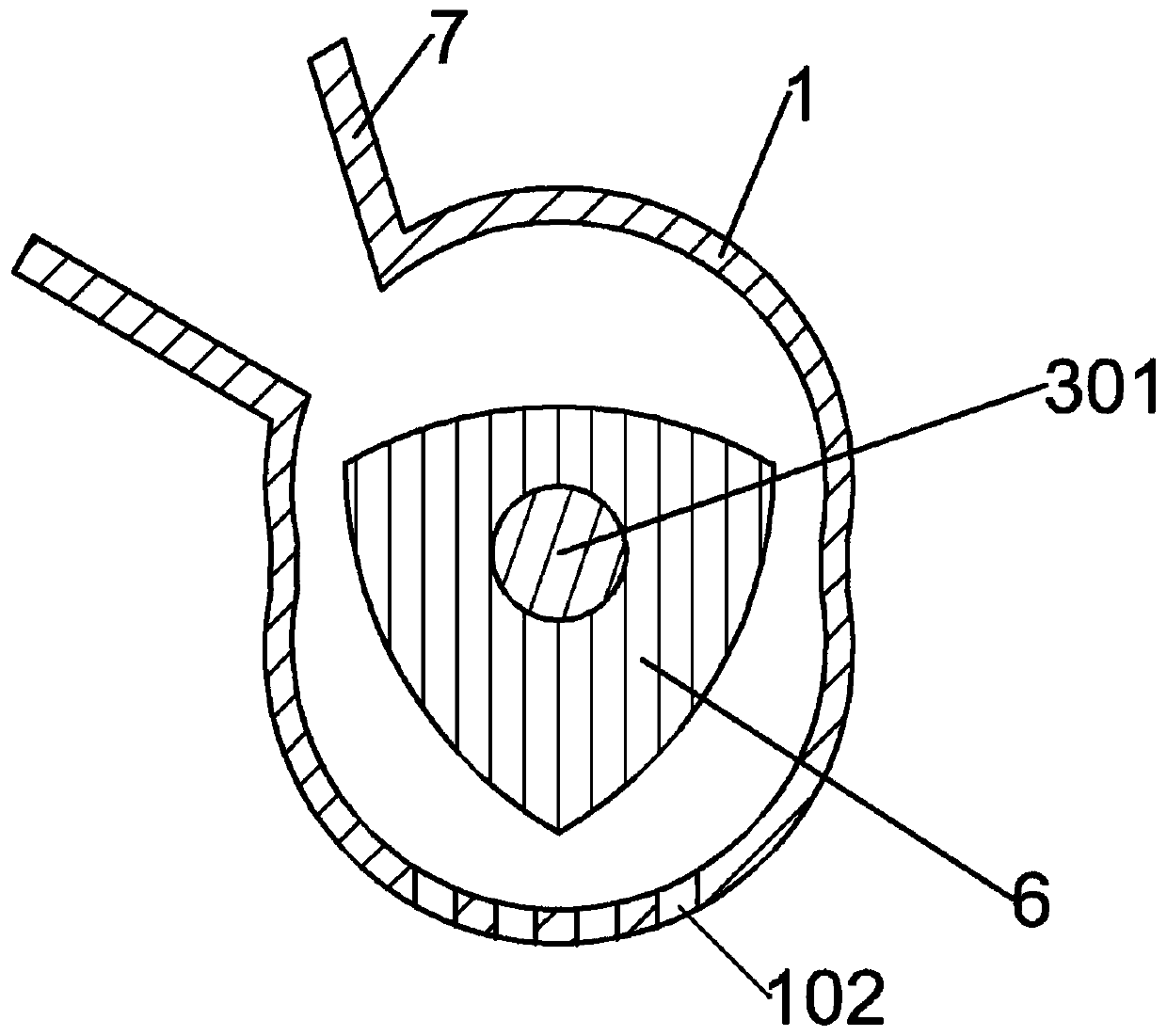

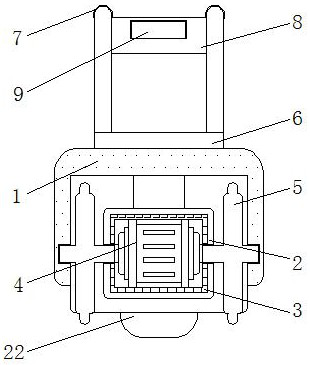

Crusher

The invention relates to the field of engineering equipment, in particular to a crusher. The crusher comprises a support, a shell fixed to the support and a crushing mechanism arranged in the shell. The crushing mechanism comprises an extrusion core and a main shaft eccentrically arranged on one side of the extrusion core. The extrusion core is in the shape of a Reuleaux triangle, a groove is formed in the other side of the extrusion core, inner teeth are arranged in the groove, and a gear matched with the inner teeth is fixed to the center of an end face of one side of the shell. A through hole is formed in the bottom of the shell, the shape of the side face of the shell is consistent with the moving track of the tip of the extrusion core, and a gap exists between the side face of the shell and the moving track of the tip of the extrusion core. The diameter of the gear is smaller than that of the groove. The main shaft is superposed to the axis of the gear. According to the crusher, three-time extrusion crushing can be achieved when the extrusion core rotates by a circle, and the crushing efficiency is greatly improved.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

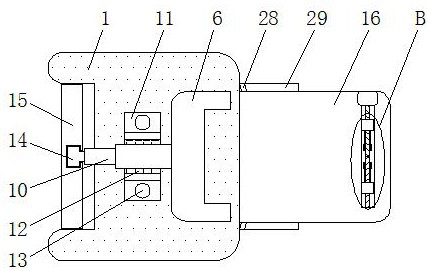

Mixing and stirring device for sealant production

PendingCN112957974AImprove mixing effectImprove impactRotary stirring mixersTransportation and packagingProcess engineeringMechanical engineering

The invention relates to the technical field of sealant production equipment, and discloses a mixing and stirring device for sealant production. The mixing and stirring device comprises a base, supporting legs are arranged at the four corners of the bottom of the base, a stirring box is fixedly mounted on the side, away from the supporting legs, of the base, a feeding hopper is arranged at a center shaft of the end, away from the base, of the stirring box, the feeding hopper is communicated with the stirring box, and a control panel is fixedly installed at the position of a center shaft of the outer wall of the front face of the stirring box. According to the mixing and stirring device for sealant production, in the stirring process, a centrifugal driving mechanism discontinuously moves a centrifugal driving ball, so that the centrifugal driving ball impacts a special-shaped rotating plate, the special-shaped rotating plate rotates to achieve a pushing effect on sealant in the stirring process, meanwhile, a vibration driving mechanism can also assist a stirring auger in stirring, so that the situation that the sealant on the stirring auger cannot be well stirred is prevented, and the stirring effect of the stirring device on the sealant is improved.

Owner:胡正兵

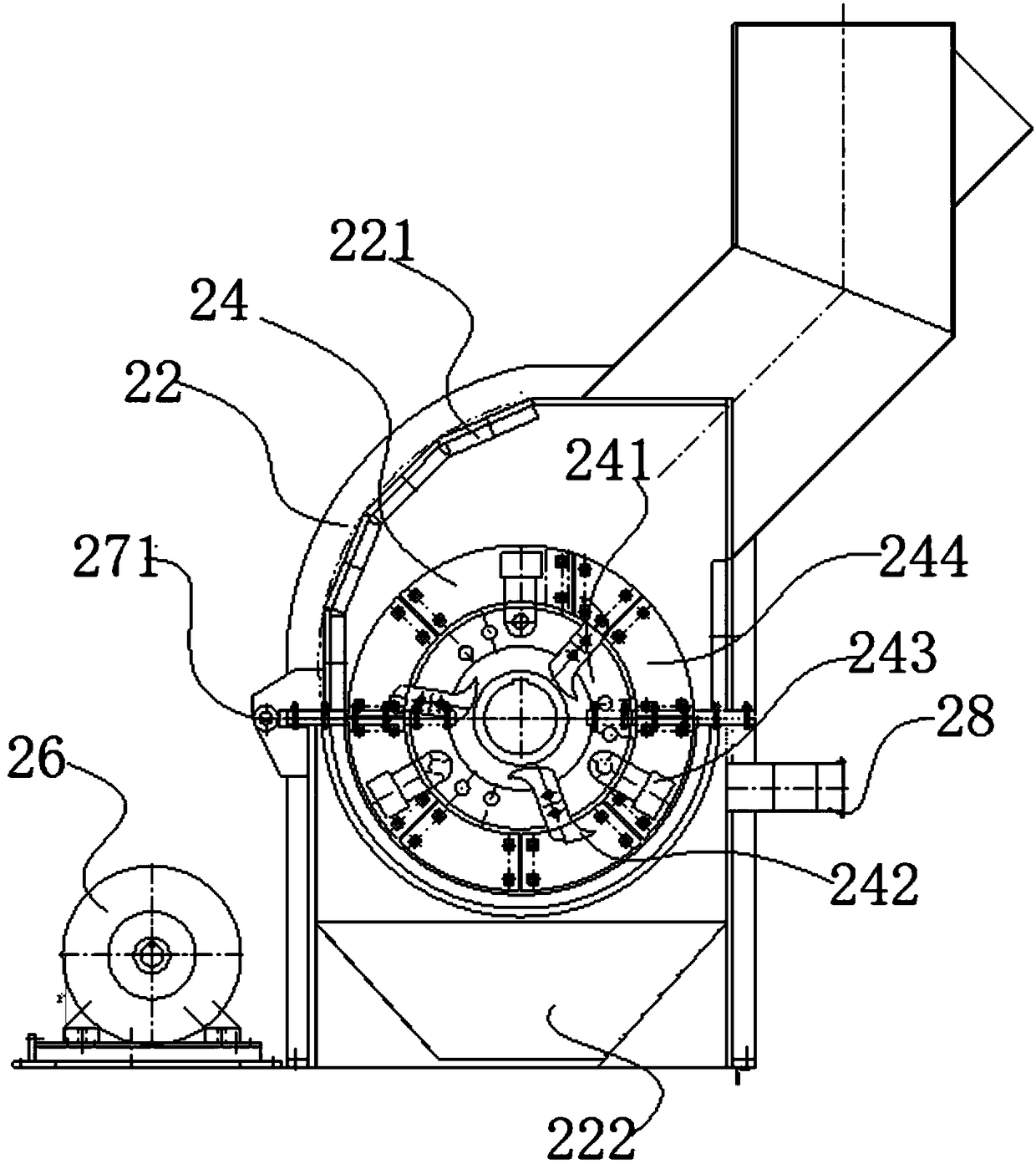

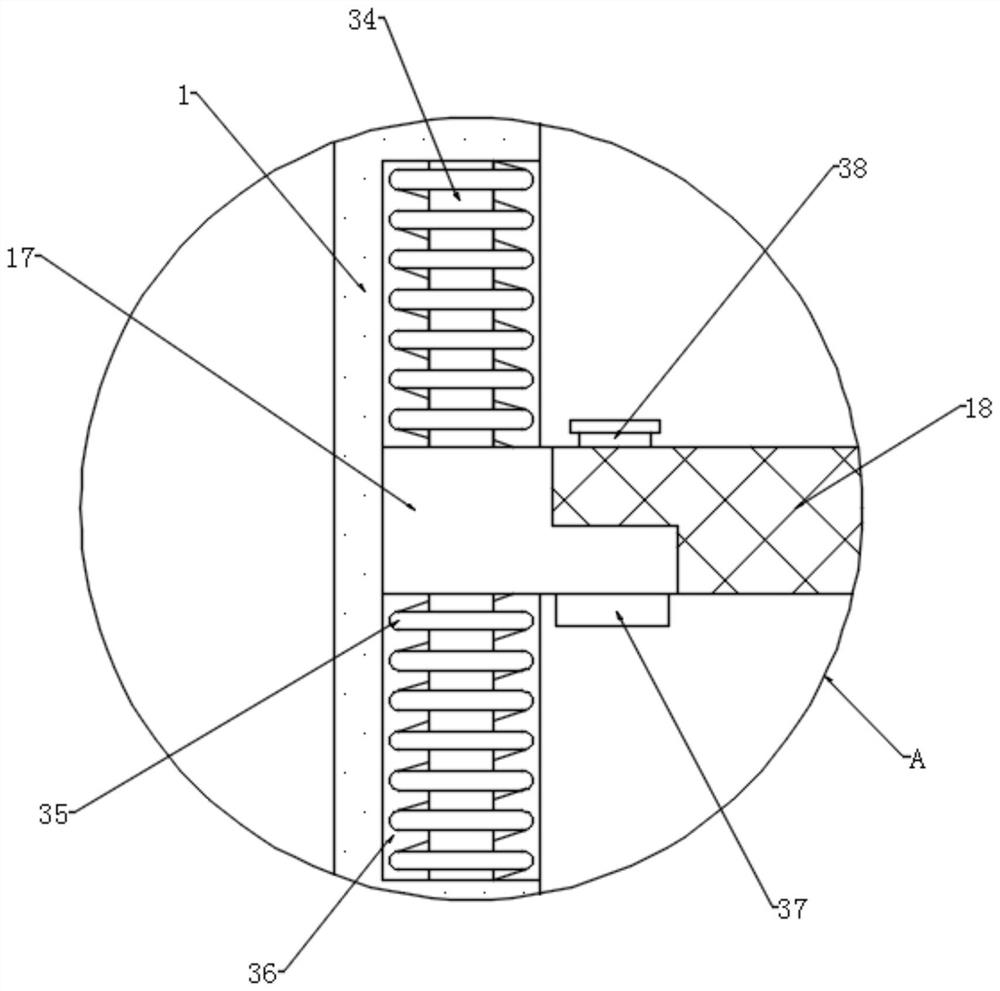

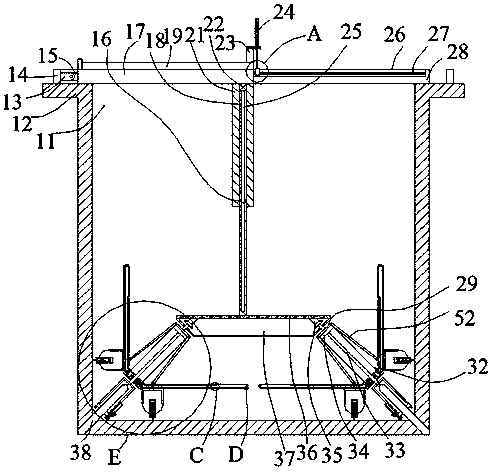

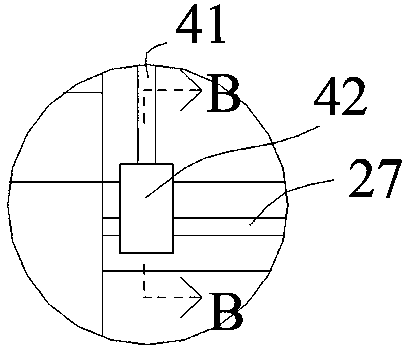

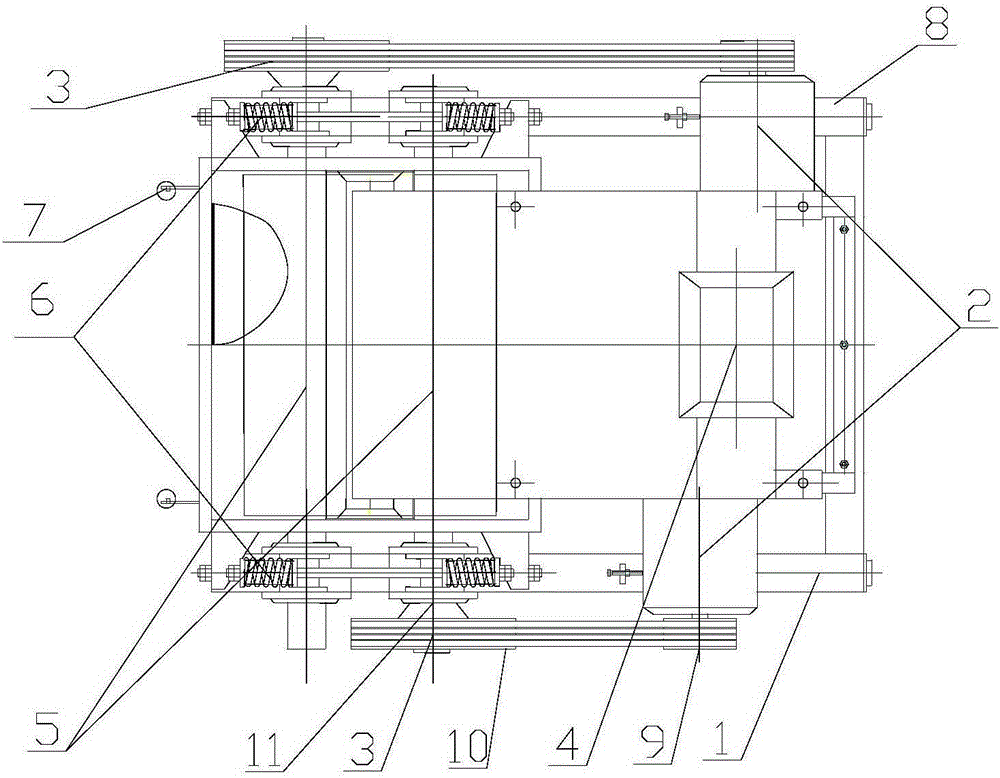

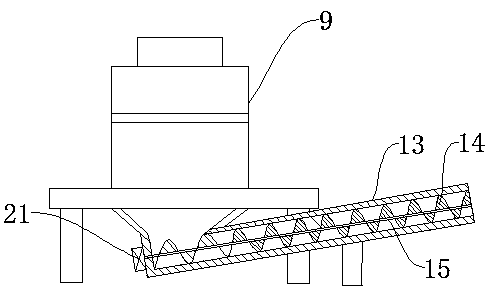

Crushing and classification device for light and thin metal, and treatment process thereof

InactiveCN108057495AAchieve the purpose of breakingEasy to operateDirt cleaningMagnetic separationThin metalFixed frame

The invention discloses a crushing and classification device for light and thin metal, and a treatment process thereof, and belongs to the technical field of classification after metal crushing. The crushing and classification device disclosed by the invention comprises a crushing device and a classification device which are arranged according to working procedures and connected through a loadingconveying belt, and the crushing device comprises a hollow case, a charge hopper formed in the top of the case, and a crushing mechanism in the case; the overall diameter of the crushing mechanism isslightly less than the width of the case, and the crushing mechanism comprises a movable cutter head, a movable cutter, a fixed cutter and a fixed cutter head; each of the movable cutter head and thefixed cutter head is annular; the classification device comprises a frame-shaped fixed frame and a magnetic roller fixed to the fixed frame through a bearing, and the loading conveying belt and a discharge conveying belt which are fixed to the fixed frame separately are arranged at the two sides of a roller surface of the magnetic roller; the tail end of the loading conveying belt is close to theroller surface of one side of the magnetic roller, and reserved with a non-iron material falling gap; and the beginning end of the discharge conveying belt is infinitely next to the roller surface ofthe other side of the magnetic roller. The problems of time waste and labor waste of metal crushing and manual classification after crushing are solved.

Owner:安徽华龙环保技术工程有限公司

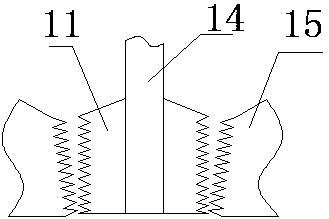

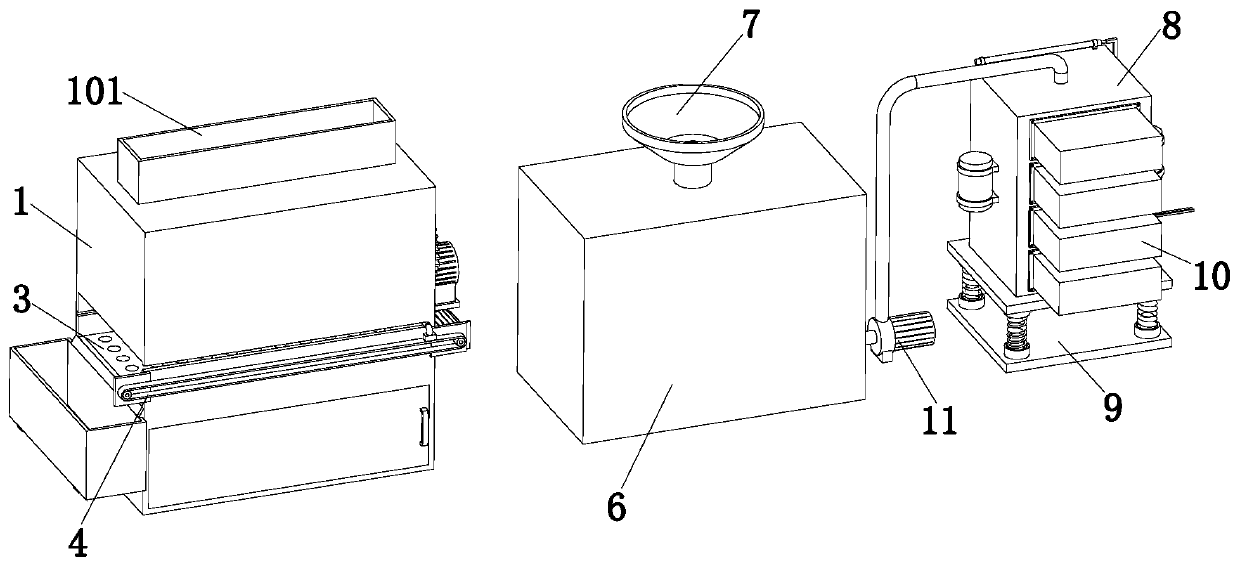

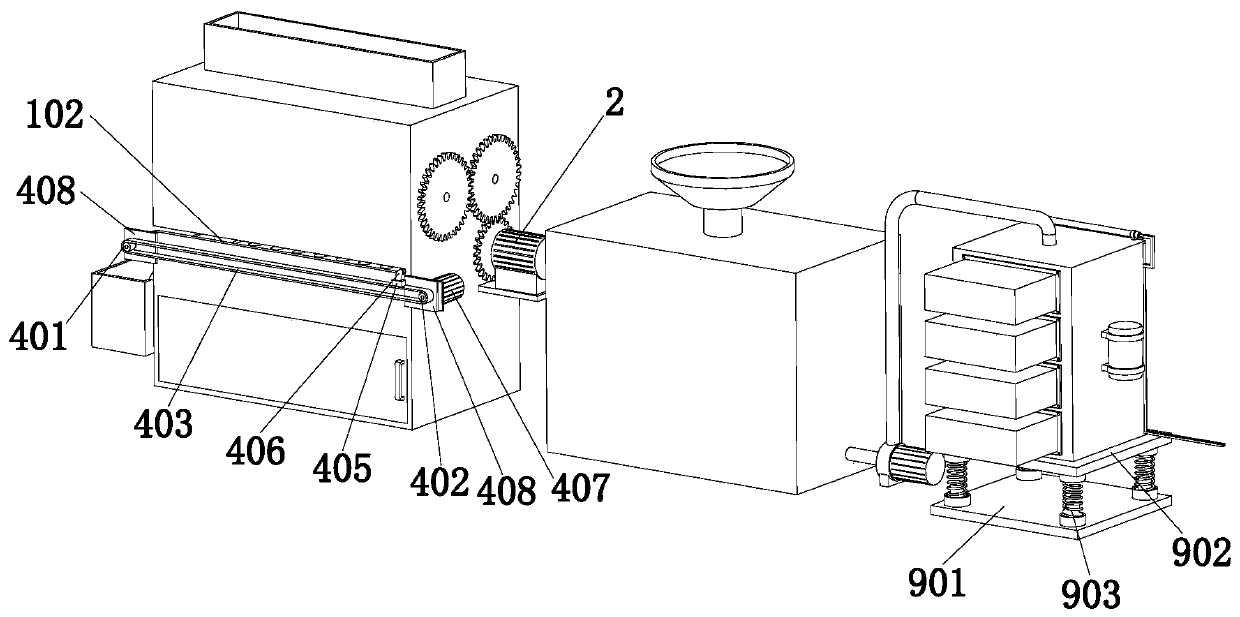

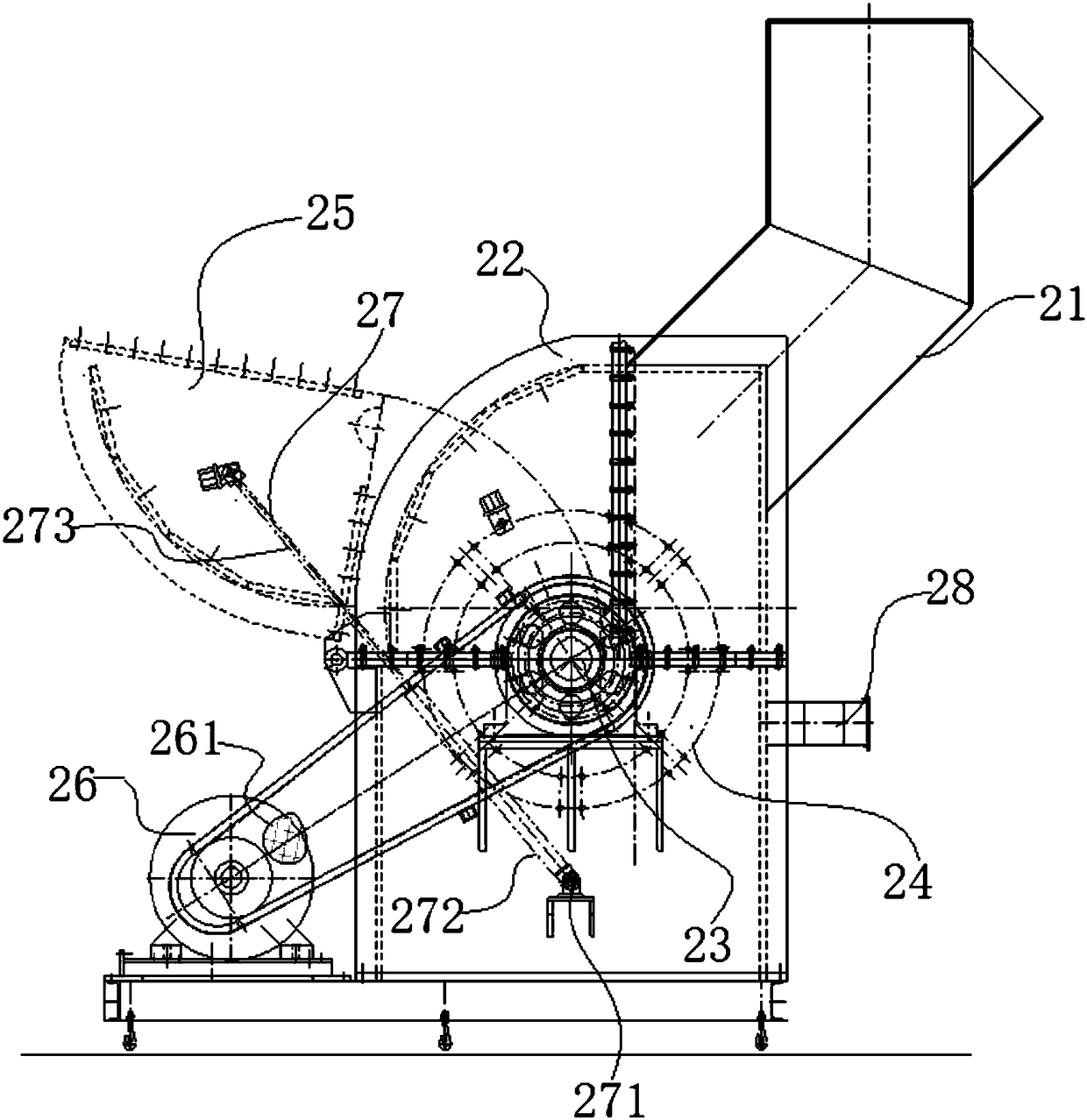

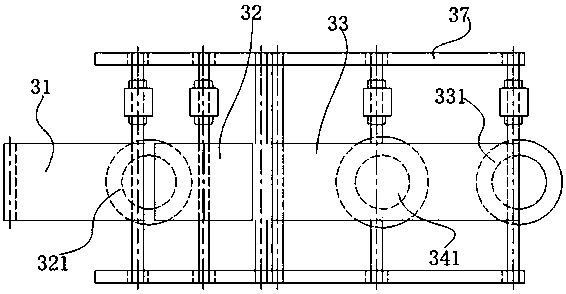

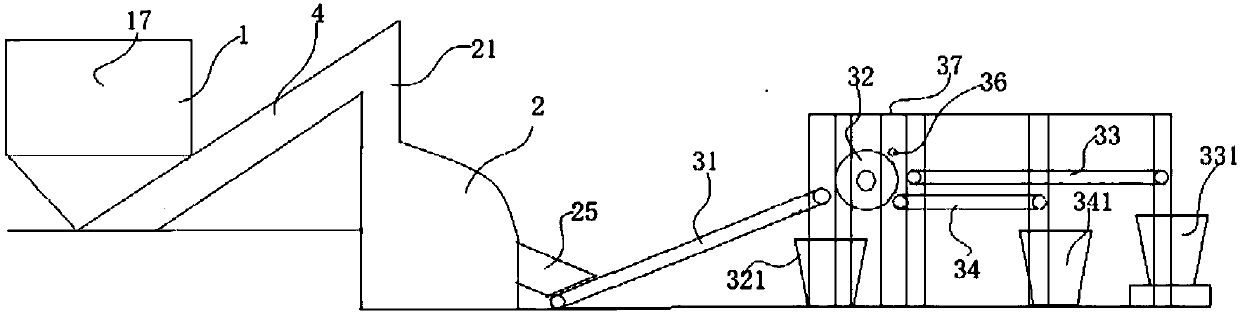

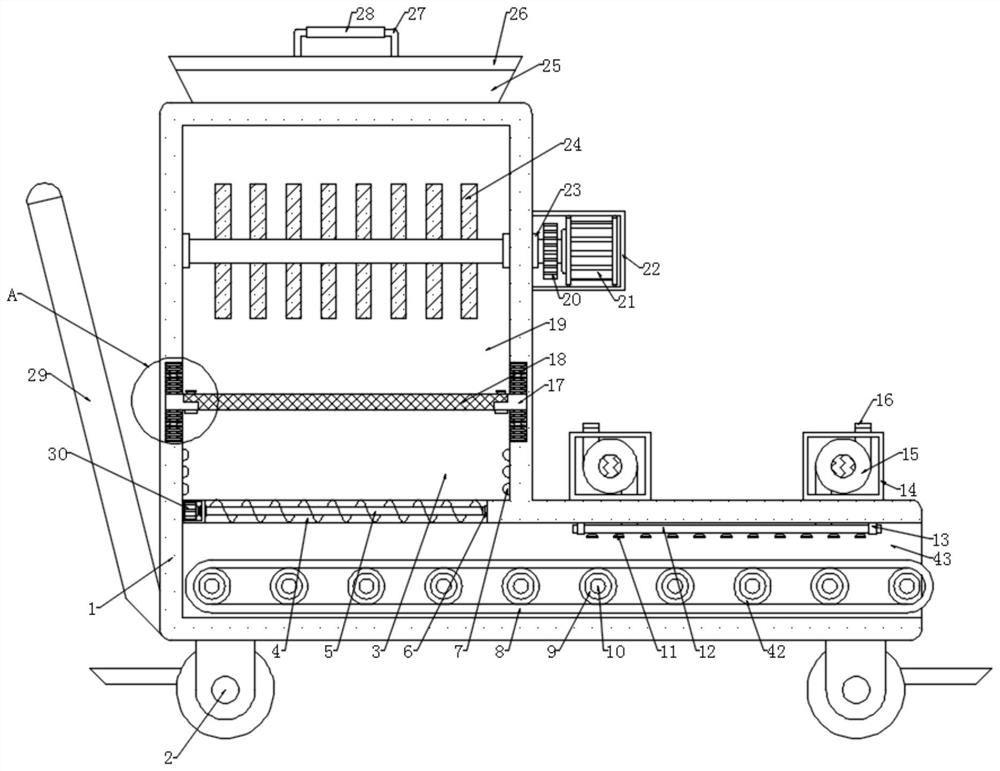

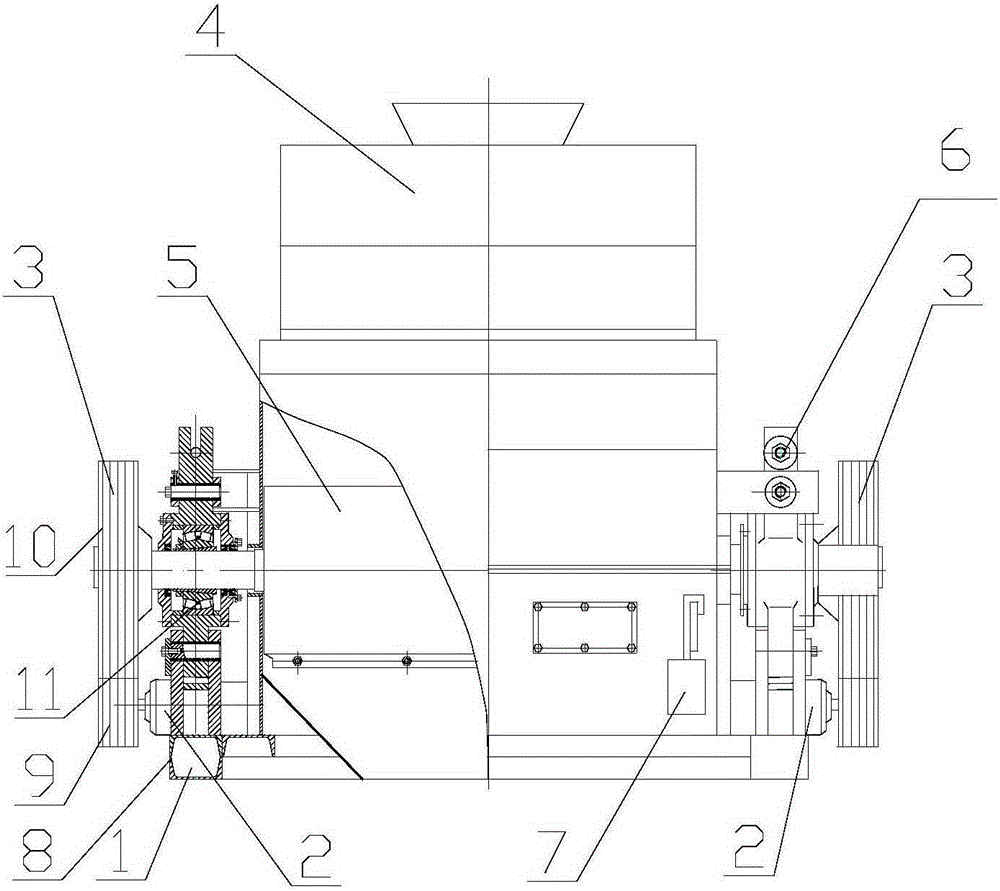

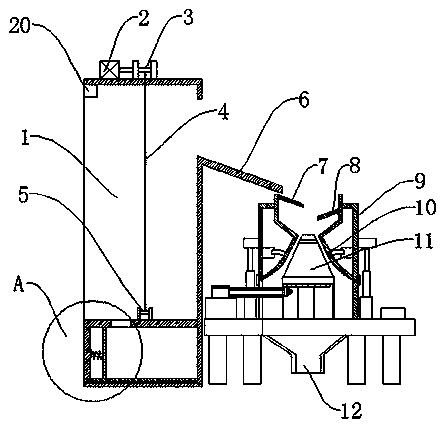

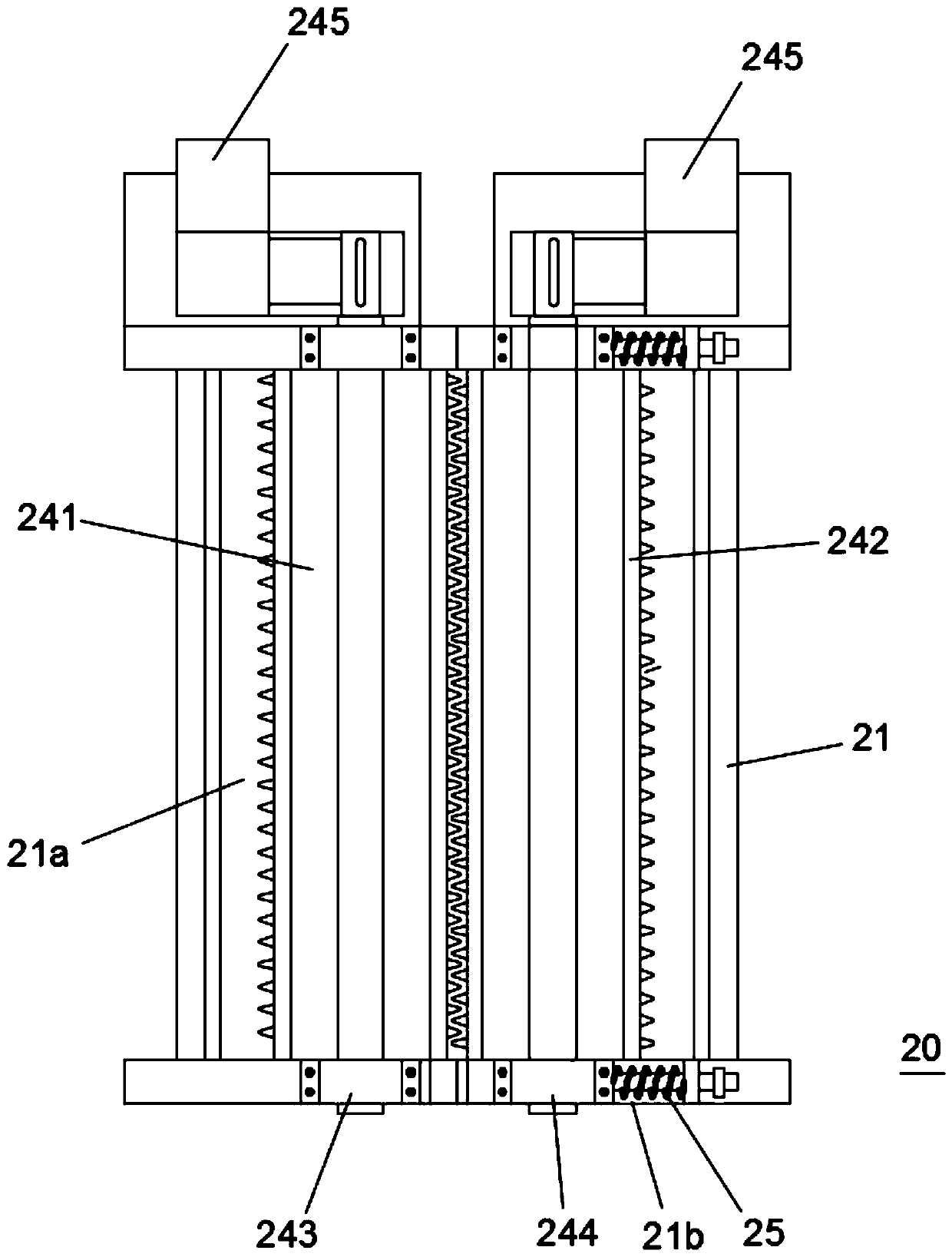

Light and thin metal fine crushing treatment device and fine crushing and sorting process thereof

InactiveCN107890939AAvoid material jamsPrevent lockDirt cleaningMagnetic separationThin metalEngineering

The invention discloses a light and thin metal fine crushing treatment device and a fine crushing and sorting process thereof and belongs to the technical field of metal crushing and sorting. The light and thin metal fine crushing treatment device comprises a tearing device, a crushing device and a sorting device which are arrayed according to working processes. The tearing device and the crushingdevice are connected through a feeding packing auger. The crushing device and the sorting device are connected through a feeding conveyor belt. The tearing device comprises a frame-shaped rack and afeed port fixed to the middle portion of the upper end face of the rack and further comprises a tearing mechanism. The crushing device comprises a hollow machine box, a feeding hopper formed in the top of the machine box and a crushing mechanism in the machine box. The sorting device comprises a frame-shaped fixing frame and a magnetic roller fixed to the fixing frame through a bearing. The two sides of the roller face of the magnetic roller are provided with a feeding conveyor belt and a discharging conveyor belt which are fixed to the fixing frame. The starting end of the discharging conveyor belt is infinitely attached to the roller face of the other side of the magnetic roller. By means of the light and thin metal fine crushing treatment device and the fine crushing and sorting processthereof, the problems that time and labor are wasted in metal crushing and manual sorting after crushing.

Owner:安徽华龙环保技术工程有限公司

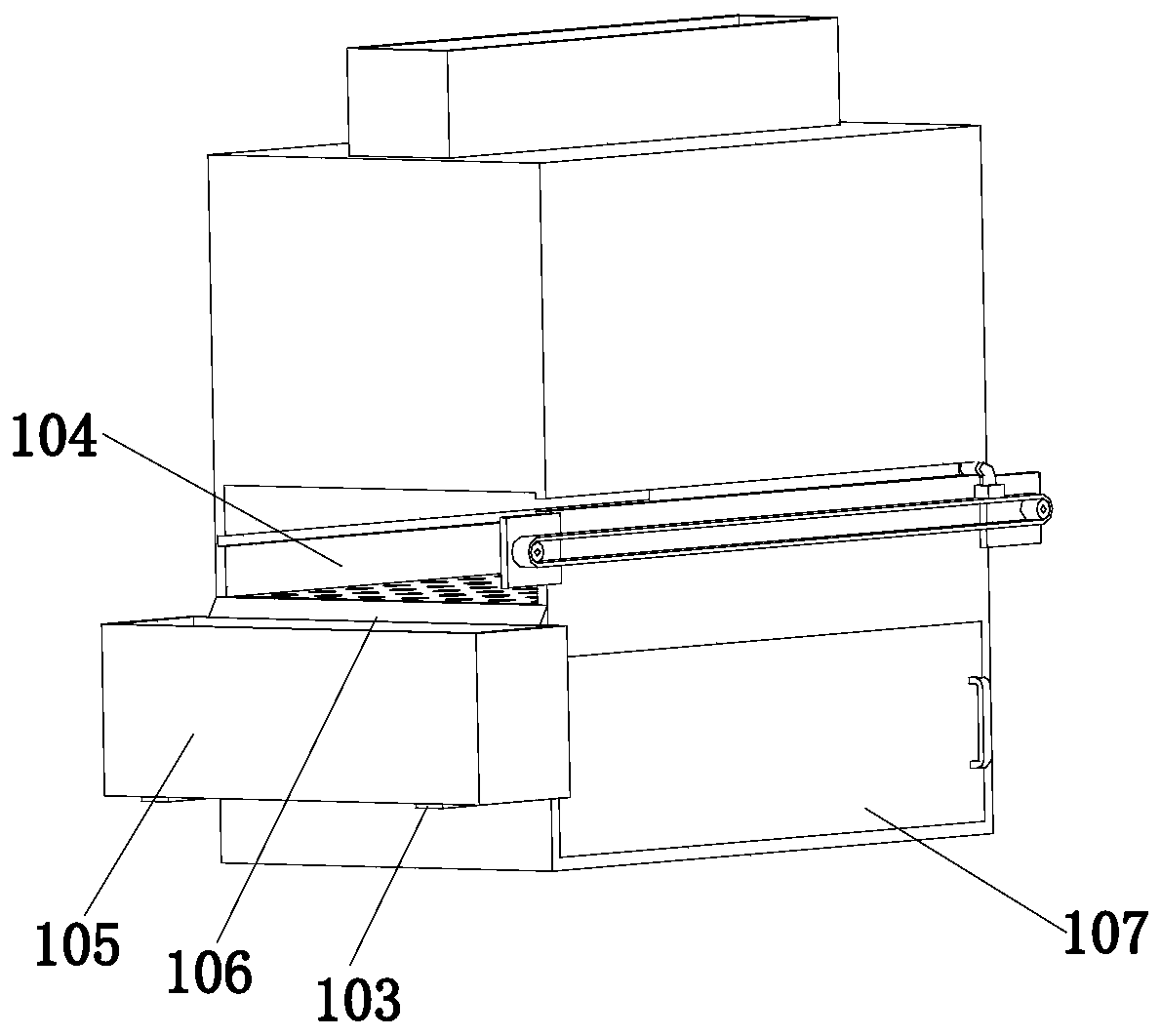

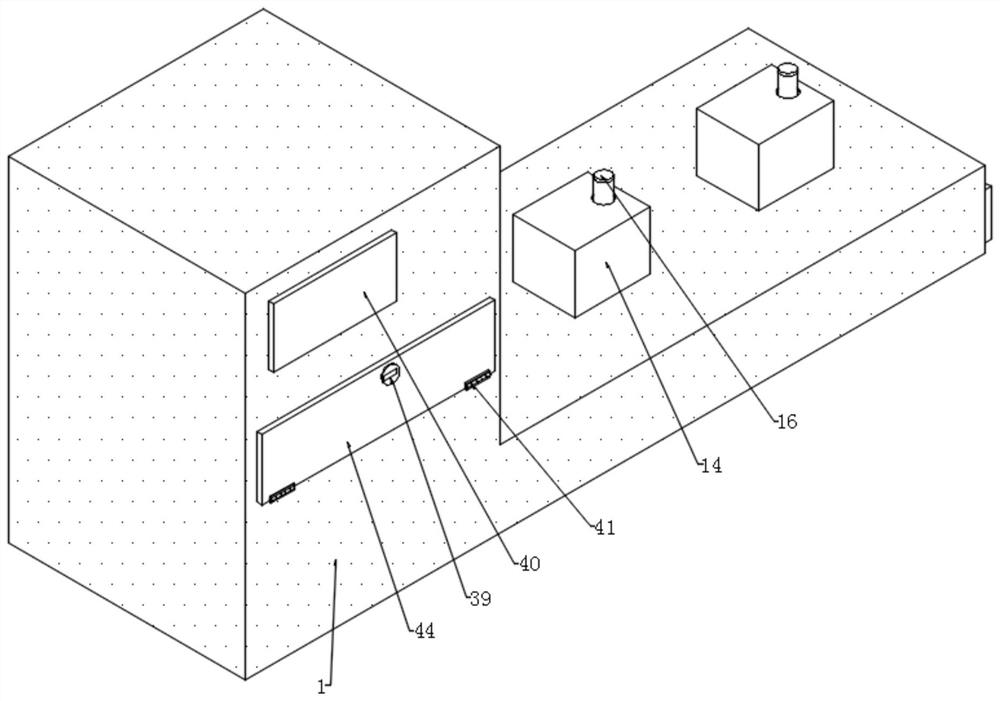

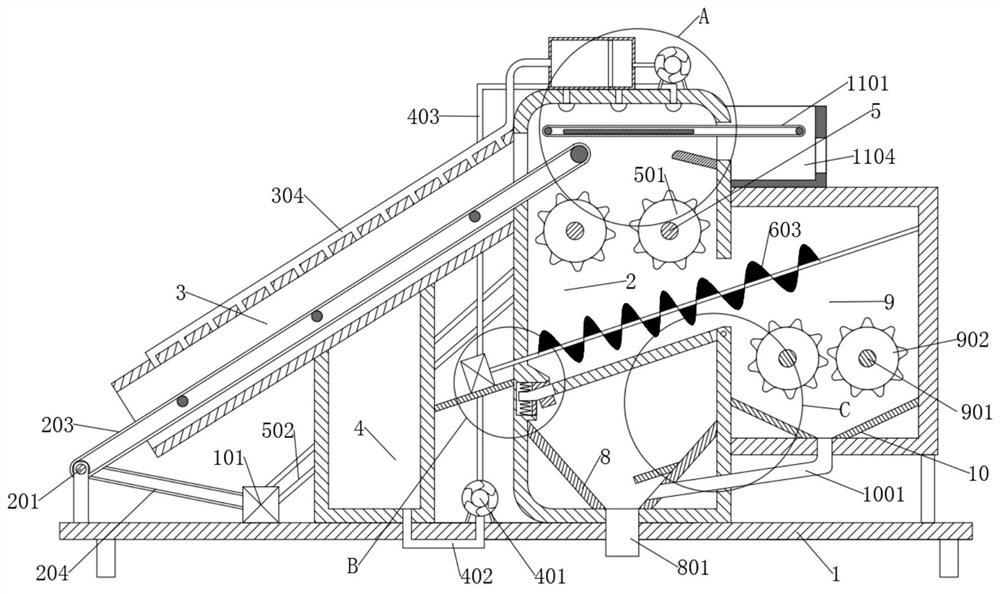

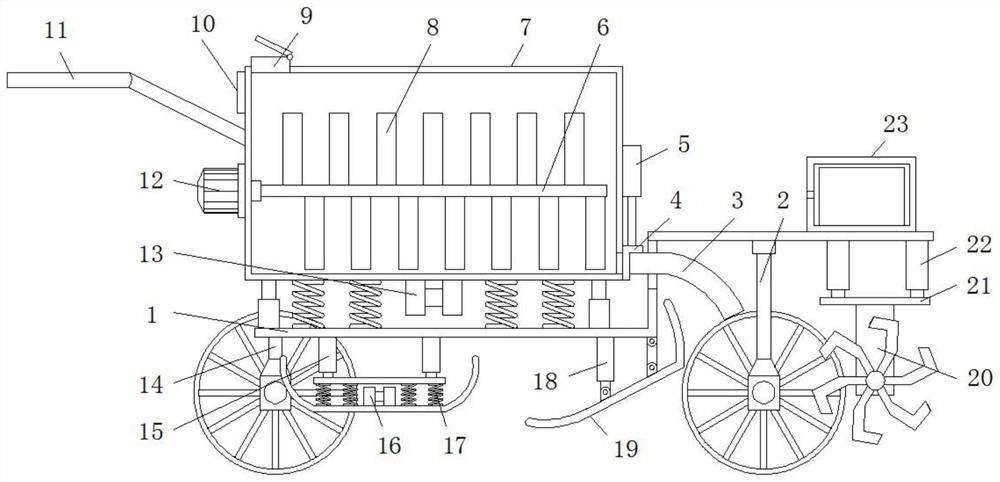

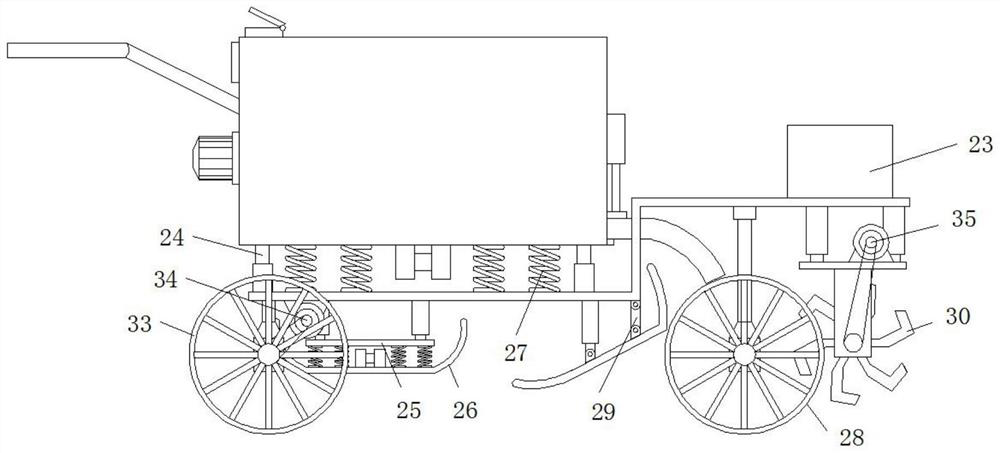

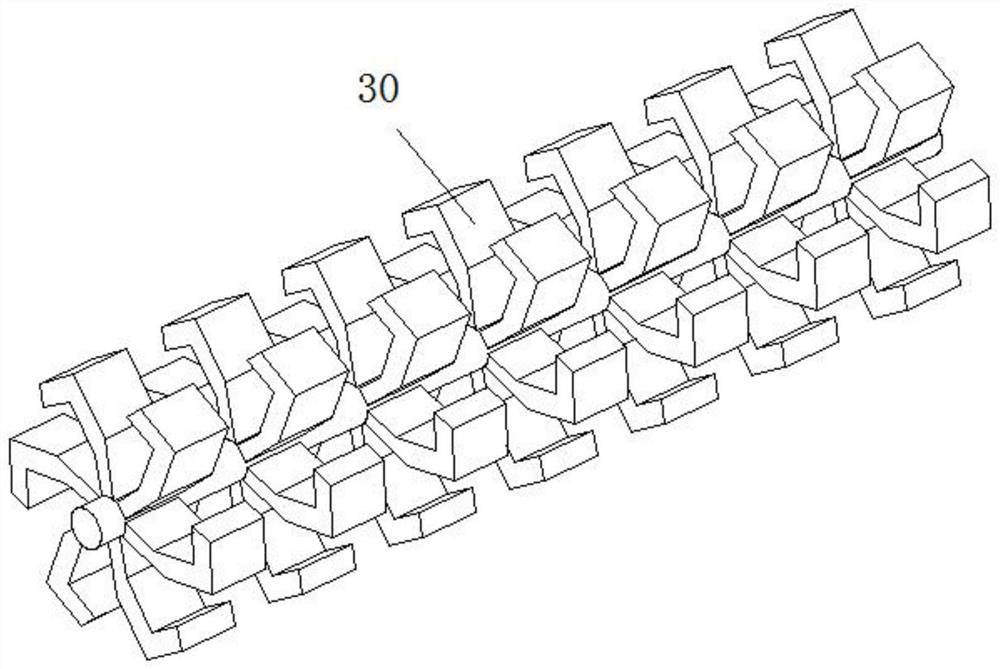

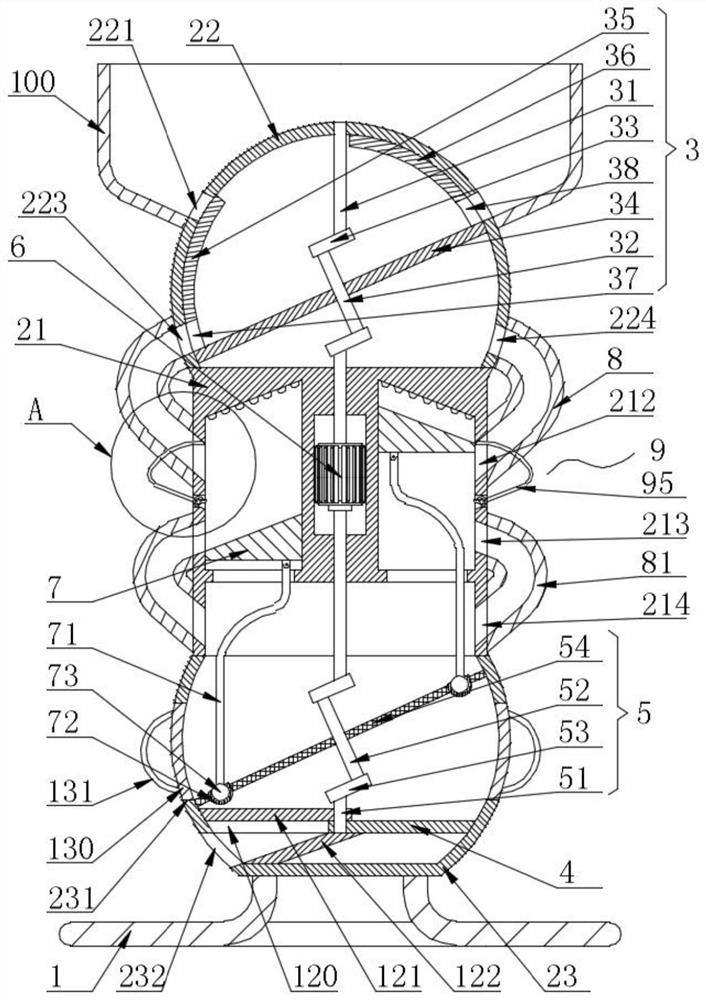

Movable multifunctional agricultural product processing equipment

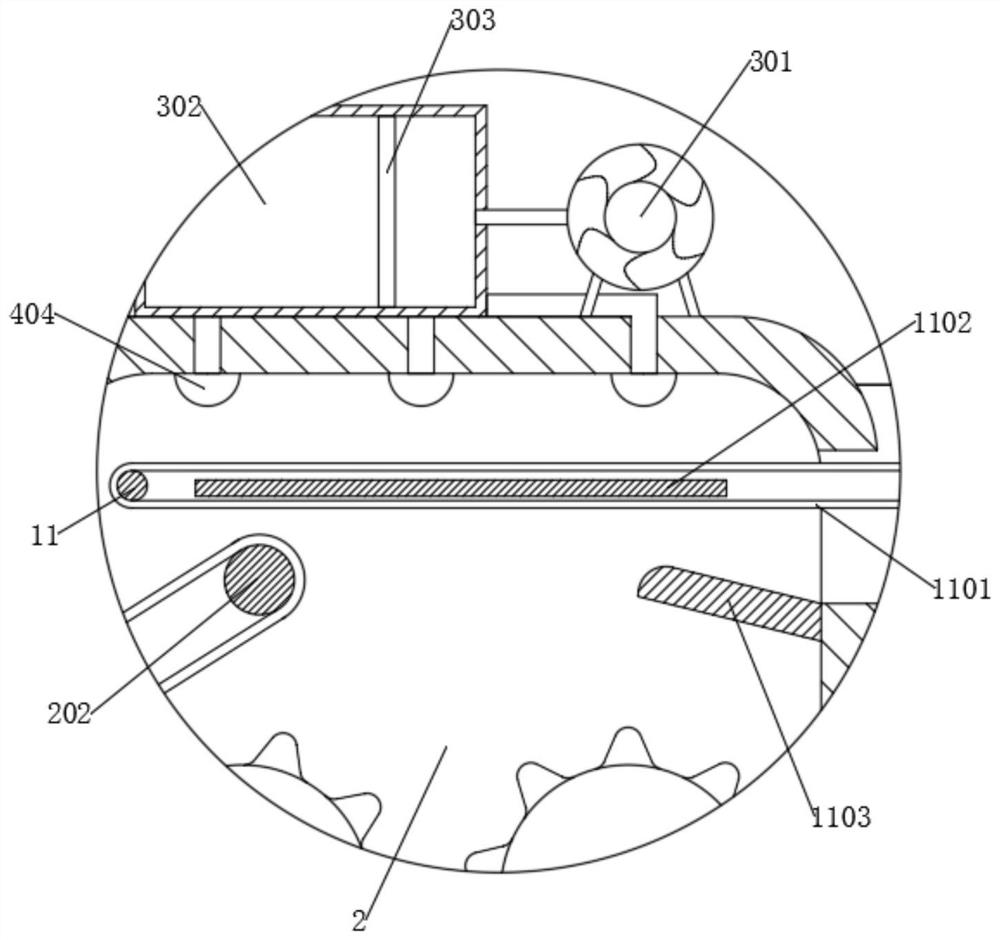

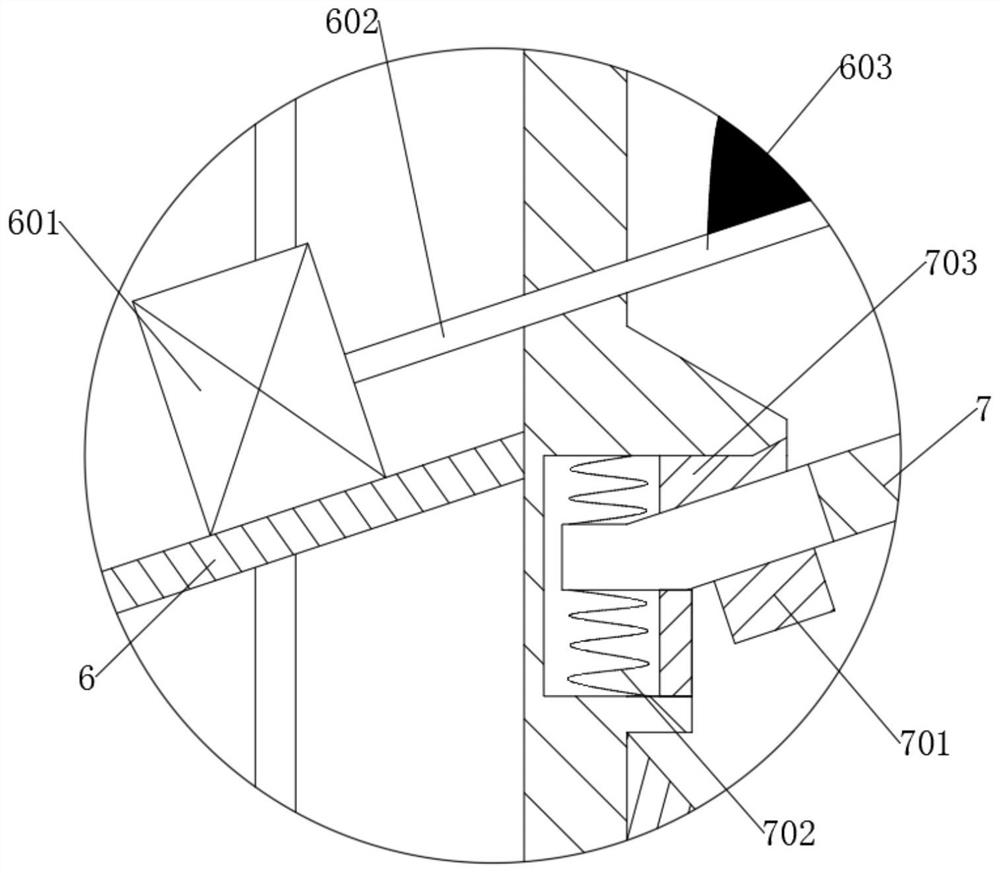

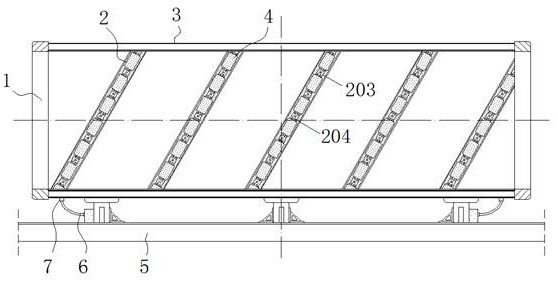

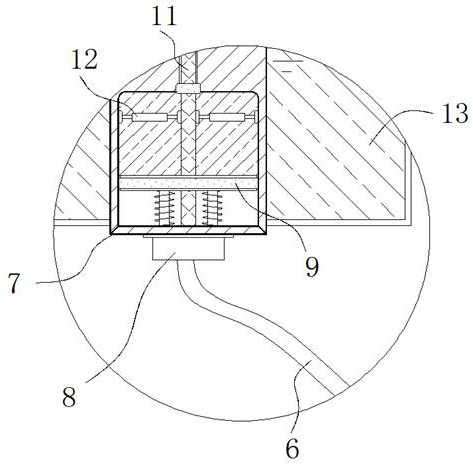

InactiveCN112675996AAchieve the purpose of breakingTo achieve the purpose of drying treatmentSievingScreeningGear wheelAgricultural engineering

The invention discloses movable multifunctional agricultural product processing equipment, and belongs to the technical field of agricultural product processing. The equipment comprises a box body, the box body is internally provided with a crushing cavity, a sterilizing cavity and a conveying cavity, the side surface of the inner wall of the crushing cavity is fixedly connected with four third bearings, first crushing rods and second crushing rods are arranged in the four third bearings in a penetrating mode correspondingly, the first crushing rods mesh with the second crushing rods, and one ends of the first crushing rods and one ends of the second crushing rods penetrate through second bearings and are fixedly connected with a driving gear and a driven gear correspondingly. The equipment has the beneficial effects that a first motor works, the driving gear can be driven to rotate, then the driven gear can be driven to rotate, the first crushing rods and the second crushing rods can rotate in a meshing mode, and thus the purpose of crushing agricultural products is achieved; a drying pump works, external gas can be heated and then conveyed to a spray head through a pipeline, and thus the purpose of drying the agricultural products in the transportation process is achieved.

Owner:新化县日新农业发展有限公司

Fruit crushing device for beverage processing

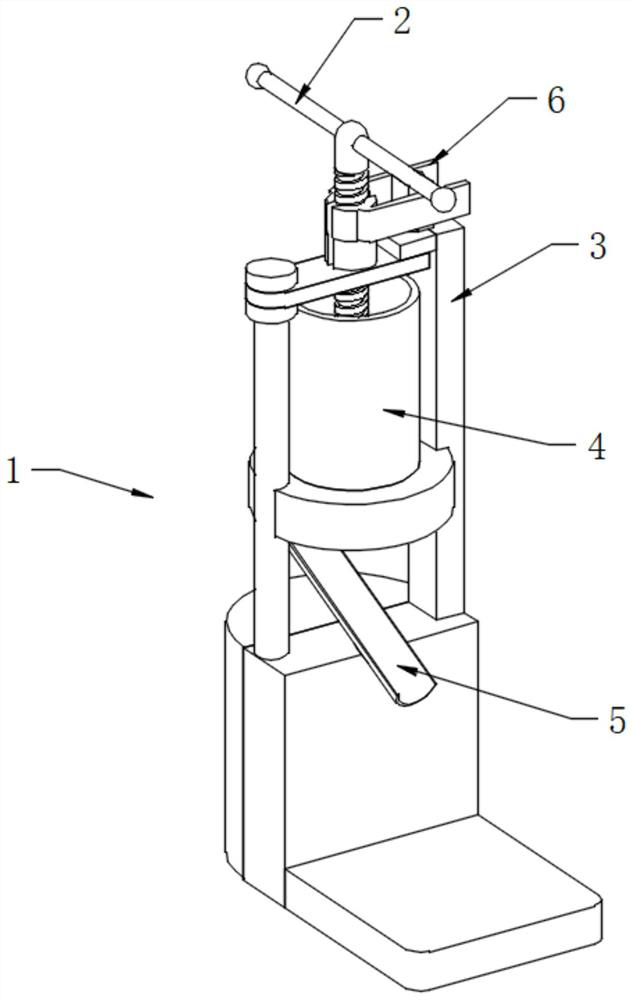

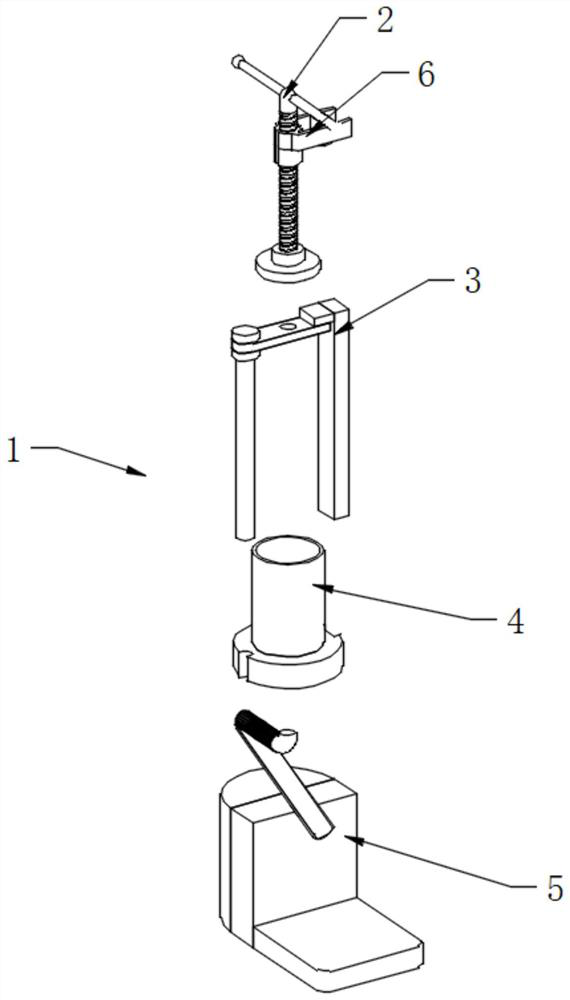

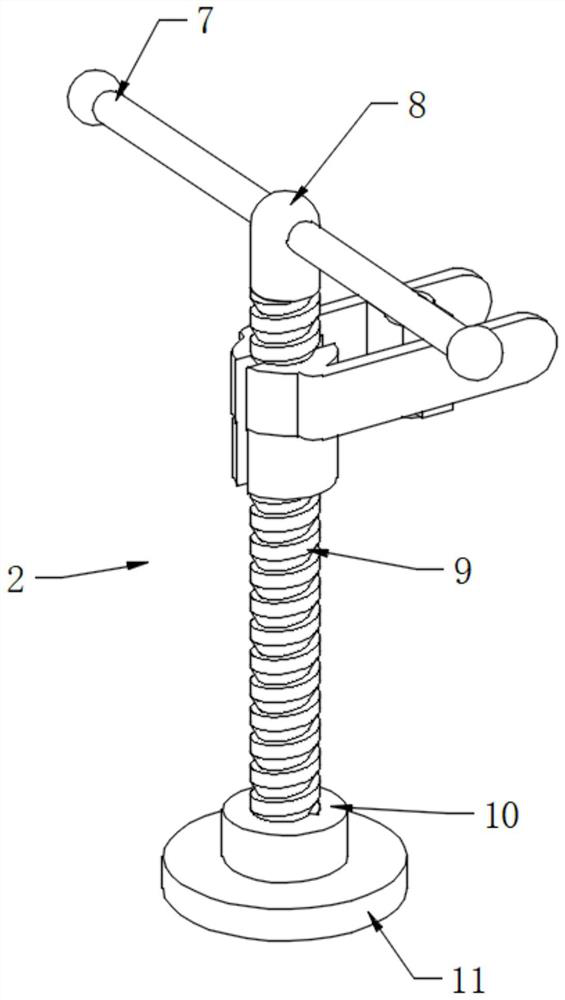

InactiveCN112060661AConvenient crushing workConvenient processing workJuice extractionPress ramBiotechnologySliding contact

The invention discloses a fruit crushing device for beverage processing. The fruit crushing device for beverage processing comprises a fruit crushing structure. The fruit crushing structure comprisesan operation main body, an operation frame, a crushing main body, a solid-liquid separation main body and a control main body, the middle of the operation main body is installed at the inner end of the control main body in a threaded manner, and the lower portion of the operation main body makes sliding contact with the crushing main body. The lower portion of the operation main body is located onthe inner side of the crushing main body, the operation main body is inserted into the inner end of the upper portion of the operation frame in a sliding manner, the lower end of the operation frameis fixedly installed at the upper end of the solid-liquid separation main body, and the outer end of the crushing main body is fixedly installed at the inner end of the upper portion of the operationframe. The upper end of the solid-liquid separation main body and the crushing main body are fixedly installed together, and the internal space of the crushing main body communicates with the upper space of the solid-liquid separation main body. According to the fruit crushing device for beverage processing, juicing work can be directly carried out after crushing, slag can be automatically discharged, and the use requirement can be better met.

Owner:绍兴市上虞裕润农业科技有限公司

Solid waste treatment device for lighting lamp manufacturing

PendingCN112916113ATo achieve the purpose of dust removalPlay the effect of dust removal againUsing liquid separation agentDirt cleaningDust controlAir pump

The invention discloses a solid waste treatment device for lighting lamp manufacturing, and belongs to the technical field of waste treatment. The solid waste treatment device for lighting lamp manufacturing comprises a bottom plate and a first crushing tank, wherein the first crushing tank is located on the bottom plate, a feeding mechanism is arranged on the side wall of the first crushing tank, the feeding mechanism is sleeved with a dust removal cylinder, a dust removal mechanism is arranged on the dust removal cylinder, a first crushing mechanism is arranged in the first crushing tank, a second crushing tank is arranged on the bottom plate, a conveying mechanism is arranged between the second crushing tank and the first crushing tank, and a second filter plate is rotationally connected to the side wall of the first crushing tank. The device is simple in structure and reliable in work, achieves the purpose of crushing through mutual cooperation of first crushing cylinders and second crushing cylinders, achieves the purpose of dust removal during crushing through interaction of an air pump and a water pump, and achieves the purpose of metal separation through an electromagnet, thereby improving the practicability.

Owner:XIAMEN FRIENDLY LIGHTING TECHNOLOGY CO LTD

Constructional engineering pollution discharge anti-blocking pipeline

PendingCN114687437ARealize the intermittent import of electric energyTo achieve the creep effectSewer cleaningVibration suppression adjustmentsElectrical conductorArchitectural engineering

The invention discloses a building engineering pollution discharge anti-blocking pipeline which comprises a plastic pipe body, embedded cavities are formed in the inner side wall of the plastic pipe body at equal intervals, an outer coating rubber strip is fixed to the outer wall of the plastic pipe body in the direction of the embedded cavities, and a conductor wire for electrical element connection is arranged in the outer coating rubber strip; an elastic rubber strip is fixed on the inner side wall of the plastic tube body along the direction of the embedded cavity; the outer support is arranged below the plastic tube body, and a wire is arranged on the outer support; the liquid sealing plate is movably mounted in the electrical communication cavity; and one end of the rubber-coated conductor penetrates through the liquid sealing plate and the electrical communication cavity and is arranged in the communication piece. When the building engineering pollution discharge anti-blocking pipeline is used, the heat expansion and cold contraction effect of liquid can be utilized, electric energy in the pipeline is intermittently guided in, components are controlled to be intermittently started, the wriggling effect of the components in the pipeline is achieved, and dirt accumulated and blocked in the pipeline is dredged.

Owner:许文娟

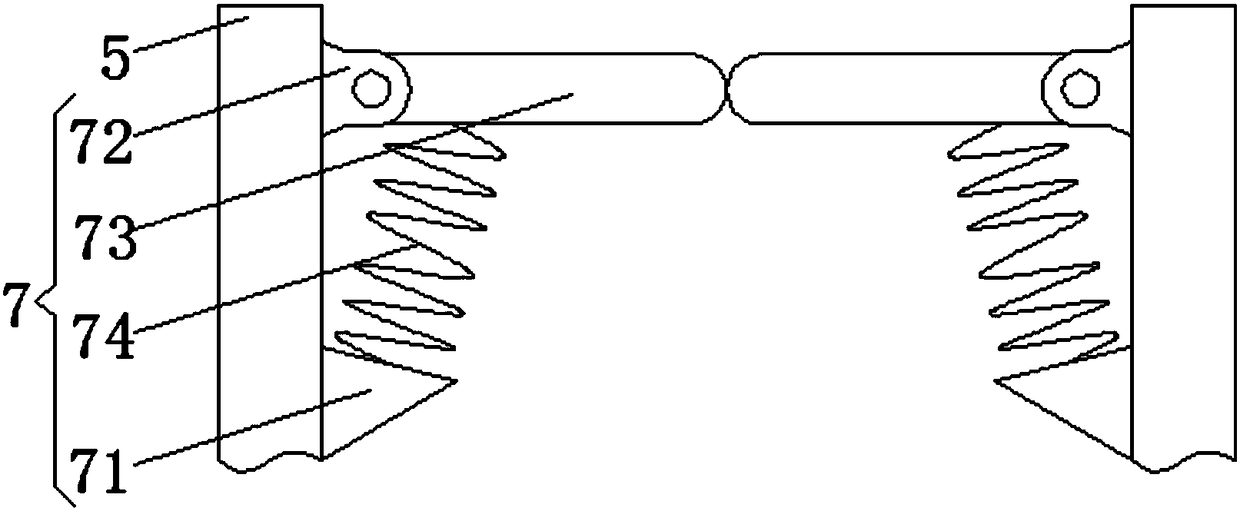

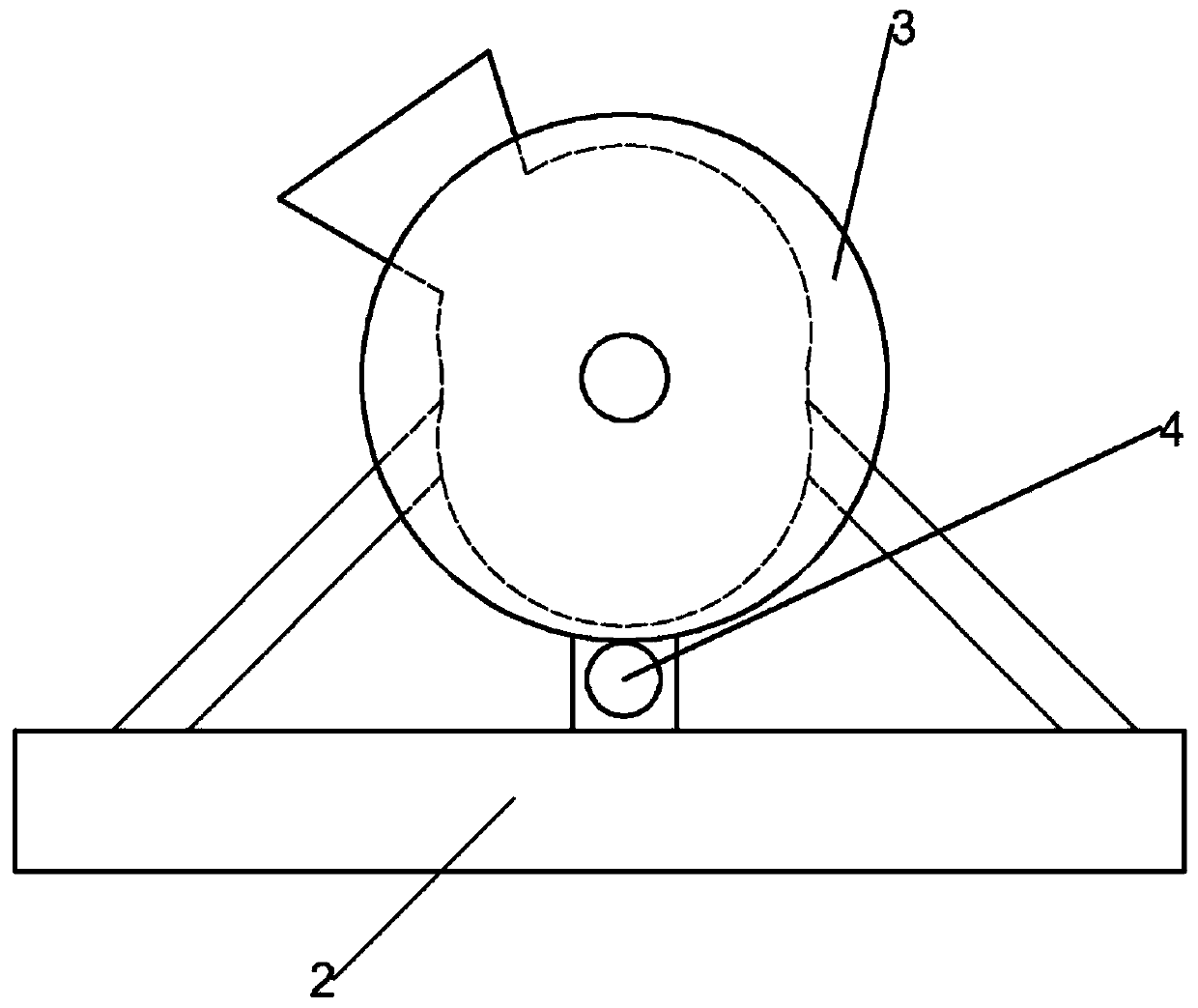

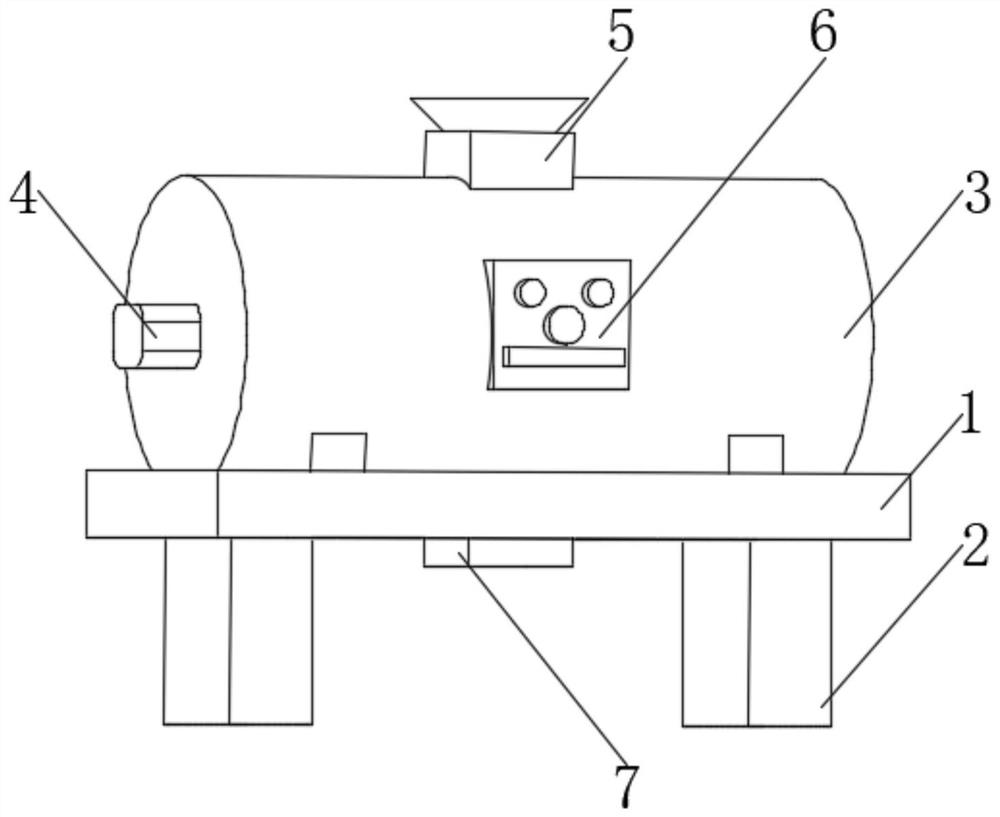

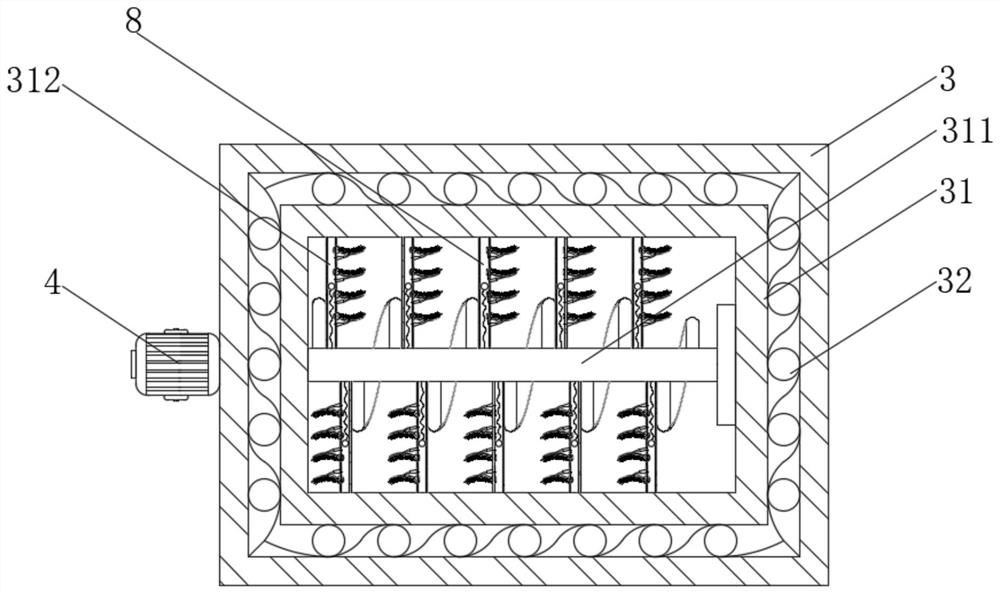

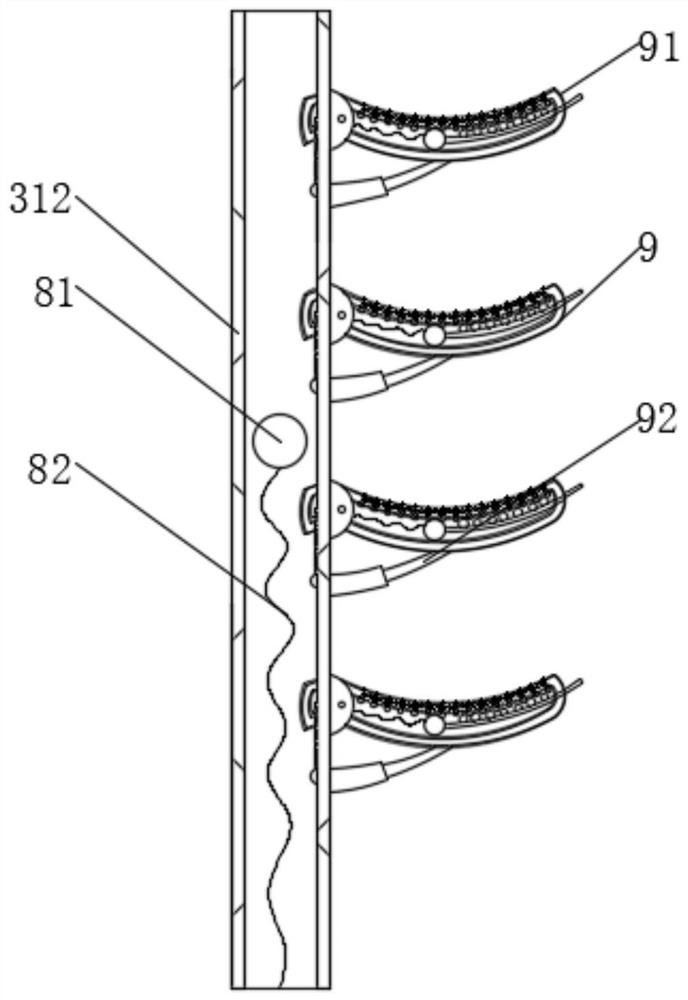

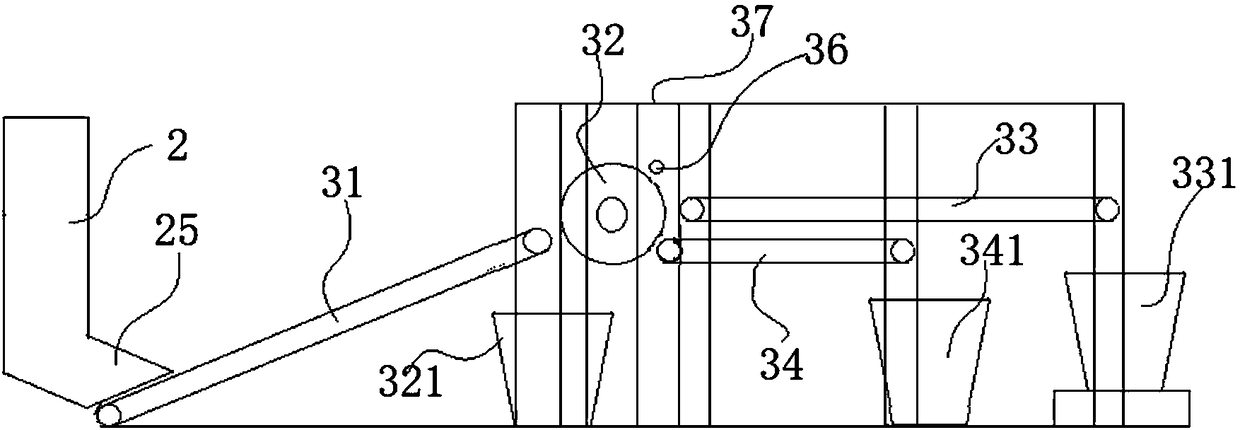

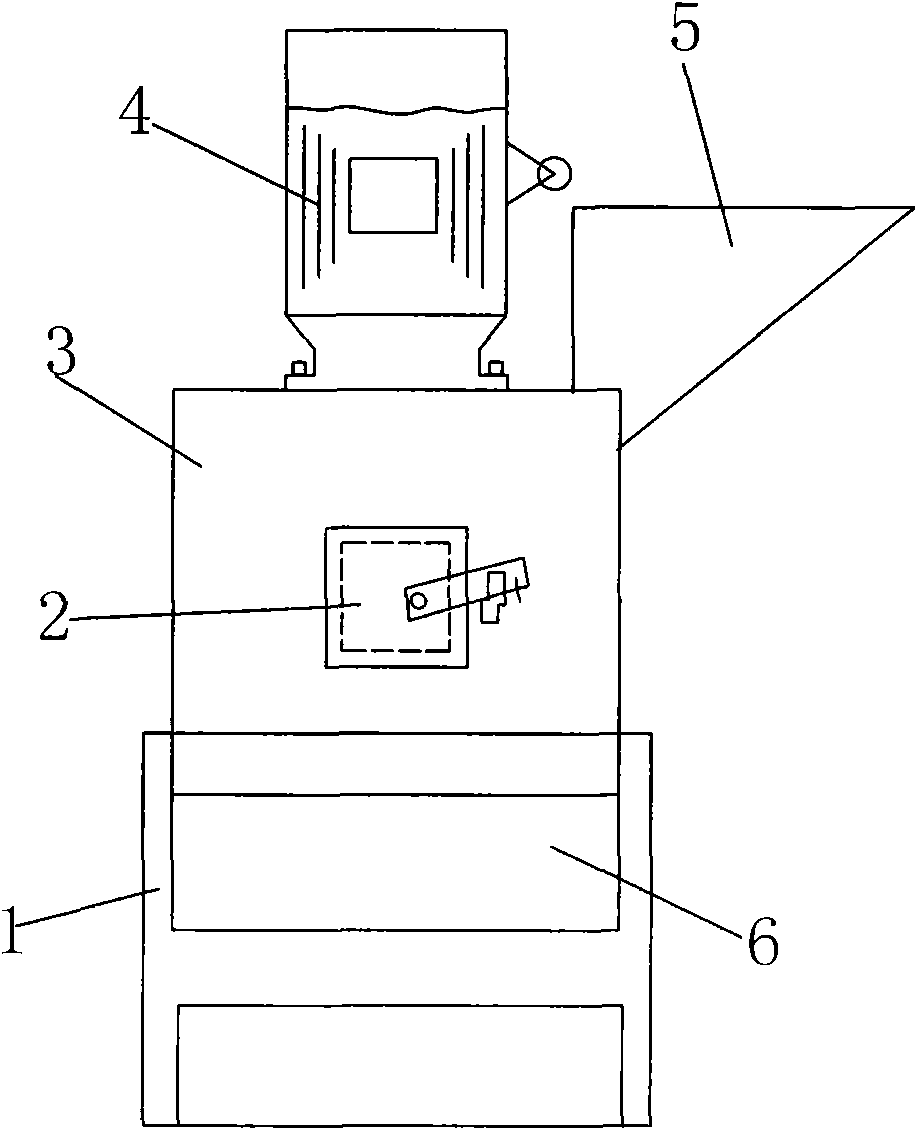

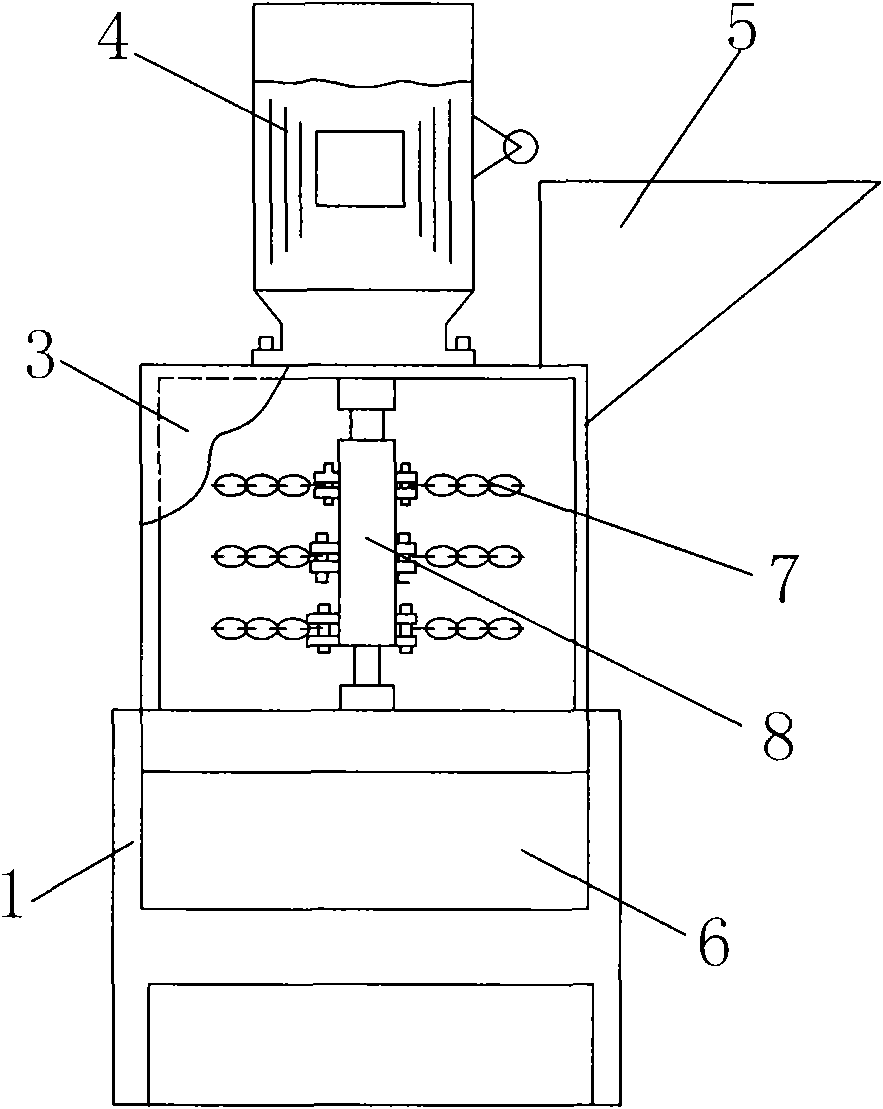

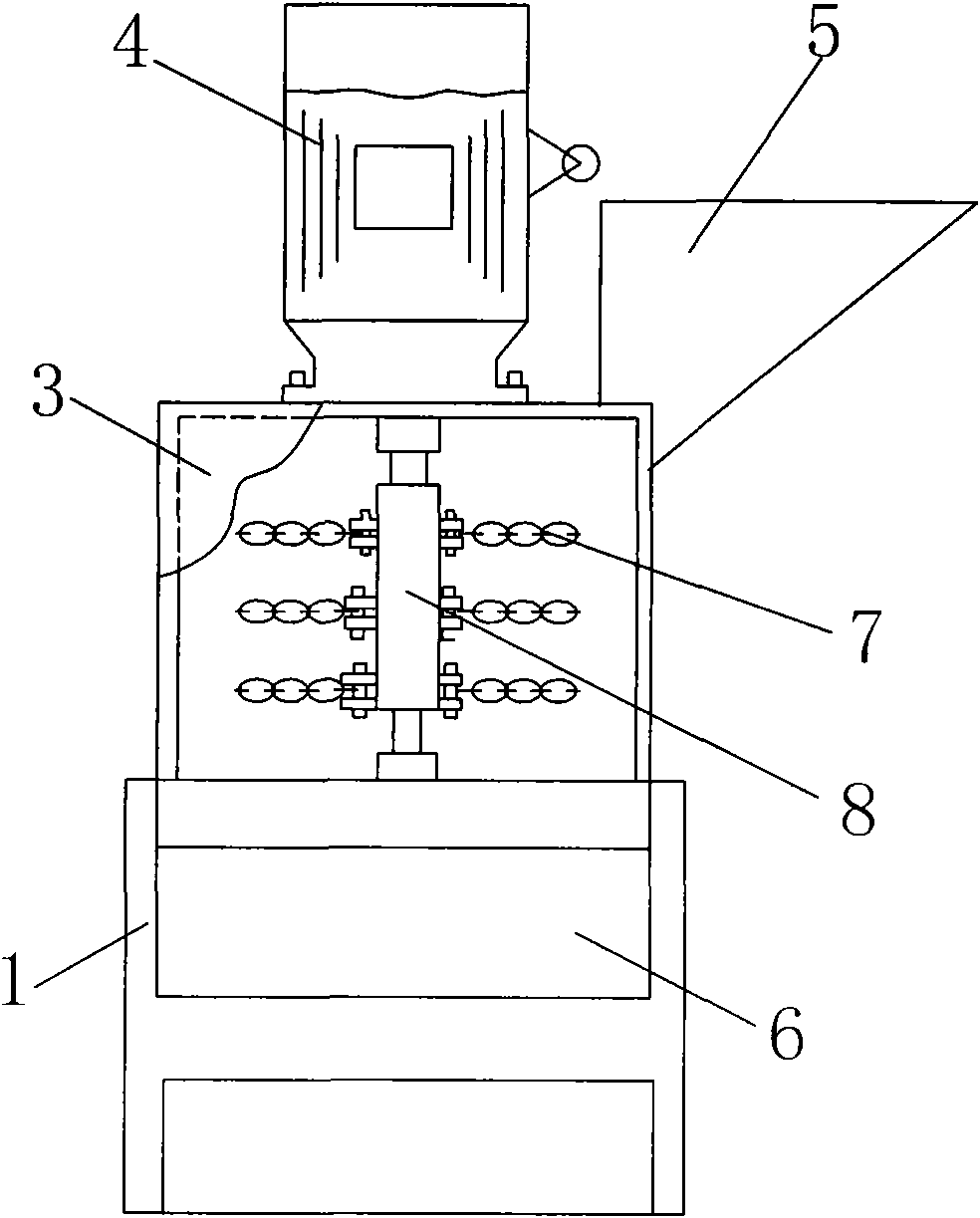

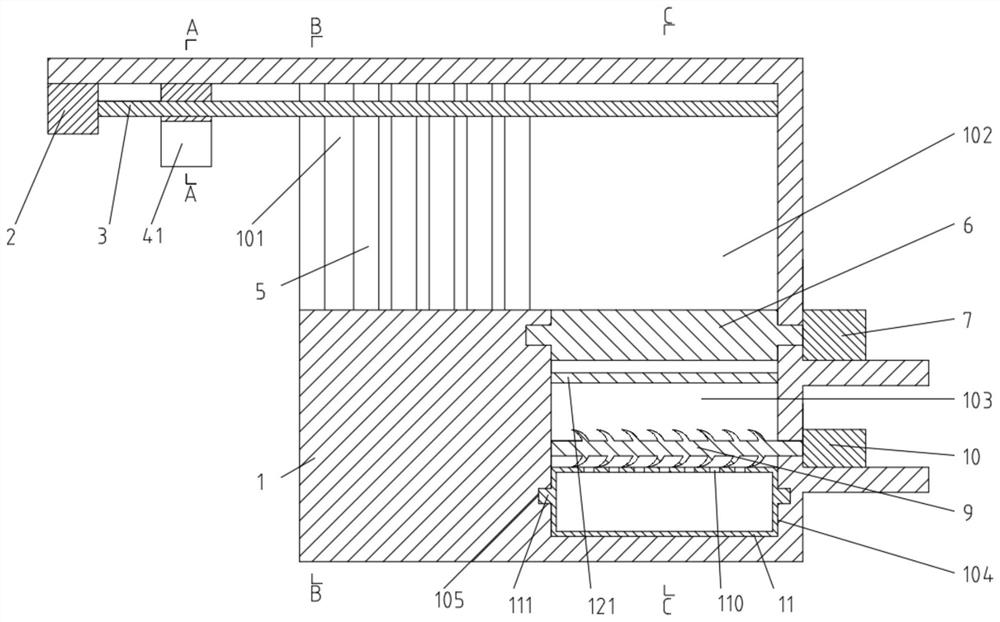

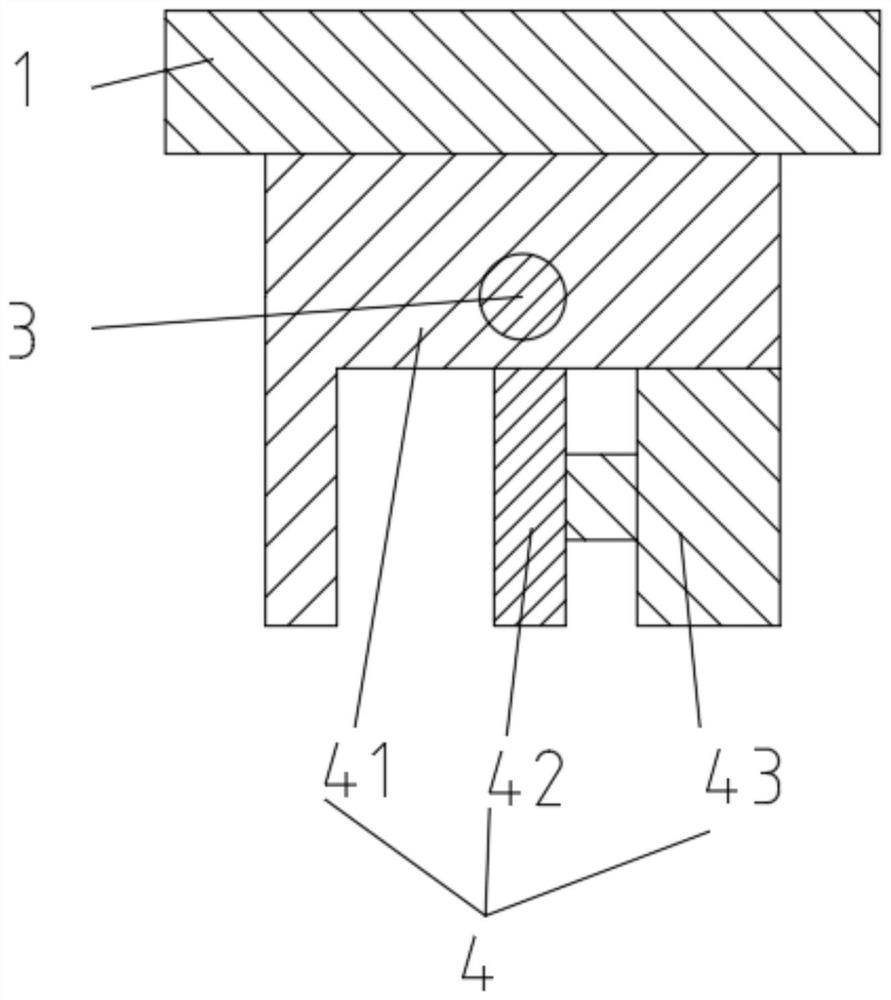

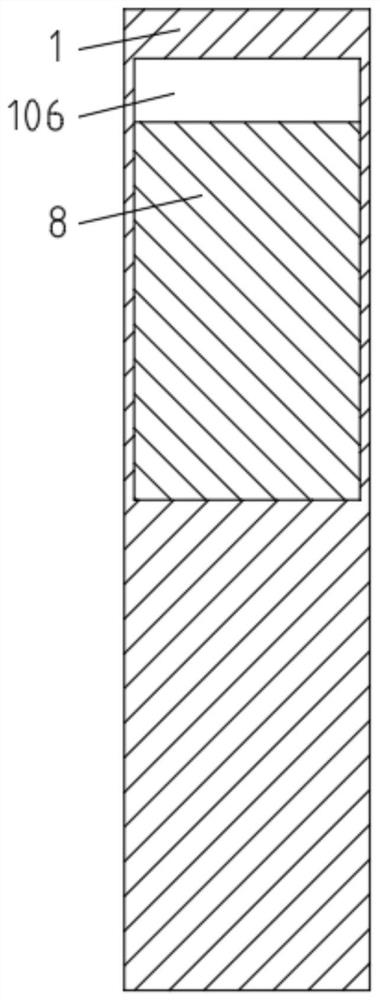

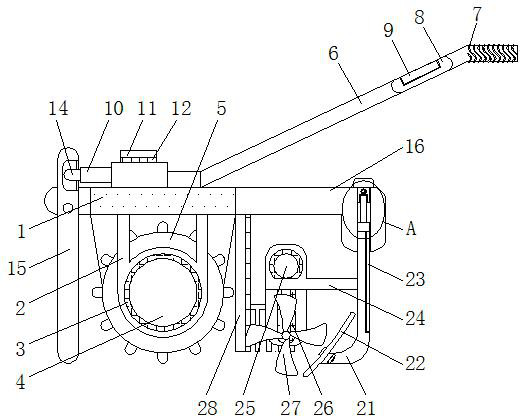

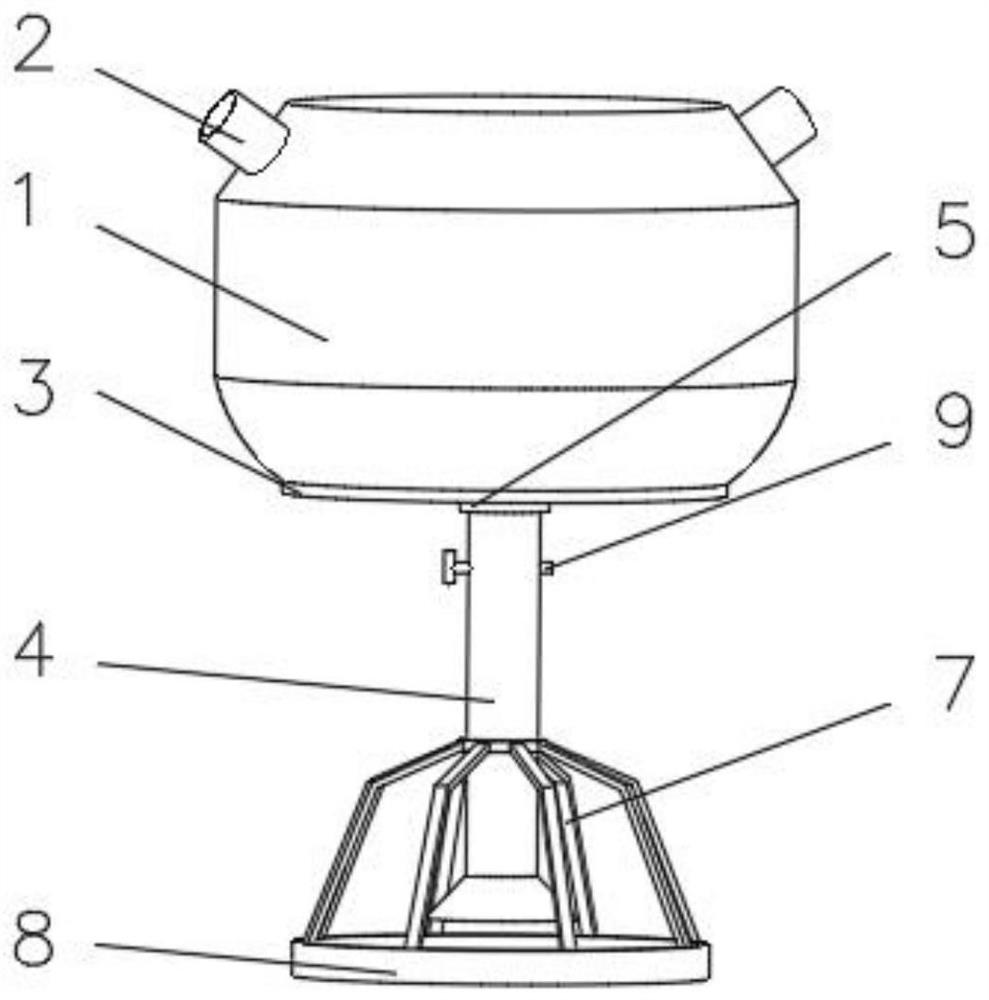

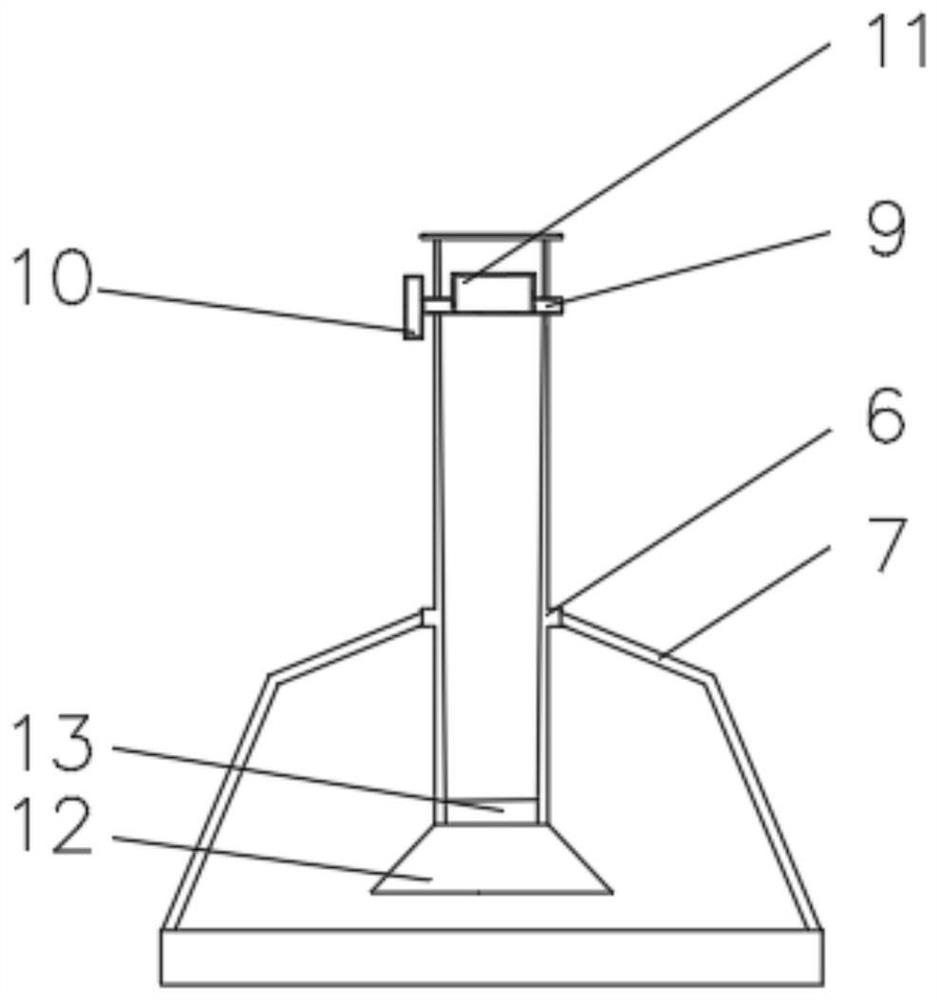

Vertical chicken manure pulverizer

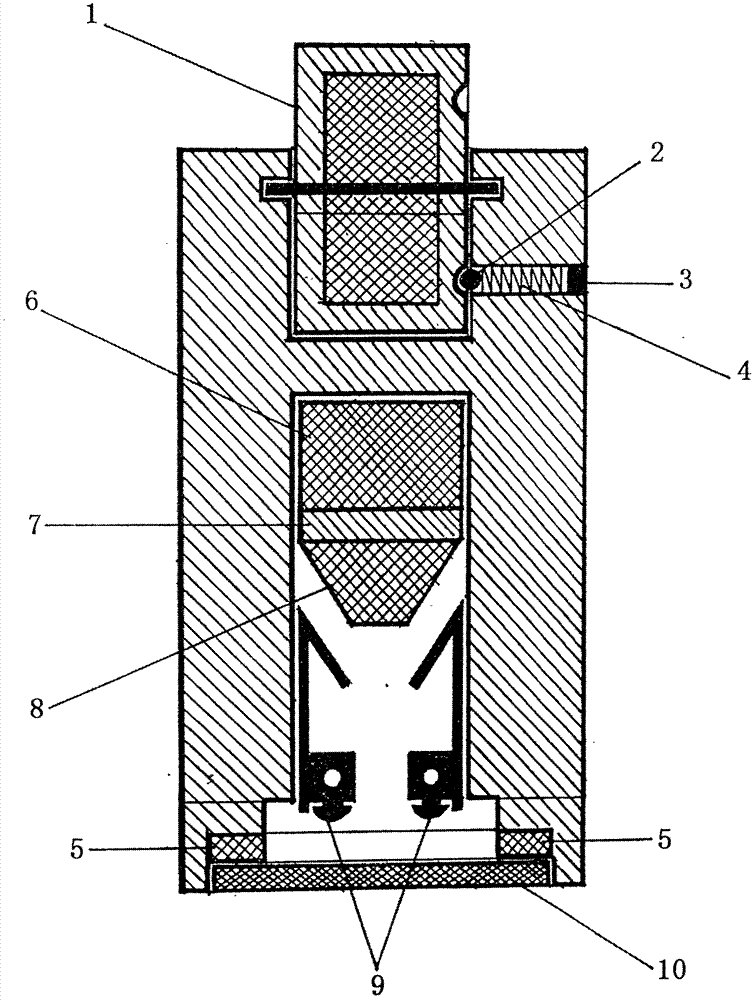

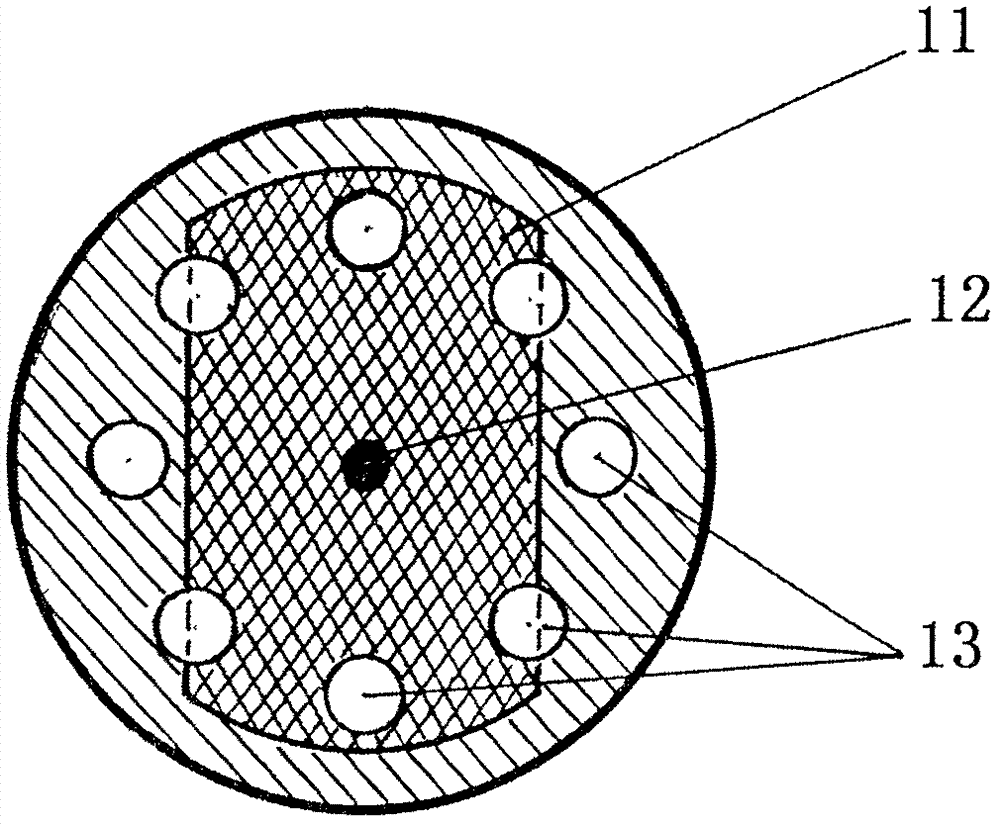

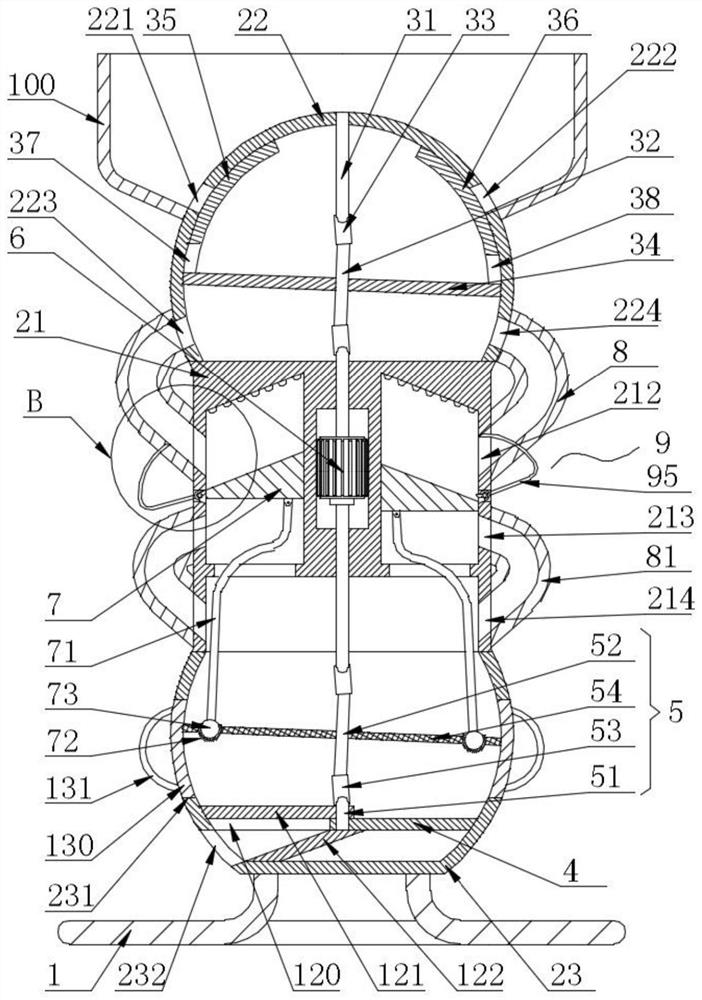

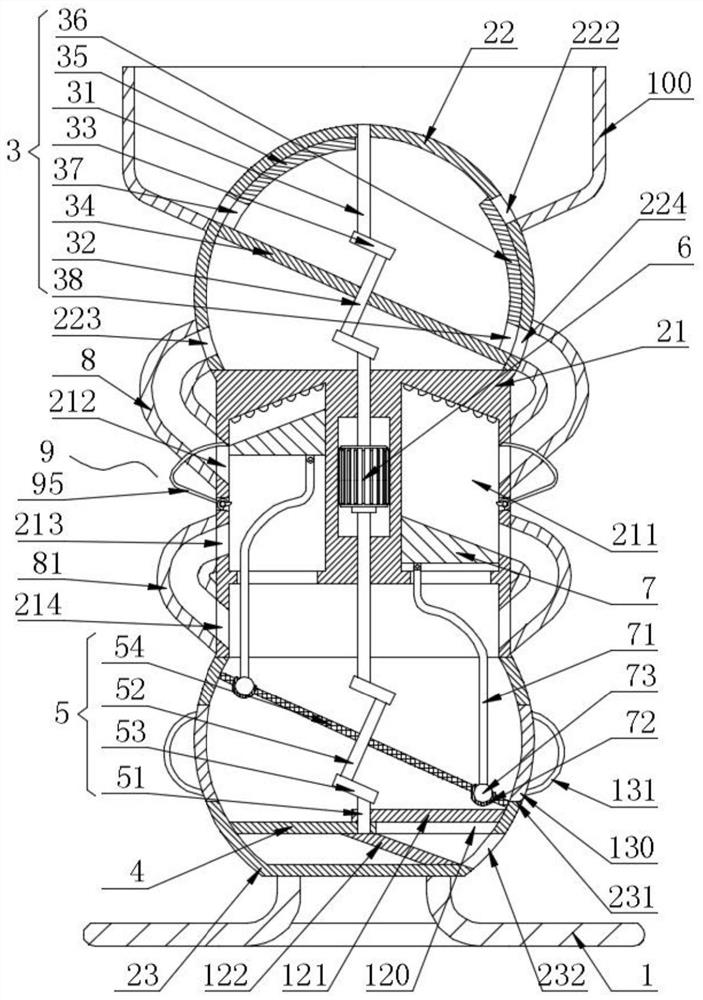

InactiveCN101890385ARealize mechanized crushingFew partsGrain treatmentsElectric machineryEngineering

The invention discloses a vertical chicken manure pulverizer which is characterized by comprising a stand (1), a shell (3) fixed on the stand (1) and a crushing device arranged in the shell (3), wherein the crushing device comprises a rotating shaft (8) and a plurality of hammer chains (7) flexibly connected to the side face of the rotating shaft (8); the upper end and the lower end of the rotating shaft (8) are flexibly connected above and below the shell (3); a discharge outlet (6) is arranged below the shell (3), and the side face above the shell (3) is provided with a feed inlet (5); a motor (4) is also fixed on the shell (3); and an output shaft of the motor (4) is in transmission connection with the rotating shaft (8) to drive the rotating shaft (8) to rotate. The vertical chicken manure pulverizer has simple structure, low use cost and high crushing efficiency.

Owner:铜陵正强禽业有限责任公司

Waterproof power supply switch

InactiveCN107170643AReach conductionAchieve the purpose of breakingMagnetic movement switchesMagnetic polesElectrode

The invention relates to a waterproof power supply switch which comprises a wheel-shaped magnet, a positioning device, a magnet slider, an electrode body, a power on indicator, an exposed chamber and a sealing chamber. The wheel-shaped magnet comprises a bar-shaped magnet, a shaft bar and a positioning round pit. The magnet slider comprises a square magnet, an insulator and a conductor. The positioning device comprises a ball, a spring and a blocking body. The wheel-shaped magnet and the positioning device are exposed outside. The magnet slider and the electrode body are sealed in a chute chamber. The wheel-shaped magnet is rotated, so that the magnetic pole changes to drive the magnet slider to produce interaction to turn on or off a power supply.

Owner:唐荣

Construction engineering stone crusher

InactiveCN111472572AHearing protectionWon't cause flyingBuilding repairsDaily livingArchitectural engineering

The invention discloses a construction engineering stone crusher which comprises a case body, wherein a top block is fixedly arranged on the upper end surface of an inner cavity; the inner cavity withan opening is arranged in the case body; the upper end surface of the case body is provided with a shielding device for sliding and sealing the inner cavity so as to shield from sound; a dismountingdevice which is fixed to the shielding device is arranged in the inner cavity; and the dismounting device adopts the combination of cutting and expansion to dismount cement walls of sewage tanks. Theconstruction engineering stone crusher is simple in structure. The construction engineering stone crusher adopts cutting and hydraulic expansion ways to fully crush cement on circumferential surface walls of the sewage tanks. In addition, the method of sealing the sewage tanks is utilized in the crushing process so as to enable the equipment to be quiet during processing, avoid the influence on the daily lives and work of surrounding people, protect the hearing of builders, avoid dust rising, and protect the environment.

Owner:杨桂英

Wall breaking and deep dewatering treatment method for remaining active sludge

ActiveCN109912174AUse less medicineReduce doseSludge treatment by de-watering/drying/thickeningActivated sludgeMagnetic separator

The invention discloses a wall breaking and deep dewatering treatment method for remaining sludge. According to the treatment method, remaining active sludge is fed into a wall breaking homogenizationgroove; a treating agent is added into the homogenizing groove; the treated sludge is subjected to osmotic pressure impact wall breaking; the wall-broken sludge is introduced into the feeding grooveof a magnetic separator, a water treatment agent, an auxiliary agent and magnetic powder are added, and a reaction is performed for a certain time; magnetic separation is performed, and solid-liquid separation is performed while the sewage is treated; and the separated water can be directly discharged or circulated, the separated solid is further subjected to dewatering treatment after magnetic powder recovery, and the sludge after the dewatering has a water content of less than or equal to 45%, and can be used as the further resource raw material.

Owner:CHINA PETROLEUM & CHEM CORP +1

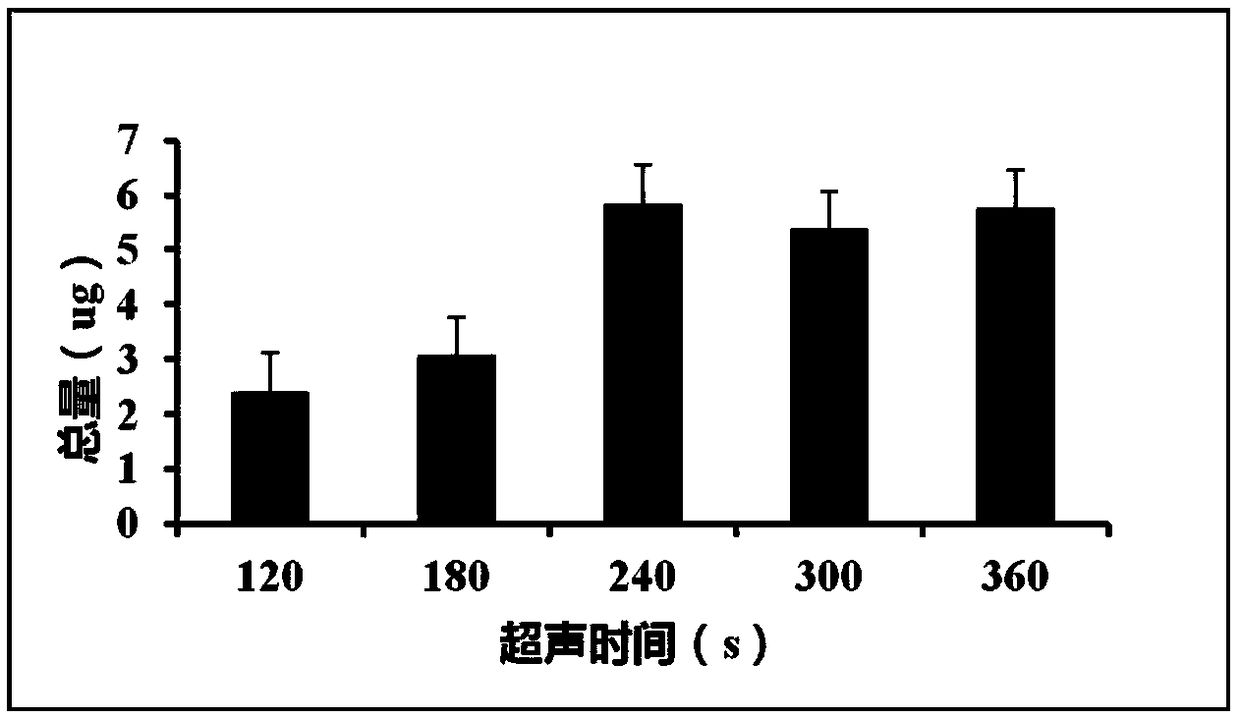

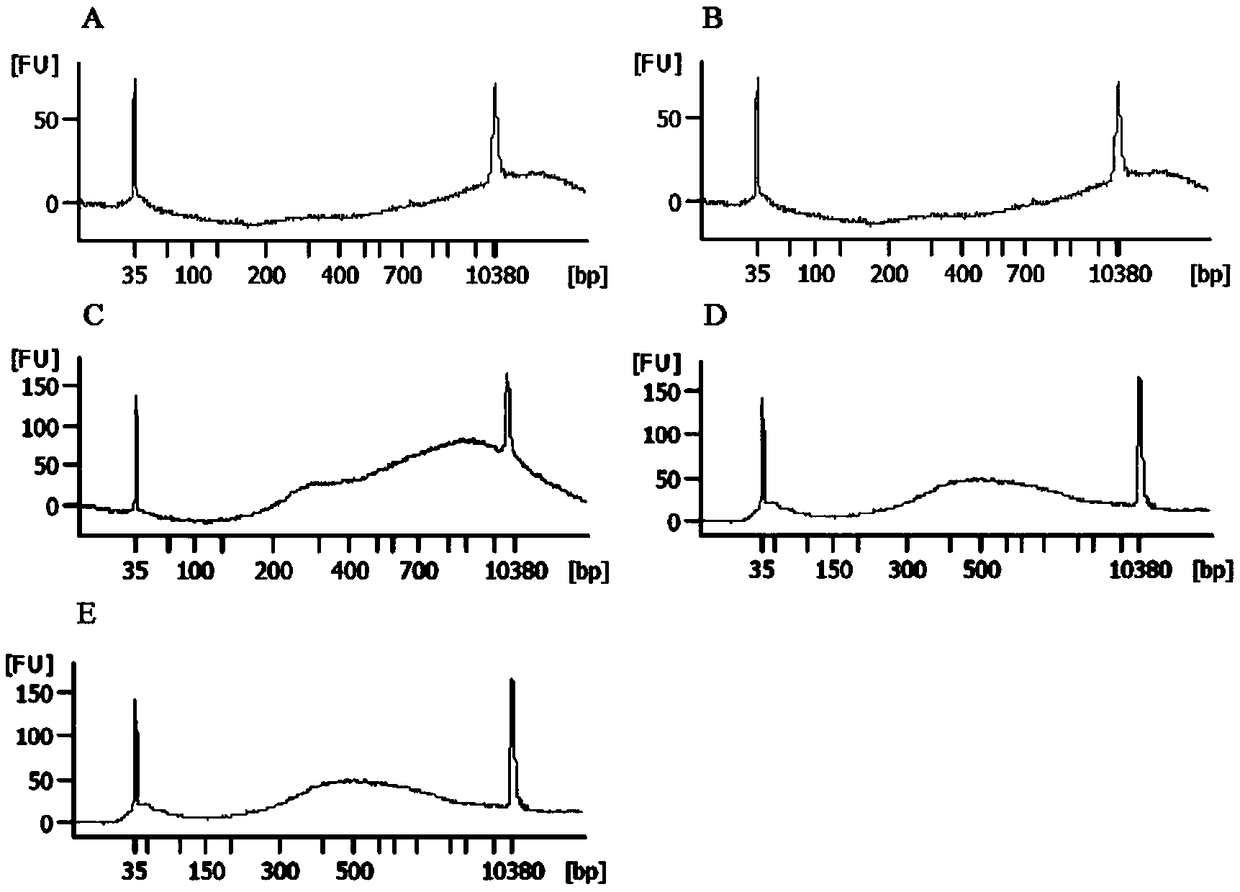

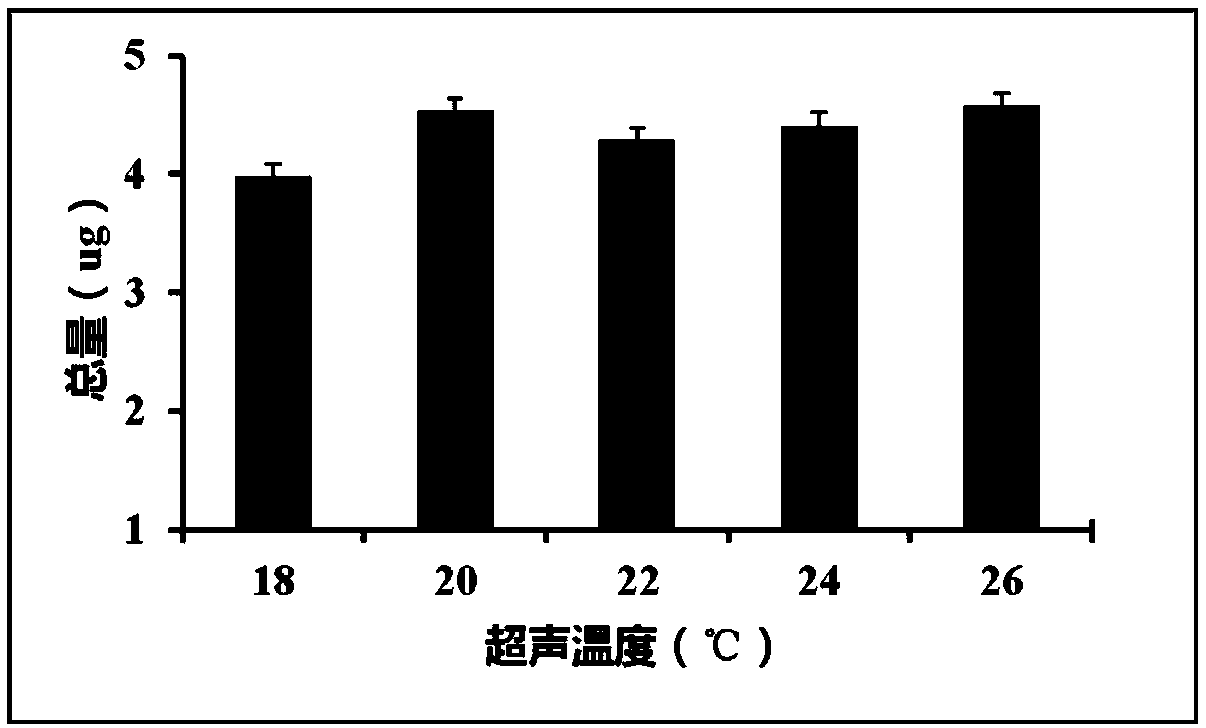

Extracting kit for formalin soaked tissue DNA and extraction method

The invention provides an extracting kit for a formalin soaked tissue DNA and an extraction method, belonging to the technical field of DNA extraction. The kit contains the following components: an SDS buffer solution, a binding buffer solution, proteinase K, DNA purified magnetic beads, a first cleansing solution, a second cleansing solution and eluant. The extraction method comprises the following steps: (1) mixing a formalin soaked tissue with the SDS buffer solution, carrying out ultrasonic crushing so as to obtain a lysis solution, and carrying out two-step digestion on the lysis solutionby virtue of proteinase K; and carrying out extraction by virtue of the DNA purified magnetic beads, and carrying out elution by virtue of the eluant, so as to obtain the formalin soaked tissue DNA.According to the extracting kit and the extraction method, the extraction of the formalin soaked tissue DNA can be realized, and the extracted DNA is good in quality and high in recycling rate.

Owner:GENE CRAB BIOTECH CO

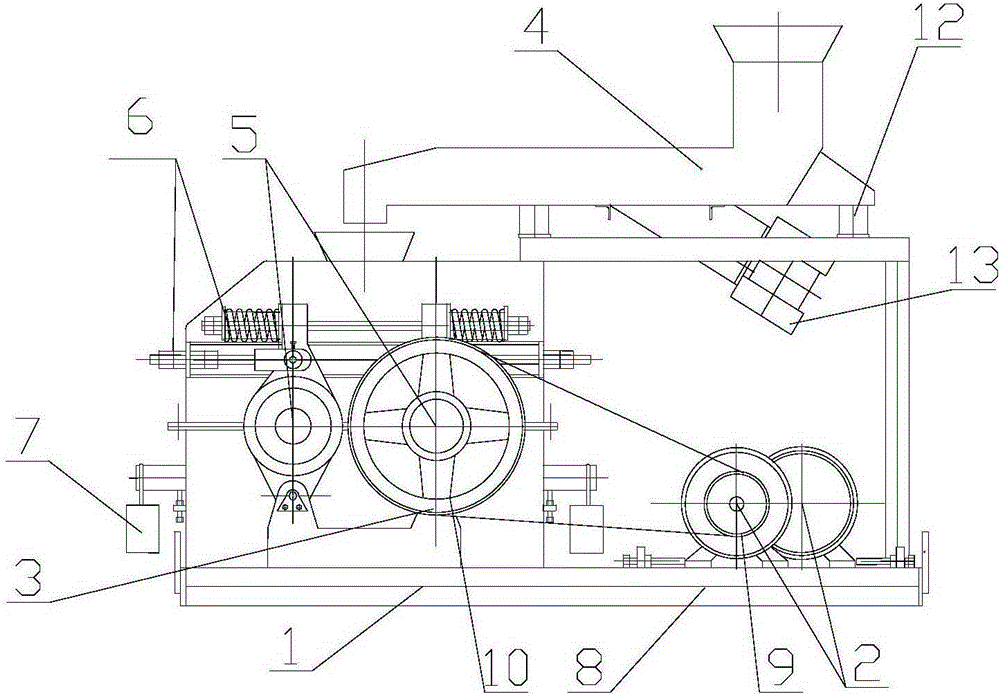

Crushing machine for salt

InactiveCN105327735AAchieve the purpose of breakingSmall granularityGrain treatmentsGranularityMaterial distribution

The invention relates to a crushing machine for salt. Two motors are connected with two crushing rollers through belt wheels. Motor spindle noses are fixed to small sheaves, crushing roller spindle noses are fixed to large sheaves, and the diameters of the two large sheaves are different. An adjustment mechanism for adjusting the gap between the crushing rollers is arranged between the two crushing rollers. A blanking hopper is arranged above the two crushing rollers. The inlet of the blanking hopper is connected with a material distribution device. According to the crushing machine for salt, materials are evenly fed to the space between the two crushing rollers through the material distribution device, the two crushing rollers are driven by the two motors respectively, shearing and squeezing functions of tooth angles of the crushing rollers are formed through the speed difference of the two crushing rollers rotating in the opposite directions, and therefore the purpose of crushing the materials is realized. The crushing machine is suitable for crushing treatment of marine salt particles to facilitate bagging, the over-crushing degree is small, and the granularity is uniform. The crushing machine for salt is simple in structure, high in reliability, small in noise, low in power consumption, adjustable in crushing granularity, compact in structure and convenient to use and repair.

Owner:ENG TECH INST CO LTD OF CNSIC

High efficient and environmental friendly ore crusher for mining capable of adjusting sizes of particles

The invention discloses a high efficient and environmental friendly ore crusher for mining capable of adjusting the sizes of particles, and belongs to the technical field of ore crushers. The high efficient and environmental friendly ore crusher for mining capable of adjusting sizes of the particles comprises a material sending support, a crushing device and a material receiving device, the material sending support is connected to the top of the crushing device, the material receiving device is connected to the bottom of the crushing device, the crushing device comprises an upper machine bodyand a lower machine body, the upper machine body is internally connected with a material inputting hopper and a fixing lining plate, the lower machine body is internally connected with a floating bush, the bottom of the floating bush is connected with an eccentric shaft, and the bottom of the lower machine body is connected with a discharging bin. According to the high efficient and environmentalfriendly ore crusher for mining capable of adjusting sizes of the particles, the stereo material sending support is arranged, working strength is reduced, the working efficiency is improved, the material receiving device is arranged, thus in-time transportation of crushed ores is guaranteed, it is avoided that the crushed ores block the discharging bin and influence the normal operation of the crushing device, an inclined plate is arranged, thus damages of the ores on the crushing device is reduced, and the service life of machinery is prolonged.

Owner:董佑军

Garbage treatment system

ActiveCN111389885AIncrease contactEasy to handleSolid waste disposalHollow article cleaningEngineeringRefuse Disposals

The invention provides a garbage treatment system which comprises a garbage crushing device, an agglomeration breaking device, a screening device and a digestion cell. The agglomeration breaking device comprises a rake plate, a separating grid plate, an executing mechanism and a winnowing mechanism. The rake plate is arranged obliquely and comprises a rake body and a plurality of separating teeth,wherein air holes, the diameters of which are 1.5-3.0 mm, are formed in the rake body and the separating teeth are distributed on the rake body; the winnowing mechanism is arranged on one side belowthe rake plate for blowing away light garbage in the garbage on the rake plate; the separating grid plate under the action of the executing mechanism can stir in another plane while vibrating in a plane, and meanwhile, the separating grid plate can overturn integrally around an axis to transport the garbage to the screen device. The screen device is used for receiving the garbage treated by the agglomeration breaking device and transferring the garbage to the digestion cell to be treated. The garbage treatment system can perform crushing, primary winnowing, screen separating and screening on the garbage successively, so that a phenomenon that the garbage is bonded and agglomerated can be avoided effectively.

Owner:GUANGDONG TESTING INST OF PROD QUALITY SUPERVISION

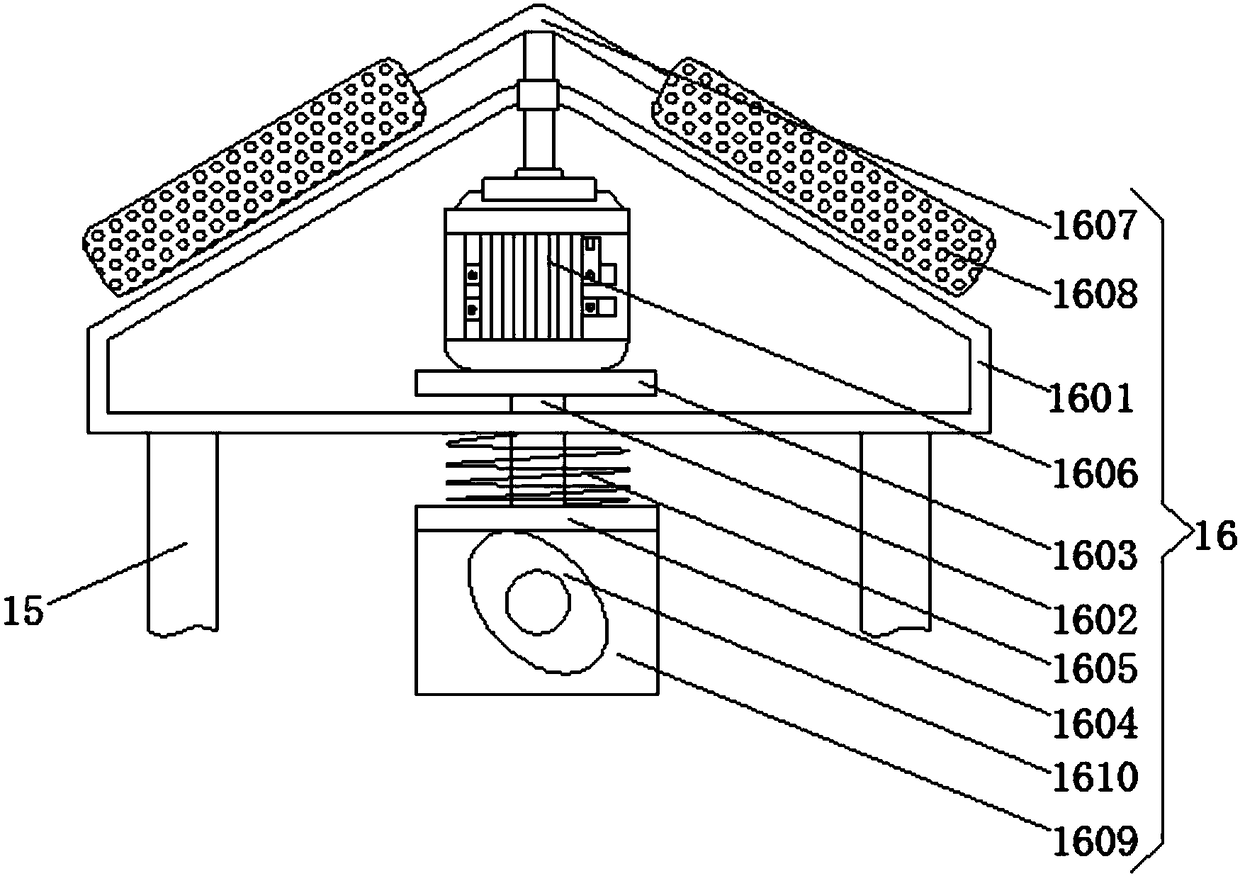

Animal carcass harmless treatment crusher

InactiveCN112845527AAchieve the purpose of breakingShorten the timeSolid waste disposalTransportation and packagingAnimal scienceBall screw

The invention discloses an animal carcass harmless treatment crusher which comprises a machine body, a first motor, a ball screw, a fixator, a heating plate and two tooth rollers. The machine body is provided with a drying chamber and a crushing chamber; an animal carcass is fixed on the fixator; the first motor operates to drive the fixator to move towards the interior of the machine body; when the animal carcass moves to the drying chamber, the heating plate heats the animal carcass so as to dry the animal carcass; after drying, the first motor operates to drive the fixator to move towards the crushing chamber; when the animal carcass moves to the crushing chamber, the tooth rollers crush the animal carcass; the two tooth rollers rotate oppositely to crush the animal carcass so as to fulfill the aim of crushing the animal carcass; and the animal carcass is dried through the drying chamber, so that time required by natural air drying of the animal carcass is shortened, thereby saving the time.

Owner:朗瀚智能装备(江苏)有限公司

Remediation device for land soil treatment

InactiveCN114309033ASmooth dischargeAchieve vibrationShaking/oscillating/vibrating mixersTransportation and packagingSoil treatmentSoil remediation

The invention discloses a remediation device for land soil remediation, which comprises a support, the left end of the top of the support is movably connected with a storage box through a first spring, the middle end of the bottom of the storage box is fixedly provided with a first vibration motor, and the left end of the bottom of the support is movably connected with a second support plate through a second electric telescopic rod. A first vibration motor and a first spring are arranged, a repairing agent in a storage box can be smoothly discharged from a discharging pipe, the phenomenon that the repairing effect is affected due to the fact that the discharging pipe is blocked is avoided, and a second electric telescopic rod, a second vibration motor, a second spring and a vibration plate are arranged, so that the repairing effect is improved. A second electric telescopic rod stretches out and draws back to adjust the height of a vibrating plate, so that the purpose of vibrating soil with different depths is achieved, a second vibrating motor can drive the vibrating plate to vibrate under the action of a second spring while vibrating, and then the treated soil is subjected to vibration mixing treatment; the mixing effect of the repairing agent and the soil is improved.

Owner:刘翔

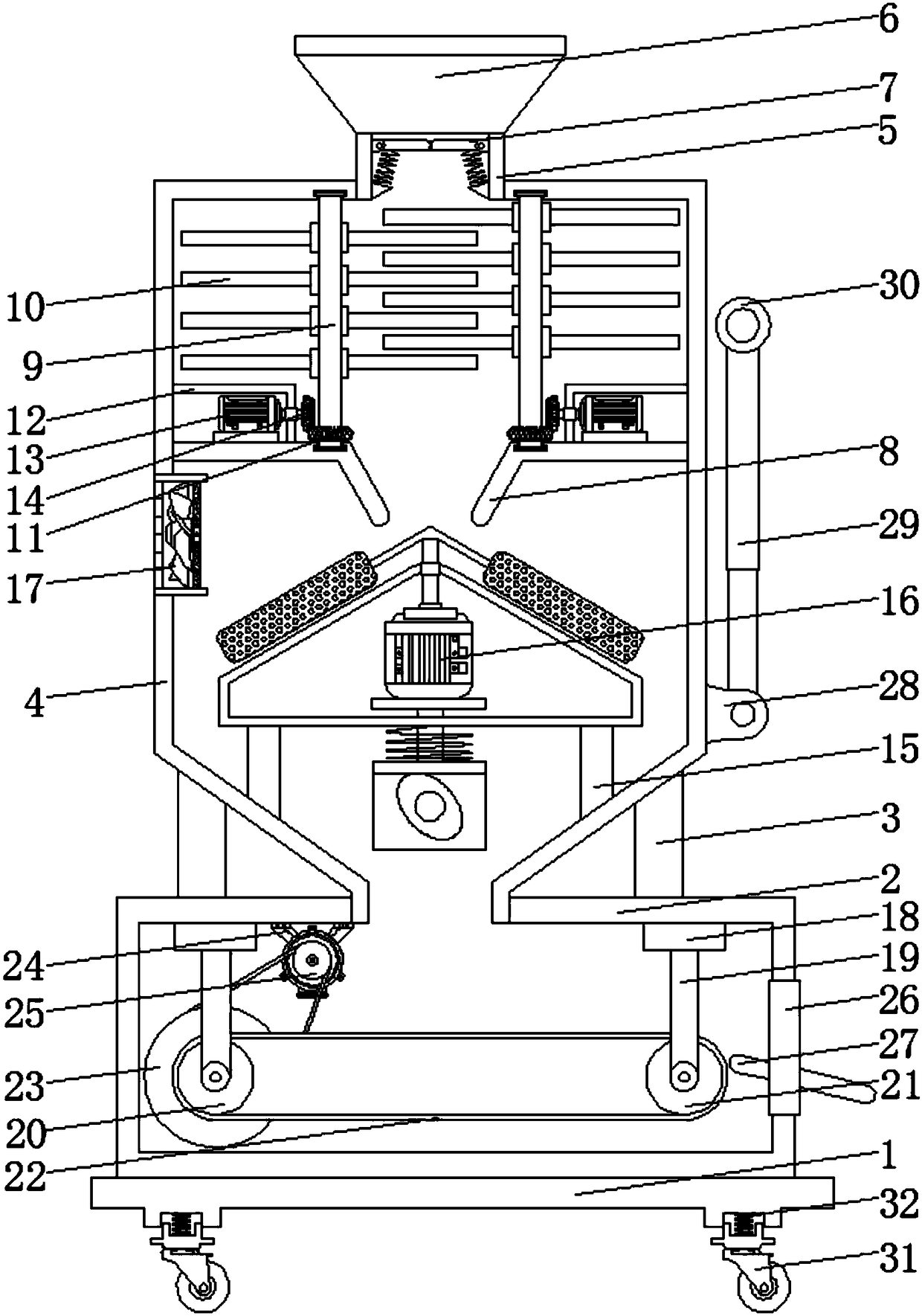

Household sesame threshing machine

ActiveCN112273063ARealize the purpose of alternate feedingAchieve the purpose of breakingThreshersAgricultural scienceAgricultural engineering

The invention discloses a household sesame threshing machine, and particularly relates to the technical field of sesame processing. The household sesame threshing machine comprises a base, a machine body is arranged above the base, the machine body comprises a middle machine body, the upper end and the lower end of the middle machine body are fixedly connected with an upper machine body and a lower machine body respectively, and the bottom end of the lower machine body is fixedly connected with the upper end of the base; and a middle cavity is formed in the middle of the middle machine body, side cavities are formed at the two sides of the middle of the middle machine body respectively, and a middle feeding port and a middle discharging port are sequentially formed in the side walls of thetwo side cavities from top to bottom. A long-shaft motor drives a material guide plate and a sieve plate to swing up and down and drives an extrusion block to move up and down, the purpose of alternately feeding the interiors of the two side cavities is achieved through swing of the material guide plate, the purpose of crushing pod shells is achieved through up-down movement of the extrusion block, and meanwhile, through swing of the sieve plate, the purpose of filtering the crushed pod shells is achieved.

Owner:李静静

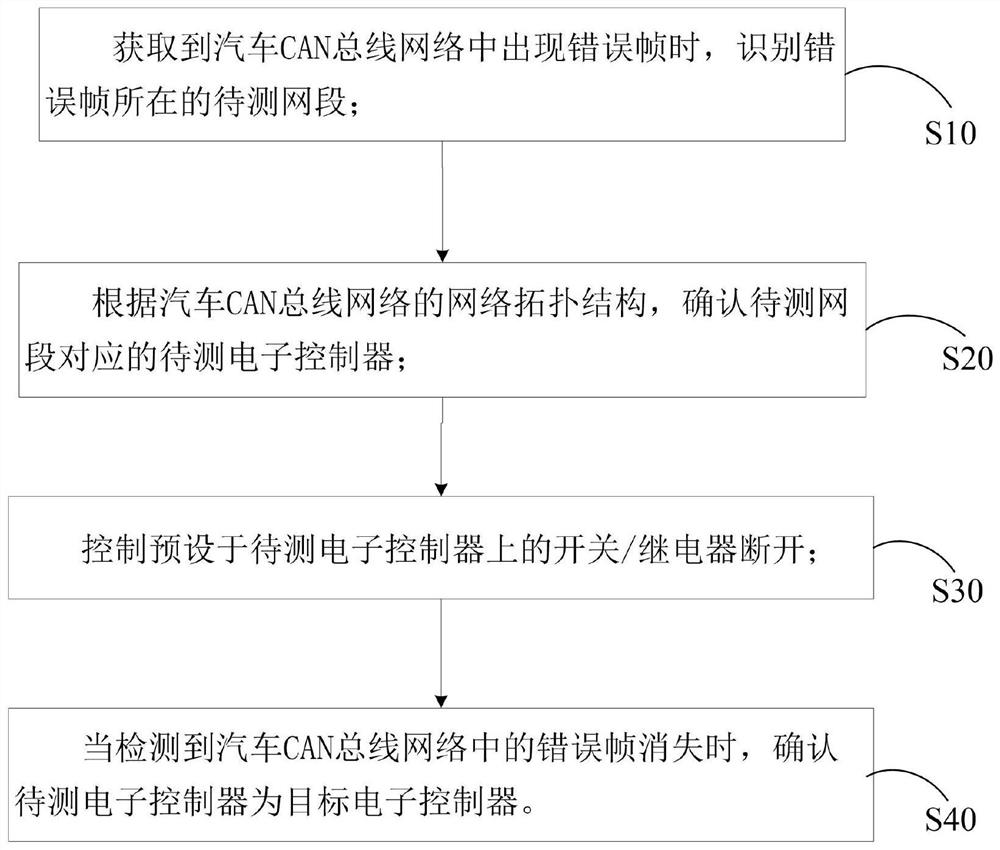

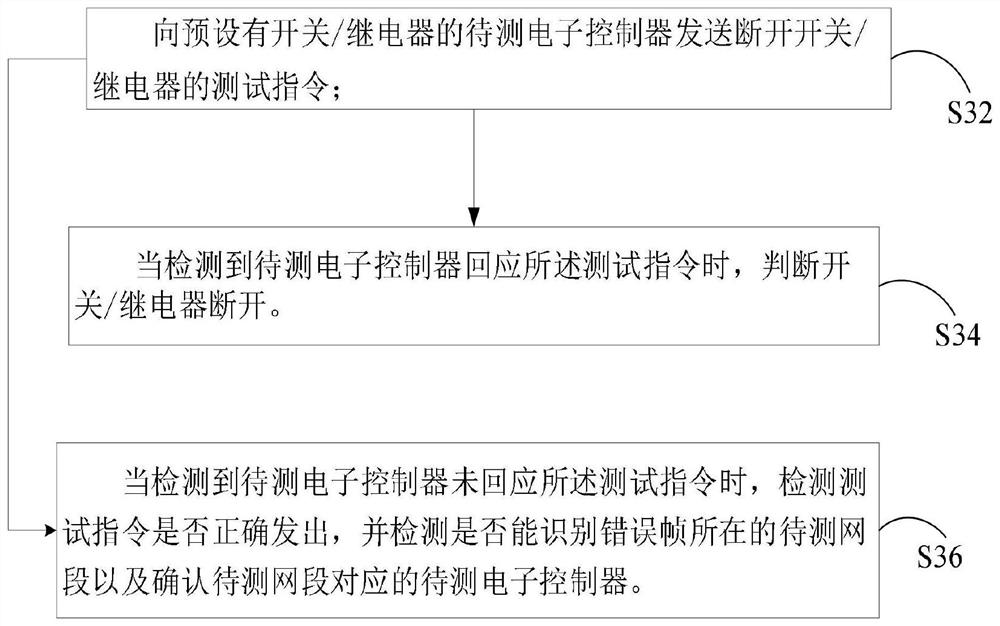

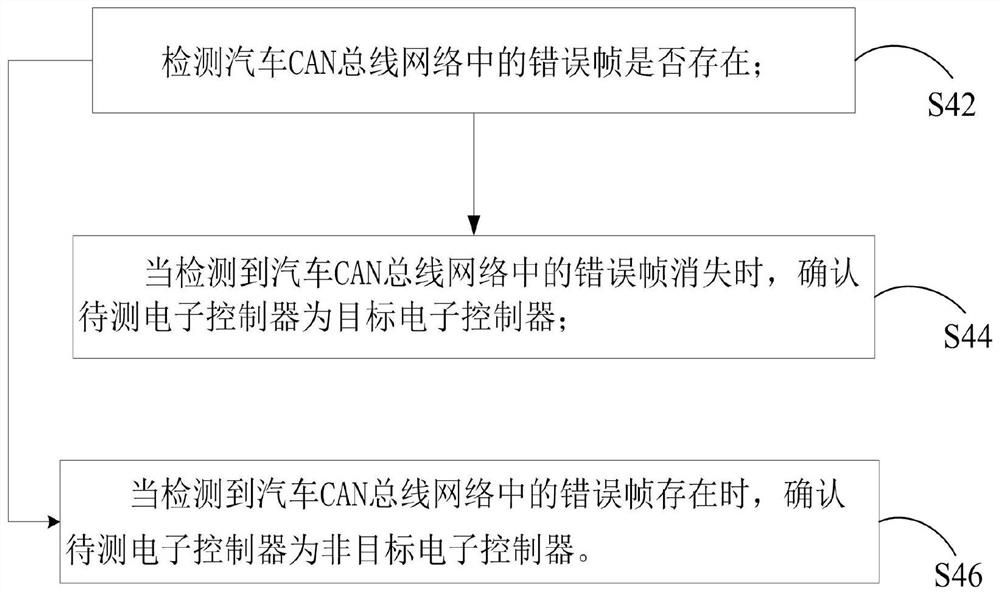

Method, system and storage medium for checking automotive can bus error frames

ActiveCN112003774BAchieve the purpose of breakingAvoid wastingSubstation remote connection/disconnectionBus networksNetwork topologyIdentification error

The invention discloses a method, a system and a storage medium for checking an automobile CAN bus error frame. The method for checking the error frame of the automobile CAN bus network includes the following steps: when obtaining an error frame in the automobile CAN bus network, identifying the network segment to be tested where the error frame is located; The electronic controller to be tested corresponding to the segment; the switch / relay preset on the electronic controller to be tested is controlled to be disconnected; when the error frame in the CAN bus network of the vehicle is detected to disappear, it is confirmed that the electronic controller to be tested is the target electronic control device. The present invention can relatively easily check and locate the controller with the error frame after the vehicle assembly is completed.

Owner:DONGFENG MOTOR CORP HUBEI

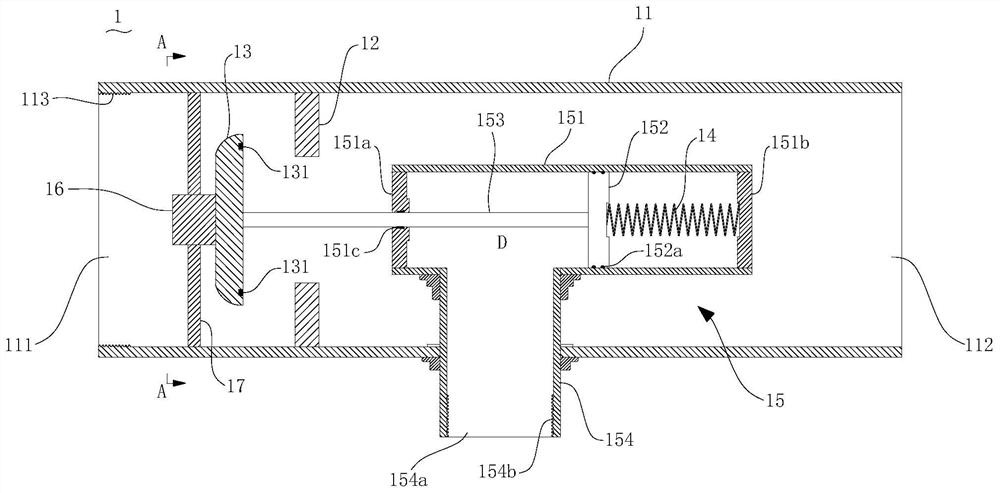

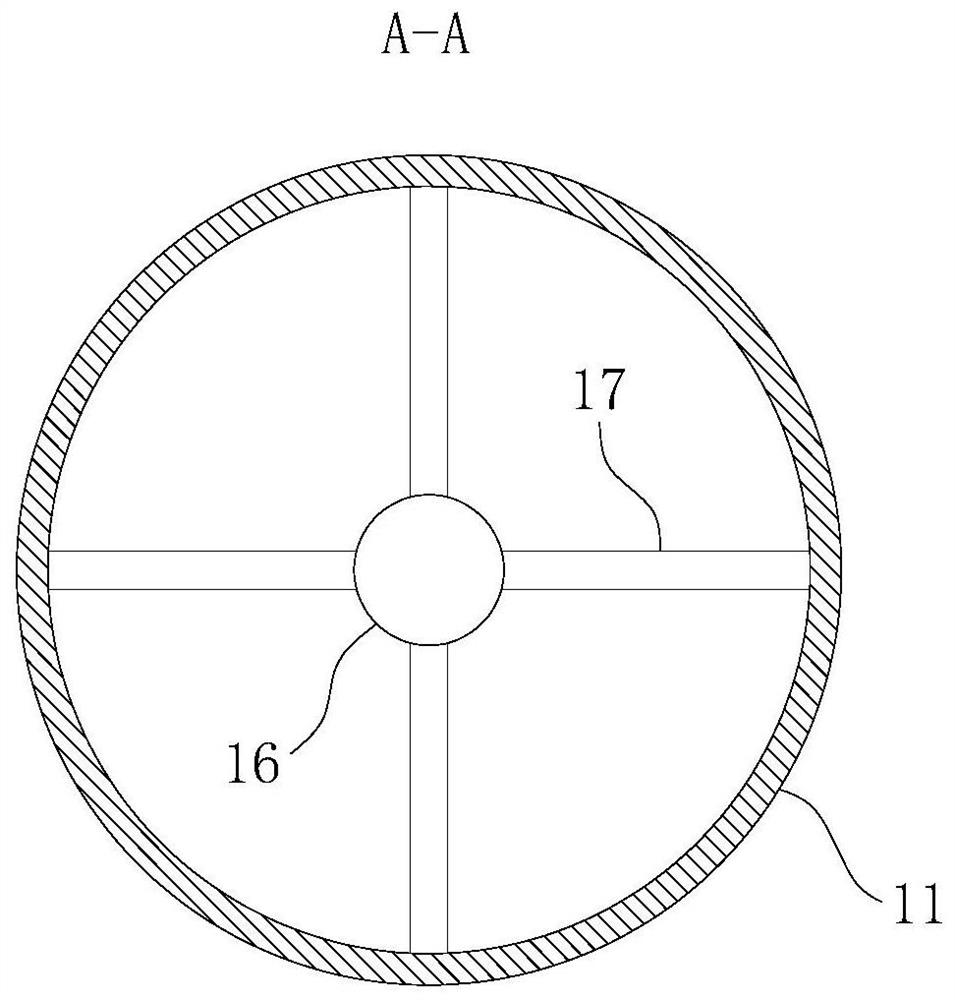

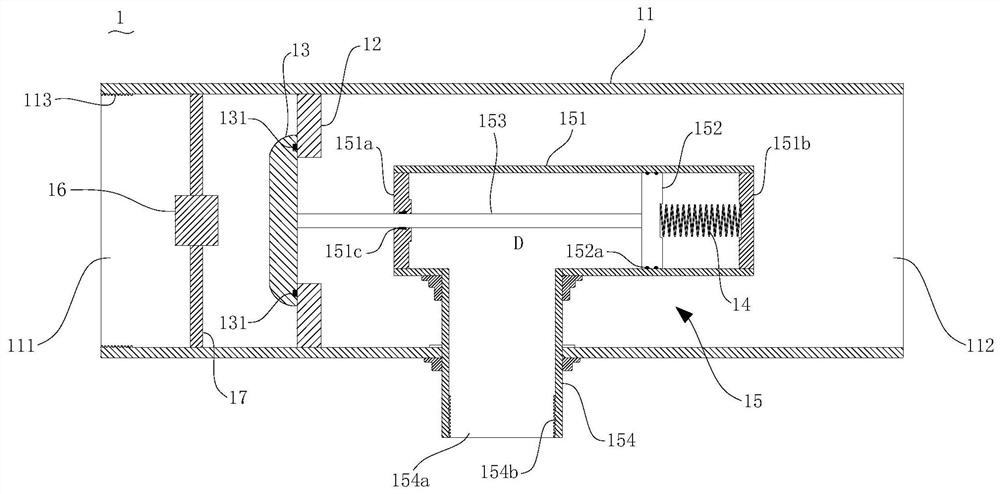

A mechanical valve with automatic shut-off function

The invention discloses a mechanical valve with automatic cut-off function which can be applied in the production process of chemical materials, comprising a valve body, a valve seat, a valve core, elastic parts, a pneumatic mechanism and a magnet; the valve seat and the valve core are arranged In the valve body, the valve core is used to contact the valve seat to close the valve; the elastic member drives the valve core to maintain a distance from the valve seat; the pneumatic mechanism includes a cylinder, a piston, a piston rod and a pipe body, the cylinder is set in the valve body, and the piston is set in the In the cylinder, the two ends of the piston rod are respectively connected with the piston and the valve core, and one end of the pipe body is connected with the inner cavity of the cylinder, and the other extends to the outside of the valve body; the magnet is set on the side of the valve core away from the valve seat; the initial In the normal state, the valve core is adsorbed on the magnet. When the amount of gas entering the cylinder from the pipe body reaches a certain level, the air pressure of the gas will cause the valve core to separate from the magnet and then quickly fit on the valve seat. After using this valve, the flow cut-off of the valve occurs instantaneously, so there will be no situation that the flow rate becomes smaller and smaller during the flow cut-off process.

Owner:浙江伟山机械有限公司

An energy-saving soil crushing device suitable for crop planting research

ActiveCN110152823BAchieve the purpose of breakingAccelerated thawingGrain treatmentsAgricultural scienceStraw

The invention discloses an energy-saving soil crushing device suitable for crop planting research, which comprises a machine body, a crushing chamber, a rolling chamber, a heating chamber and a screening chamber. The motor is installed, the motor is a biaxial motor, and the left end of the motor is fixedly connected to the rotating shaft; A screen, the first slide is set on the outside of the first screen; a screening chamber is provided at the lower part of the rolling chamber, a second screen is installed in the screening chamber, and a compression spring is fixedly connected to the right end of the second screen; The invention has reasonable design, high energy saving and high efficiency, can fully crush and screen frozen soil, and simultaneously uses one motor to complete multiple programs, thus saving a large amount of energy.

Owner:JIANGXI DONGJIAN AGRI DEV CO LTD

Automatic ridge ditching device convenient to turn, start and stop

InactiveCN114258761AEasy to turn start and stopEasy to adjustSpadesAgricultural machinesElectric machineStructural engineering

The automatic ridge ditching device comprises a supporting plate, a first buffering cushion, a controller, an air cylinder and a single-head motor, a bearing plate is fixedly connected to the lower side of the middle of the supporting plate, and a first double-head motor is installed on the inner side of the first buffering cushion; the upper surface of the right end of the supporting plate is fixedly connected with a connecting plate, the inner side of the upper end of the connecting plate is fixedly connected with a reinforcing plate, the air cylinder is located on the upper surface of the middle of the left end of the supporting plate, the inner side of the inner end of the hoop is connected with a second buffering pad in an adhering mode, and the left side of the air cylinder is fixedly connected with a clamping block. According to the automatic ridge ditching device convenient to turn, start and stop, the ditching depth can be conveniently adjusted, soil can be conveniently crushed, shunted and dispersed, the ditching efficiency is high, the ditching effect is good, internal electrical elements can be conveniently buffered and protected, and the service life of the automatic ridge ditching device convenient to turn, start and stop is long.

Owner:邳州长勺农业发展有限公司

Feeding device

InactiveCN112602626AIncrease feed rateUniform feedingCleaning using toolsAvicultureEngineeringControl theory

The invention discloses a feeding device, and relates to the technical field of feeding. The feeding device comprises a charging frame, wherein a feeding pipe communicates with the position, close to the top, of one side of the charging frame, a bottom plate is installed on the side, away from the feeding pipe, of the charging frame, a discharging pipe communicates with the side, close to the bottom plate, of the charging frame, and the position, close to the bottom plate, of the discharging pipe is sleeved with a reinforcing ring, the outer side of the discharging pipe is sleeved with a fixing ring, supports are evenly installed on the side, away from the discharging pipe, of the fixing ring, a feeding frame is fixedly connected to the ends, away from the fixing ring, of the supports, a rotating rod is installed at the position, close to the fixing ring, of one side of the discharging pipe, one end of the rotating rod penetrates through the discharging pipe and is fixedly connected to a rotating plate, and a crushing device is installed on one side of the rotating rod, and a baffle is installed at the end, close to the feeding frame, of the discharging pipe. According to the feeding device, feeds are effectively prevented from adhering to the inner wall of the feeding frame, and the phenomenon that the feed is accumulated at corners to hinder eating by chicks is avoided.

Owner:姚方金

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com