Crusher

A technology of crusher and crushing mechanism, applied in grain processing and other directions, can solve the problem that jaw crusher cannot meet the demand of crushing output, and achieve the effect of wide range of use and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

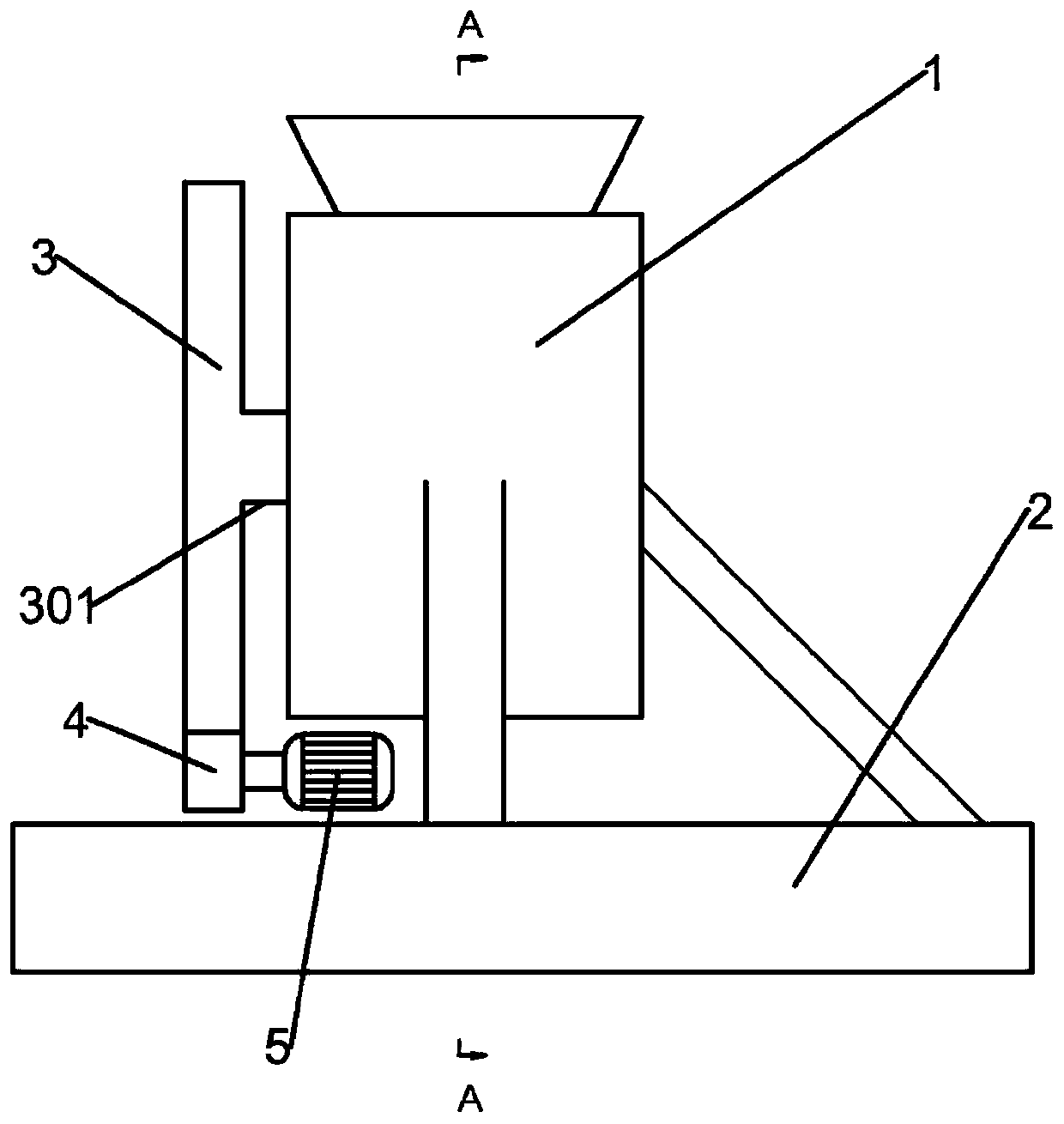

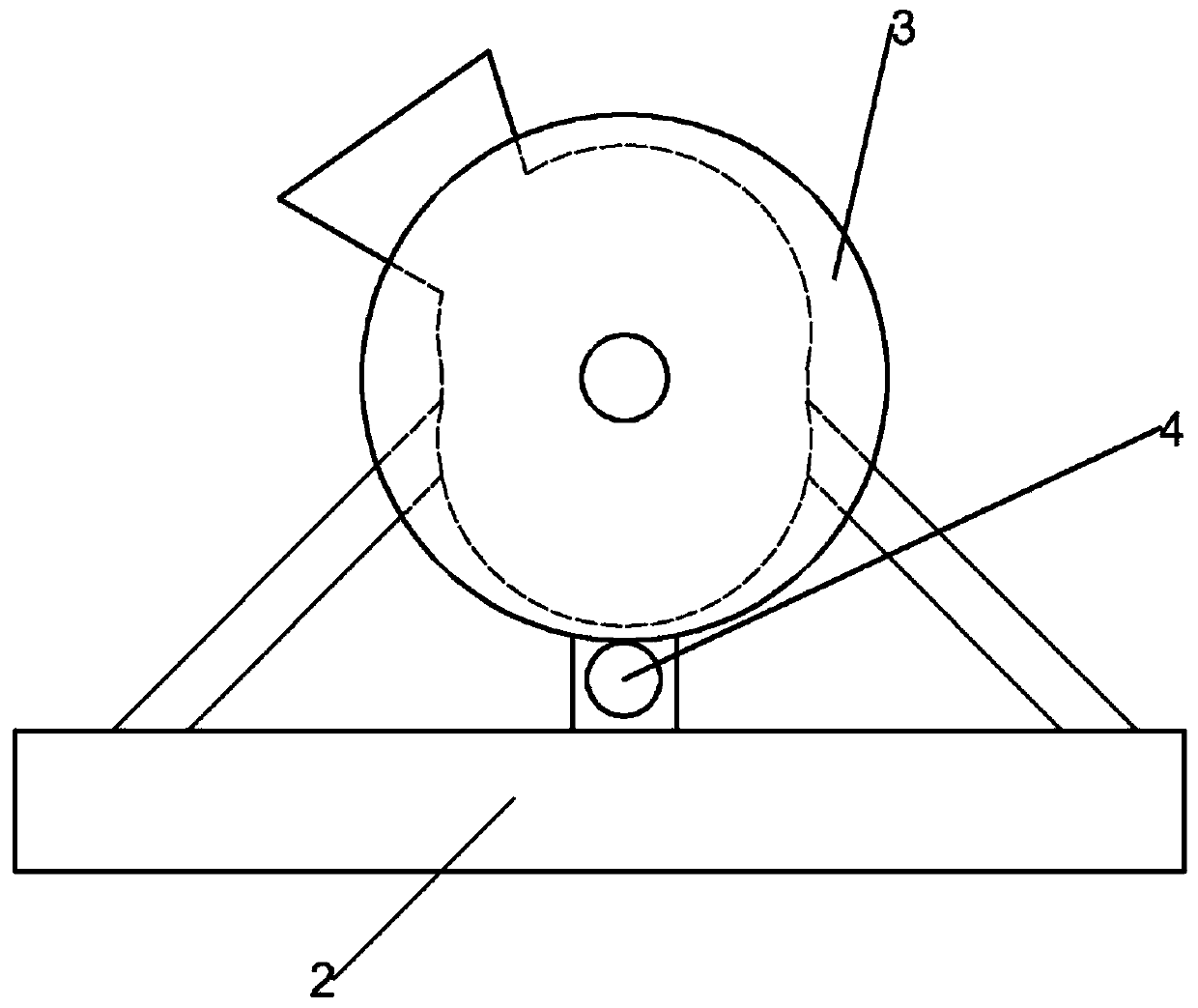

[0031] refer to Figure 1-6 , this embodiment provides a crusher, including a bracket 2, a housing 1 fixed on the bracket 2, a crushing mechanism arranged inside the housing 1, and a driving device for driving the crushing mechanism to rotate; the housing 1 The upper part is provided with a feed inlet 7;

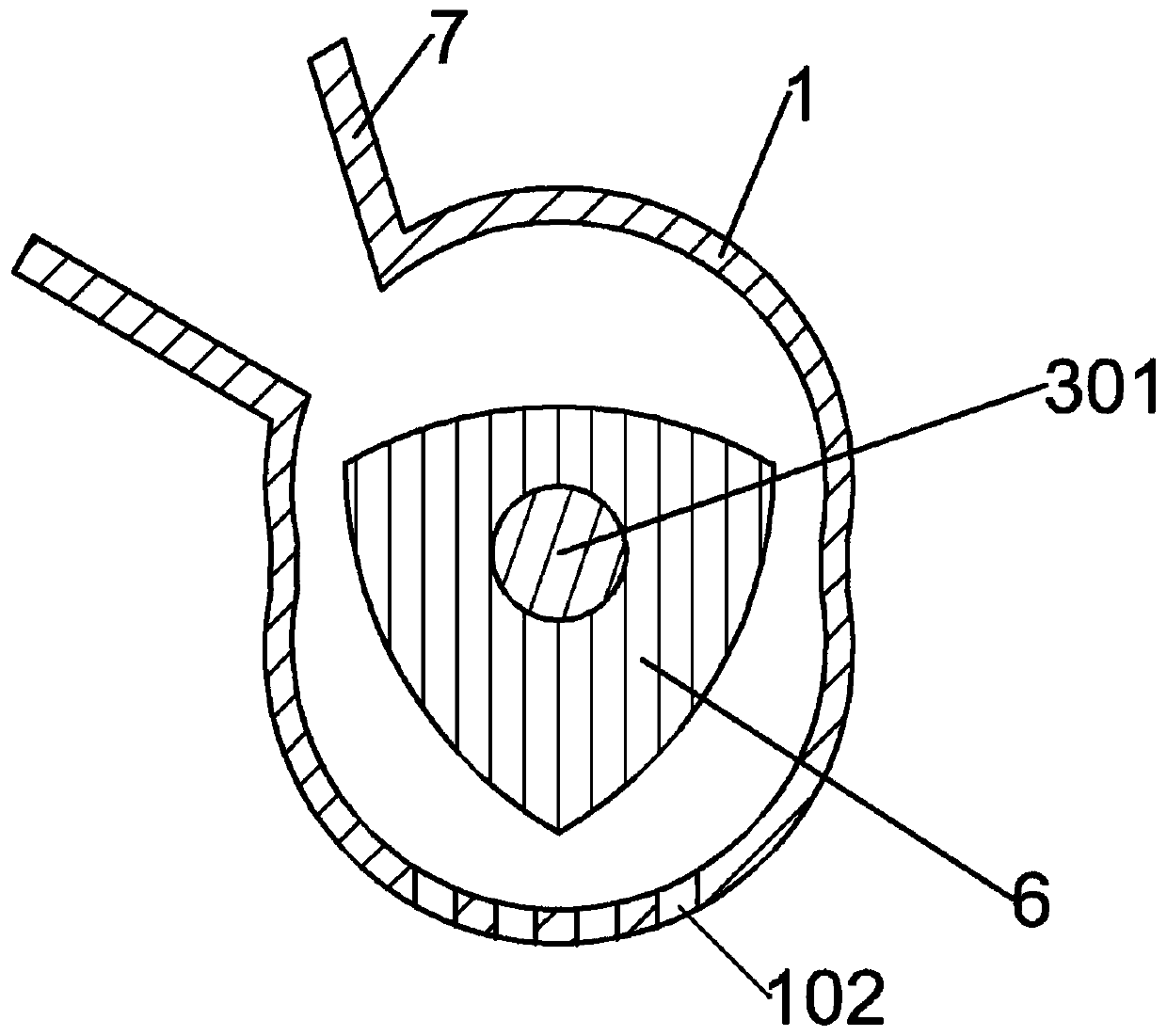

[0032] The crushing mechanism includes an extruding core 6 and a main shaft 301 eccentrically arranged on one side of the extruding core 6; the extruding core 6 is a Lelo triangle, and the other side of the extruding core 6 is provided with a groove, and an internal tooth 601 is arranged in the groove , the center of the end face of one side of the housing 1 is fixed with a gear 101 that cooperates with the internal teeth 601; the bottom of the housing 1 is provided with a through hole 102, and the shape of the side of the housing 1 is consistent with the running track of the tip of the extrusion core 6 and there is a gap; by adjusting The gap between the housing 1 and the ...

Embodiment 2

[0041] refer to Figure 7 The difference between the crusher of this embodiment and the first embodiment is that the side wall of the extrusion core 6 is provided with piercing teeth 602, and the inner wall of the housing 1 is provided with piercing teeth 602 with the same shape as the extrusion core 6. By adding The piercing teeth 602 effectively pierce the crushed material during the process of reducing the space formed by the edge of the extrusion core 6 and the shell 1, further enhancing the crushing effect of the crusher.

[0042] By adjusting the gap between the housing 1 and the extrusion core 6, crushed objects with different target particle sizes can be realized, so that the crusher can be used in a wider range.

[0043] During the rotation of the extrusion core 6, the gap between the extrusion core 6 and the inner wall of the casing 1 will change from large to small, so as to achieve the purpose of crushing.

[0044] A gap is reserved between the casing 1 and the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com