A mechanical valve with automatic shut-off function

A mechanical and functional technology, applied in the types of functional valves, mechanical equipment, fluid distribution valves, etc., can solve the problems of smaller valves, prolonged discharge time, and small valve flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

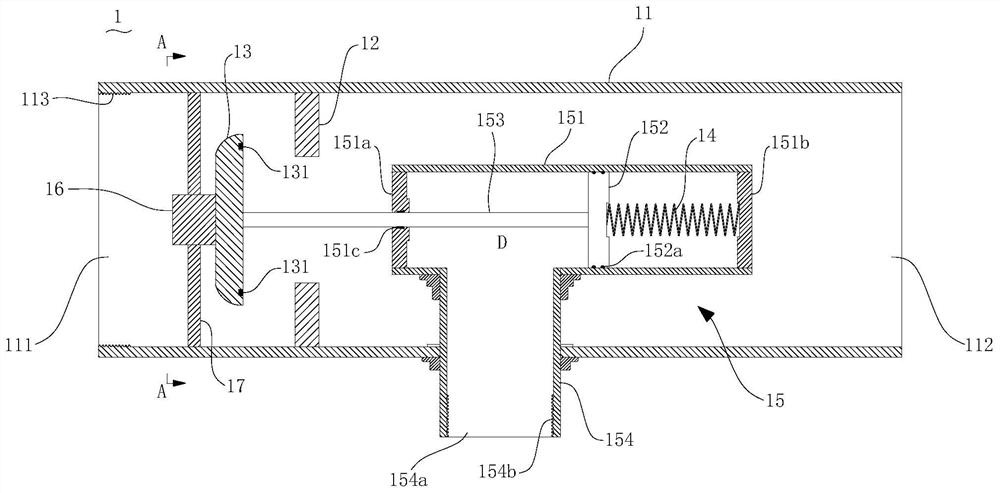

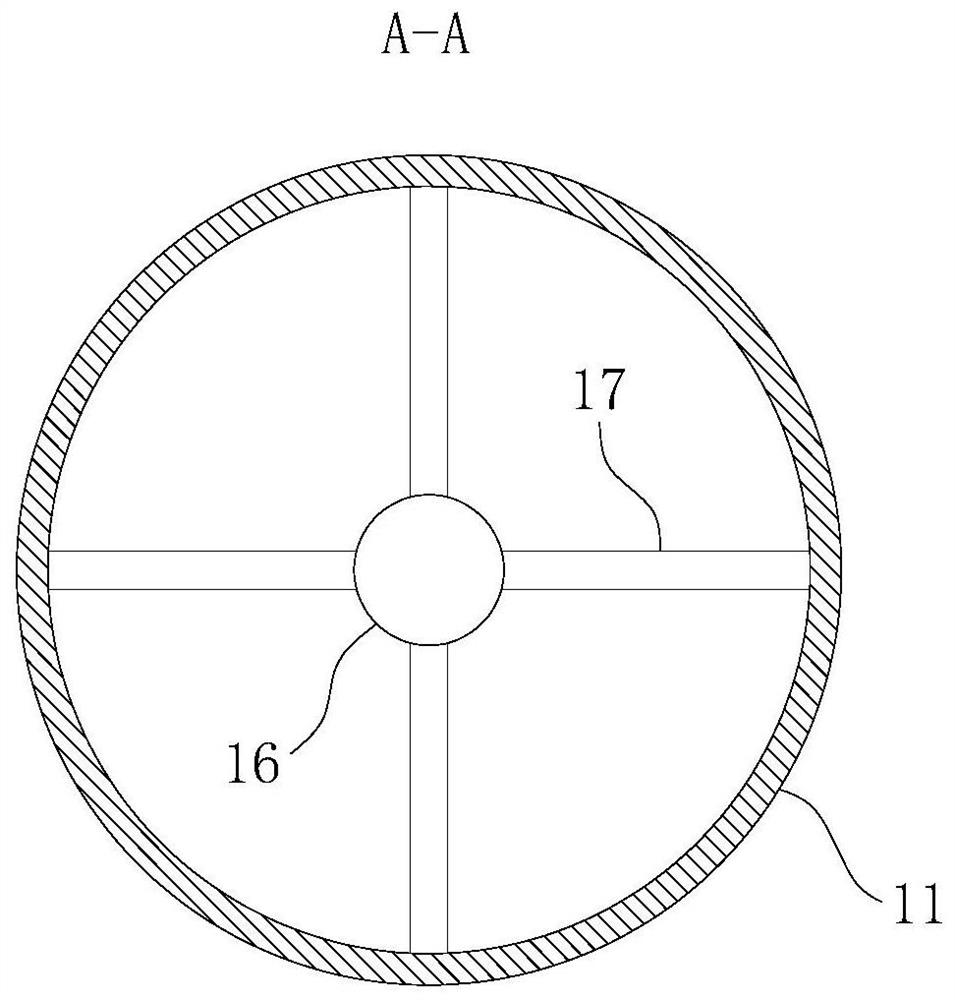

[0040] see Figure 1-Figure 3 As shown, the present invention provides a mechanical valve 1 with an automatic shut-off function, which includes a valve body 11 , a valve seat 12 , a valve core 13 , an elastic member 14 , a pneumatic mechanism 15 and a magnet 16 .

[0041] One end of the valve body 11 is the liquid inlet end 111 and the other end is the liquid outlet end 112 .

[0042] The valve seat 12 is arranged in the inner cavity of the valve body 11 .

[0043] The valve core 13 is arranged in the inner cavity of the valve body 11, and is used to interfere with the valve seat 12 to block the communication between the liquid inlet end 111 and the liquid outlet end 112 of the valve body 11, and the valve The core 13 is made of ferromagnetic material.

[0044] The elastic member 14 is used to impart a force to the valve core 13 to drive the valve core 13 to move to the side away from the valve seat 12;

[0045]The pneumatic mechanism 15 includes a cylinder 151 , a piston 1...

Embodiment 2

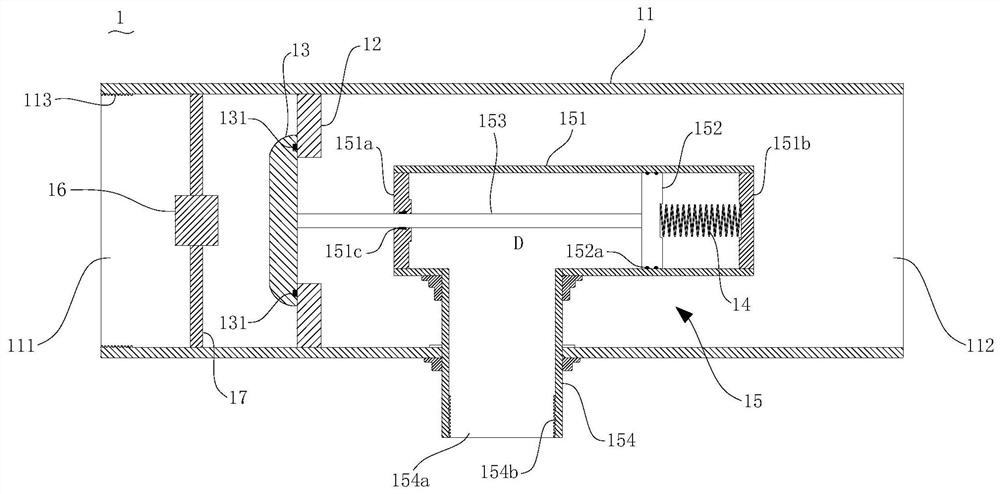

[0065] see Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the elastic member 14 is also a compression spring and is located in the cylinder 151, but one end of the elastic member 14 is fixed on the second end 151b of the cylinder 151, and the other is One end is the free end, which is not connected to the piston 152, and when the valve core 13 is adsorbed on the magnet 16, there is a distance between the free end of the elastic member 14 and the piston 152, which is usually greater than or equal to 2 cm.

[0066] the purpose of doing this is:

[0067] In Embodiment 1, when the valve core 13 is disengaged from the magnet 16, the piston 152 will immediately squeeze the elastic member 14, and after the elastic member 14 is squeezed, the N 2 will increase, so it will hinder the movement of the piston 152 and the valve core 13 to a certain extent. If the valve core 13 does not quickly leave the strong magnetic field area of the magnet 16 at t...

Embodiment 3

[0069] see Figure 5 and Image 6 As shown, this embodiment provides a container, which includes a container body 2 and the valve 1 of the first embodiment or the second embodiment. The valve 1 is erected on the top of the container body 2 , and an extension pipe 3 is connected below the pipe body 154 of the valve 1 , and the extension pipe 3 extends to a position in the container body 2 near the bottom.

[0070] More specifically, the pipe body 154 of the valve 1 is connected with the extension pipe 3 through the first joint 4, and both ends of the first joint 4 have threads, which can be connected with the pipe body 154 and the extension pipe 3 respectively; The liquid inlet end 111 of the body 11 is connected with the liquid supply pipeline 6 through the second joint 5, and both ends of the second joint 5 have threads, which can be connected with the valve body 11 and the liquid supply pipeline 6 respectively; the liquid supply pipeline The front end of 6 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com