Patents

Literature

187results about How to "Improve mixing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

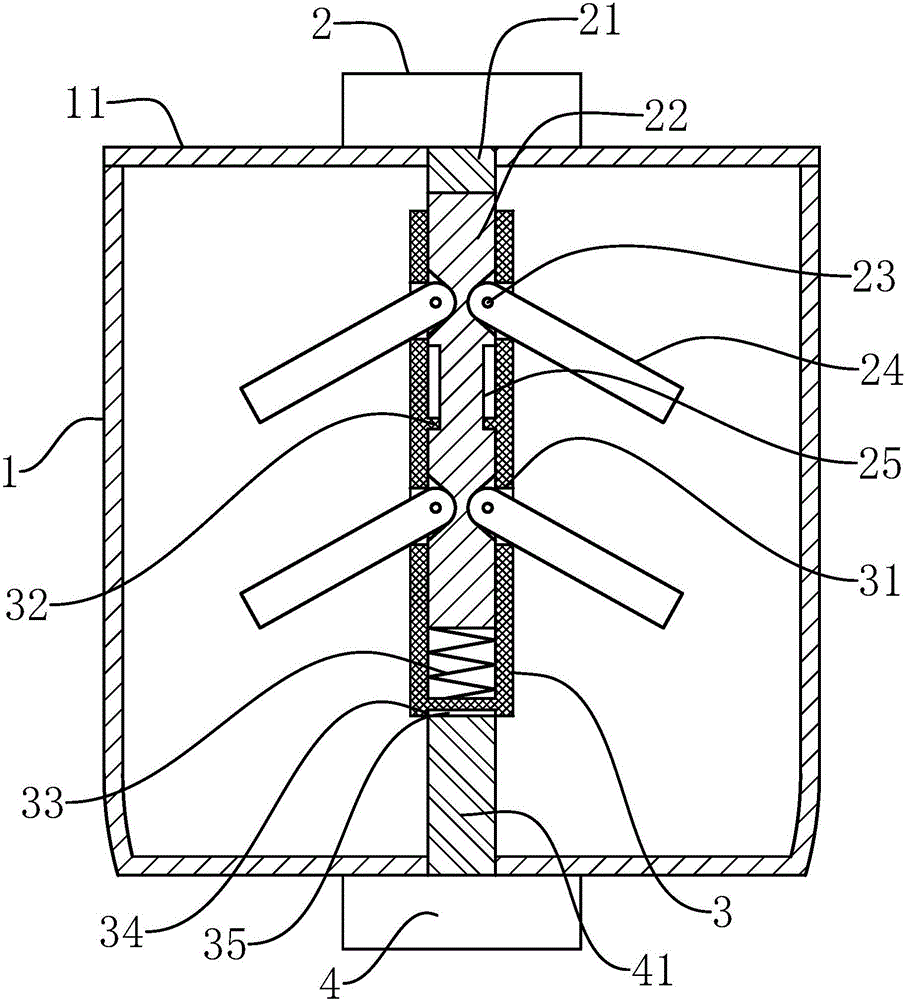

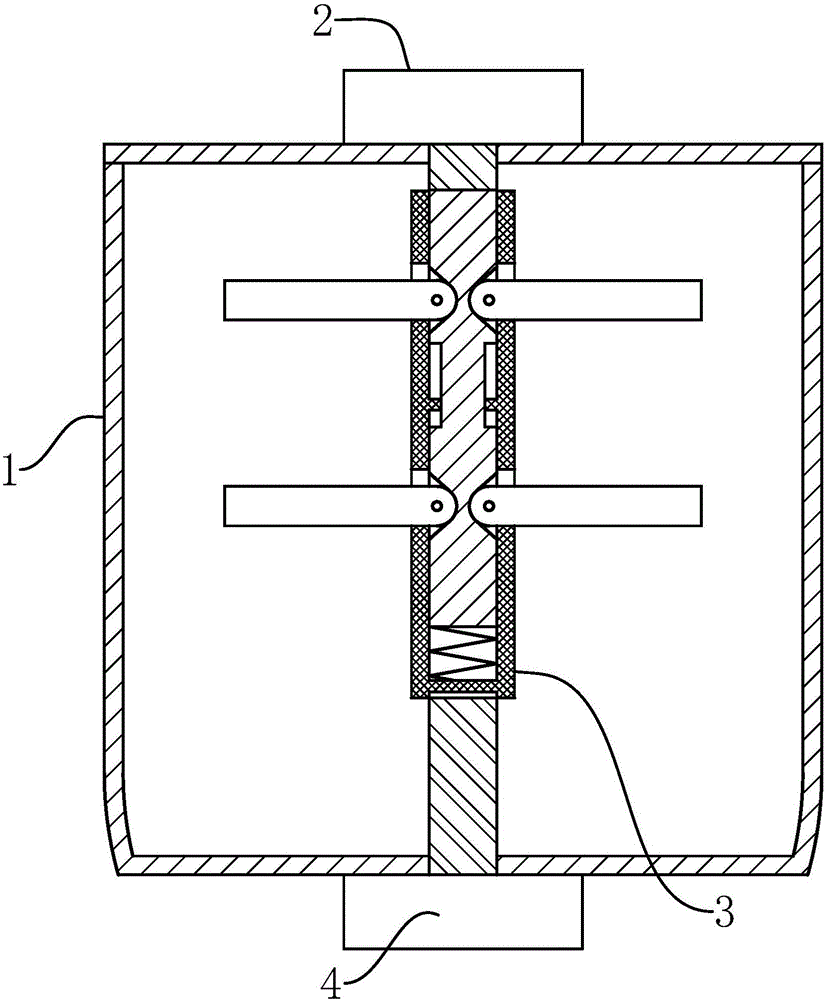

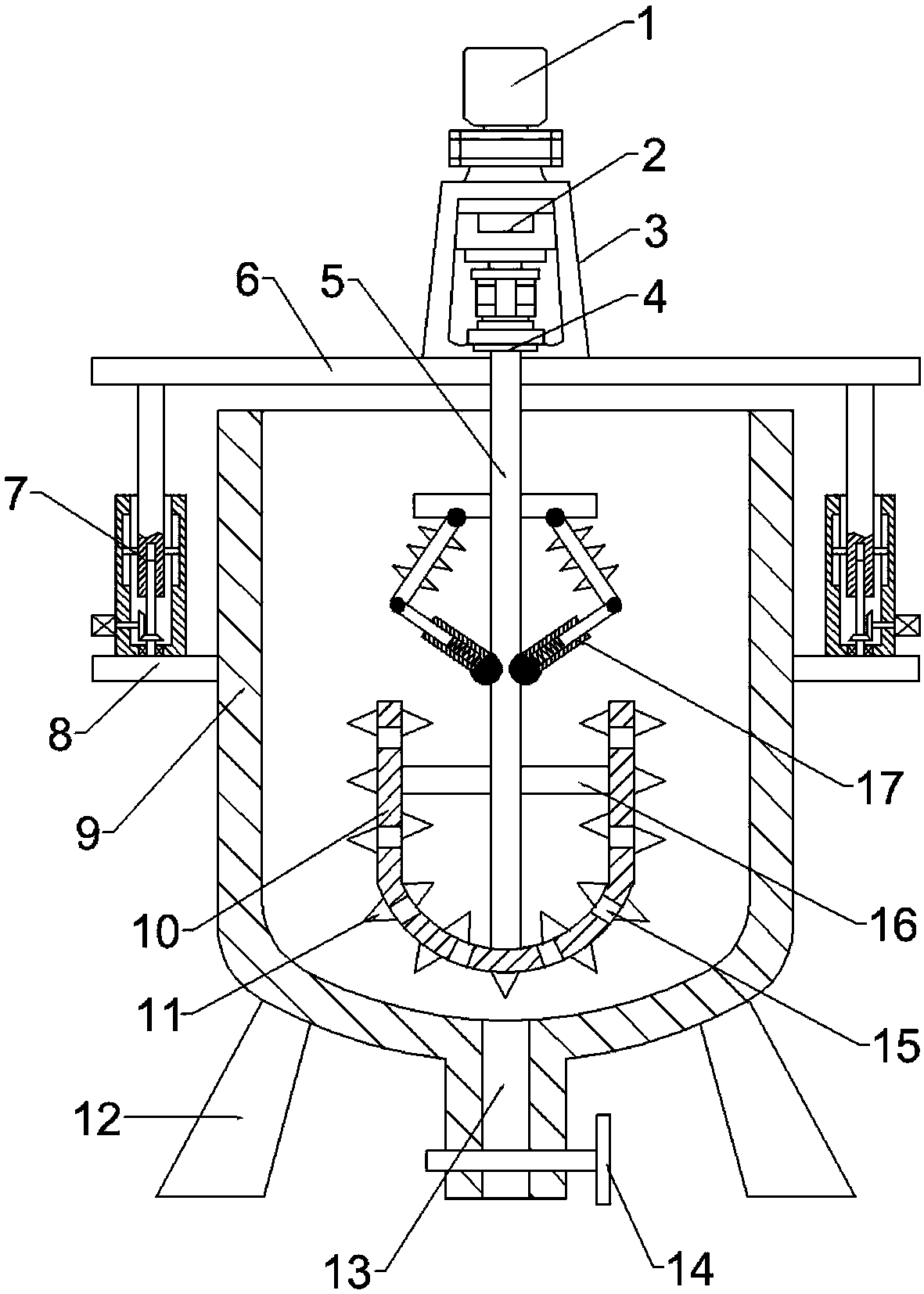

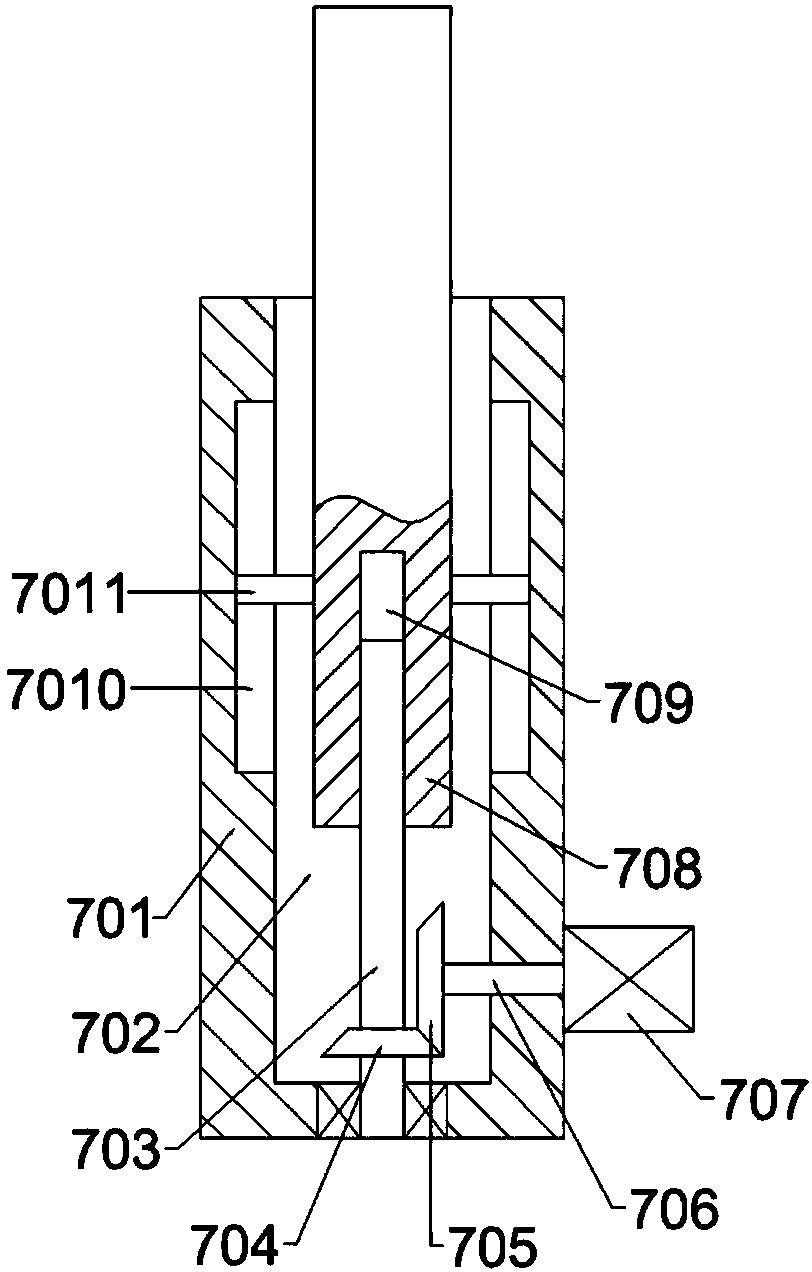

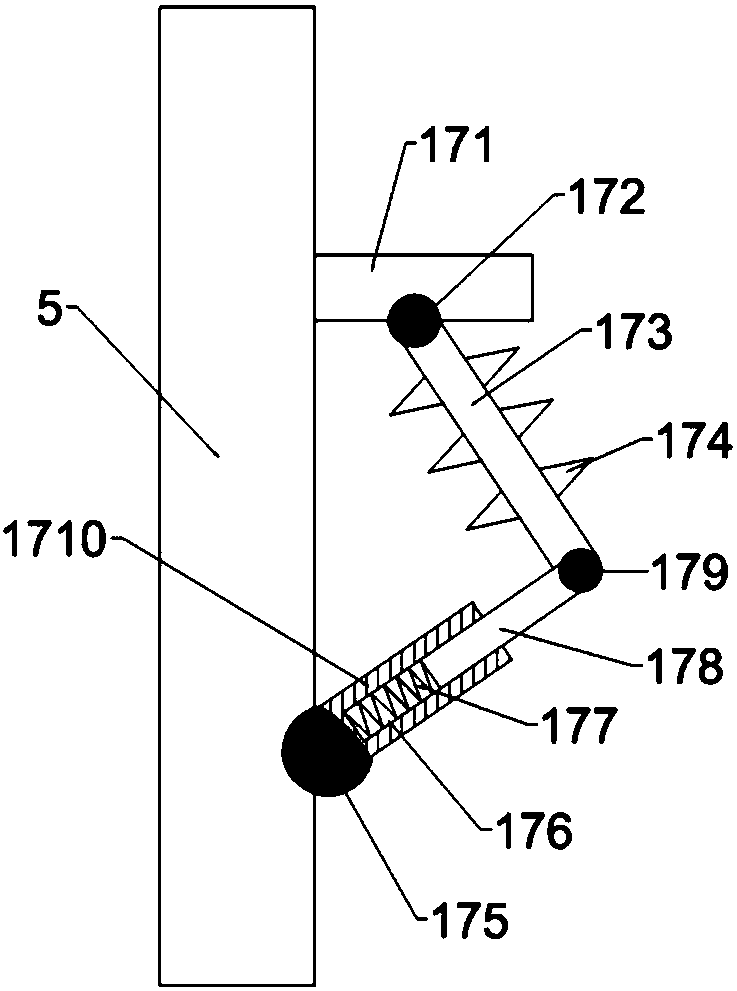

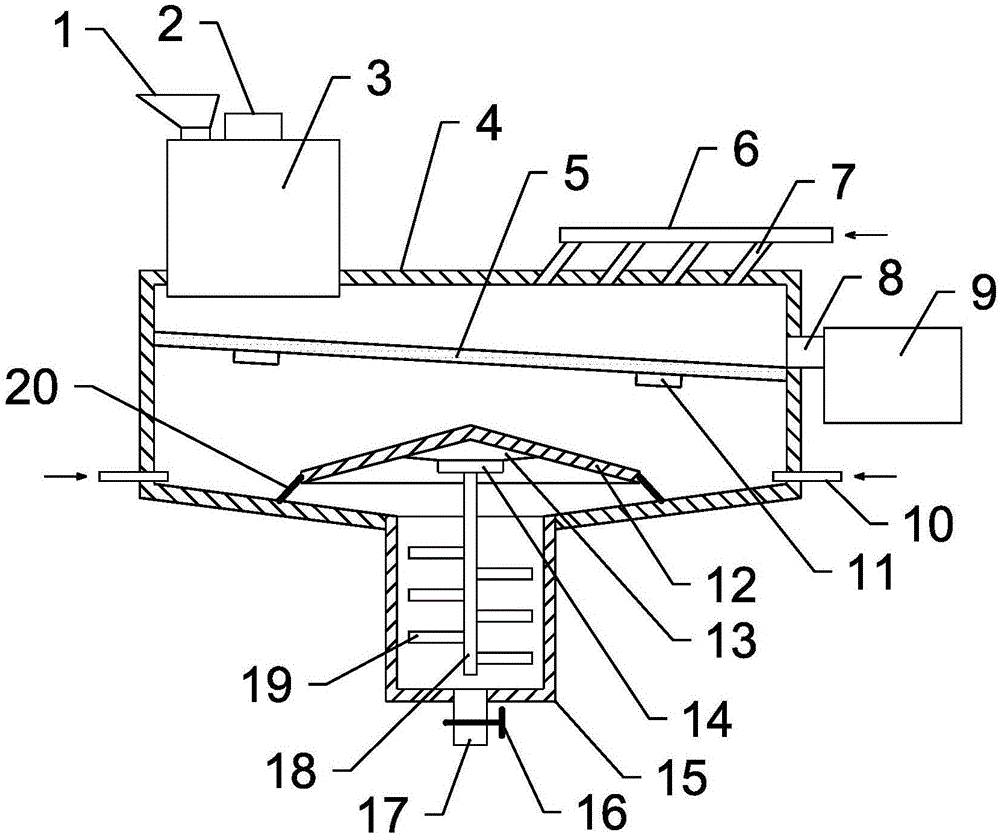

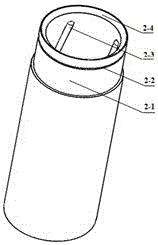

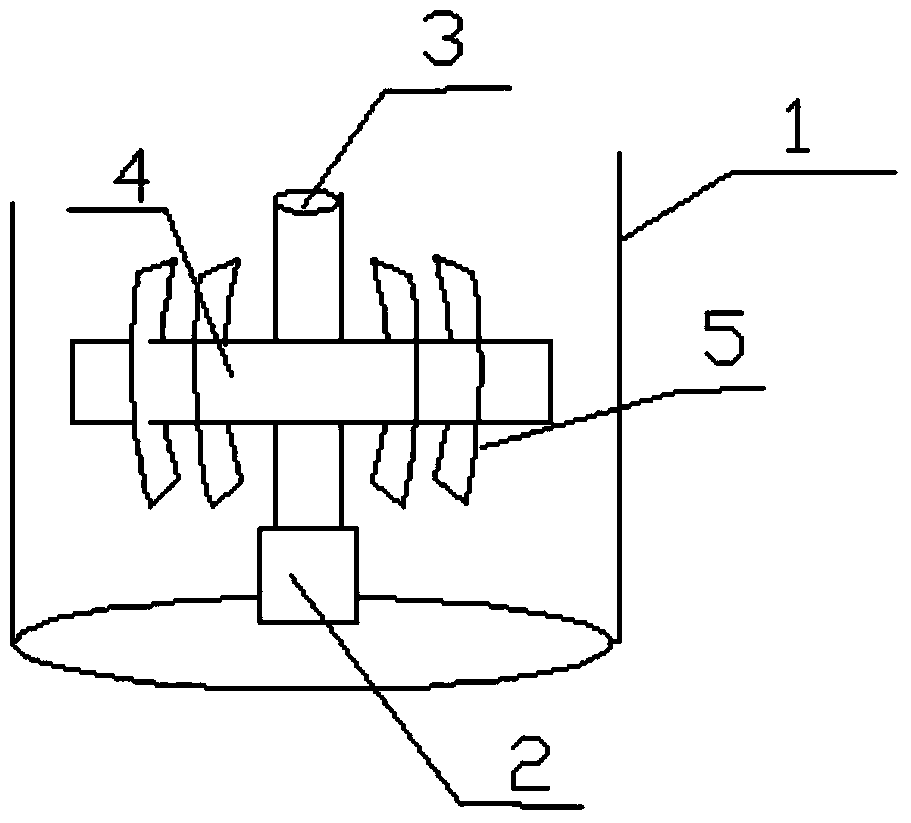

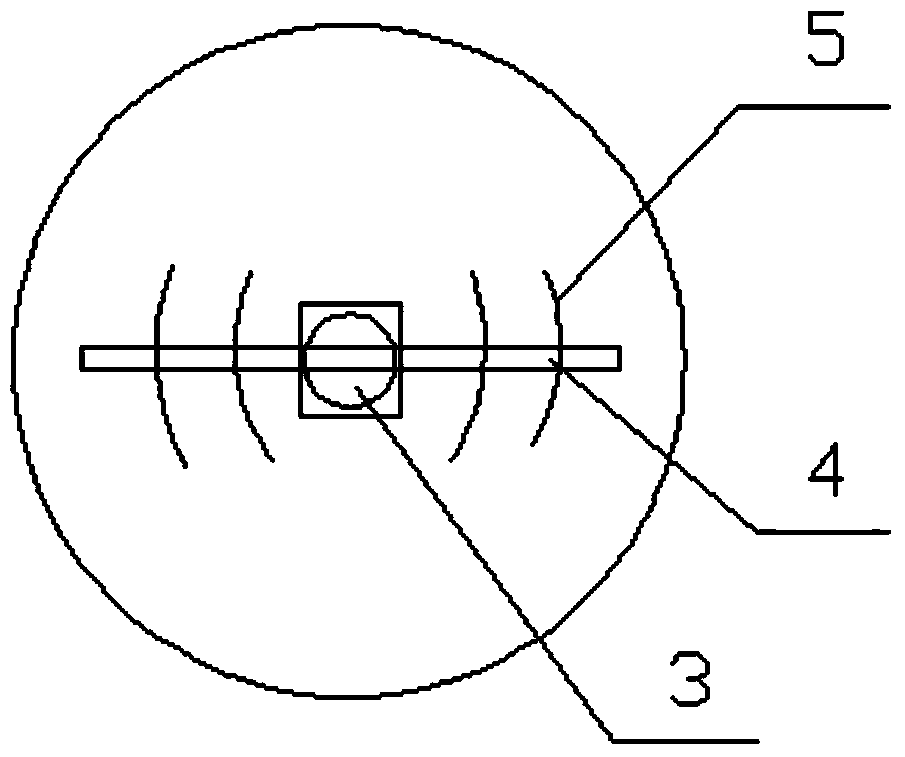

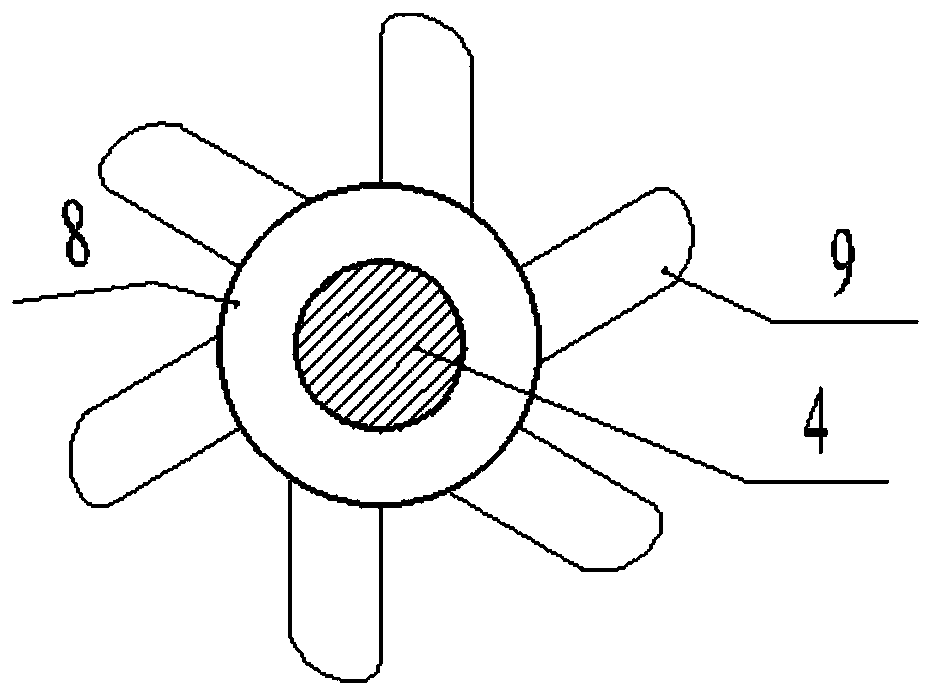

Rapid stirring mechanism of pharmacy stirring machine

ActiveCN105854684AImprove mixing effectImprove the mixing effectRotary stirring mixersTransportation and packagingMotor shaftPulp and paper industry

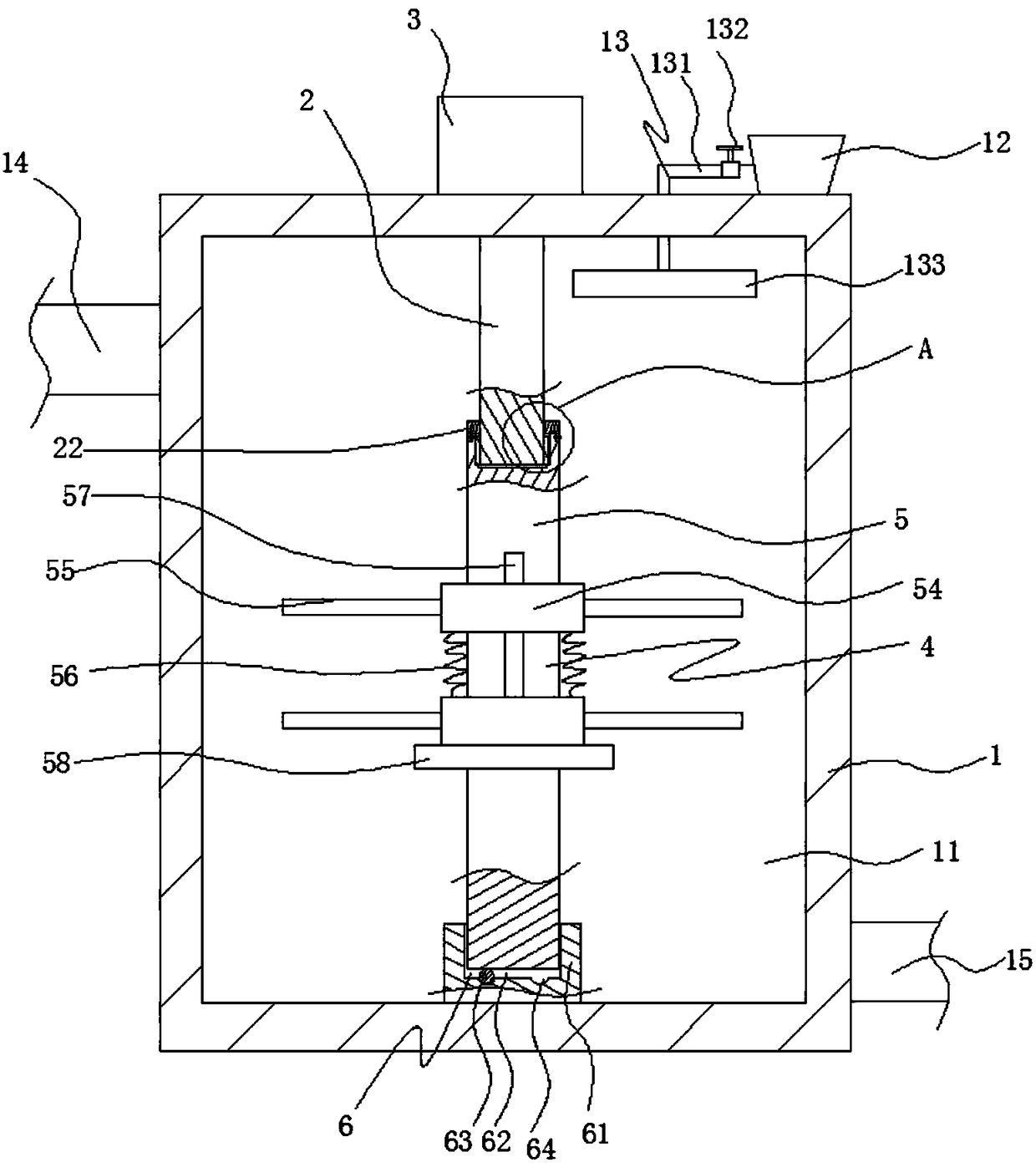

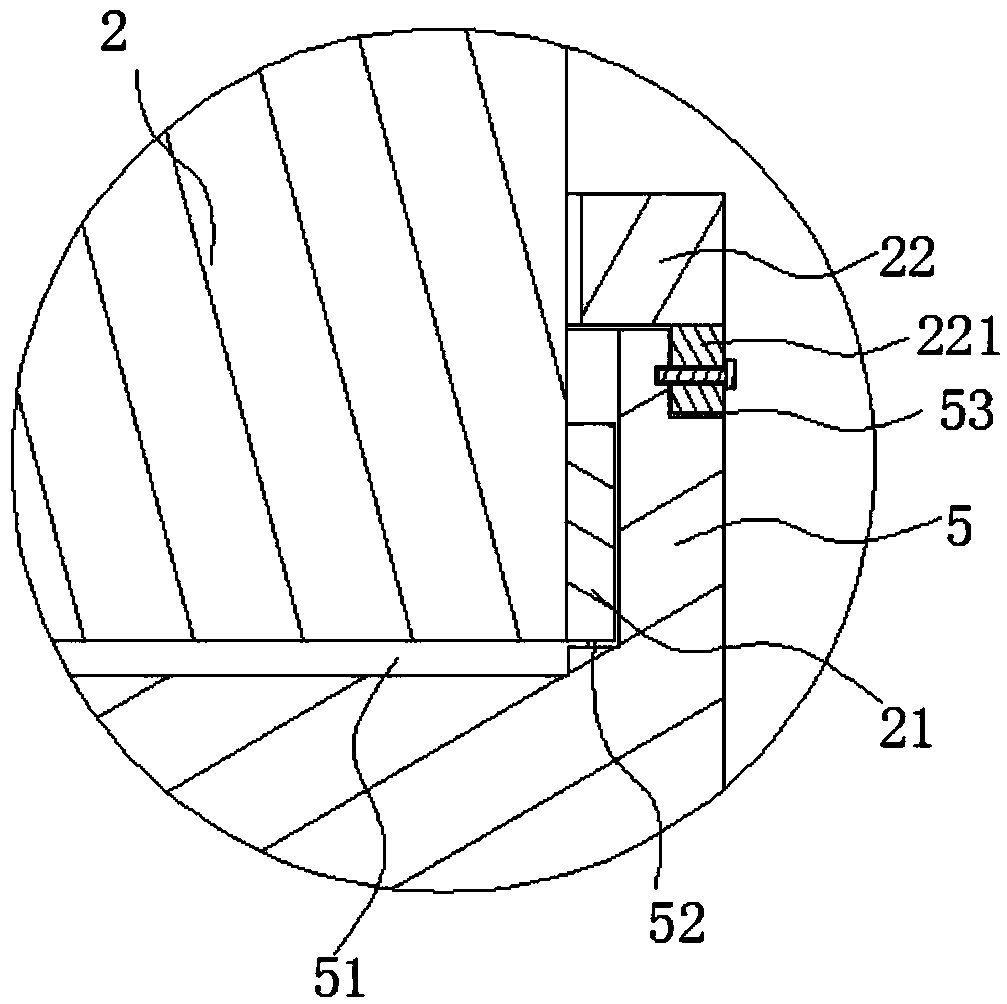

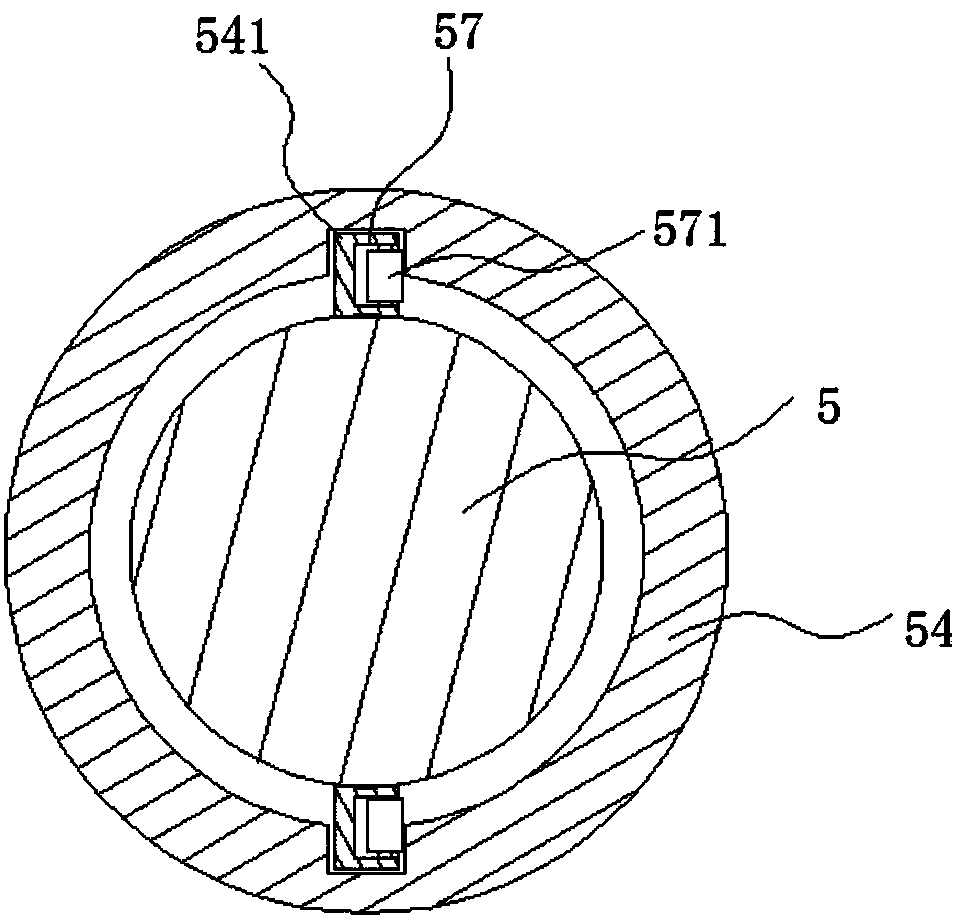

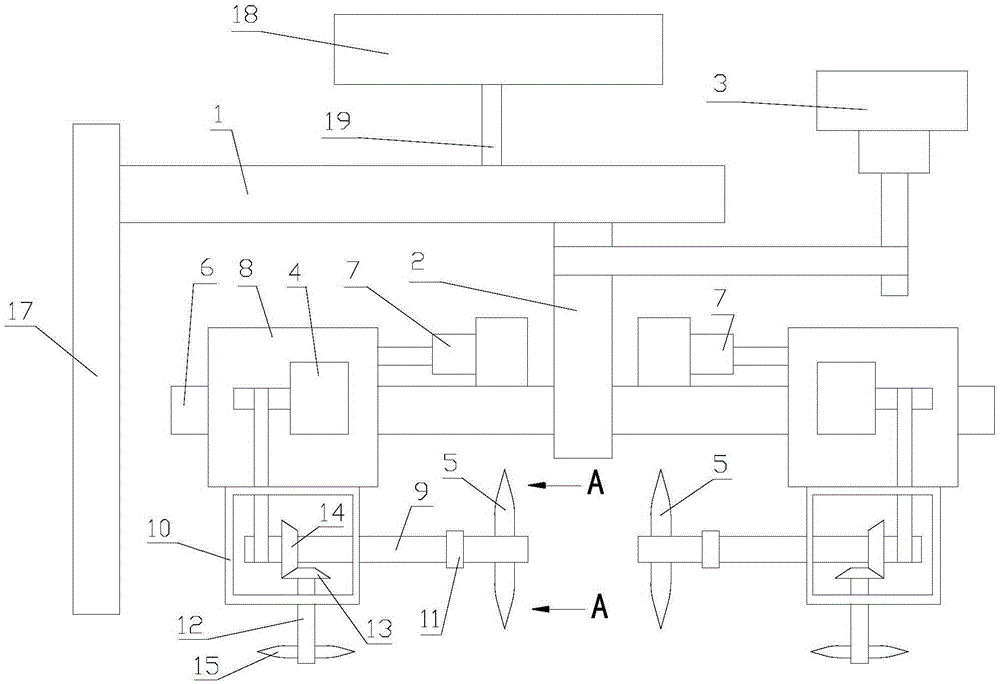

The invention provides a rapid stirring mechanism of a pharmacy stirring machine, and belongs to the field of pharmacy machines. By means of the rapid stirring mechanism, the problem that an existing stirring mechanism is low in stirring efficiency is solved. The rapid stirring mechanism of the pharmacy stirring machine comprises a barrel, a sleeve and stirring paddles, wherein a motor and an air cylinder are fixed to the top and the bottom of the barrel respectively, and a stirring shaft is connected to a motor shaft; the stirring shaft is sleeved with the sleeve, through holes are formed in the sleeve, and hinging parts are arranged on the stirring shaft; the stirring paddles penetrate through the through holes and are hinged to the hinging parts, a compression spring is arranged between the top face of the bottom end of the sleeve and the end of the stirring shaft, the stirring shaft and the sleeve are provided with sliding grooves and sliding blocks respectively, the sliding blocks are embedded into the sliding grooves, the compression spring pushes the sleeve, and the sliding blocks are located at the bottom ends of the sliding grooves accordingly; at the moment, the through holes abut against the stirring paddles, the stirring paddles are turned downwards, a pushing rod abuts against the bottom face of the bottom end of the sleeve, the stirring paddles are driven to rotate in the mode that the stirring shaft is matched with the sleeve, the pushing rod is stretched to push the sleeve, and the through holes push the stirring paddles to move up and down. The stirring mechanism is higher in stirring efficiency.

Owner:WENLING ZHICHUANG NETWORK TECH CO LTD

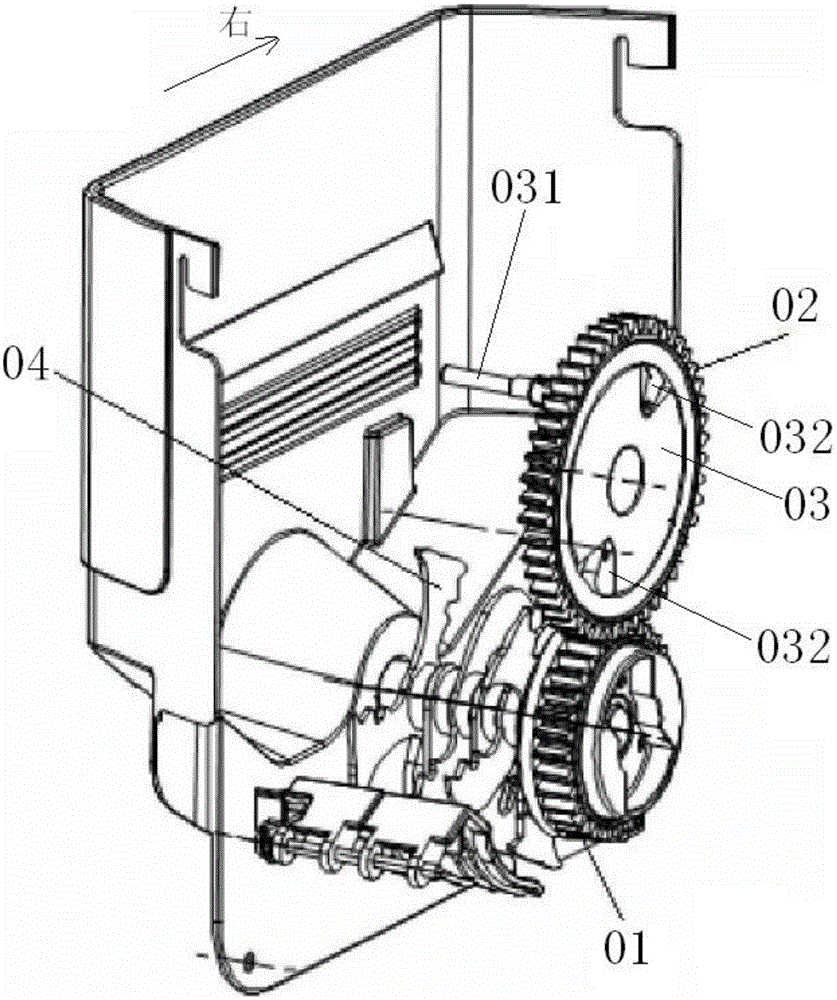

Ice crushing device and refrigerator

ActiveCN105423672AIncrease relative motionImprove mixing effectDomestic cooling apparatusLighting and heating apparatusIce storageEngineering

The embodiment of the invention provides an ice crushing device and a refrigerator and relates to the technical field of equipment for preparing ice blocks. The ice crushing device and the refrigerator aim at solving the problem that an existing ice crushing device cannot fully stir ice blocks accumulated in a barrel-shaped container. The ice crushing device comprises an ice storage barrel, a rotatable stirrer is arranged in the ice storage barrel, a rotatable ice knife assembly is arranged below the stirrer, and the axis of a rotary shaft of the stirrer and the axis of a rotary shaft of the ice knife assembly are mutually on lines in different planes. The ice crushing device is used for an ice maker arranged on the refrigerator.

Owner:HISENSE RONSHEN GUANGDONG REFRIGERATOR

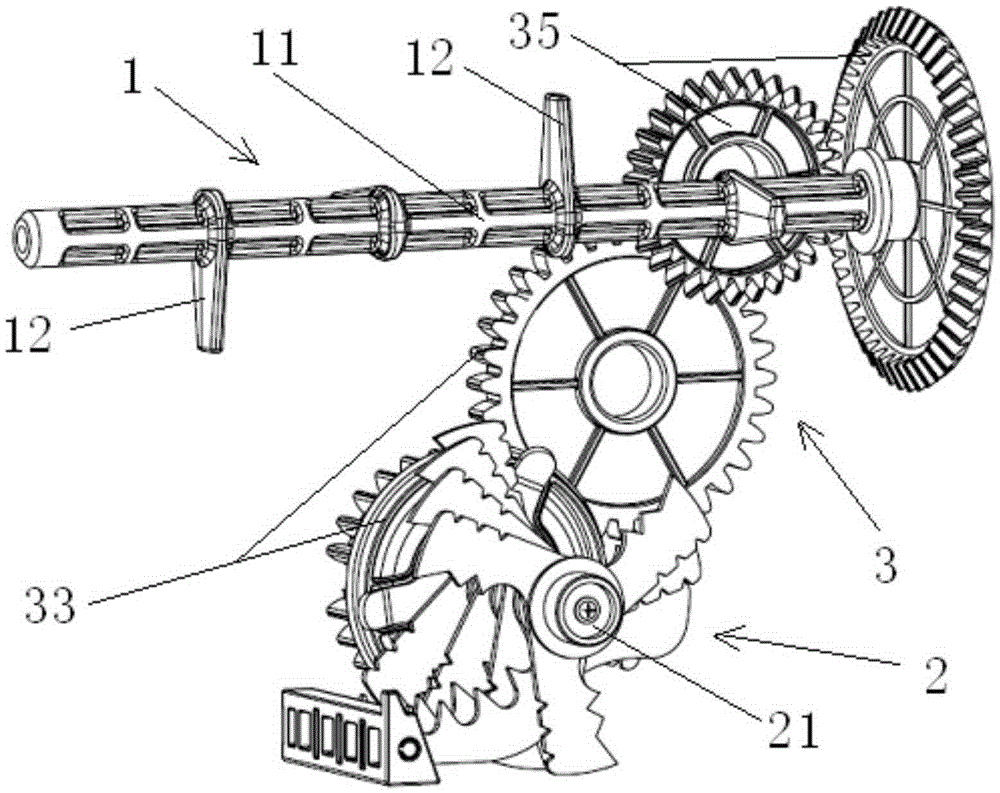

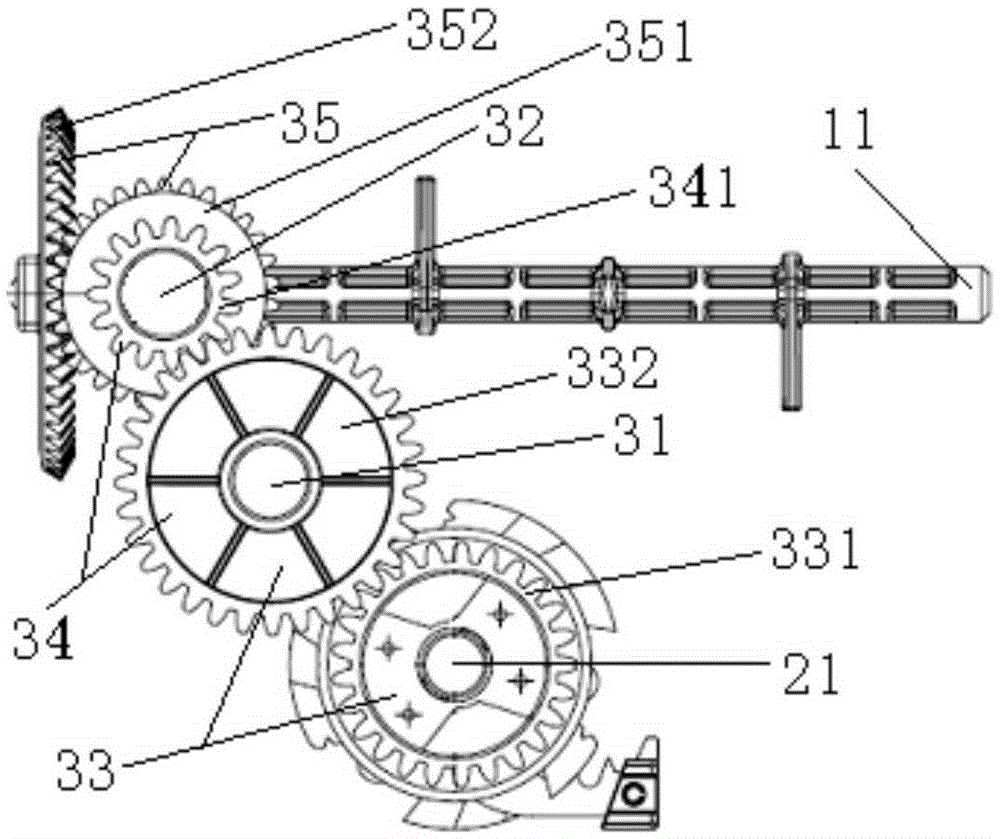

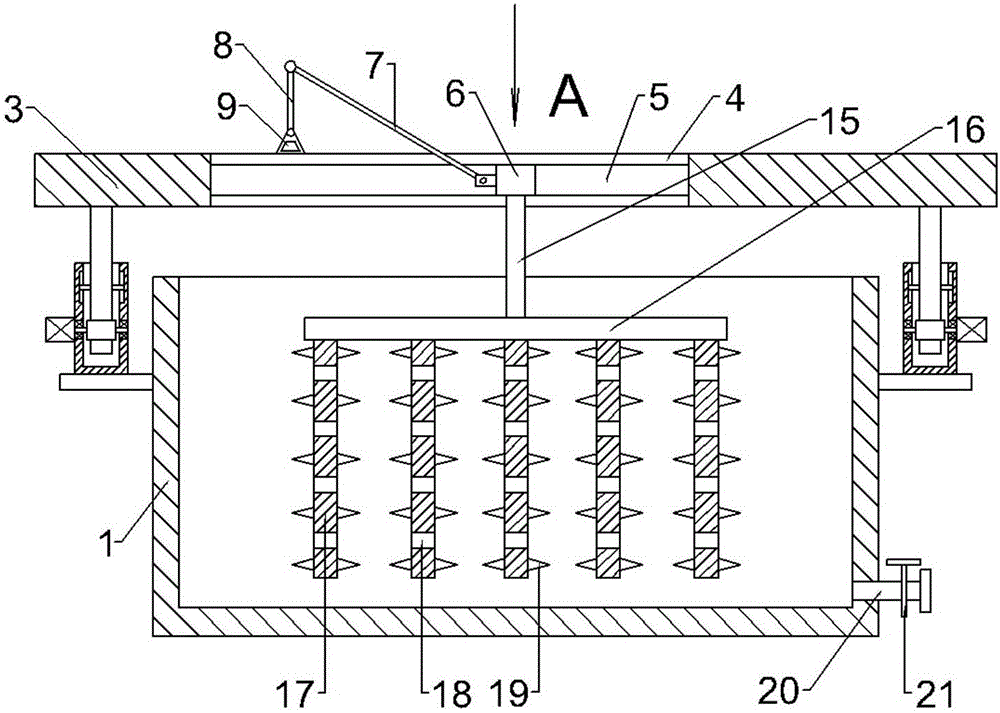

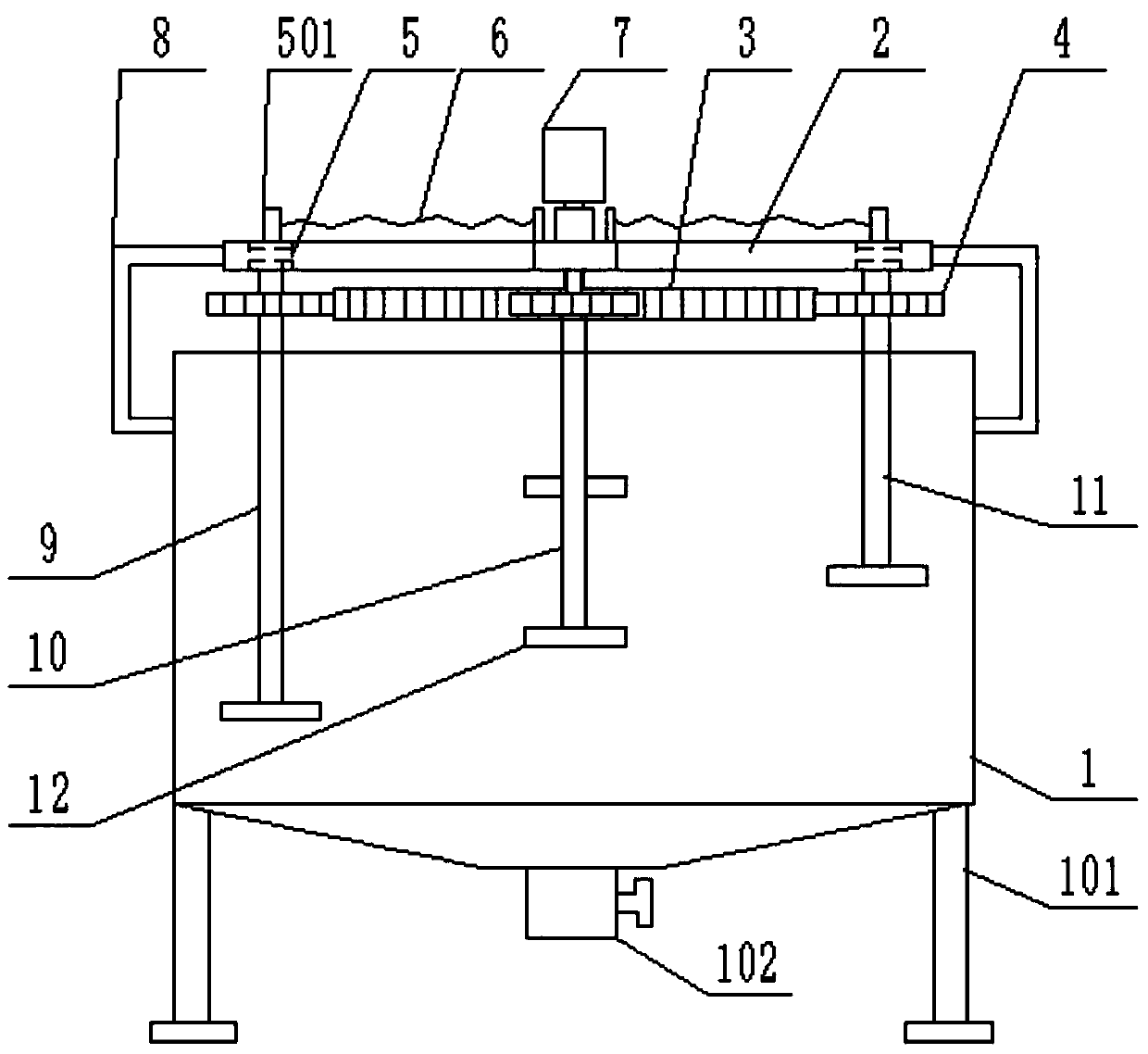

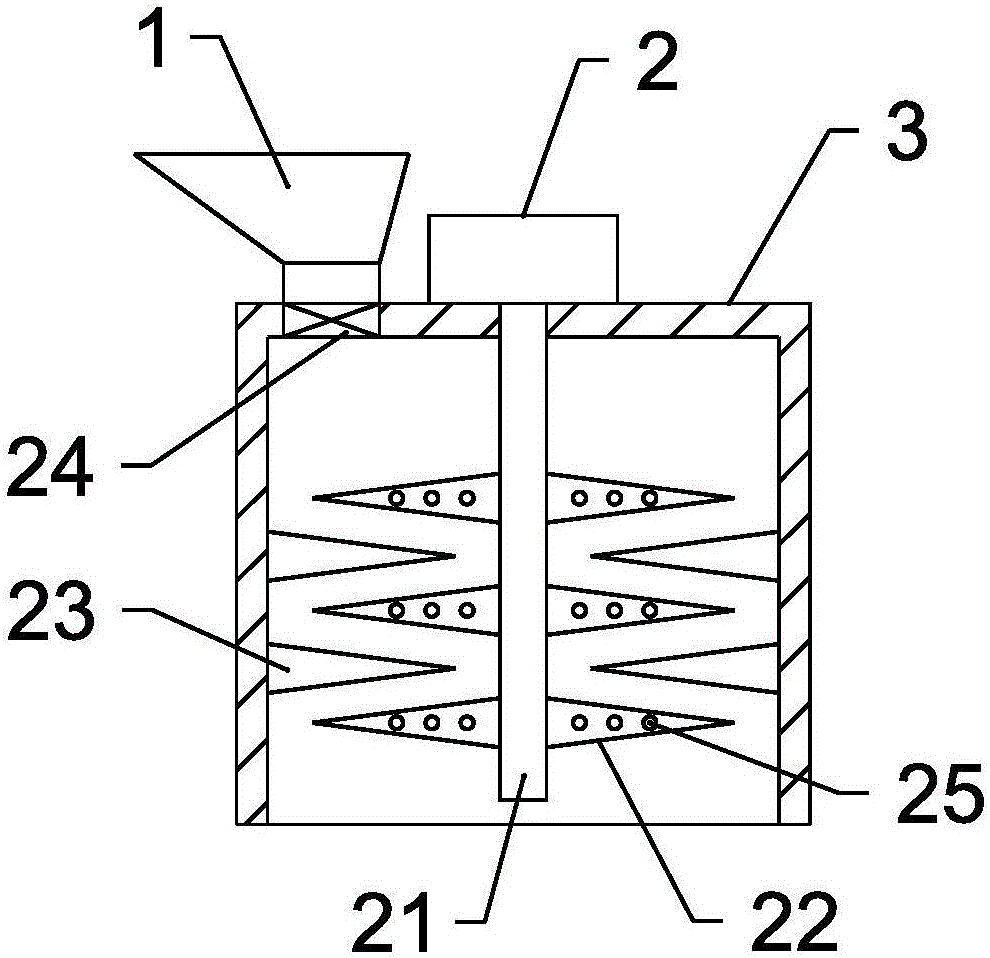

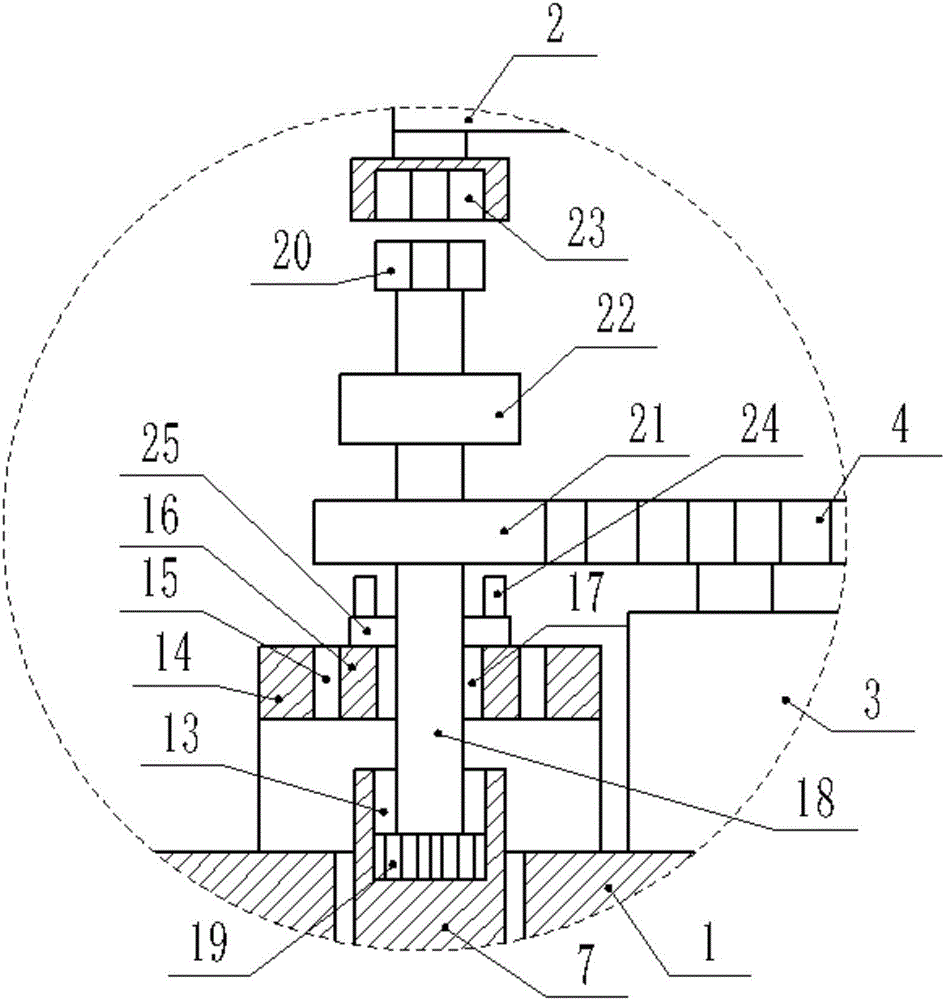

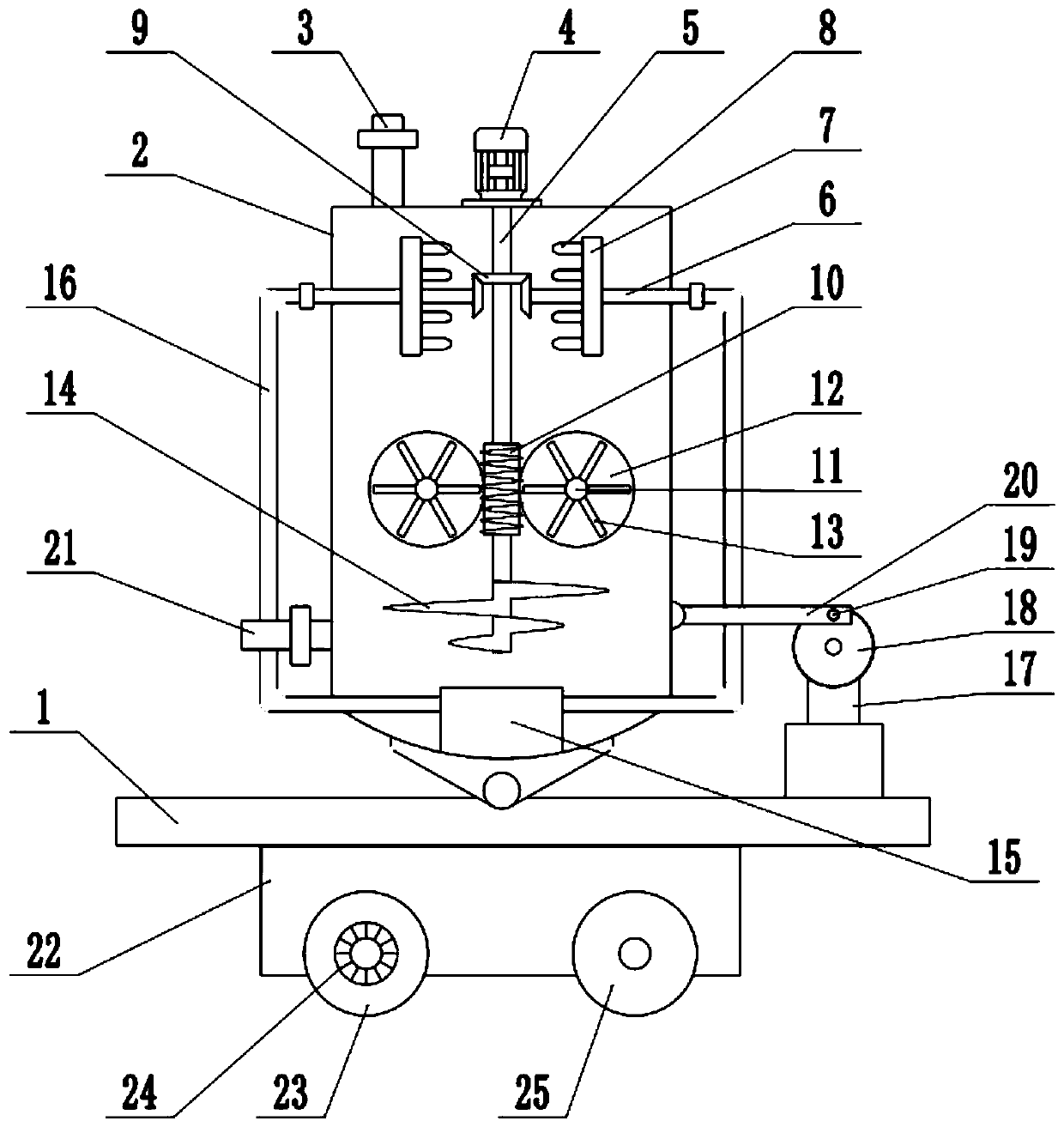

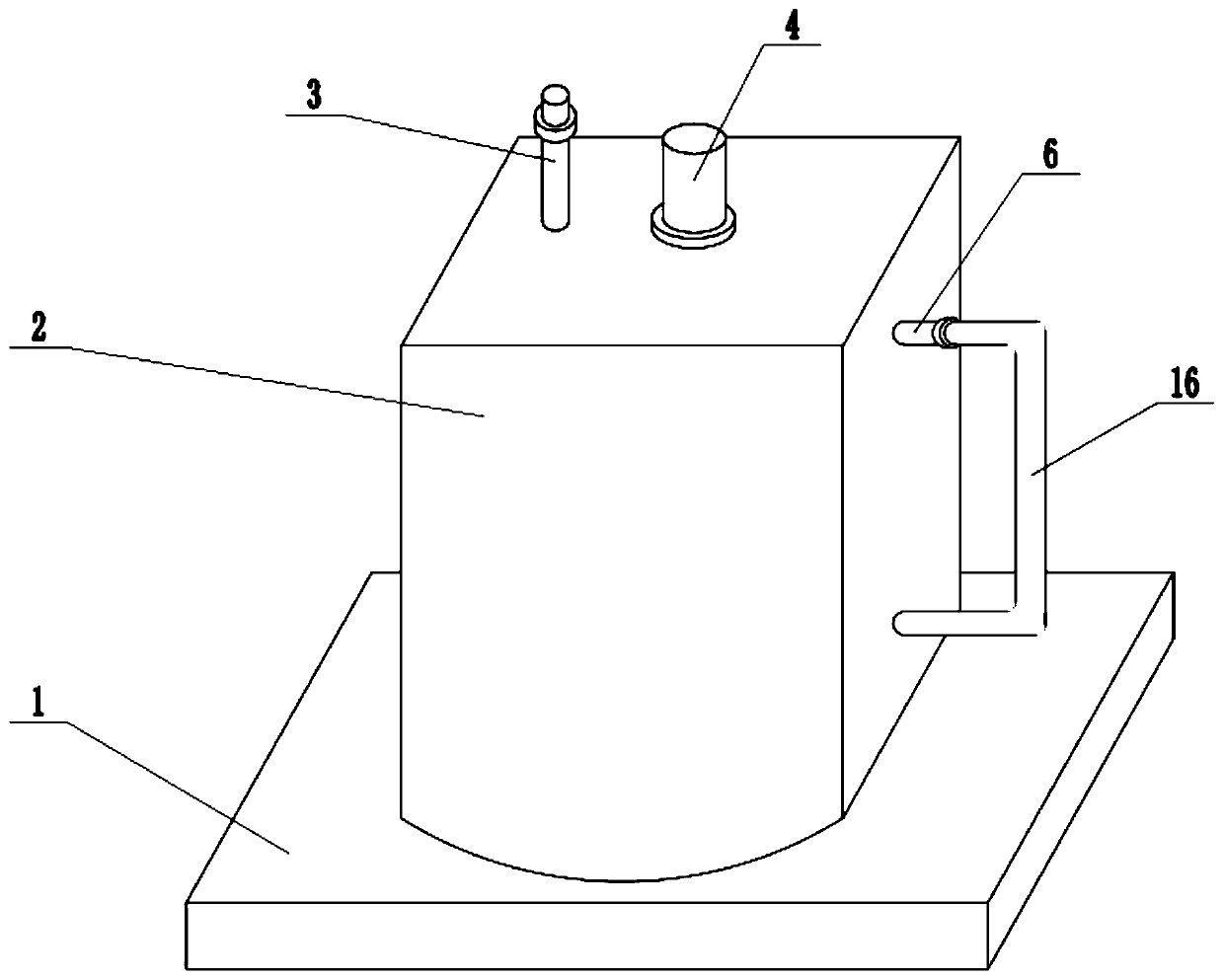

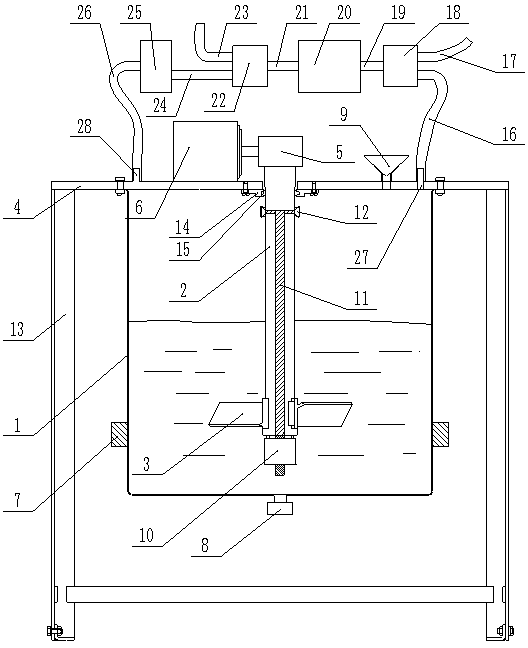

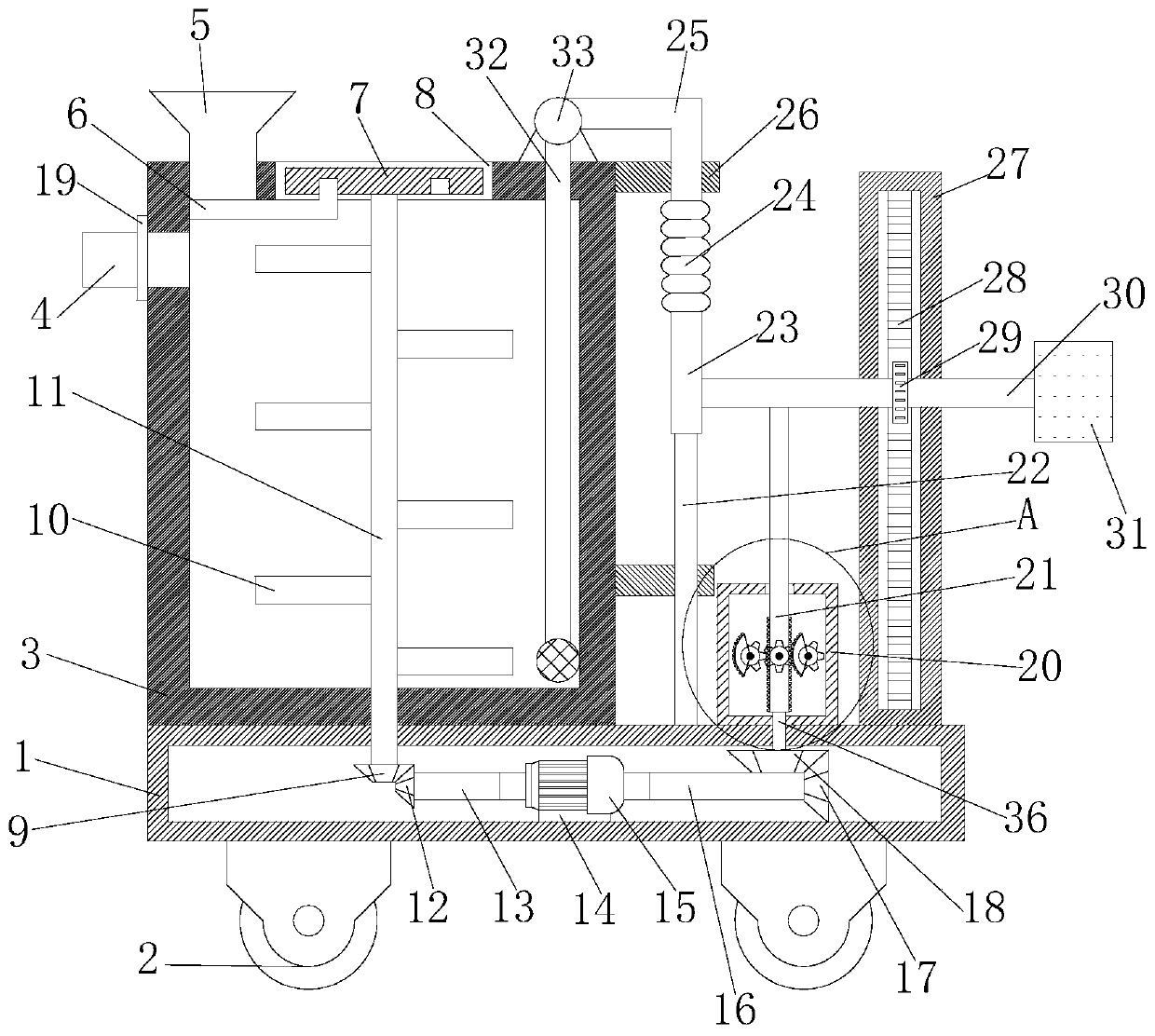

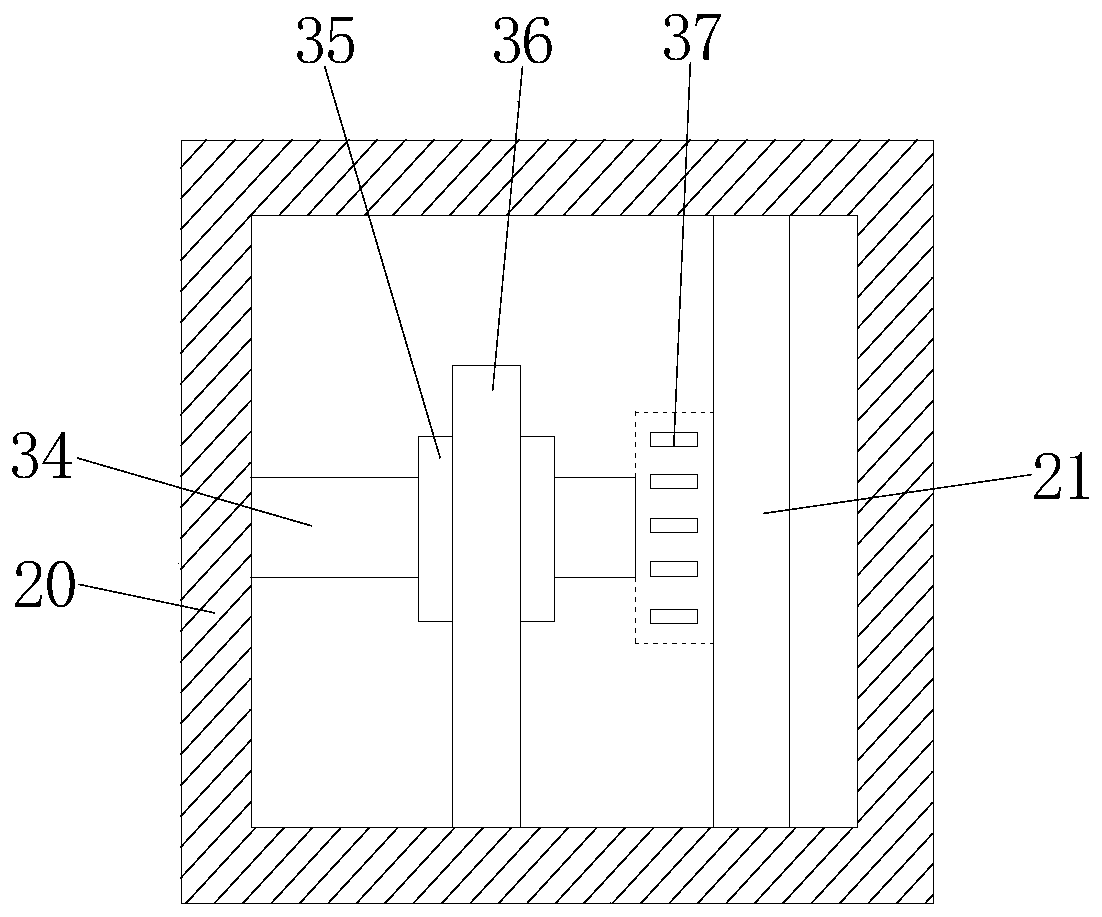

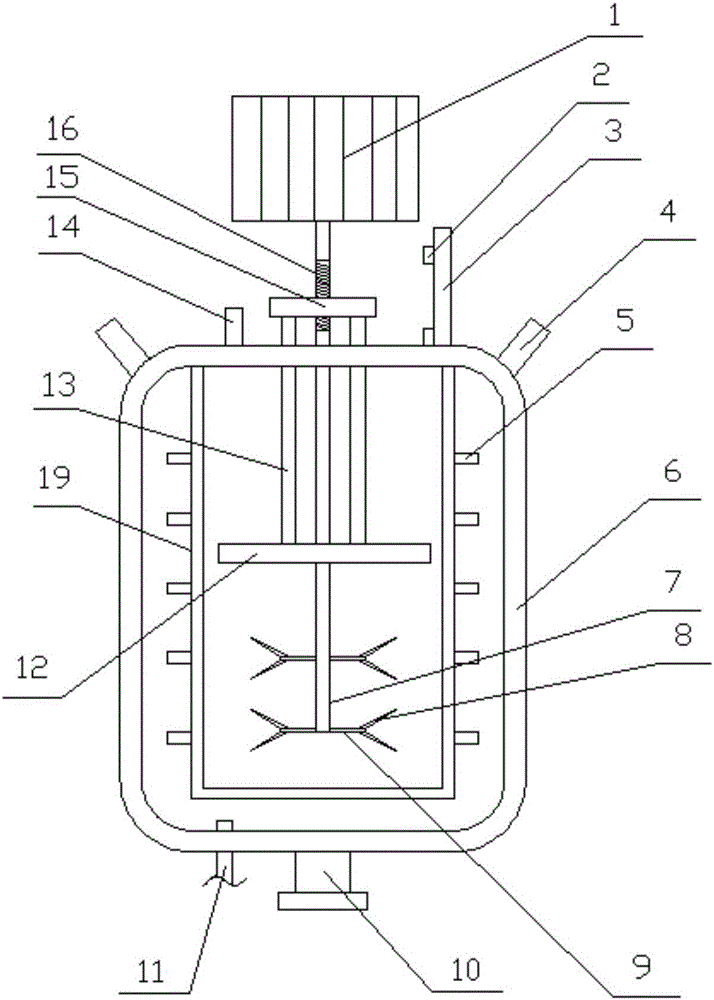

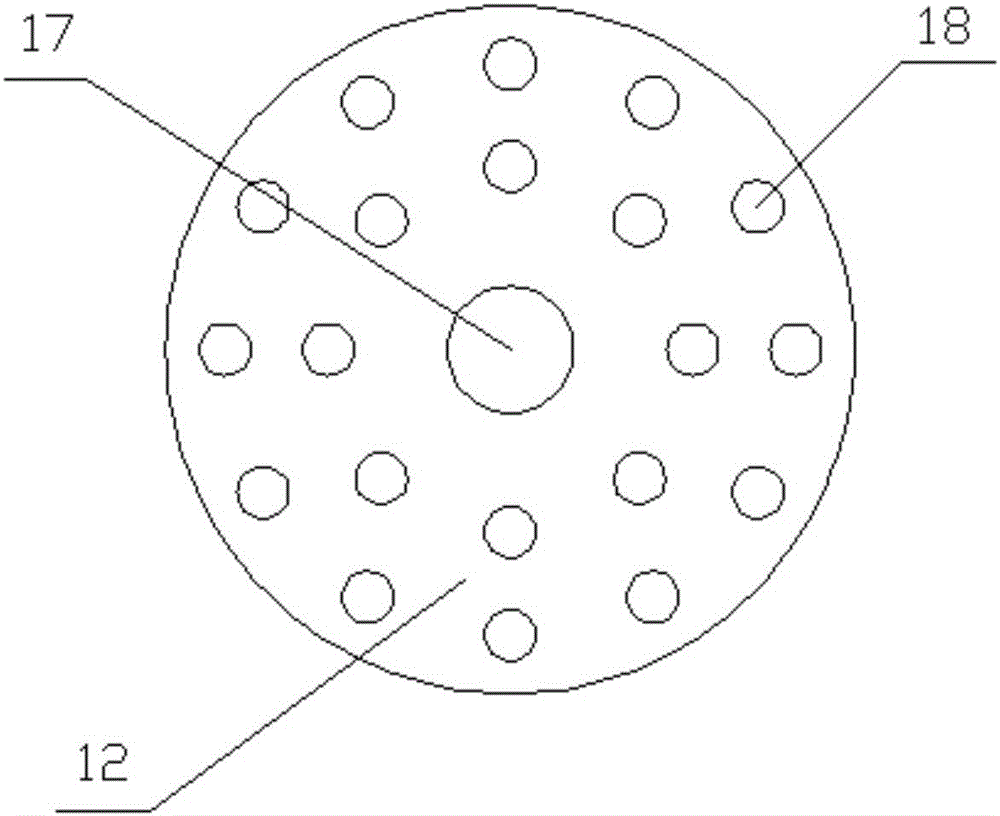

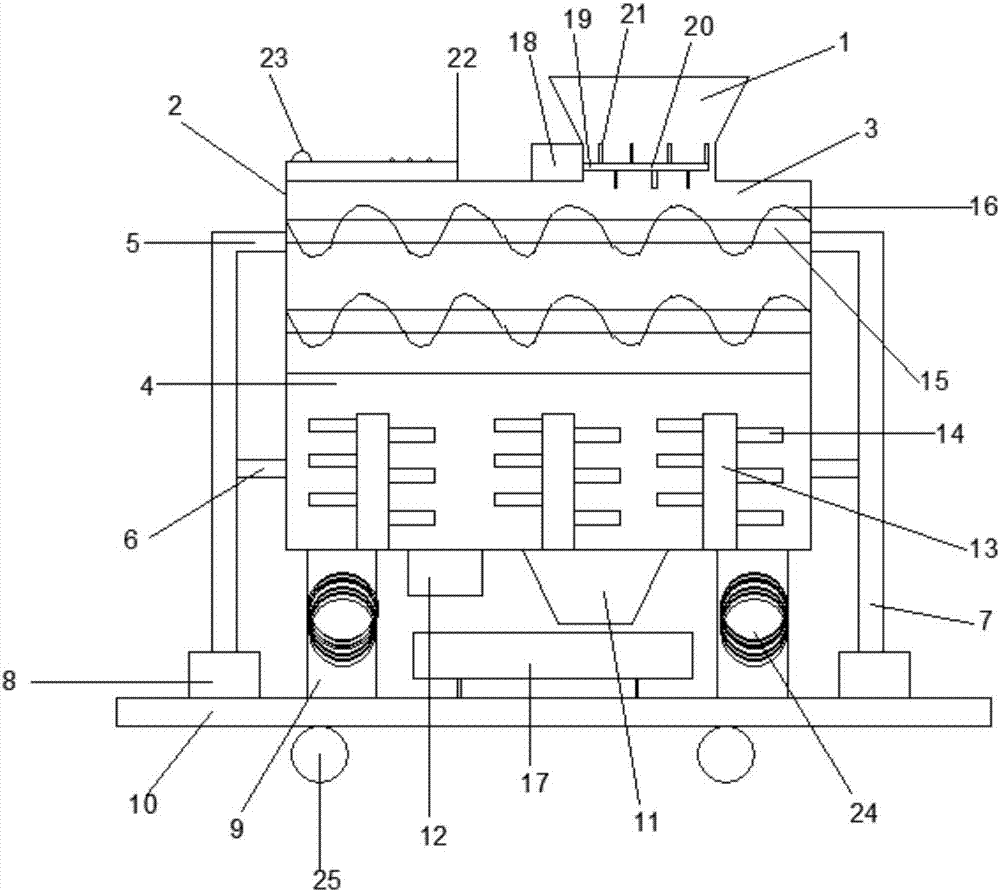

Variable-disturbance range polycarboxylate superplasticizer preparing equipment

InactiveCN107617358AChange the mixing rangeImprove mixing effectShaking/oscillating/vibrating mixersRotary stirring mixersEngineeringSuperplasticizer

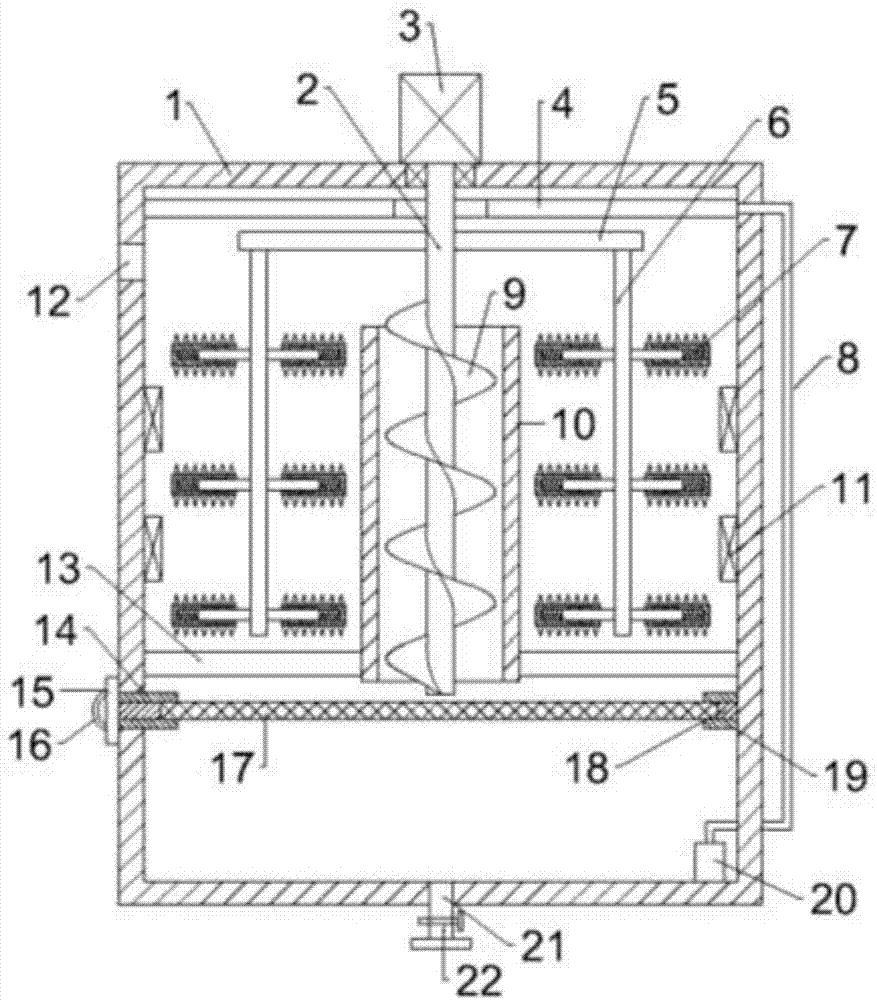

Variable-disturbance range polycarboxylate superplasticizer preparing equipment comprises a kettle body, a transmission device, a machine frame and a first rotating shaft, wherein mounting bases are symmetrically arranged on the outer side wall of the kettle body; lifting bodies are fixedly mounted on the mounting bases; the free ends of the two lifting bodies are jointly fixedly connected with amounting plate; the transmission device is fixed to the mounting plate through the machine frame; the transmission device is connected with the first rotating shaft positioned inside the kettle body.The variable-disturbance range polycarboxylate superplasticizer preparing equipment has the beneficial effects as follows: through stretch and retraction of the lifting bodies, lifting of the mountingplate is driven so as to drive the first rotating shaft to lift in the kettle body, and the first rotating shaft drives a stirring body to lift, so that the stirring range is changed and the stirringeffect is effectively improved; the first rotating shaft drives the stirring body to rotate, stirring bulges arranged on the stirring body stir and mix materials, and during rotation of the stirringbody, the materials enter and exit from through holes to form a turbulent flow, so that the mixing effect is further improved.

Owner:TIANJIN KECHUANG FUXIN TECH CONSULTING CO LTD

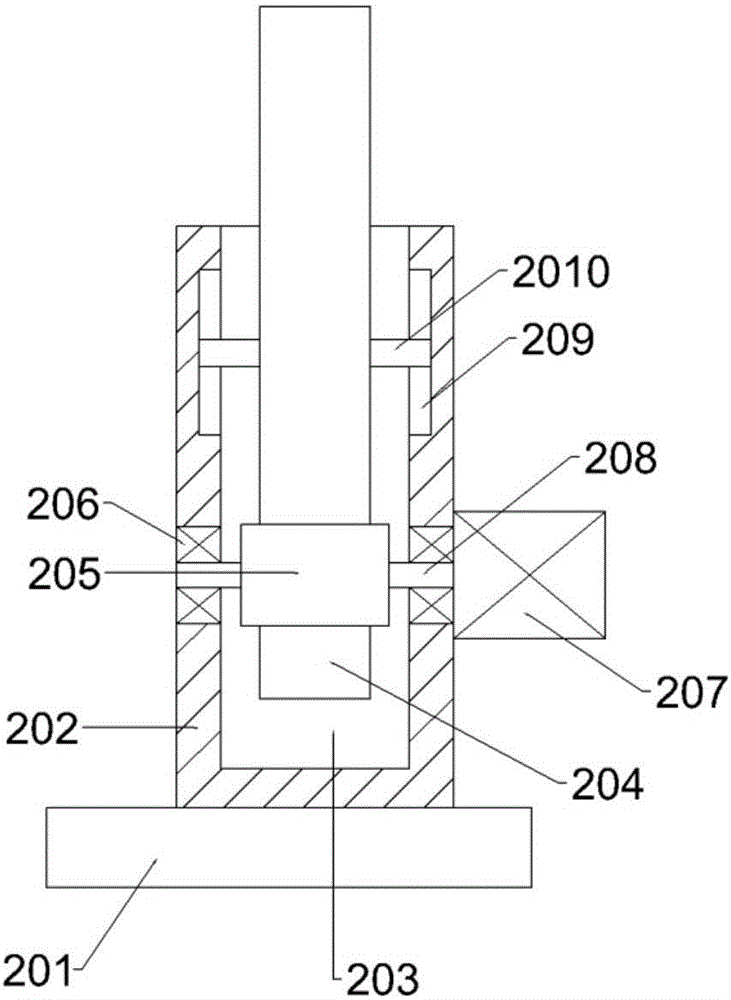

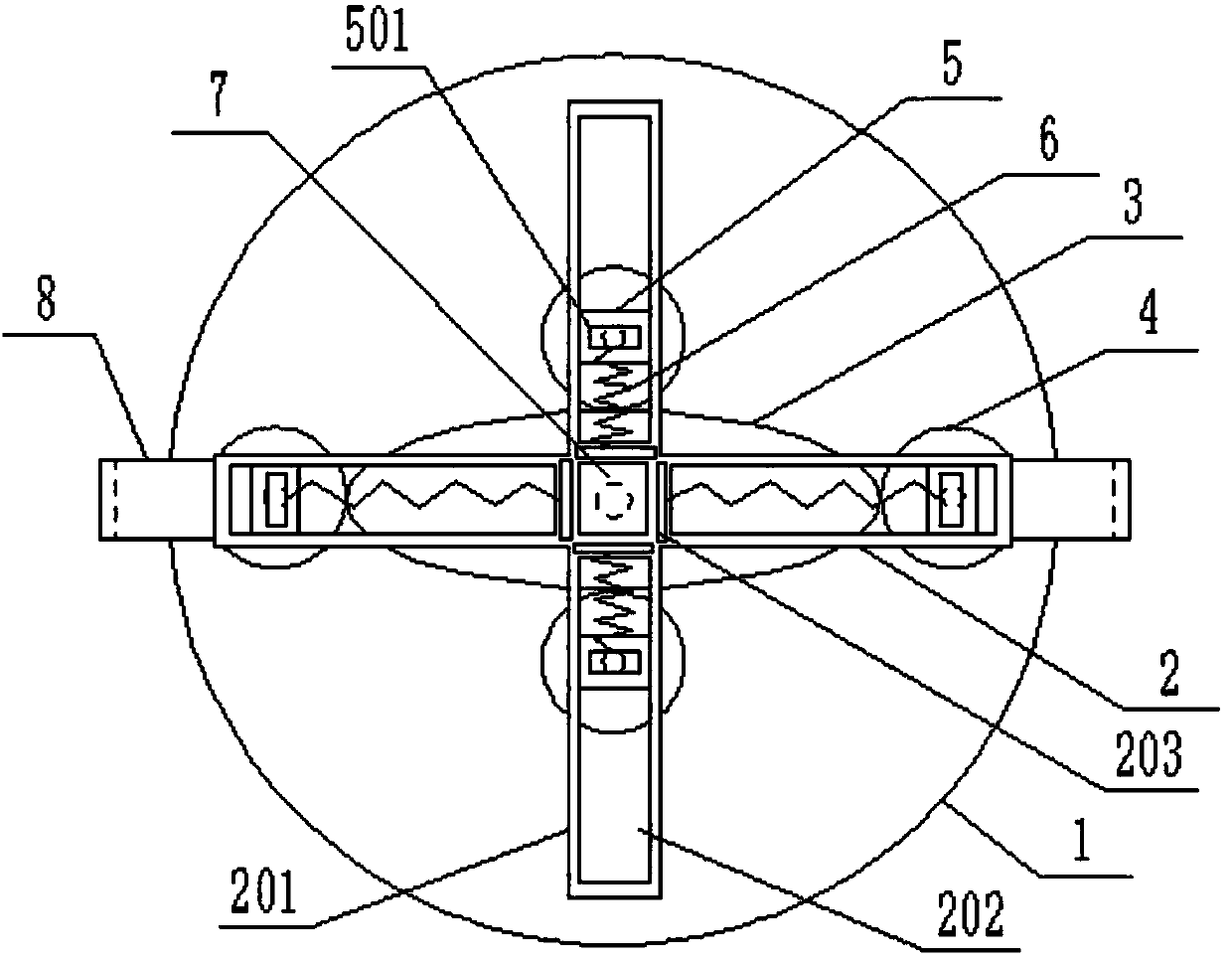

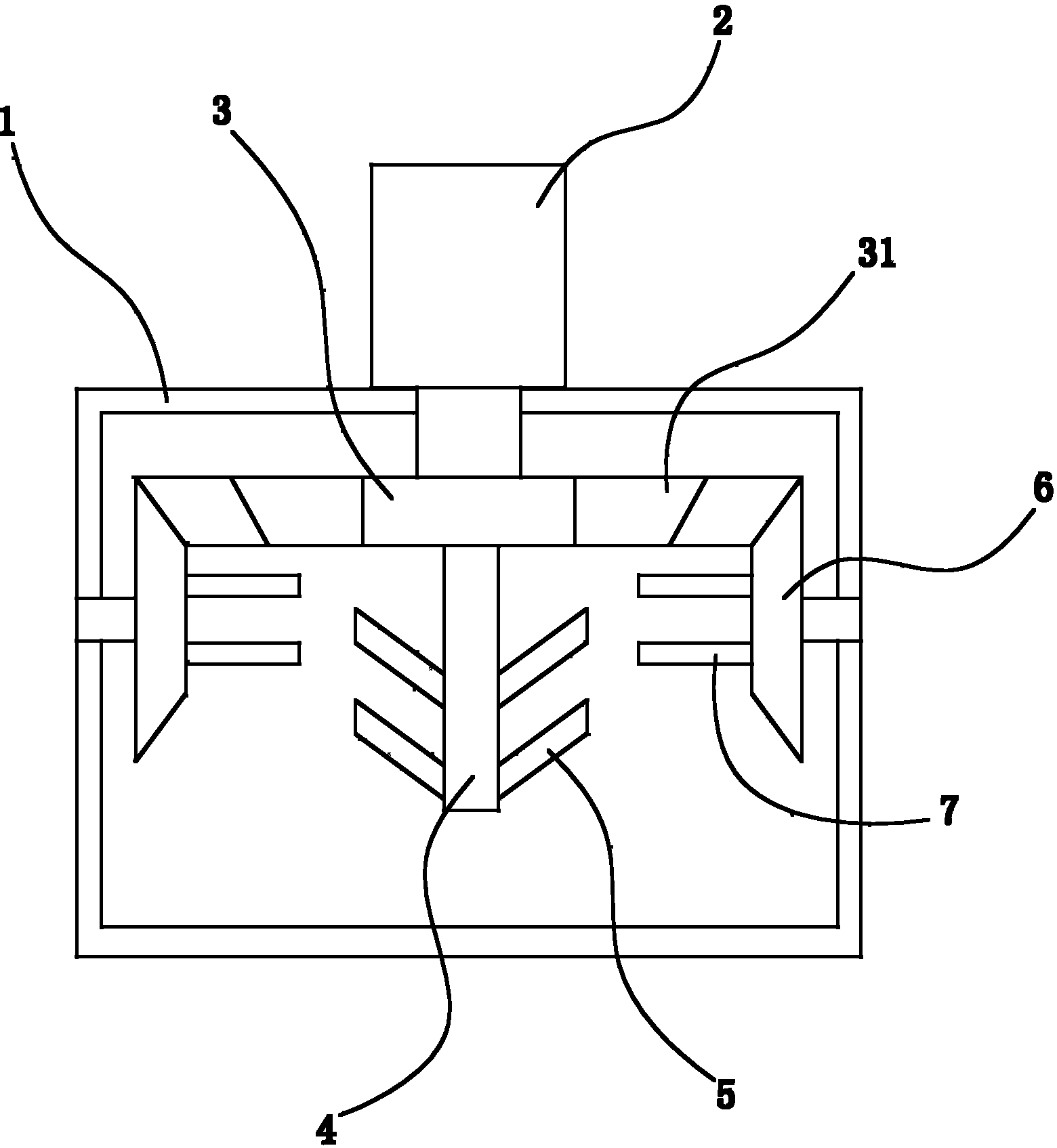

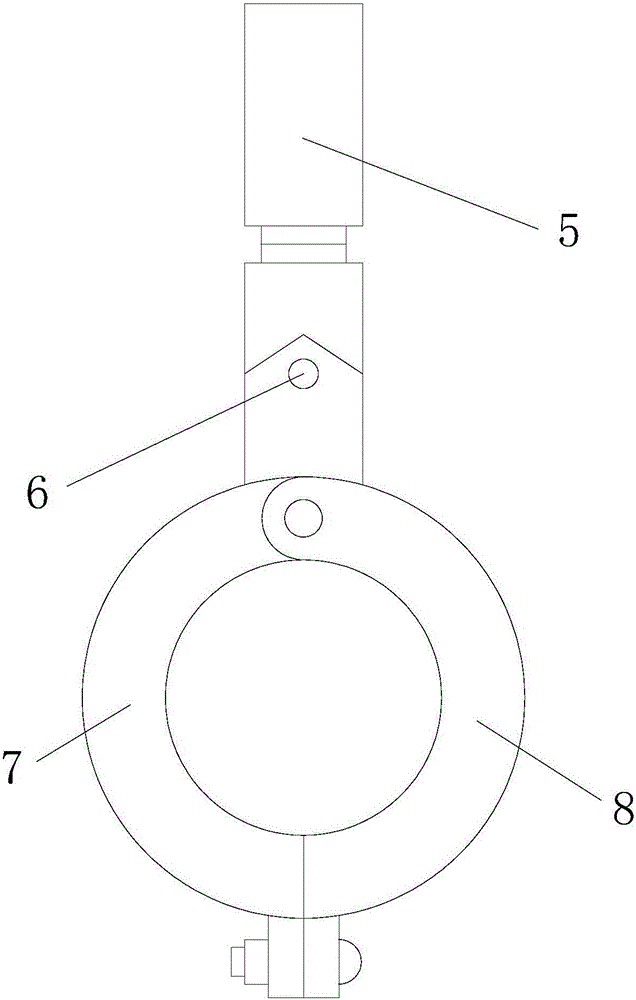

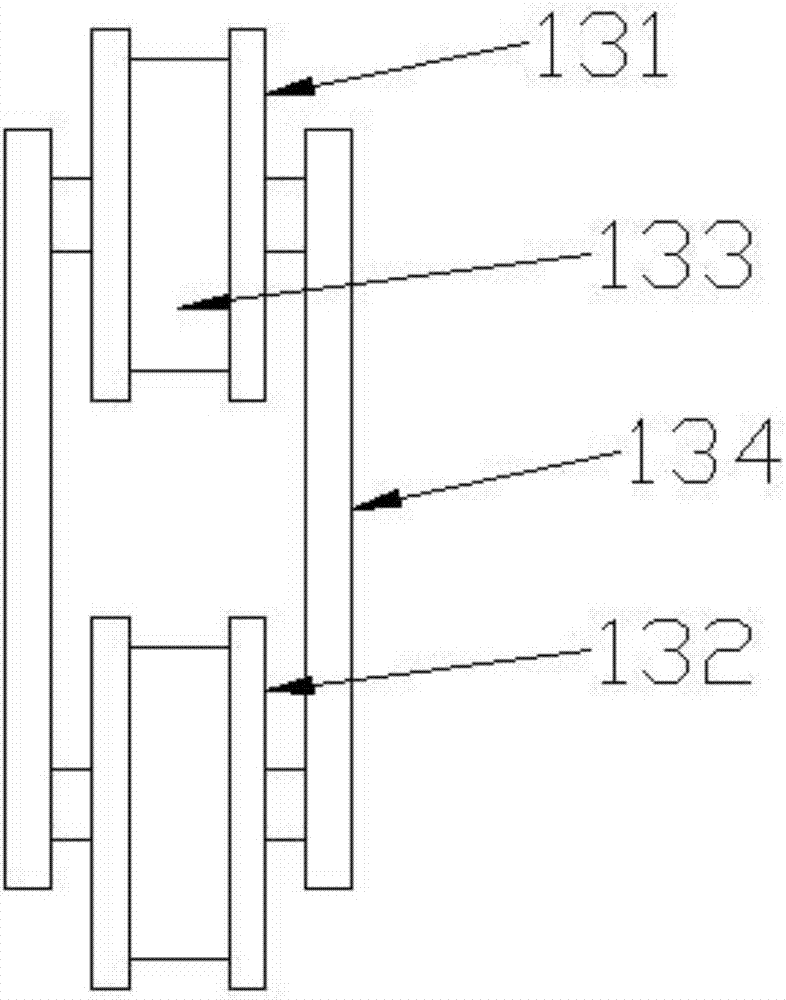

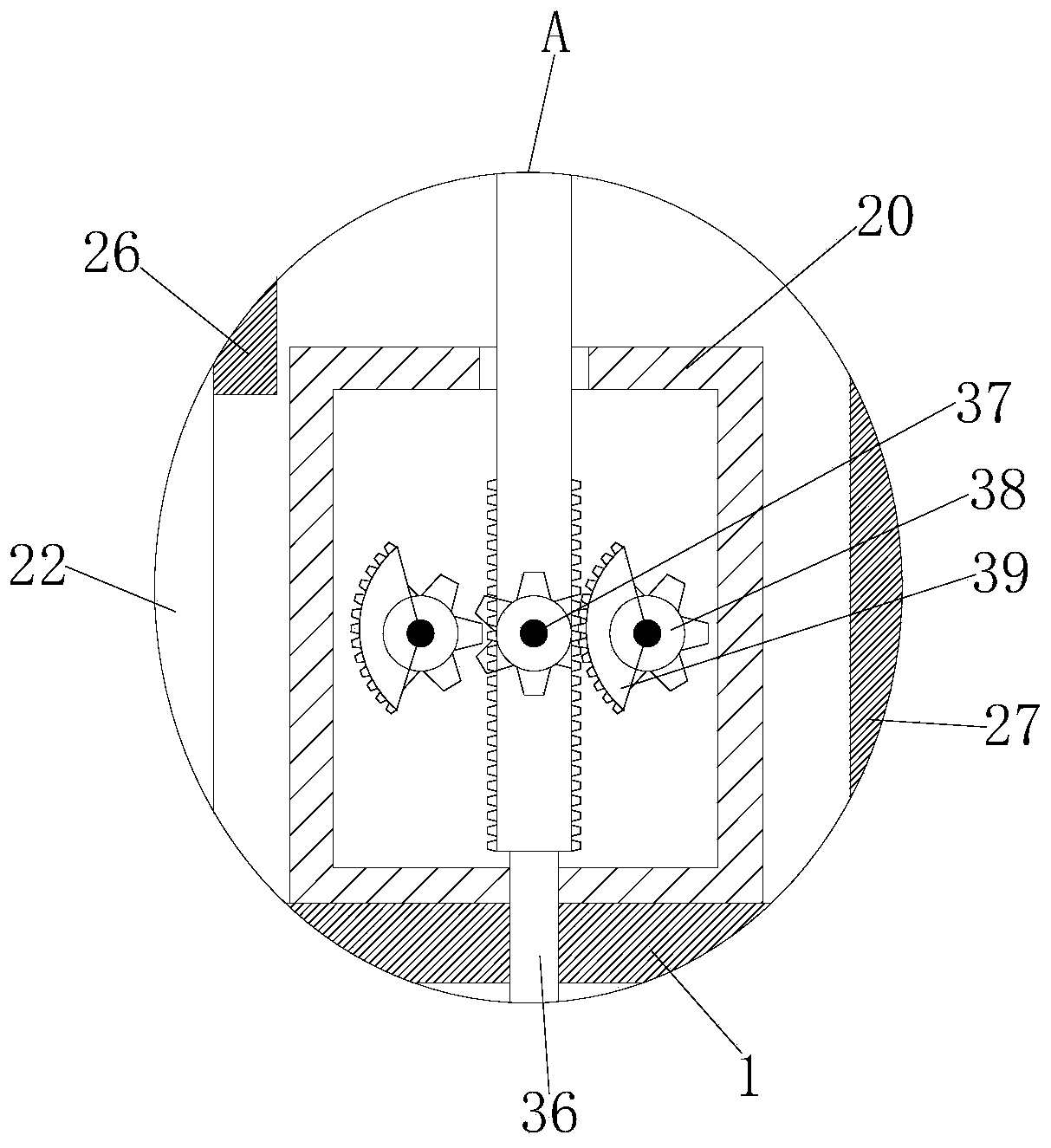

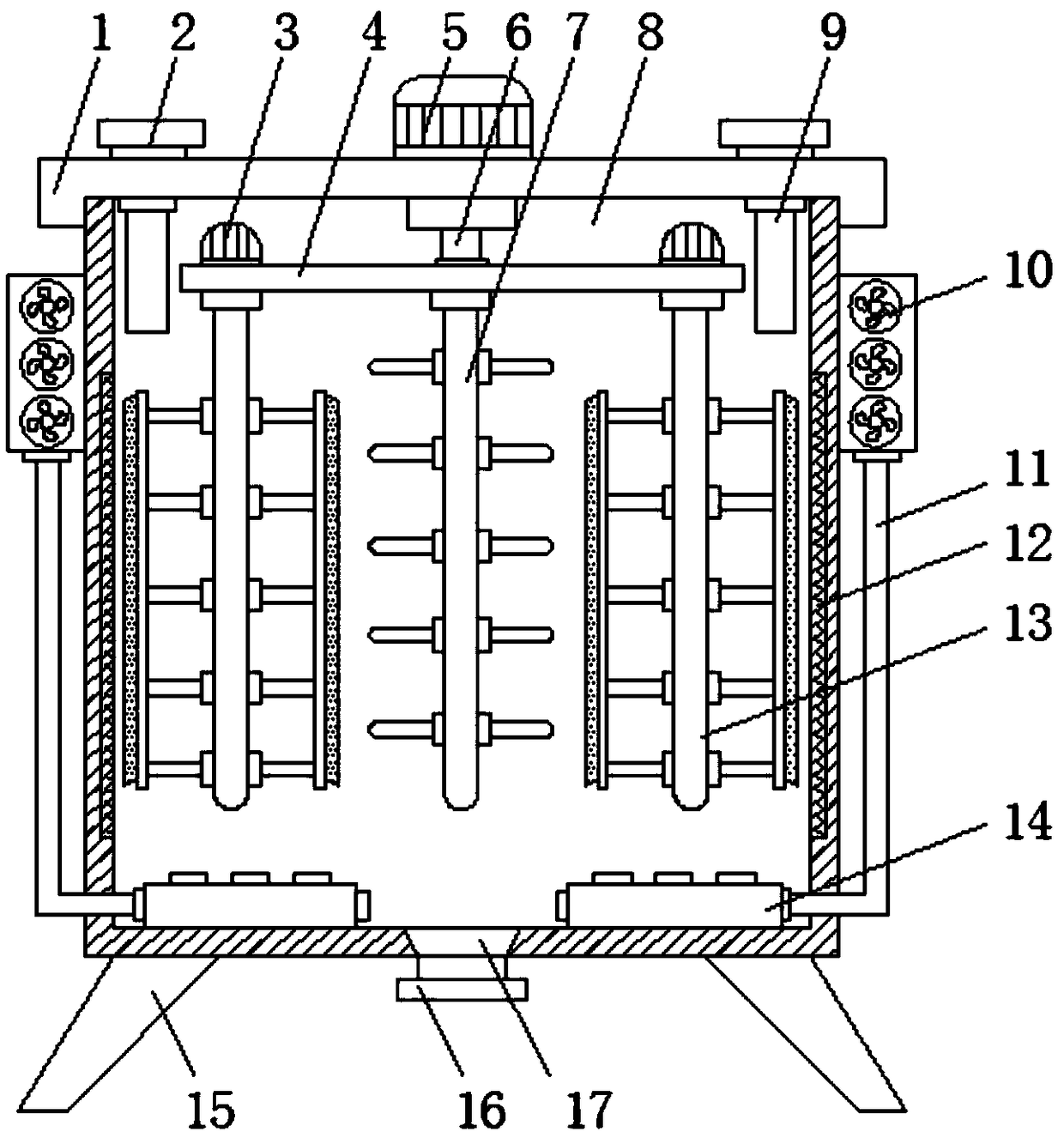

Flocculation tank for wastewater treatment based on rack and gear lifting principle

InactiveCN107434287AImprove mixing effectImprove flocculation effectSedimentation separationWater/sewage treatment by flocculation/precipitationEngineeringMotor drive

The invention discloses a flocculation tank for wastewater treatment based on a rack and gear lifting principle. The flocculation tank comprises a tank body, two lifting devices are symmetrically and fixedly connected to the side walls of the tank body, the lifting device comprises a mounting seat, the mounting seat is fixedly connected to the outer side wall of the tank body, a support column is fixedly connected to the upper side of the mounting seat, a groove is arranged in the support column, the opening of the groove faces up, a rack is arranged in the groove, the lower part of the rack is engaged with a gear, the gear is fixedly connected to a first rotating shaft and the first rotating shaft is erected on the support column. A second motor drives a second rotating shaft to rotate, the second rotating shaft drives a crank to rotate, and the crank drives a connection rod to rotate so that the connection rod drives a sliding block to move left and right in a chute and the sliding block drives a stirrer to move left and right in the tank body and thus stirring effects are improved. Horizontal turbulent flow through holes on a turbulent flow plate carry out perturbance on sewage and a flocculant so that the flocculation effect of the sewage is improved.

Owner:苏州雨谦工品科技有限公司

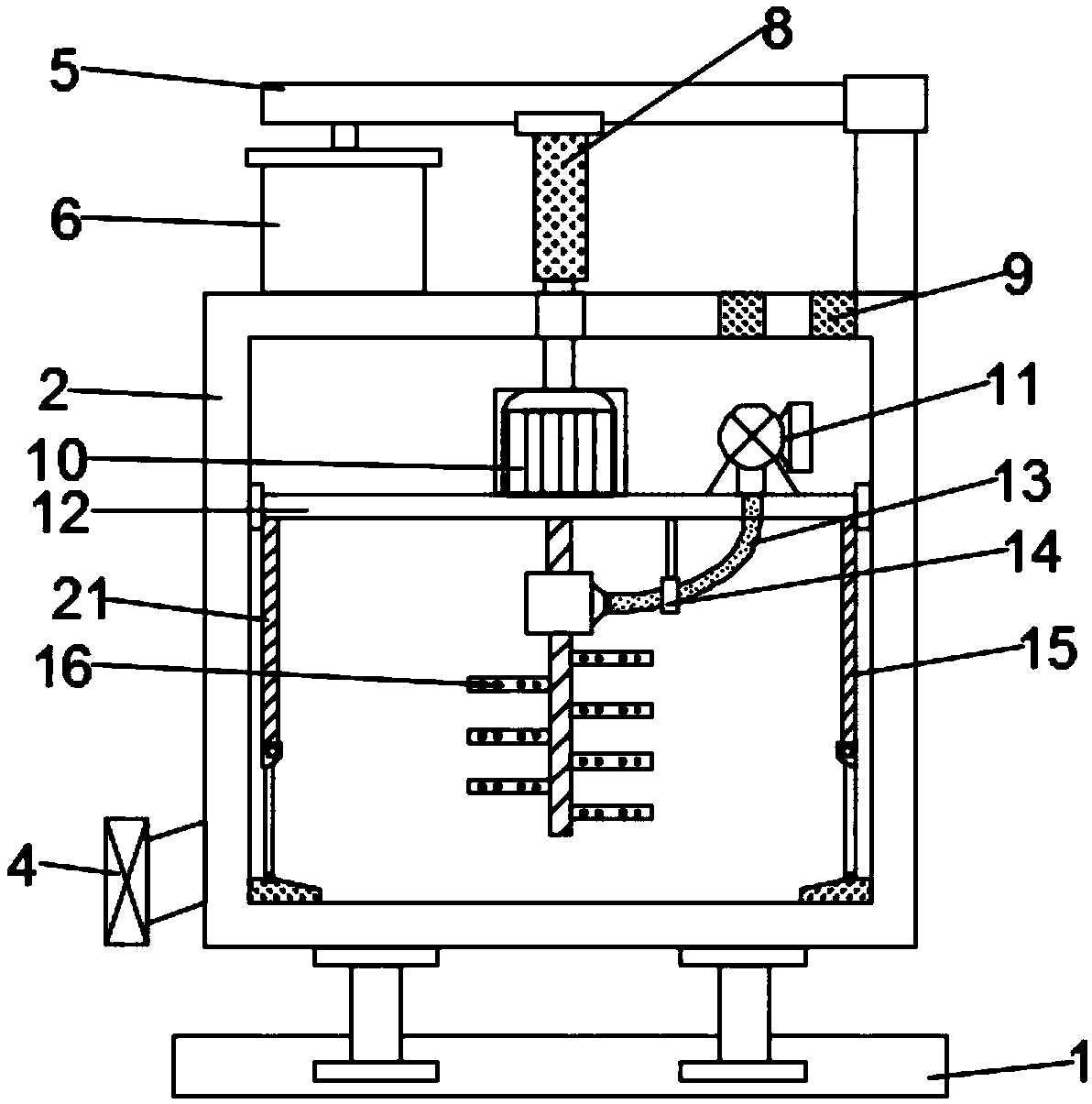

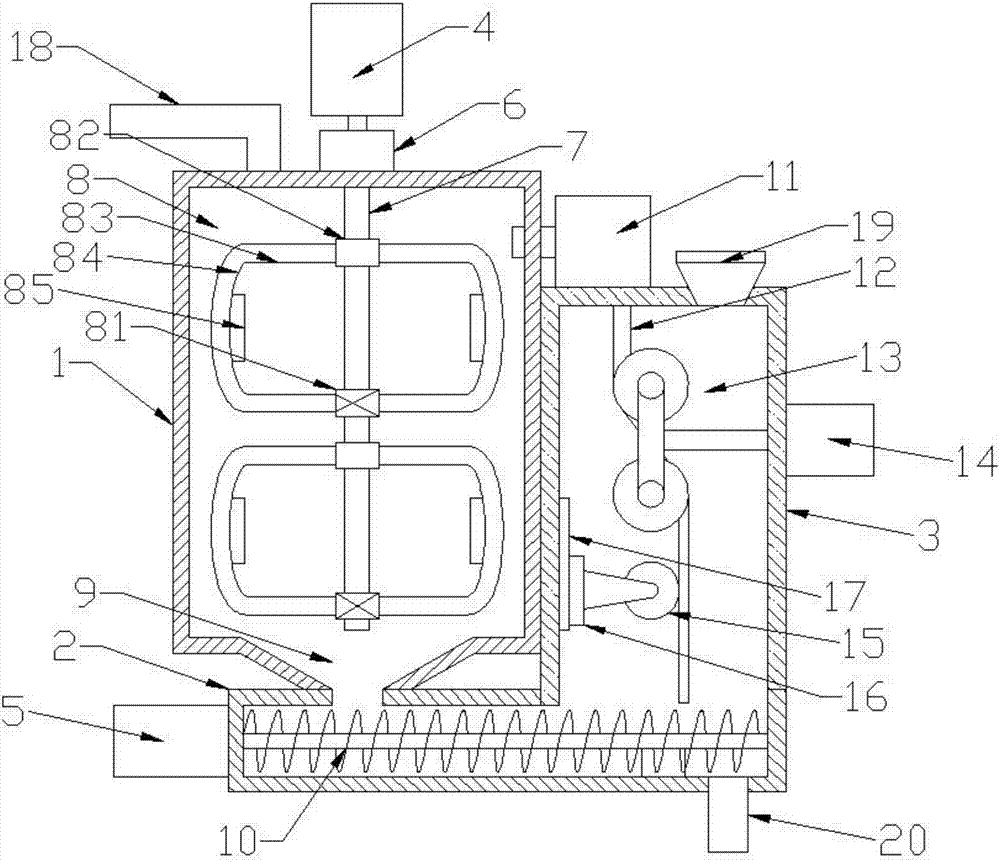

Filtering and stirring device for coating production

ActiveCN107551636AImprove filtration efficiencyImprove mixing effectRotary stirring mixersMixer accessoriesElectric driveCoating

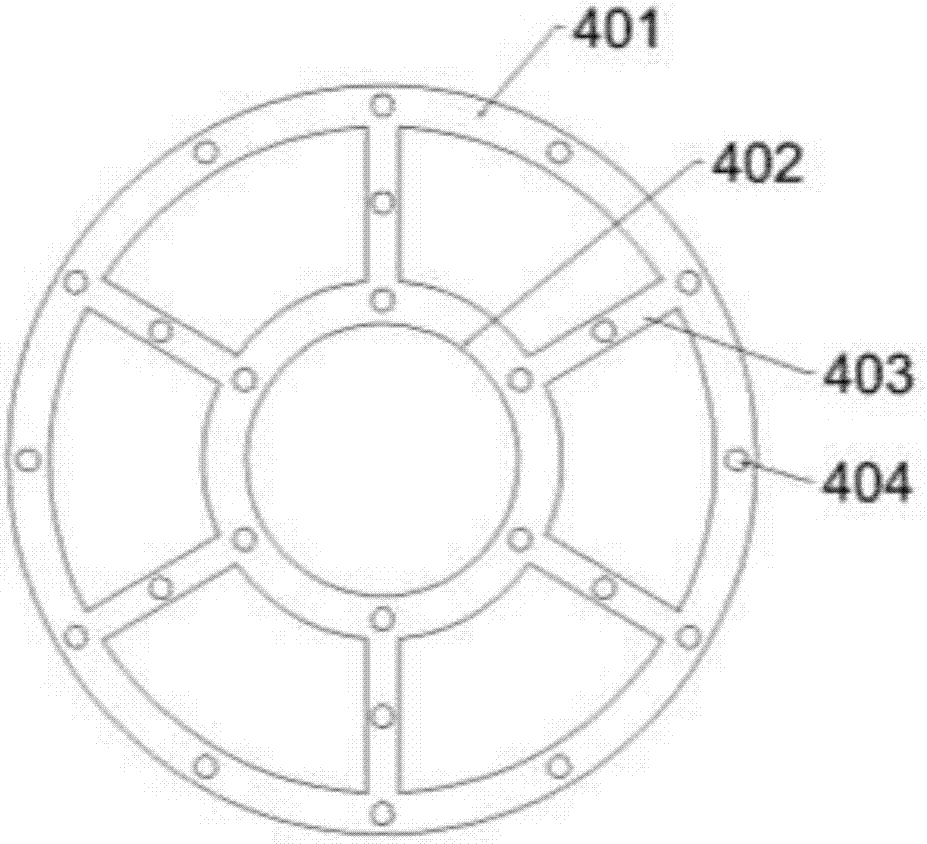

The invention discloses a filtering and stirring device for coating production. The filtering and stirring device comprises a box, wherein a feeding pipe is arranged in the middle of the box; a belt wheel is arranged in the position, located on the feeding pipe, of the top of the box and connected with a driving mechanism through a driving belt; an impurity suction pipe is arranged on the inner side of the feeding pipe; the upper end of the impurity suction pipe is connected with a suction device; a plurality of second stirring blades are arranged on the inner side wall of the feeding pipe; afilter screen is arranged below the feeding pipe; multiple first springs are arranged in the circumferential direction of the upper side of the outer ring of the filter screen; the upper ends of the first springs are connected with electric drive pushers; a second spring is arranged in the middle of the bottom of the filter screen; multiple diagonal bars are arranged in the circumferential direction of the outer side of the feeding pipe; first stirring blades matched with the filter screen are arranged at the lower ends of the diagonal bars; screw blades for lifting a coating are further mounted at the lower part of the feeding pipe. The stirring and filtering effects of the coating are good, impurities are convenient to clean, and the device has higher popularization and utilization value.

Owner:YIZHENG JINMEILIN CONSTR MATERIAL

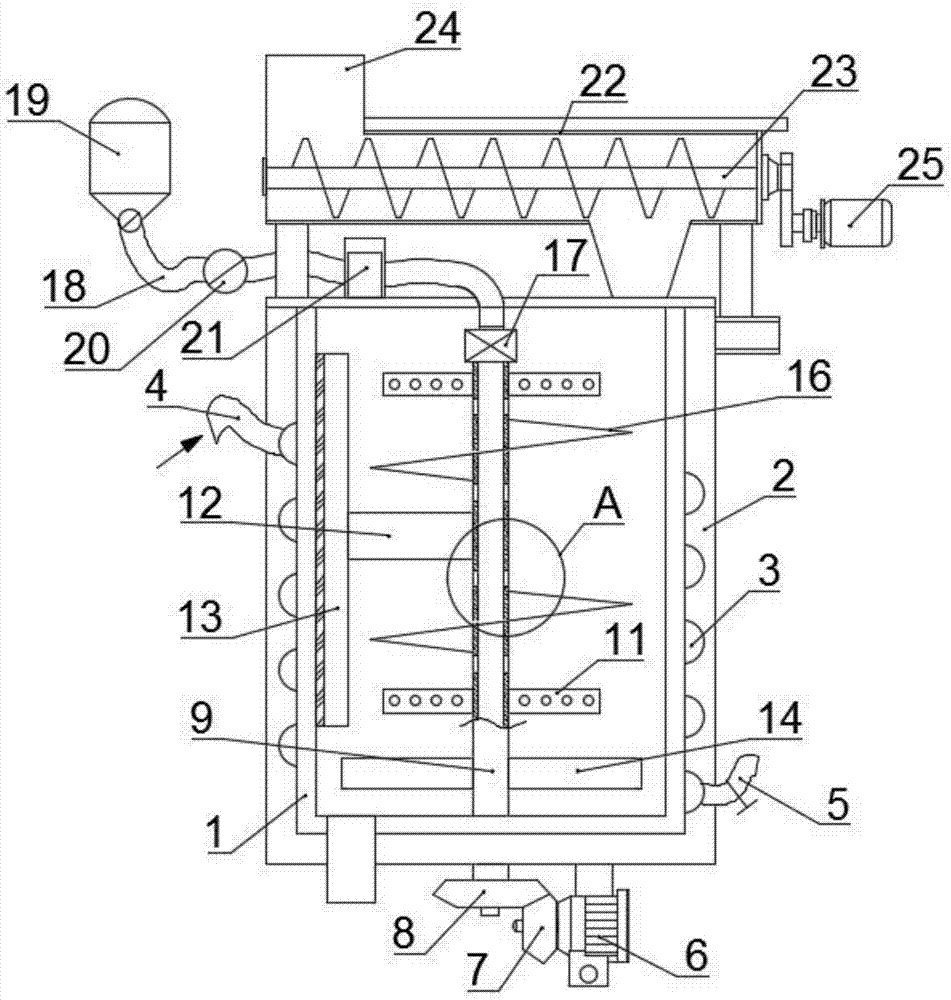

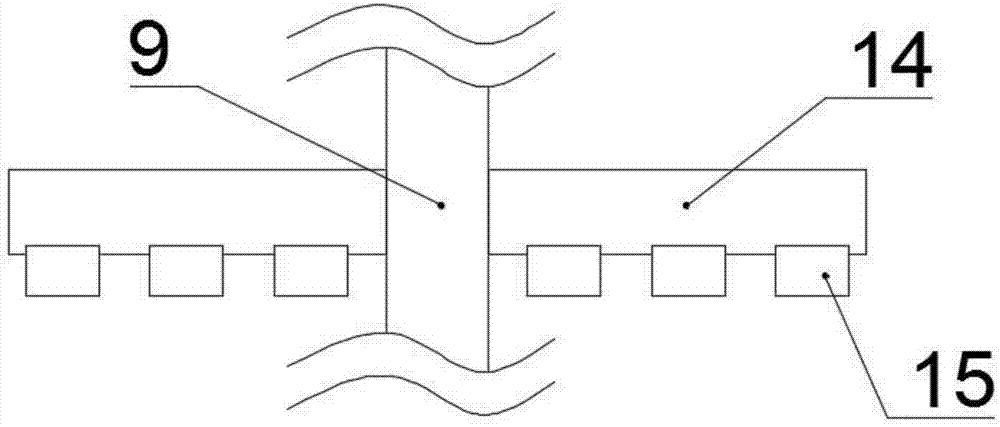

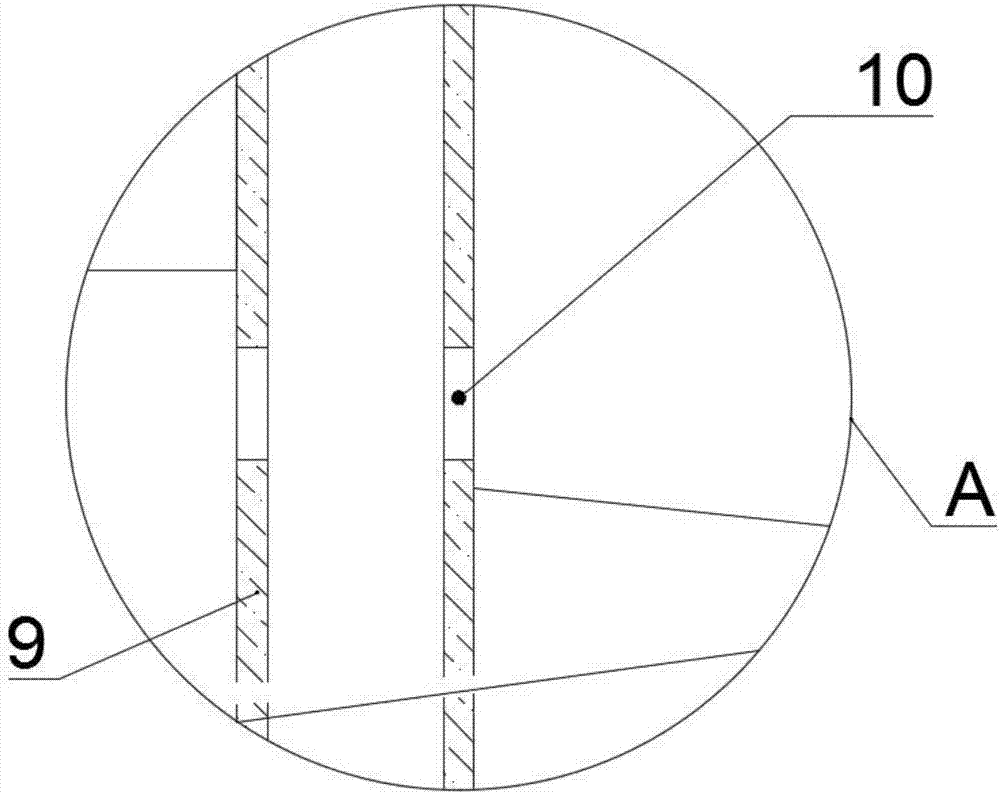

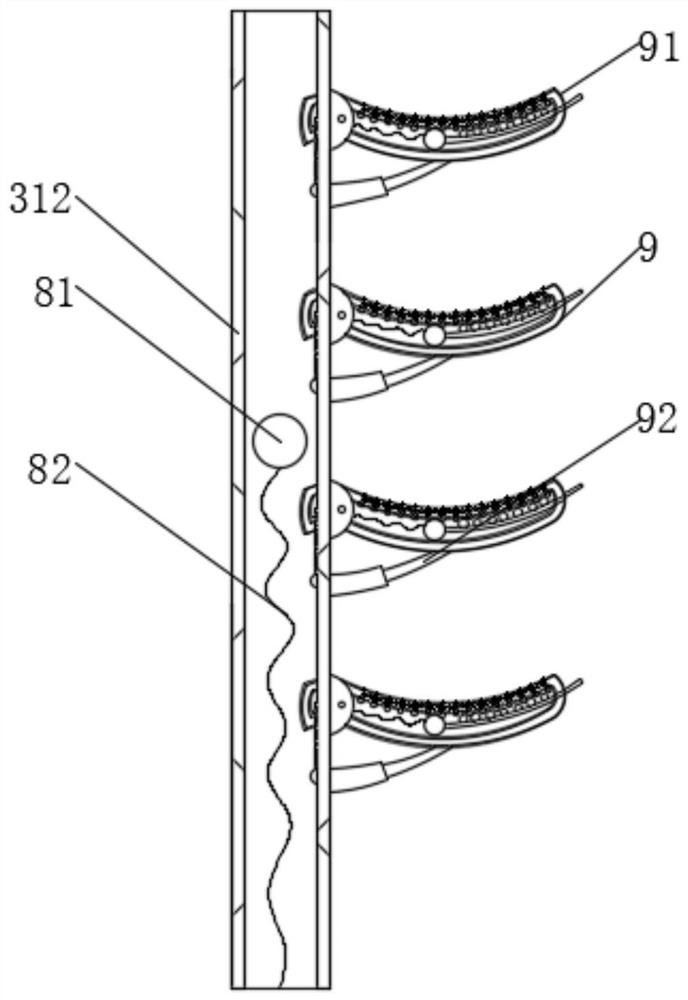

Soil remediation device based on drip washing and microbial remediation theory

InactiveCN107457265AImprove mixing effectImprove the mixing effectContaminated soil reclamationRADIUSMotor drive

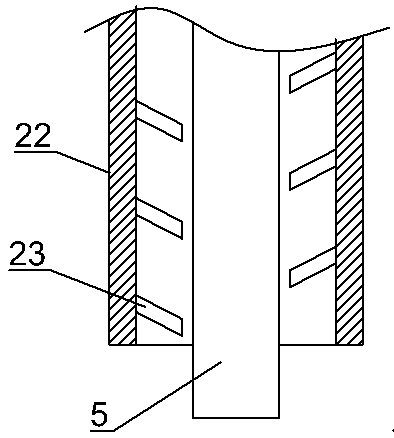

A soil remediation device based on the principles of rinsing and microbial remediation, comprising a housing, a sleeve is arranged inside the housing, the bottom of the sleeve is fixedly connected to the inner side wall of the housing through several fixing rods, and the sleeve is provided with There is a rotating shaft, the top of the rotating shaft extends upwards through the top of the housing, and the top of the rotating shaft is fixedly connected with the output shaft of the motor, and the part of the rotating shaft inside the sleeve is arranged with spiral blades; the upper part of the rotating shaft is symmetrically fixedly connected with two A horizontal rod, the lower side of the other end of the horizontal rod is fixedly connected with a vertical rod, and a plurality of stirring devices are evenly arranged on the vertical rod. The beneficial effect of the present invention is that the motor drives the rotating shaft to rotate, the rotating shaft drives the vertical rod to rotate through the horizontal rod, the vertical rod drives the rotation of the stirring device, and the moving rod on the stirring device is away from the vertical rod after being subjected to centrifugal force, thereby driving the stirring blade The mixing radius is enlarged, and the mixing effect of the soil is improved.

Owner:谢添

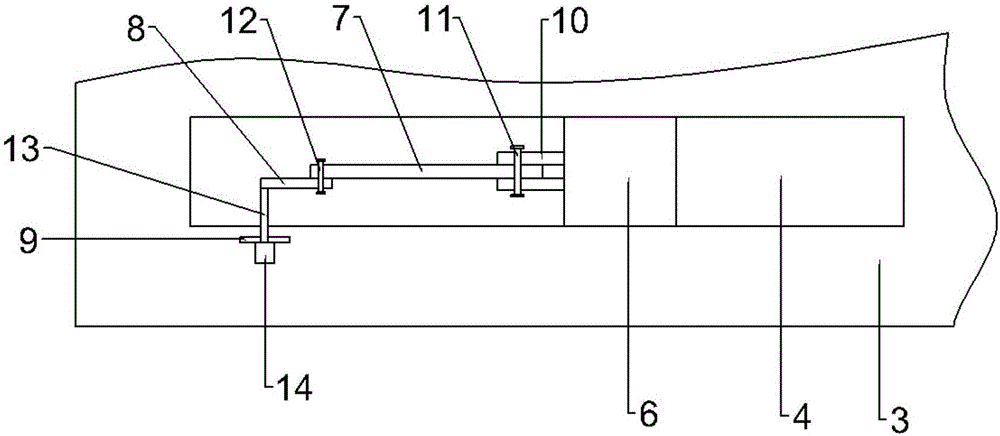

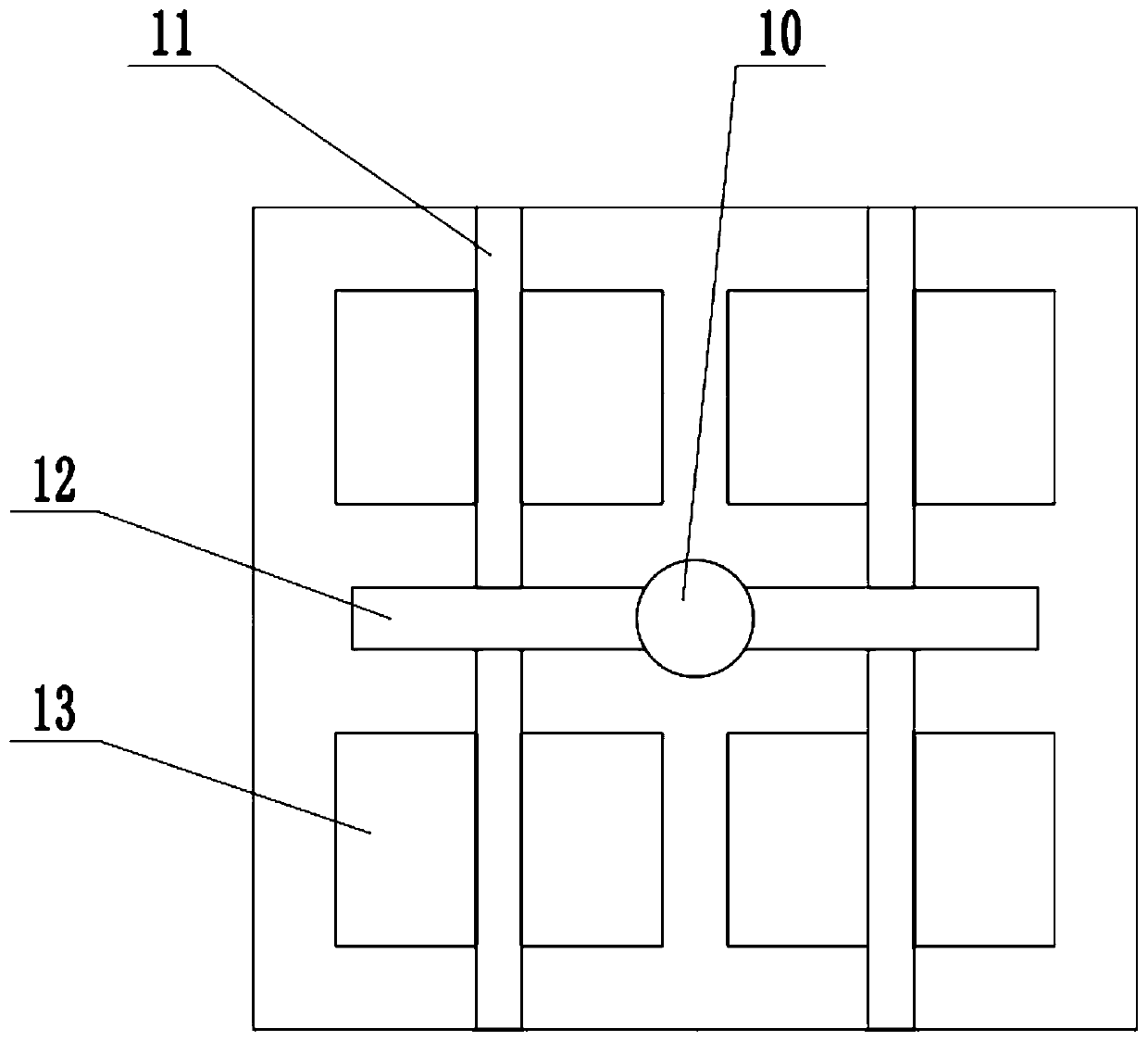

Coating stirring equipment

ActiveCN108031357AImprove mixing effectImprove stirring efficiencyTransportation and packagingRotary stirring mixersCoatingBiochemical engineering

The invention discloses coating stirring equipment which comprises a stirring cylinder and a cross bracket, wherein the cross bracket is arranged right above the top opening of the stirring cylinder;two symmetrically arranged fixing brackets are fixedly connected with the side wall of the stirring cylinder; one end of each fixing bracket is fixed on the side wall of the stirring cylinder; the other end of each fixing bracket extends to the top opening of the stirring cylinder; the cross bracket comprises four support plates which are perpendicular to one another and extend outwards; free endsof two support plates positioned on a same straight line are fixedly connected with corresponding fixing brackets; a chute which penetrates through one support plate in a length direction is formed in each support plate; a sliding block is clamped inside each chute in a sliding manner. Compared with conventional coating stirring equipment, the coating stirring equipment is capable of effectivelyimproving stirring effects and stirring efficiency.

Owner:湖南太子化工涂料有限公司

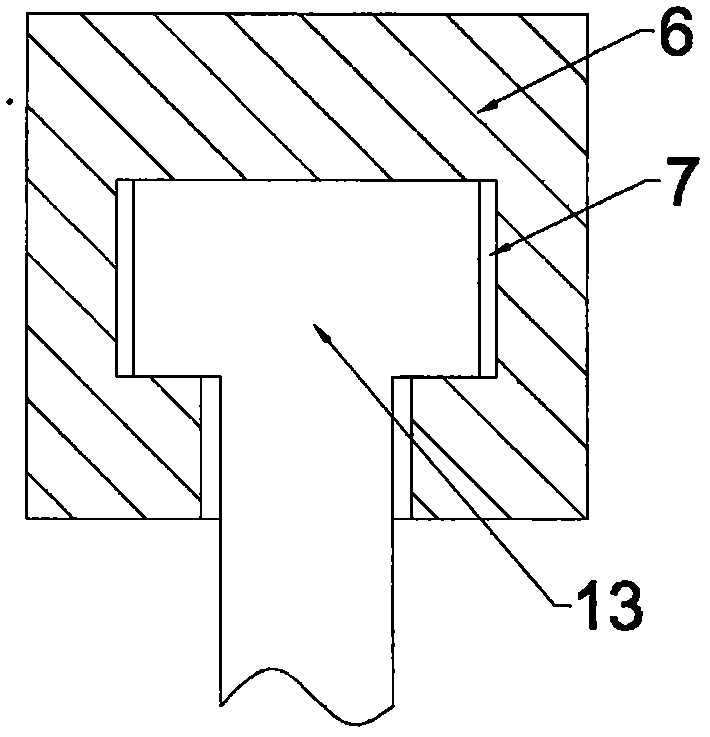

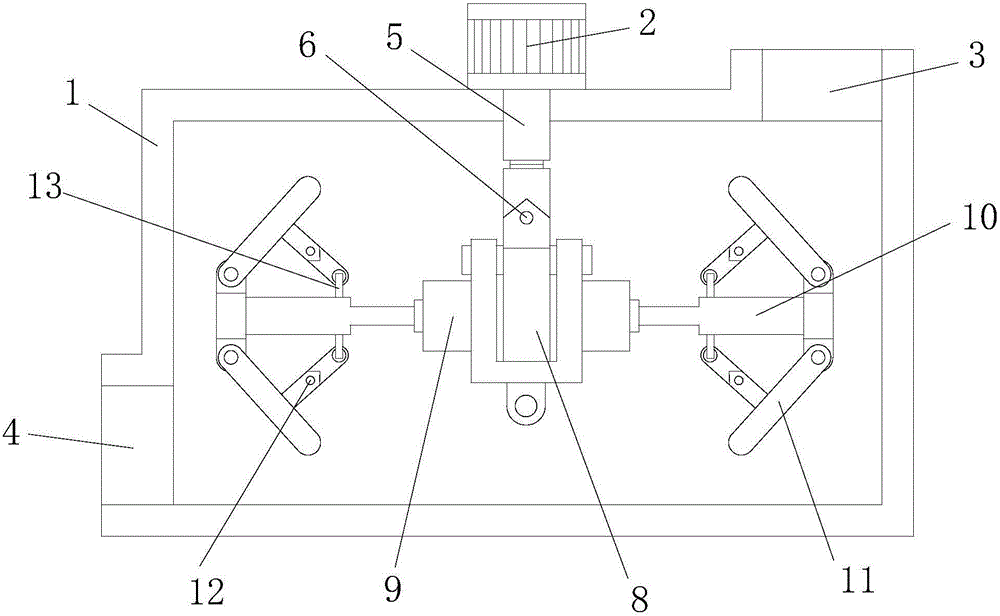

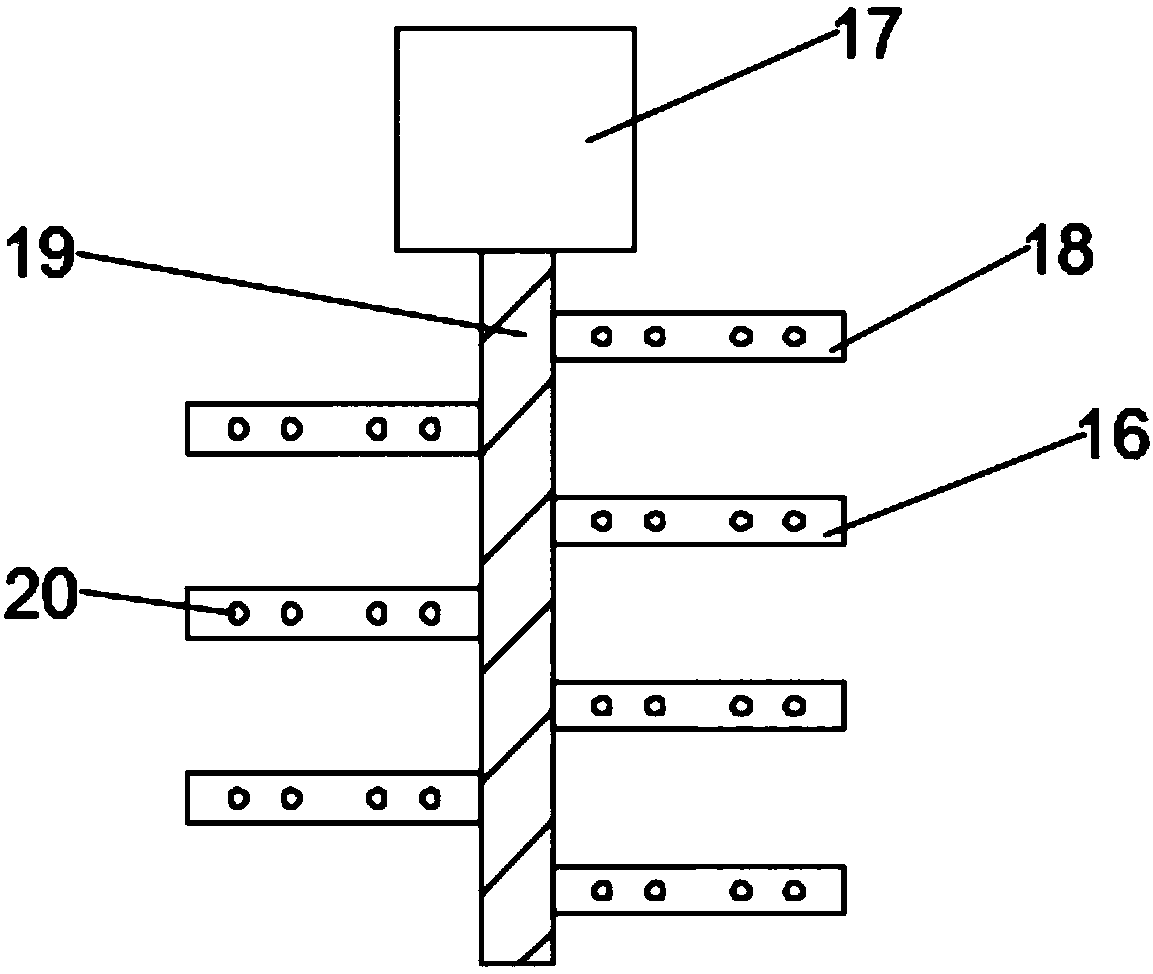

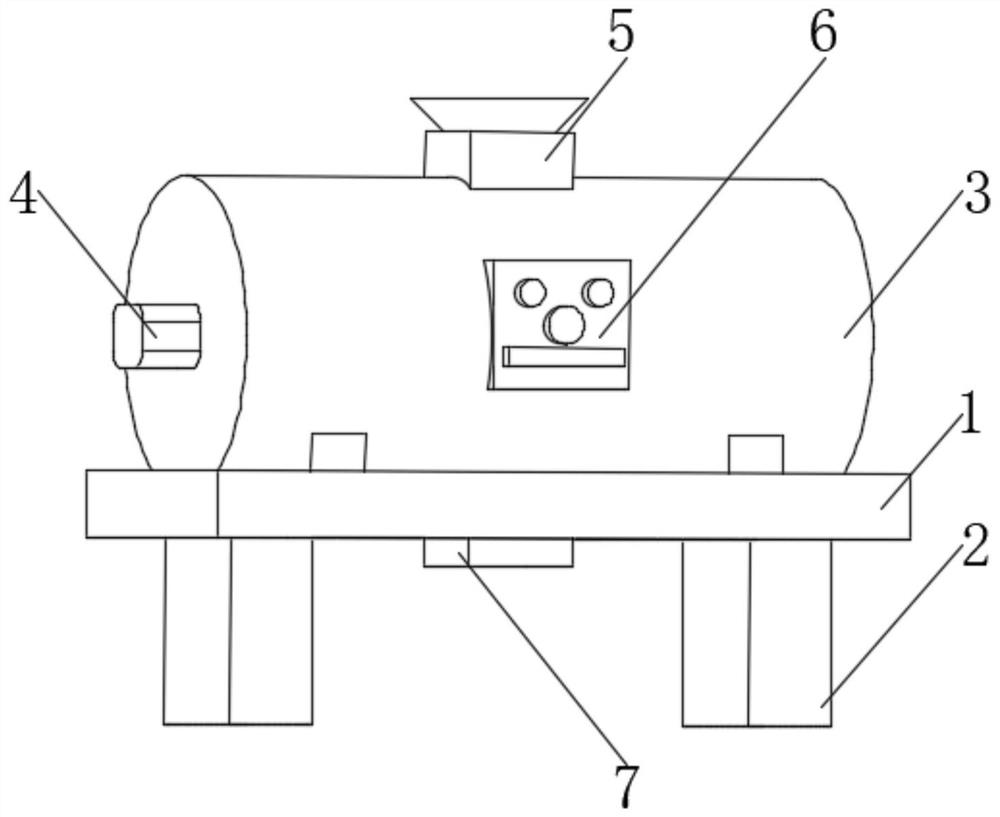

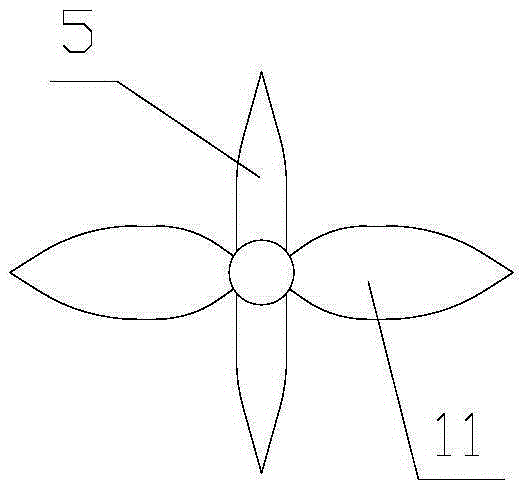

Stirring device for processing health food

InactiveCN105688711AImprove mixing effectImprove production qualityTransportation and packagingRotary stirring mixersProduct processingEngineering

A stirring device for processing health food comprises a kettle, wherein a rotating shaft is arranged in the kettle; the top of the rotating shaft is connected with a variable frequency motor positioned above the kettle; two mounting columns are symmetrically arranged on the upper part and the lower part of the rotating shaft; a sliding groove is formed in each mounting column; the sliding grooves are T-shaped; a sliding block is arranged in each sliding groove; the sliding blocks are also T-shaped and are matched with the sliding grooves; one sides, which are close to the rotating shaft, of each sliding block and the corresponding sliding groove are fixedly connected with each other through a first spring; a stirring rod is fixedly connected between the two sliding blocks positioned above and below the same side of the rotating shaft; a plurality of connecting rods are uniformly arranged on the stirring rod; a slider sleeves each connecting rod; and each slider is fixedly connected with the stirring rod through a second spring. The stirring device for processing the health food has the beneficial effect that the stirring range can be changed as needed, the stirring effect is expanded, the product processing quality is improved, and production efficiency is also improved.

Owner:金柯楠

Comprehensive processing device for coal ash recycling

The invention discloses a comprehensive processing device for coal ash recycling. The comprehensive processing device for coal ash recycling comprises a smashing box, a comprehensive processing box, an impurity box and a stirring box. The smashing box is arranged on the left side of the top of the comprehensive processing box in a communication manner. The stirring box is arranged in the middle of the bottom of the comprehensive processing box in a communication manner. The internal right end of the comprehensive processing box inclined downwards to be provided with a vibrating sieve. The upper side of the right end of the vibrating sieve is provided with an impurity pipe in a communication manner on the side wall of the comprehensive processing box, and the right end of the impurity pipe is connected with the impurity box. A plurality of air inlet branch pipes are arranged on the right side of the top of the comprehensive processing box in a communication manner and communicate with an air inlet header pipe. Water inlet pipes are arranged on the bottom of the left side and the bottom of the right side of the comprehensive processing box. A guide plate is arranged on the lower portion of the interior of the comprehensive processing box, and a plurality of supporting springs are arranged on the outer circle of the comprehensive processing box. The comprehensive processing device is used for comprehensively processing the coal ash, is good in smashing and stirring effect and capable of sieving, filtering and removing impurities, carrying out drying and pulping operation, has multiple purposes and is beneficial to popularization.

Owner:HEFEI ZHIHUI LONGTUTENG INTPROP CO LTD

Electric stirring cup capable of being operated manually

InactiveCN106582384AImprove mixing effectReduce damageRotary stirring mixersTransportation and packagingAgricultural engineeringBevel gear

The invention discloses an electric stirring cup capable of being operated manually. The electric stirring cup comprises a cup body, a hand wheel and an electric motor, wherein a top plate of the cup body is rotationally connected with a transmission shaft, the lower end of the top plate of the cup body is fixedly connected with a bevel gear I, the lower end of the transmission shaft is fixedly connected with a coupling shaft, a stirring shaft is rotationally connected to the coupling shaft, the upper end of the stirring shaft is fixedly connected with a bevel gear II, and the lower part of the stirring shaft is fixedly connected with a stirring blade; and the upper end of the transmission shaft is provided with a gear groove, the upper end of the top plate of the cup body is fixedly connected with a support plate, a middle rotating shaft is rotationally connected with the center of the support plate through a rolling bearing, a driving shaft is in slip connection with the center of the middle rotating shaft through a linear bearing, the lower end of the driving shaft is fixedly connected with a driving gear, the upper end of the driving shaft is fixedly connected with a fixture block, and a transmission gear is fixedly connected to the driving shaft. The electric stirring cup disclosed by the invention is good in rotation effect and small in damage to a sample, can be switched between manual operation and electric operation conveniently, is convenient and flexible in use, and is labor-saving and efficient.

Owner:HEFEI ZHIHUI LONGTUTENG INTPROP CO LTD

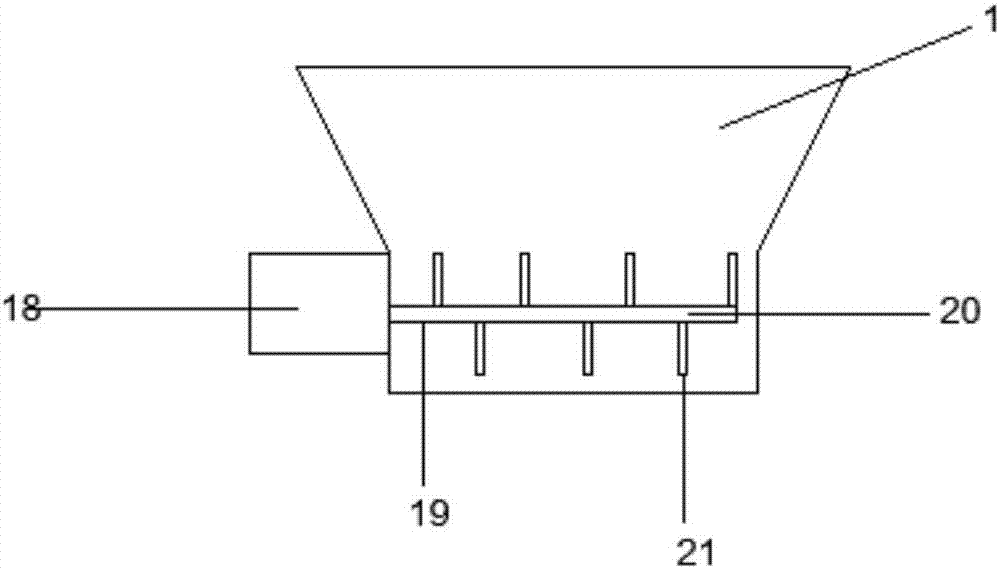

Continuous feeding type chemical industrial liquid and material mixing processor

InactiveCN107336354AEnhanced material activityImprove mixing effectCement mixing apparatusCleaning using liquidsChemical industryEngineering

The invention discloses a continuous feeding type chemical industry liquid material mixing processor, which comprises a mixing shell, a heating coil arranged in a spiral shape is arranged on the outer wall of the mixing shell, and the inside of the shaft body of the mixing and stirring shaft is A hollow structure is provided and several small spraying holes are opened on the outer wall of the shaft body, a flow control switch and a small water pump are installed on the body of the water delivery pipeline, and plate-type Stirring blades and spiral stirring blades, a strip scraper is installed at the end of the horizontal support rod, a premix conveyor is fixed above the mixing shell, and a universal roller is installed at the lower end of the hydraulic telescopic rod through a connecting sleeve . The invention can achieve rapid temperature rise, realize automatic cleaning of the inner cavity after work, fully stir, improve the mixing effect of subsequent materials, facilitate moving and positioning, and save time and effort.

Owner:孙洁

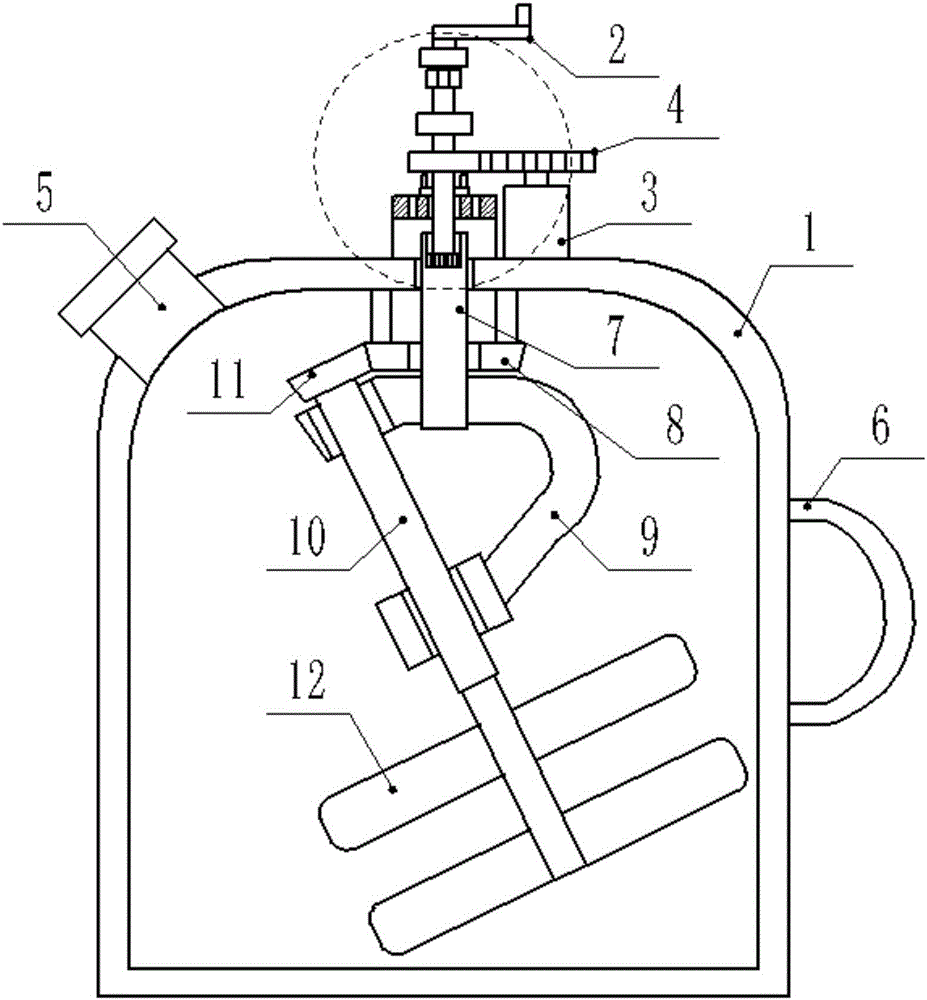

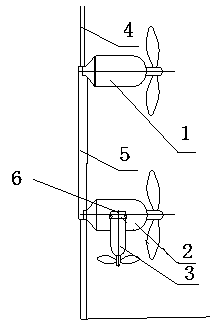

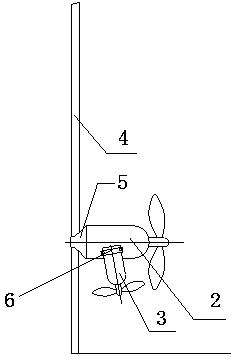

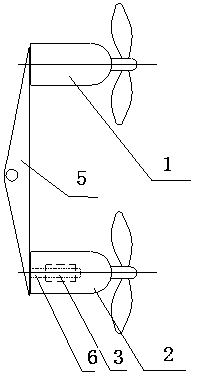

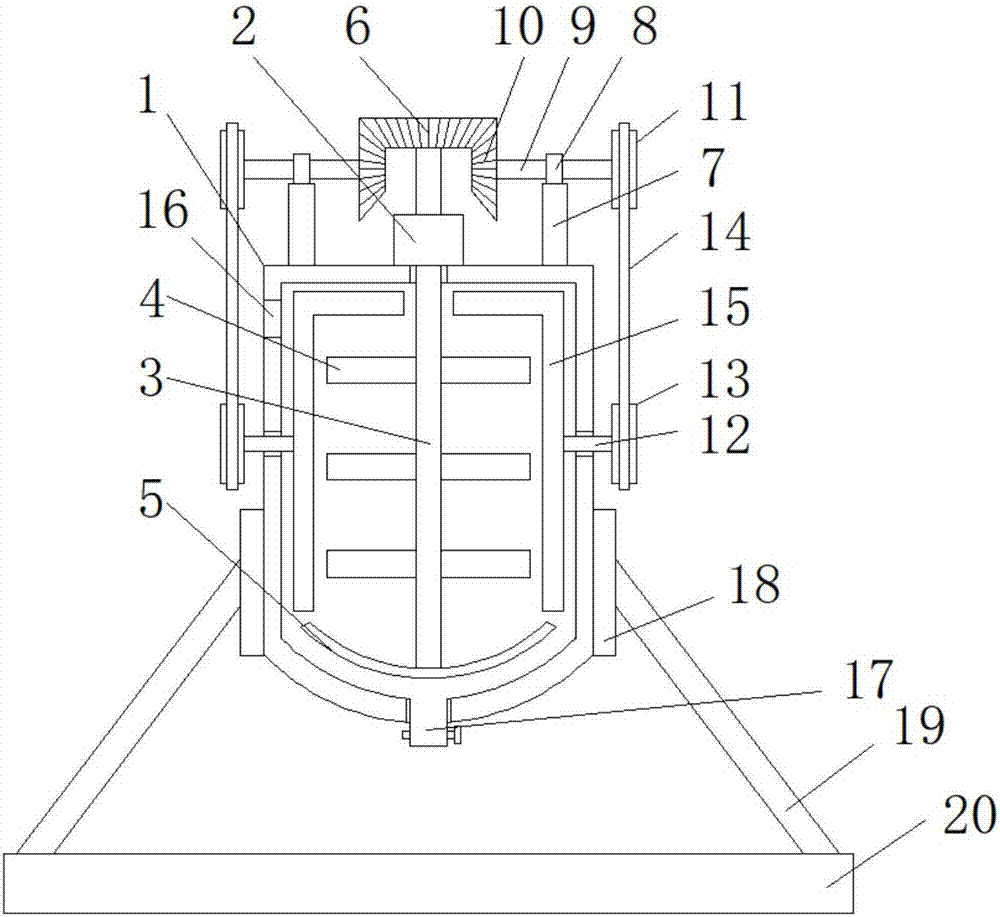

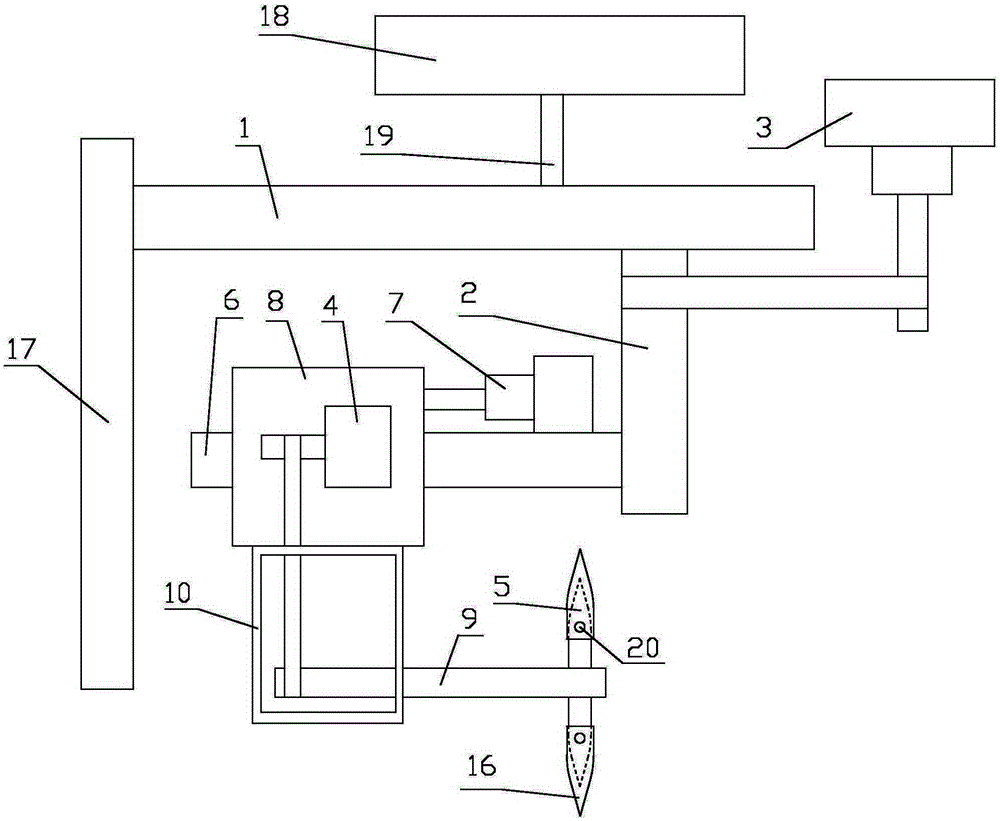

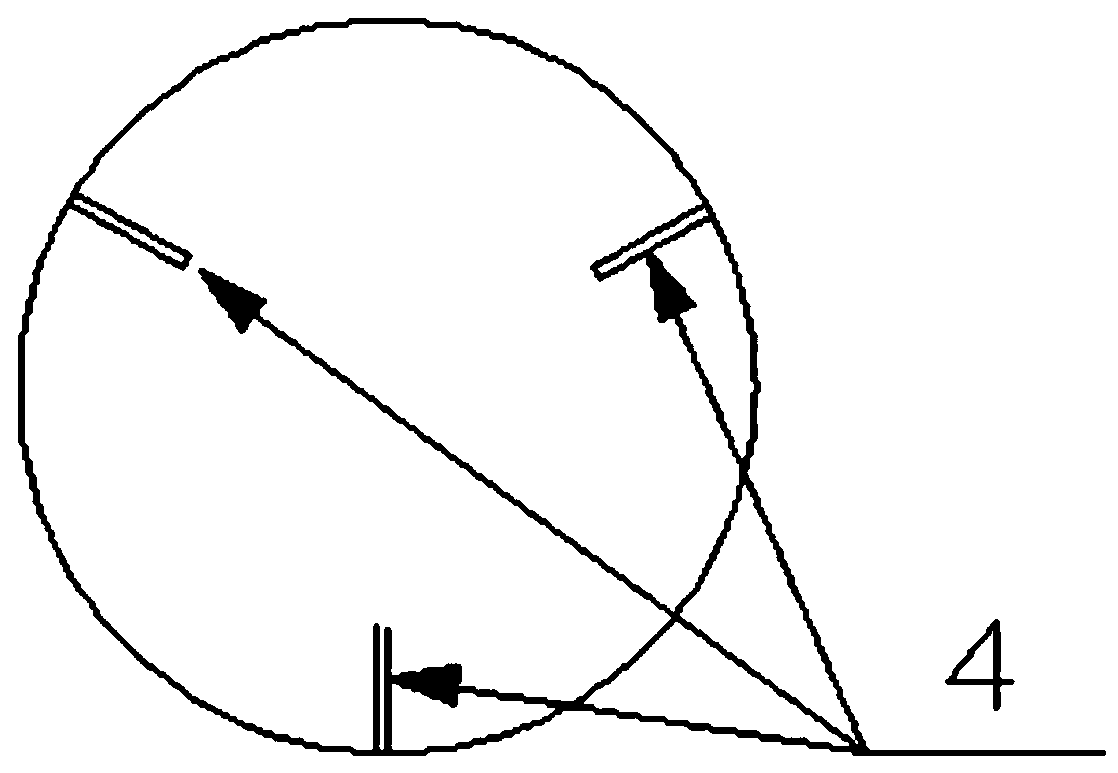

Submersible stirrer system for sewage treatment

ActiveCN104043369AImprove all-roundImprove mixing effectMixersWater/sewage treatmentEngineeringSewage

The invention relates to a submersible stirrer system for sewage treatment. The submersible stirrer system comprises a first submersible stirrer and a second submersible stirrer, wherein the axes of the rotating shafts of the first submersible stirrer and the second submersible stirrer are parallel with the surface of the bottom of a sewage pool; an installing plate is arranged at the bottom of the second submersible stirrer; a third submersible stirrer is arranged on the installing plate; the axis of the rotating shaft of the third submersible stirrer is arranged in a certain angle with that of the rotating shaft of the second submersible stirrer; and by additionally arranging the third submersible stirrer at the lower part of the second submersible stirrer, the sludge at the bottom of the sewage pool can be sufficiently stirred. According to the submersible stirrer system, the sludge at the bottom of the sewage pool can be specially stirred; and meanwhile, three submersible stirrers cooperate with each other, so the 360 DEG stirring effect of the sludge in a large-size sewage pool can be improved.

Owner:JIANGSU UNIV

Swing-type paint mixing device for construction of roads and bridges

InactiveCN110252186AThe paint is well mixedImprove mixing effectTransportation and packagingMixer accessoriesCirculating pumpConvection

The invention relates to the field of construction equipment for roads and bridges, specifically to a swing-type paint mixing device for construction of roads and bridges. The swing-type paint mixing device comprises a frame, a stirring tank, a first motor and a driving shaft, wherein the stirring tank is arranged above the frame; the bottom of the stirring tank is hinged to the upper surface of the frame; a first motor is arranged on and fixedly connected with the top of the stirring tank; the shaft extending end of the first motor is fixedly connected with a driving shaft, and the left and right sides of the driving shaft are respectively provided with hollow rotating shafts; spraying discs are arranged to penetrate the middle parts of the hollow rotating shafts; a circulation pump is fixedly connected with the bottom of the stirring tank; and the upper surface of the frame is equipped with a swinging mechanism. Stirring plates are used for stirring paint in the stirring tank so as to uniformly mix the paint; then the paint is conveyed to the spraying discs by using the circulation pump and sprayed out through nozzles to make the paint generate convection current; the rotation directions of the two spraying discs are opposite, so paint mixing is more sufficient, and stirring effect is further improved; and the swinging mechanism is arranged to drive the stirring tank to swing left and right, so paint mixing is more uniform.

Owner:赣州市兴顺辉科技有限公司

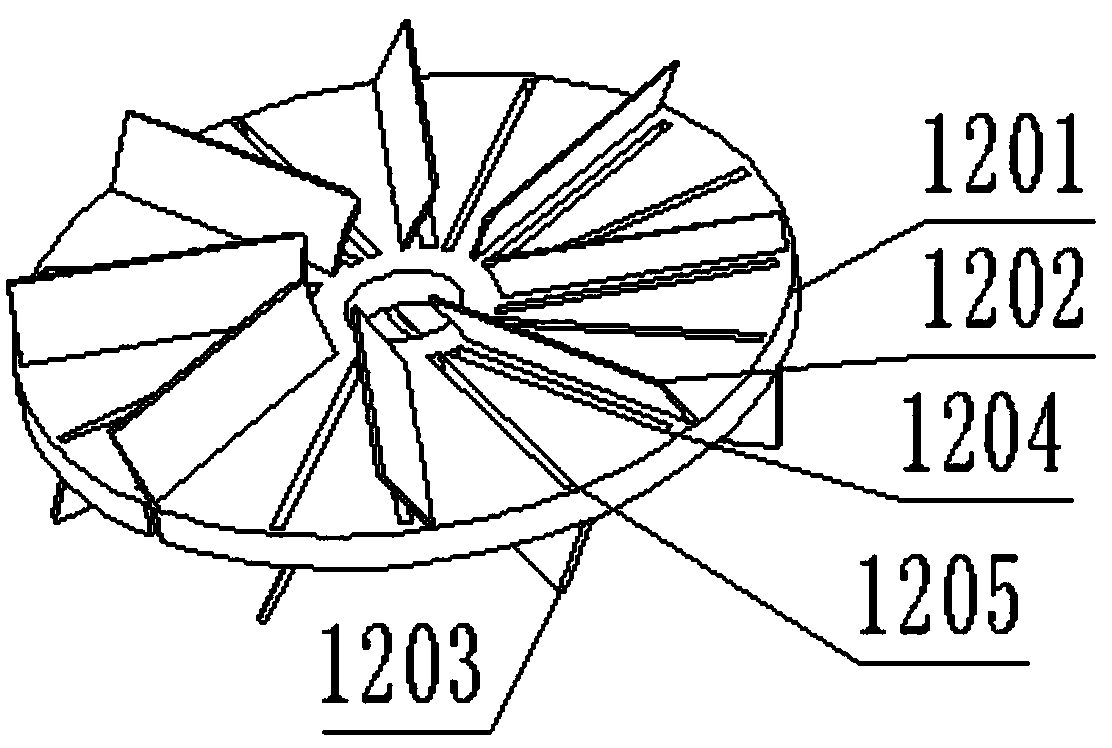

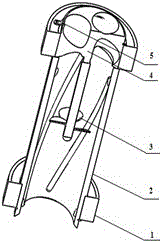

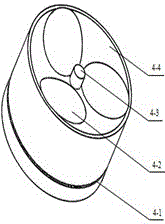

Foaming agent downhole stirring device applicable to foam draining gas recovery process

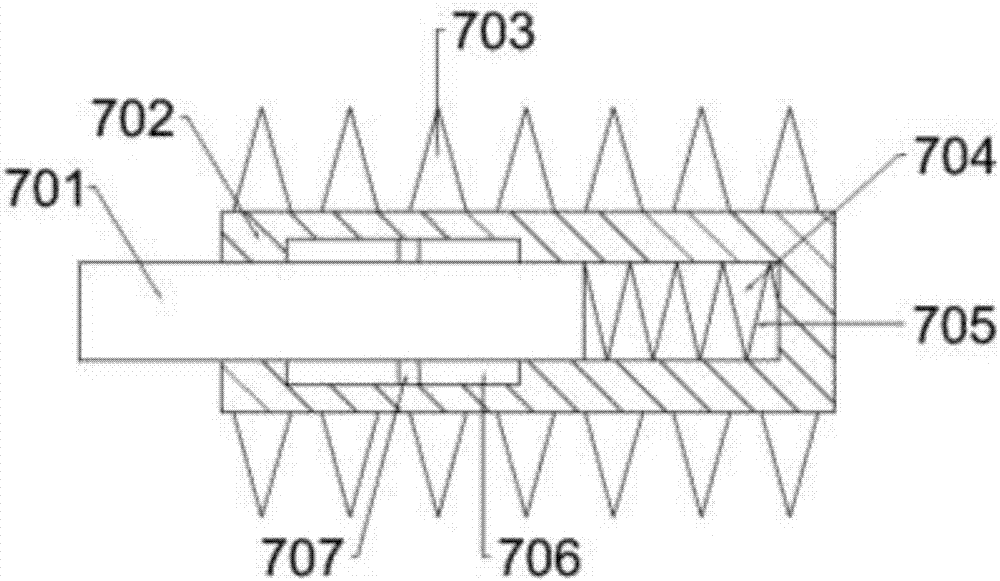

InactiveCN106677752AIncrease liquid carrying effectImprove mixing effectTransportation and packagingFluid removalDivision HeadFoam drainage

The invention provides a foaming agent downhole stirring device applicable to the foam draining gas recovery process. The foaming agent downhole stirring device comprises a working barrel, rotating blades, spiral guide rails, a rotary diversion head, bearings and shaft barriers. The whole device can be installed in a tubing nipple. An inside chamber of 45 degrees is arranged at the inlet end of the working barrel. The four uniformly-distributed spiral guide rails are arranged on the inner wall of the working barrel. The rotary diversion head is provided with three spiral channels which are circumferentially and uniformly distributed and can be used for changing the flowing track of fluid, so that counterforce is provided for the rotary diversion head and enables the rotary diversion head to rotate. The rotating blades are connected with a rotary shaft through spot welding, and serve as a second power source. The inlet end of the working barrel and the outlet end of the rotary diversion head are each provided with two bearings and two shaft barriers correspondingly so that the rotating friction force of the whole device can be reduced, and the bearings and the shaft barriers are used in cooperation with the tubing nipple. The rotary division head, the rotating blades and the spiral guide rails serve as the power source and have the effect of stirring, the foam generating quantity is greatly increased, and the foam draining efficiency is improved.

Owner:SOUTHWEST PETROLEUM UNIV

Sealed mixing tank wall washing device

The invention provides a sealed mixing tank wall washing device, comprising a mixing system, a nozzle system and a ventilation system, wherein the mixing system is connected with the nozzle system, and the mixing system is connected with the ventilation system. According to the present invention, a lower end of a shaft is provided with a through hole, materials just below the shaft is pumped by a pump mounted on the bottom of the shaft and is sprayed to a tank wall through a nozzle on the top, solids coagulated on the tank wall is rinsed off, the tank wall is kept clean and the mixing effect of the materials is improved. The nozzle of the device is a direct flow nozzle which sprays liquid linearly, and is rotated with the shaft to rinse off the tank wall in all directions, thus the problem of some dead angles cannot be sprayed is prevented. The ventilation system is used for generating positive pressure, negative pressure and drying steam, and exhausting toxic gases for the apparatus.

Owner:嘉兴笼列电子商务有限公司

Stirrer for mixing chemical engineering medicinal liquid

InactiveCN104226138AImprove mixing effectRapid responseRotary stirring mixersMotor shaftWheel and axle

The invention relates to a stirrer of mixing chemical engineering medicinal liquid. The stirrer comprises a reactor and a stirring device arranged in the reactor, wherein the stirring device is driven by a motor and comprises a bevel gear driving disk axially connected to a motor shaft; the two sides of the bevel gear driving disk are respectively meshed with side bevel gears; wheel shafts of the bevel gears on two sides are respectively perpendicular to a disk shaft of the bevel gear driving disk; the center of the lower surface of the bevel gear driving disk is fixedly connected with a center stirring rod; a plurality of stirring blades are fixedly connected with the side surface of the center stirring rod; the inner side surfaces of the side bevel gears are fixedly connected with side stirring rods; the side stirring rods are symmetrically arranged about the wheel shafts of the side bevel gears. According to the chemical engineering medicinal liquid mixing stirrer, the bevel gear driving disk drives the side bevel gears to rotate so as to simultaneously stir medicinal liquid in the reactor in multiple directions; therefore, the stirring effect is greatly enhanced, and the reaction is accelerated and is more thorough.

Owner:无锡纳润特科技有限公司

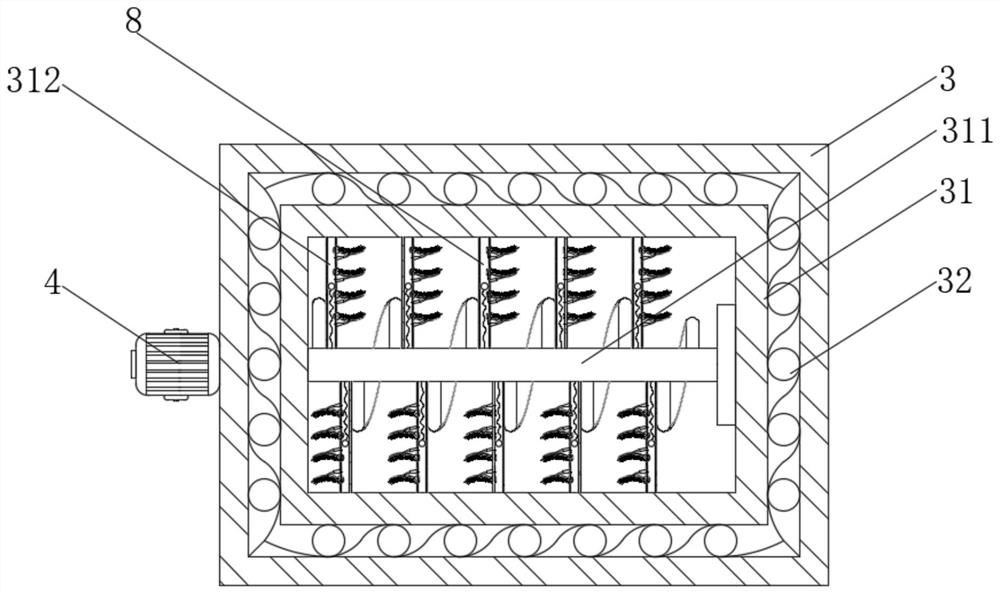

Material mixing device used for rice dumpling processing

PendingCN107875876AImprove mixing effectNovel structureRotary stirring mixersTransportation and packagingEngineeringChemical engineering

The invention discloses a material mixing device used for rice dumpling processing, comprising a stirring box, wherein the stirring box is of a cavity structure, a motor is fixedly arranged in the middle of the top end of the stirring box, the motor is a dual-shaft motor, a stirring shaft is fixedly connected to an output shaft at one end of the motor, one end of the stirring shaft runs through the stirring box and is fixedly connected with a stirring vane, two groups of stirring shafts are both fixedly connected with a plurality of groups of stirring rods, the stirring rods are all located inthe stirring box, an output shaft at the other end of the motor is fixedly connected with a driving gear, support pillars are fixedly arranged on two sides of the top end of the stirring box, bearings are fixedly arranged at the top ends of the two groups of support pillars, the interiors of the bearings are both rotationally connected with a horizontally arranged first connecting rod, and one end of the first connecting rod is fixedly connected with a driven gear. The material mixing device is favorable for improving the material stirring effect, and is novel in structure, reasonable in design, convenient to operate, suitable for popularization and strong in practicability.

Owner:从江县任氏民族特色食品加工作坊

Agitator for pig iron casting sand mixing

InactiveCN106001404ASimple structureImprove mixing effectMould handling/dressing devicesElectric machineryDual axis

The invention relates to the field of stirring pig iron castings, in particular to a mixer for sand mixing of pig iron castings, comprising a housing, a motor is fixedly installed on the upper end of the housing, a feeding port is arranged on the right side of the motor, and the housing There is a discharge port under the left side wall of the motor, a transmission rod is fixedly installed at the lower end of the motor, and a hydraulic telescopic rod is fixedly installed at the other end of the transmission rod. The mixer for pig iron casting sand mixing has a simple structure. The combination of hydraulic telescopic rods realizes that the mixer can stir evenly up and down and improves the mixing effect. At the same time, the installation of the mixing components is facilitated by clamping the double-axis motor. The pig iron raw material is stirred more evenly, which further improves the stirring effect.

Owner:HANSHAN ZHAOXIA CASTING

Chemical raw material mixing tank with lifting and stirring device

PendingCN108927043AAvoid accumulationImprove mixing effectTransportation and packagingRotary stirring mixersChemical productsMixing tank

The invention discloses a chemical raw material mixing tank with a lifting and stirring device. The chemical raw material mixing tank comprises a support base, a tank body, a lifting plate, a scrapingassembly and a stirring assembly, wherein the tank body is arranged above the support base, support legs are welded to four corners of the bottom surface of the tank body, and the support legs are fixed on the support base; a support crossbar is arranged above the tank body in a parallel mode, the right end of the support crossbar is welded to the tank body, and a material filling mouth is formedin the upper part of the rear wall of the tank body; the material filling mouth communicates with the tank body, a material discharge mouth is formed in the bottom of the left side wall of the tank body, and the material discharge mouth communicates with the inner cavity of the tank body; the chemical raw material mixing tank has the characteristics that the lifting plate is slidably mounted on the top of the inner cavity of the tank body, the scraping assembly is welded to both ends of the lifting plate, and the stirring assembly is arranged in the middle of the lower part of the lifting plate. The chemical raw material mixing tank has efficient stirring, and the mixed materials can be discharged quickly and conveniently, so that the production quality of chemical products is ensured, and the chemical raw material mixing tank is suitable for application and promotion.

Owner:嘉兴迪迈科技有限公司

Variable-diameter mixing machine for coating processing

PendingCN106943928AImprove mixing effectImprove mixing efficiencyFlow mixersRotary stirring mixersCirculating pumpRaw material

The invention discloses a variable-diameter mixing machine for coating processing. The machine comprises a mixing tank, a horizontal conveying tank and a circulating tank, wherein a speed reducer is connected to the lower end of an output shaft of a first motor; two groups of stirring components are arranged on a stirring rod; each stirring component comprises a fixed sleeve, a movable sleeve, a support rod, an elastic stirring fin and a balancing weight; the bottom part of a lower hopper is communicated with the horizontal conveying tank; the circulating tank is communicated to the upper side of the right end of the horizontal conveying tank; a plastic hose is communicated to one end of a circulating pump, and winds on an adjusting mechanism; the adjusting mechanism is formed by an upper guide wheel, a lower guide wheel, a pipe trough and an installation plate. According to the variable-diameter mixing machine for coating processing provided by the invention, the arranged stirring components are used for mixing raw materials in a stirring barrel, the stirring speed of a stirring shaft is adjusted through the speed reducer during a stirring process, and the degrees of outwards stretching the elastic stirring fins through the balancing weights are different according to different rotary speeds, so that the stirring radius is changed, stirring are carried out at different positions, and the stirring effect is improved.

Owner:李姗姗

Garden irrigation device convenient for saving water

InactiveCN111418328AImprove mixing effectIncrease the irrigation areaTransportation and packagingRotary stirring mixersNutrientElectric machinery

The invention belongs to the technical field of garden irrigation, and particularly relates to a garden irrigation device convenient for saving water, which comprises a base, a water tank, an adjusting tank and an adjusting box are mounted at the top of the base, the base is of a hollow structure, a motor seat is mounted on the inner wall of the base, and a double-shaft motor is mounted on the motor seat; one end of a first rotating shaft and one end of a second rotating shaft are installed on two output shafts of the double-shaft motor respectively, a first bevel gear is fixedly installed atthe other end of the second rotating shaft, a second bevel gear is meshed with the first bevel gear, and one end of a screw is fixedly installed on the second bevel gear. And the other end of the screw rod extends into the adjusting box and is fixedly engaged with a turbine. The position of the spray head can be adjusted, meanwhile, the spray head can rotate, the irrigation effect is greatly enhanced, comprehensive irrigation is achieved, the fruiting rate is increased, the adding amount can be intermittently controlled when nutrient materials are added, the mixing effect is good through rotation of the rotating rod, and absorption of plants is promoted.

Owner:罗厚镇

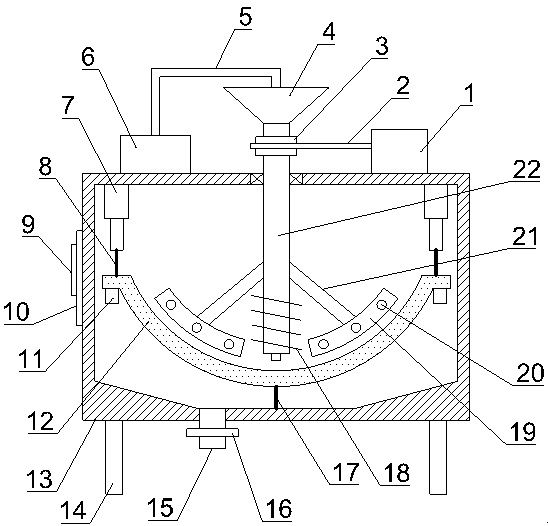

Stirrer

InactiveCN104353380AIncrease the number of stirringImprove mixing effectRotary stirring mixersEngineering

The invention discloses a stirrer which comprises a housing, a motor mounted in the bottom center of the housing, a stirring shaft vertically mounted above the motor and a stirring cross beam vertically fixed to the stirring shaft, and is characterized by further comprising stirring plates vertically fixed to the two ends of the stirring cross beam, wherein the stirring plates are arc-shaped and are oppositely and symmetrically arranged at the two ends of the stirring cross beam; the stirring cross beam penetrates through the centers of the arc-shaped stirring plates. According to the stirrer, the stirring plates are arranged on the stirring cross beam, so that stirring parts are added; the stirring operation is performed through the stirring cross beam and the stirring plates, so that the stirring frequency is increased and the stirring effect is improved; through the arrangement of the arc-shaped stirring plates, while the effort and energy are saved during stirring, the stirring efficiency is greatly improved and the stirring effect is relatively remarkable; due to layer-by-layer design of trapezoidal radian of the arc-shaped stirring plates, the area of contact between the stirring plates and stirring materials is enlarged, the materials are fully stirred, and the stirring effect is good.

Owner:WUXI LEHUA AUTOMATION TECH

Electric coating stirring device

InactiveCN109225013AImprove mixing effectStirring speed is fastTransportation and packagingRotary stirring mixersElectric machineryCoating

The invention discloses an electric coating stirring device which comprises a stirring barrel main body; a barrel cover is arranged on the upper end of the stirring barrel main body; a first motor isarranged on the barrel cover; a rotating shaft is connected with an output end of the first motor; a fixed plate is connected with the lower end of the rotating shaft; a first stirring shaft is arranged at the center of the bottom of the fixed plate; a stirring blade is arranged on the first stirring shaft; second stirring shafts are arranged on the two sides of the first stirring shaft; second motors are arranged on the two ends of the surface of the fixed plate; stirring rods are arranged on the two sides of the second stirring shafts; brush plates are arranged on the stirring rods; electricheating plates are arranged in the two sides of an inner wall of the stirring barrel main body; air exhaust pipes are arranged on the two ends of the bottom in the stirring barrel main body; air blowers are arranged on the two sides on the exterior of the stirring barrel main body. In the electric coating stirring device, the first stirring shaft and the second stirring shafts are matched with each other, so that the stirring scope is expanded, the stirring is uniform and thorough, the time of stirring is reduced and the stirring efficiency is effectively increased.

Owner:合肥瀚鹏新能源有限公司

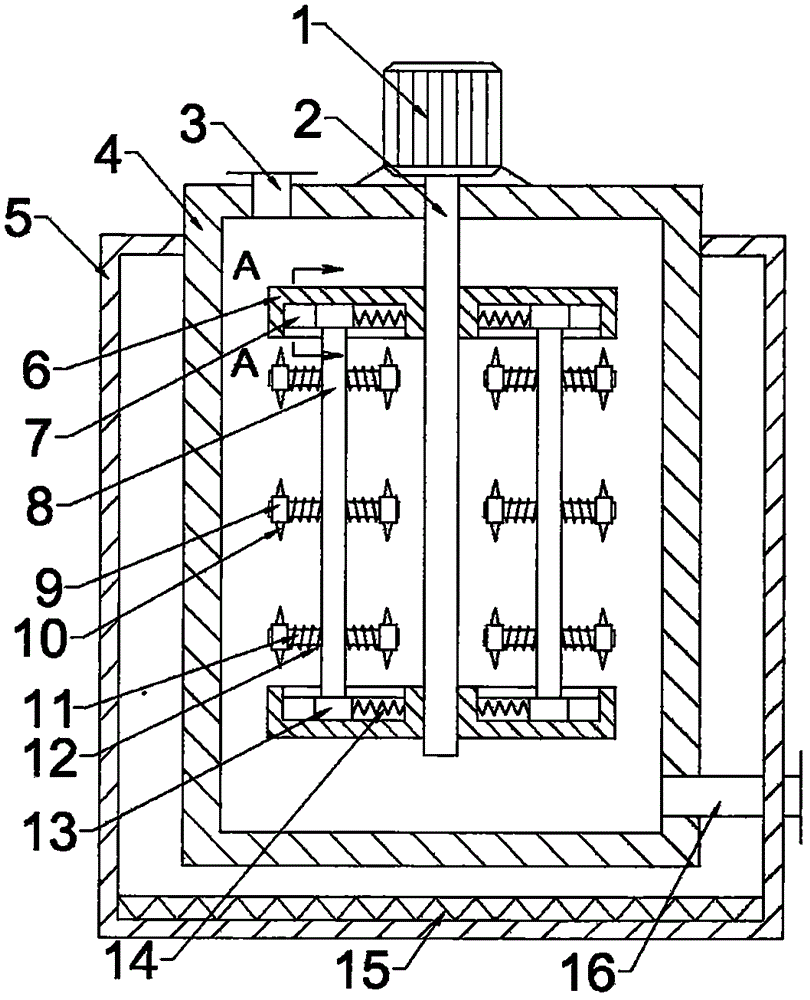

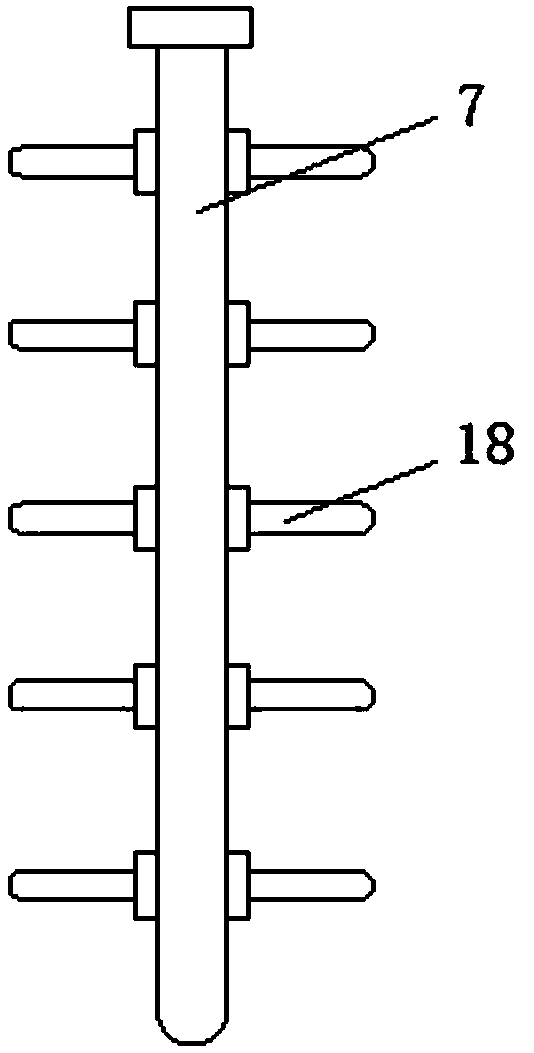

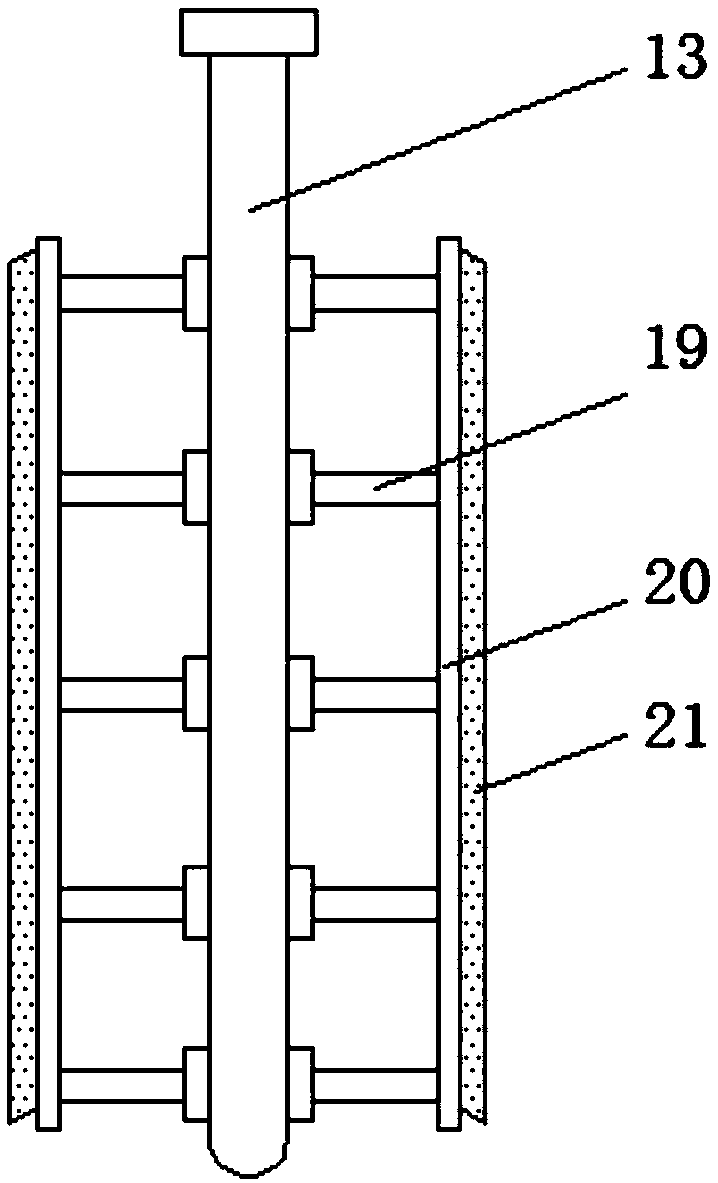

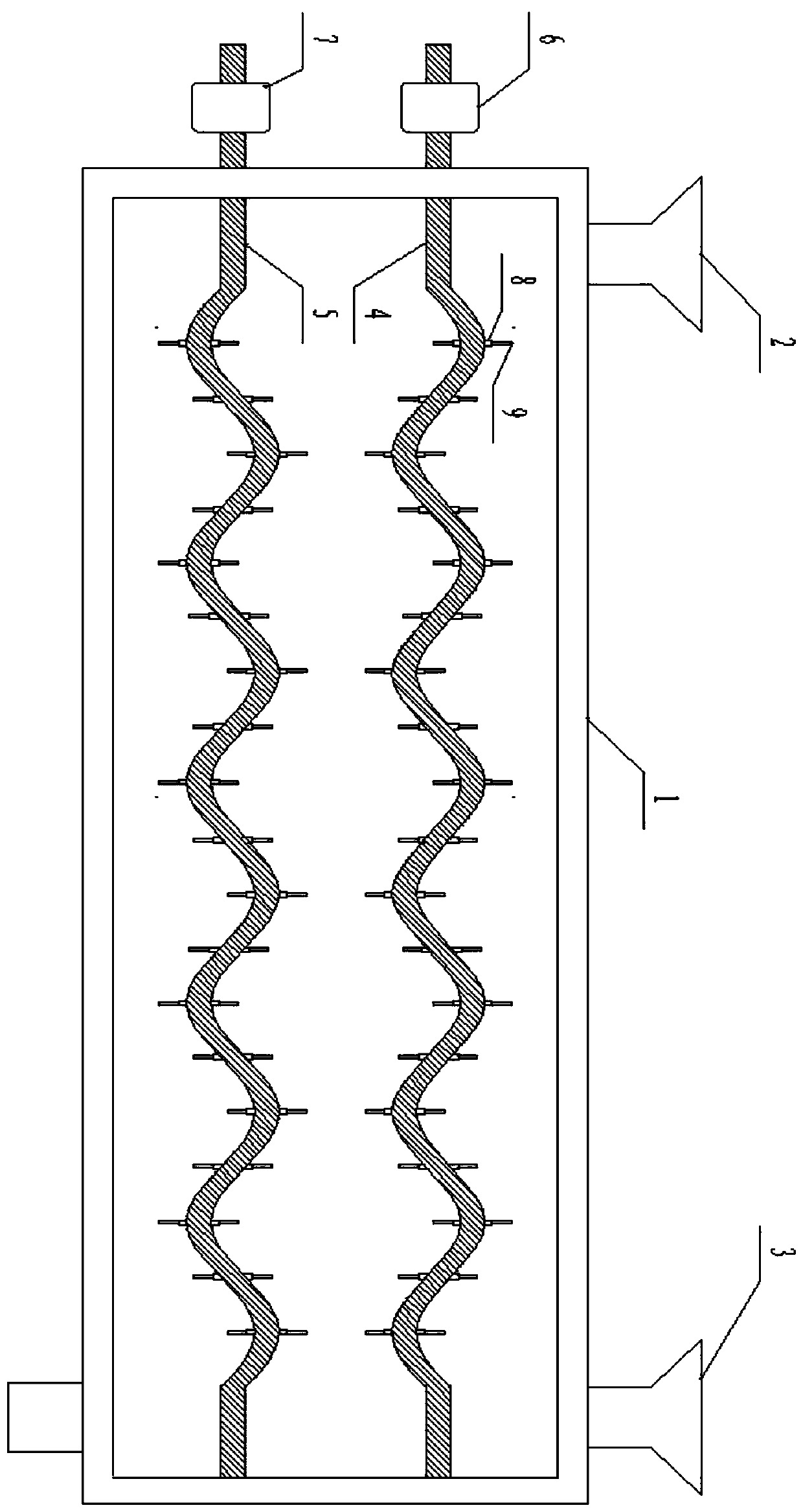

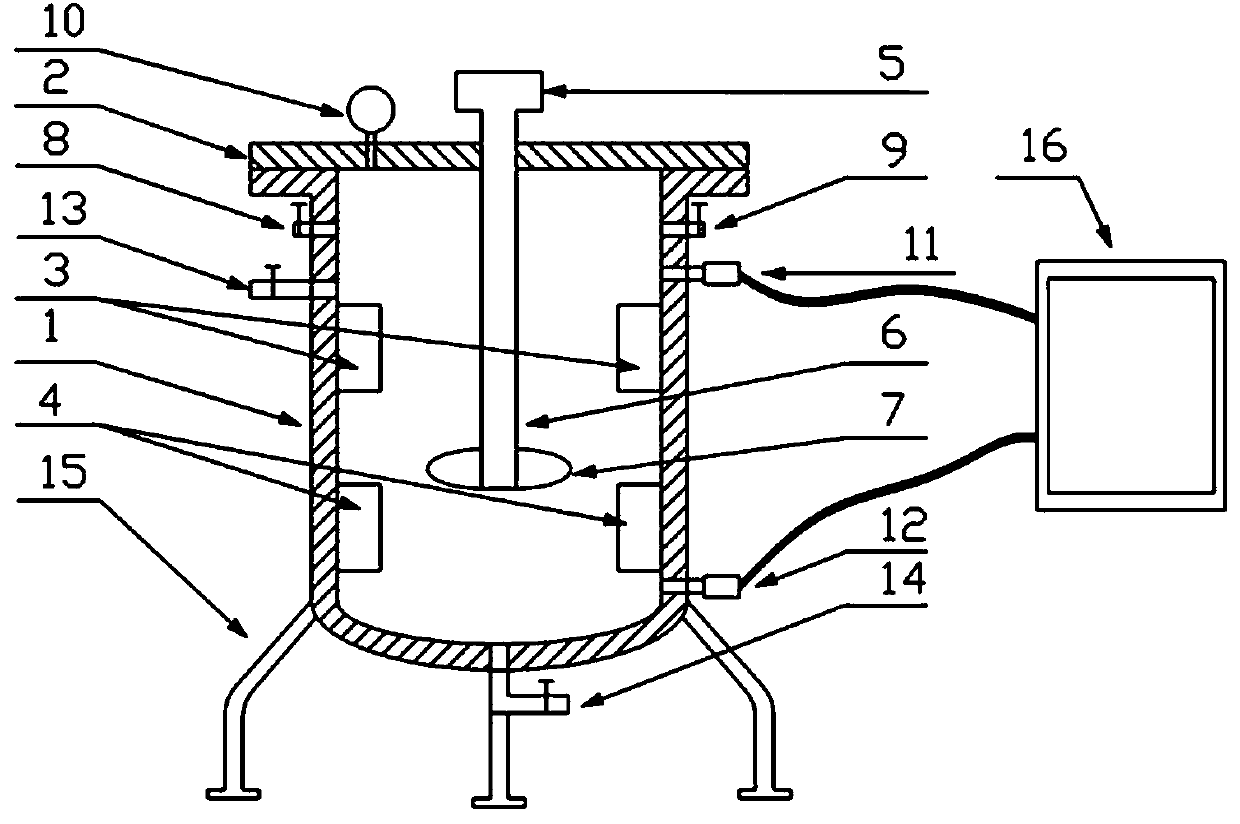

Method for blending polymerization glue solution and dissolving glue solution

The invention discloses a method for blending a polymerization glue solution and a dissolving glue solution. The method comprises the following steps of: firstly preparing the polymerization glue solution and the dissolving glue solution; and secondly, adding the polymerization glue solution and the dissolving glue solution respectively to a glue solution blending and stirring shearing device, andstarting a stirring motor to drive a first stirring shaft and a second stirring shaft to rotate relative to each other, wherein the first stirring shaft and the second stirring shaft rotate in opposite directions; as the stirring shafts is wave-shaped, the mixed solution is stirred up and down; the first stirring shaft is used for bringing the upper mixed solution downwards; the second stirring shaft is used for bringing the lower mixed solution upwards; the upper mixed solution and the lower mixed solution are mixed at the middle position, so that the mixed solutions are axially mixed as a whole; and meanwhile, the stirring shafts drive paddles to rotate in a stirring process, so that the local shearing and stirring of the mixed solution is realized.

Owner:益凯新材料有限公司

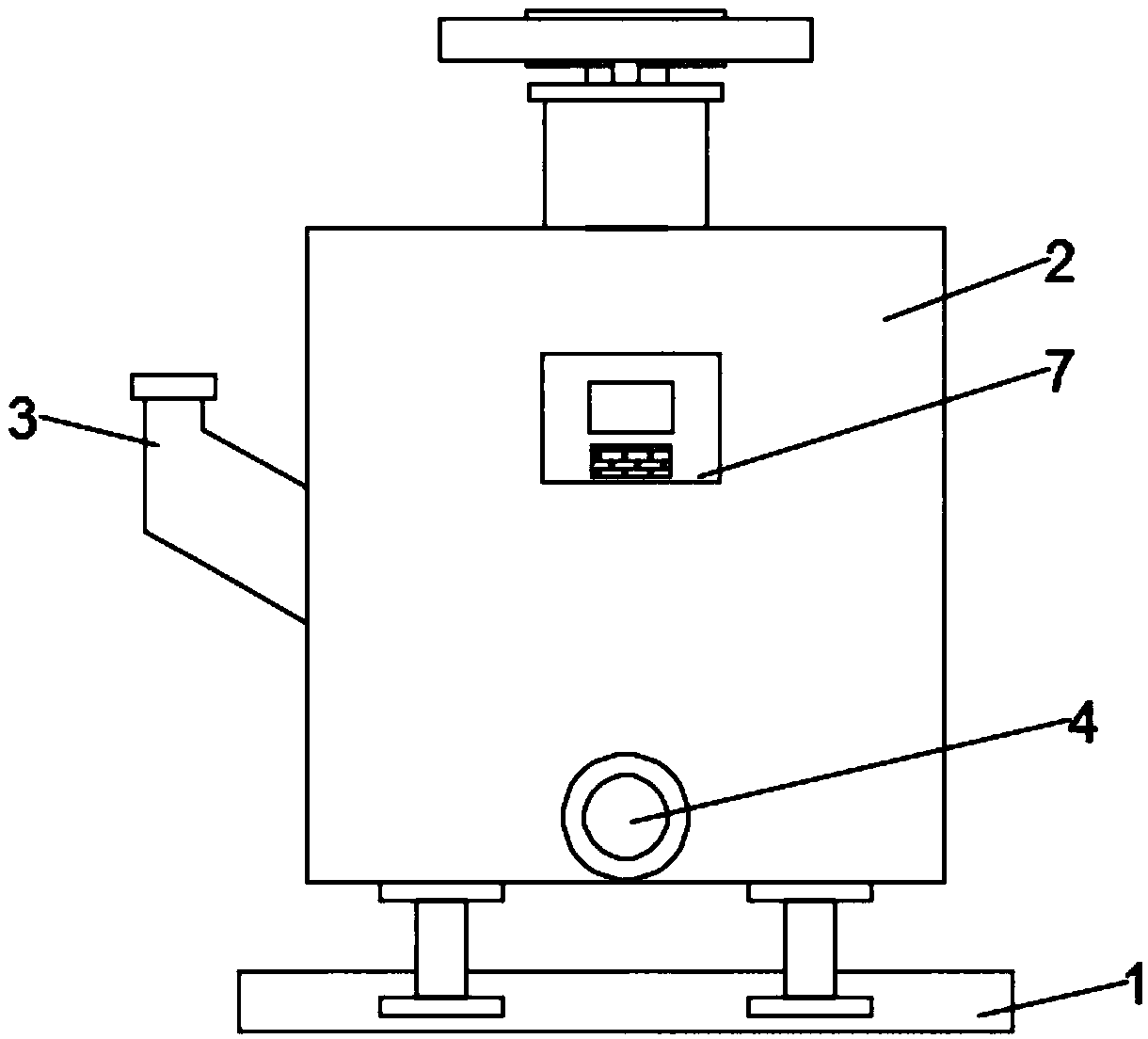

Mixing and stirring device for sealant production

PendingCN112957974AImprove mixing effectImprove impactRotary stirring mixersTransportation and packagingProcess engineeringMechanical engineering

The invention relates to the technical field of sealant production equipment, and discloses a mixing and stirring device for sealant production. The mixing and stirring device comprises a base, supporting legs are arranged at the four corners of the bottom of the base, a stirring box is fixedly mounted on the side, away from the supporting legs, of the base, a feeding hopper is arranged at a center shaft of the end, away from the base, of the stirring box, the feeding hopper is communicated with the stirring box, and a control panel is fixedly installed at the position of a center shaft of the outer wall of the front face of the stirring box. According to the mixing and stirring device for sealant production, in the stirring process, a centrifugal driving mechanism discontinuously moves a centrifugal driving ball, so that the centrifugal driving ball impacts a special-shaped rotating plate, the special-shaped rotating plate rotates to achieve a pushing effect on sealant in the stirring process, meanwhile, a vibration driving mechanism can also assist a stirring auger in stirring, so that the situation that the sealant on the stirring auger cannot be well stirred is prevented, and the stirring effect of the stirring device on the sealant is improved.

Owner:胡正兵

Industrial wastewater treatment tank

InactiveCN108187548AImprove mixing effectImprove processing effectShaking/oscillating/vibrating mixersTransportation and packagingIndustrial wastewater treatmentDrive motor

The invention discloses an industrial wastewater treatment tank, which comprises a tank body, an agitating chamber, a rotary shaft, and a driving motor, an agitating vibrator is arranged on the rotaryshaft, the agitating vibrator comprises an agitating shaft, an elastic agitating assembly, and a driving assembly, the agitating shaft is in rotation-stopping fit with the rotary shaft, the elastic agitating assembly is arranged on the agitating shaft, and the driving assembly cooperates with the agitating shaft and is used for driving the agitating shaft to move up and down; and a feed bin and achemical sprayer cooperating with the feed bin are arranged on the tank body. By arranging the agitating shaft capable of moving up and down in the rotation process of the rotary shaft on the rotaryshaft and arranging the elastic agitating assembly on the agitating shaft, the agitation effect of the industrial wastewater treatment tank is enhanced as wastewater is disinfected, thus the treatmenteffect is increased; in addition, by arranging the feed bin and the chemical sprayer on the tank body, disinfectant can be uniformly spread into wastewater in the tank body in the process of agitation, and thereby the speed of treatment is increased.

Owner:魏玉来

Submersible water impeller for sewage stirring

The invention discloses a submersible water impeller for sewage stirring. The submersible water impeller for sewage stirring comprises a support column, a first motor and a support rod; one end of the support rod is rotatably connected with the support column, the support rod is provided with N impelling units, each impelling unit comprises a second motor and first blades, the first motor is in transmission connection with the support rod, and the second motors are in transmission connection with the first blades. According to the submersible water impeller for sewage stirring, an area where sedimentation is serious can be flexibly selected to be stirred according to the sewage sedimentation condition, and therefore the stirring effect is improved; maintenance is convenient, selection can be performed according to the actual condition of sewage, and therefore the flexibility is good; the overall device is simple in structure and convenient to use.

Owner:合肥安奎思成套设备有限公司

Efficient and environment-friendly reaction kettle

InactiveCN105833820AIngenious structural designImprove mixing effectChemical/physical/physico-chemical stationary reactorsEnvironmentally friendlyEngineering

The invention relates to an efficient and environment-friendly reaction kettle which comprises a casing, a heating mechanism, a stirring mechanism and a cross flow mechanism. The upper end of the casing is provided with a feeding port, and the lower end of the casing is provided with a discharging port. The heating mechanism comprises a water inlet pipe, a water outlet pipe, a heating barrel and fins arranged on the heating barrel. The stirring mechanism comprises a motor, a screw rod, a rotating shaft and a stirring assembly. The cross flow mechanism comprises a cross flow plate, a sliding rod and a driving block. The efficient and environment-friendly reaction kettle is ingenious in structure. Through the cross flow mechanism and the stirring mechanism, the stirring effect can be greatly improved, raw materials are stirred more evenly and react fully, and the waste of the raw materials is reduced. Through water heating, not only is the reaction kettle environmentally friendly, but also heat released by hot water can accelerate the reaction speed, and the working efficiency is improved.

Owner:齐宽宽

Plastic mixing equipment

The invention discloses plastic mixing equipment which comprises a case, a control panel, a feed port, upper air pipes, lower air pipes, fans, a motor, a discharge port and a belt conveyer; the control panel and the feed port that are arranged at and formed in the top of the case; a mixer is arranged in the feed port; the upper air pipes are arranged on the sides of the case; the lower air pipes are arranged below the upper air pipes; the fans are arranged below the lower air pipes and are fixed to a bottom plate; the motor, the discharge port and the belt conveyer are arranged below the case and are located in the middle of a rack; the interior of the case is divided into an upper case part and a lower case part; first main shafts are arranged in the upper case part; screw blades are arranged on the first main shafts; second main shafts are arranged in the lower case part; and blades are uniformly arranged on the second main shafts. In a double mixing mode, a mixing dead angle is eliminated, the mixing effect is improved comprehensively, plastic raw materials are kept in a suspension state in a mixing process and can not be accumulated at a place, the mixing effect is further guaranteed, an unfavorable condition that the mixing is stopped due to raw material accumulation is avoided, and the working safety performance is improved.

Owner:合肥智慧殿机械设计有限公司

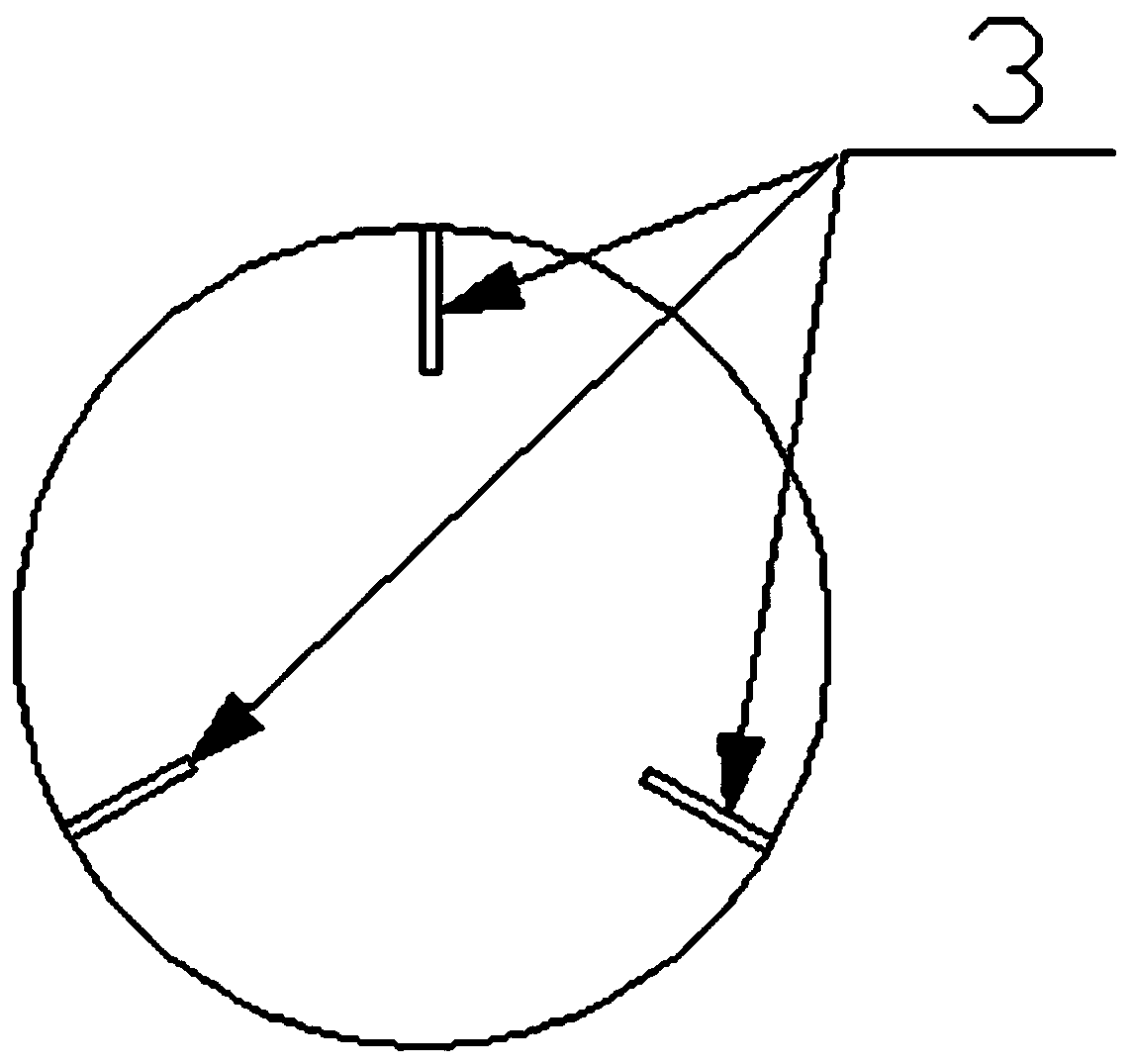

Flotation pulp-mixing method and flotation pulp-mixing equipment capable of improving mineralization effect

The invention belongs to the fields of pulp pretreatment technologies and equipment before flotation, and discloses a flotation pulp-mixing method and flotation pulp-mixing equipment capable of improving a mineralization effect. The equipment has a function of simultaneously realizing pressurization / decompression and mechanical stirring, and can flexibly adjust the gas holdup in pulp, therefore, an equipment support is provided for studying the influence of the gas holdup on cavitation; specifically, the concentration of gas, namely the gas holdup, in the pulp is adjusted in real time to improve the cavitation effect, promote the agglomeration among fine particles, and increase the apparent diameter so as to increase the collision probability of the fine particles and bubbles during the flotation process, and improve the mineralization effect. Specifically, the gas holdup in the pulp is adjusted by pressure regulation, and the gas holdup in the pulp is controlled at 5% to 40%, and theconcentration of the gas in the pulp is reasonably increased, thereby facilitating the occurrence of the cavitation, promoting the agglomeration among the fine particles and increasing the apparent diameter, improving the collision probability of the fine particles and the bubbles in the flotation process, and improving the mineralization effect.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com