Kitchen waste treatment device and kitchen waste treatment method

A technology of kitchen waste and treatment device, applied in the field of kitchen waste treatment device, can solve the problems of inability to dispose of food waste, environmental and personal harm, inconvenience in handling and dumping, etc., so as to shorten the subsequent processing time, facilitate storage and The effect of transportation and improved storage safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

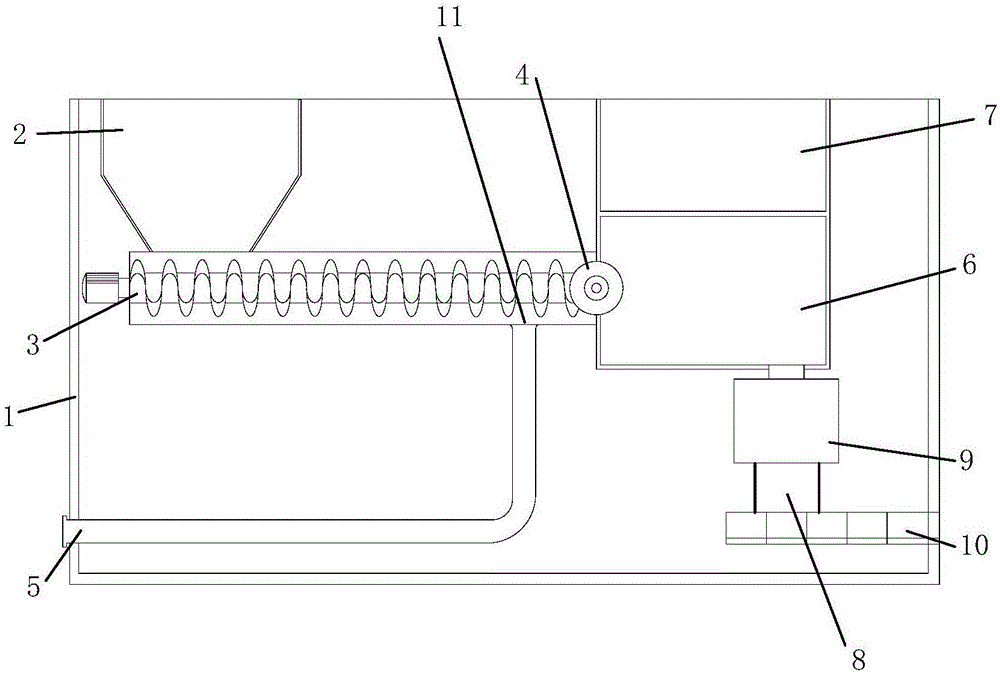

[0017] Such as figure 1 As shown, the kitchen waste treatment device of the present embodiment includes a housing 1, in which a feed hopper 2, a screw conveyor 3, a mixing chamber 6, an EM bacteria storage tank 7 and a filling and sealing machine 9 are arranged. , the feed hopper 2, the screw conveyor 3, the stirring and mixing chamber 6 and the filling and sealing machine 9 are connected in sequence, and the discharge port of the screw conveyor is provided with a valve 4, and the feed port side of the valve is The pipe wall of the screw conveyor below is provided with a sewage outlet 11, and the sewage outlet is connected with the sewage discharge pipeline 5, and a screen is installed on the sewage outlet, and an EM bacteria storage tank 7 connected thereto is provided above the mixing chamber. The bottom of the filling and sealing machine is also provided with a conveying device 10 .

[0018] Add the food waste into the feed hopper 2, the food waste in the feed hopper falls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com