Method for blending polymerization glue solution and dissolving glue solution

A technology of polymerizing glue and glue, applied in the field of rubber, can solve problems such as incompatibility, density, mutual solubility, viscosity difference, long time, etc., and achieve the effect of improving the stirring effect and solving the dead angle of stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

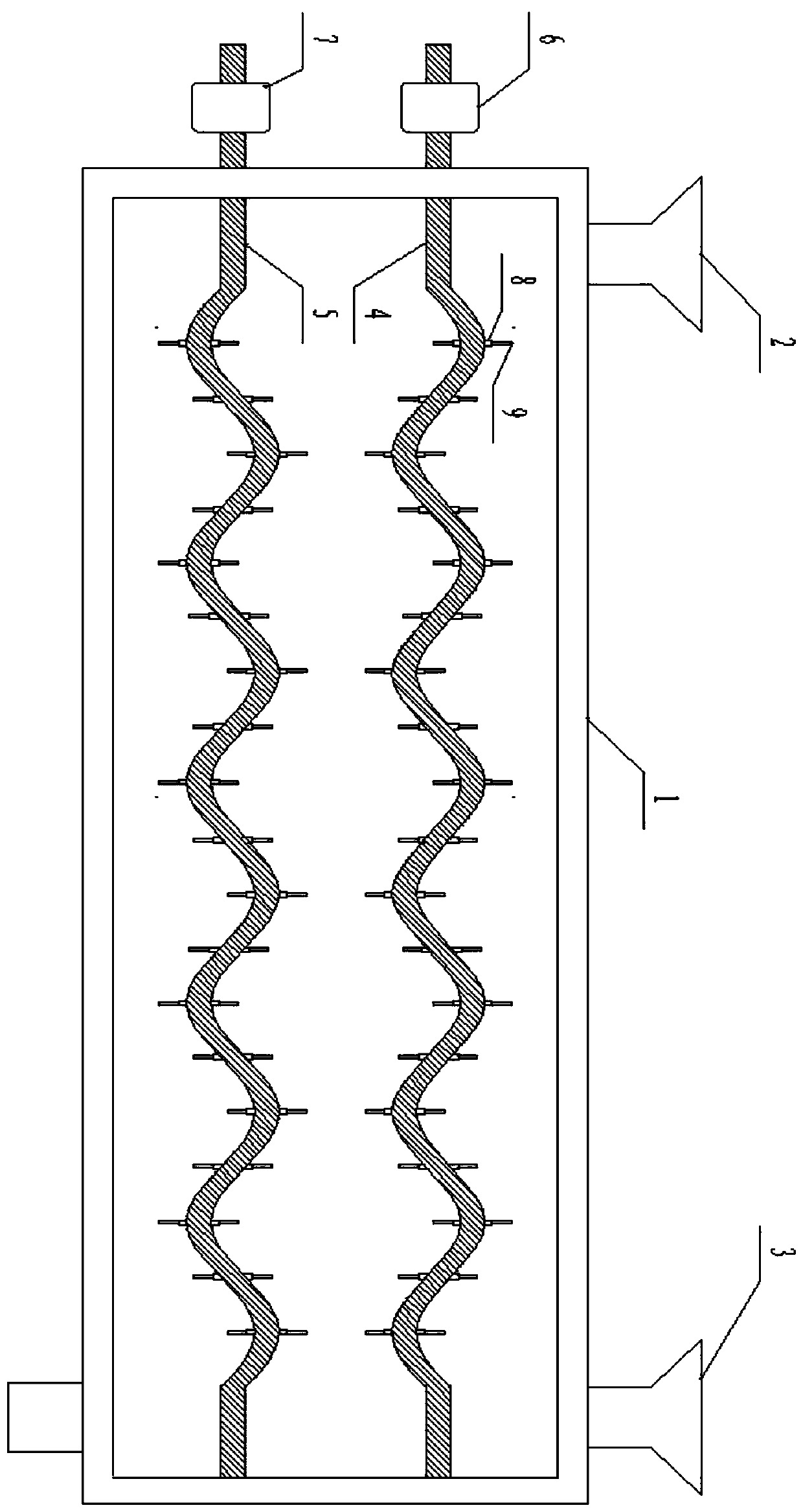

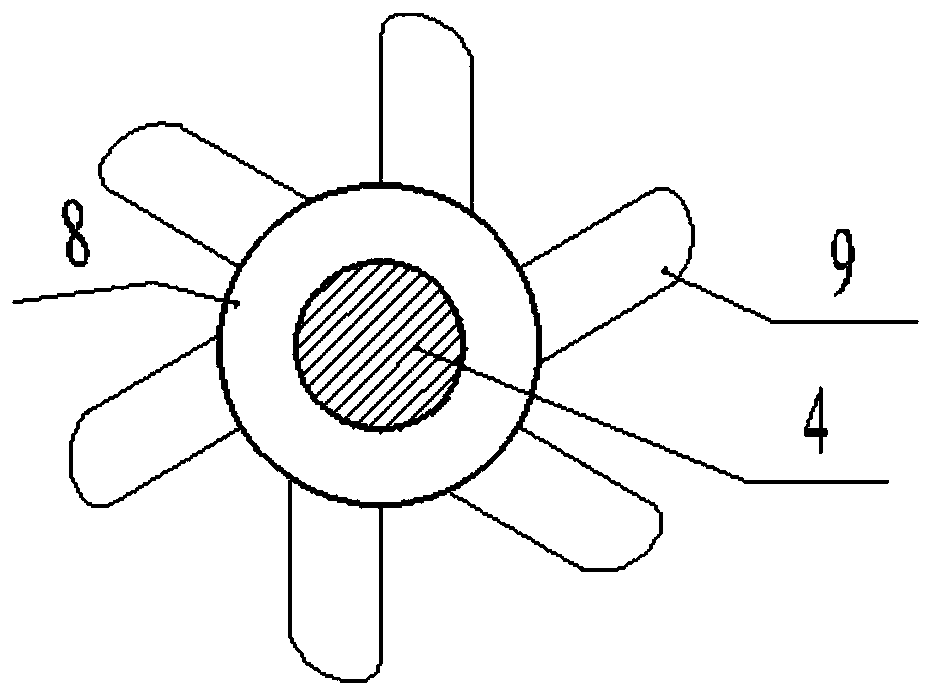

[0018] The present invention will be further described below in conjunction with the drawings and specific embodiments.

[0019] (1)Prepare polymer glue solution and dissolving glue solution; the polymer glue solution used is to replace and deoxidize the reactor with high-purity nitrogen, add a mixture of cyclohexane and hexane, then add butyl lithium, add 200 parts of benzene after heating The mixed monomer of ethylene and 50 parts of butadiene is polymerized to obtain a polymer glue solution. The dissolving glue solution used is a mixture of solution polymerized styrene butadiene rubber and hexane. The mass ratio of the solution polymerized styrene butadiene rubber and hexane is 1: 8. A stirring and shearing device was added to stir, the stirring speed was 1200 rpm, the stirring temperature was controlled at 45° C., and the stirring was carried out for 6 hours to obtain the dissolved solution of polystyrene butadiene rubber.

[0020] (2) The polymer glue solution and the dissolv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com