Method and device for extracting xylose from viscose fiber waste

A viscose fiber and waste technology, applied in the field of xylose extraction, can solve the problems of large input of raw materials and equipment, inability to popularize and utilize, and high requirements for corrosion resistance, and achieve the effect of reducing steam loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

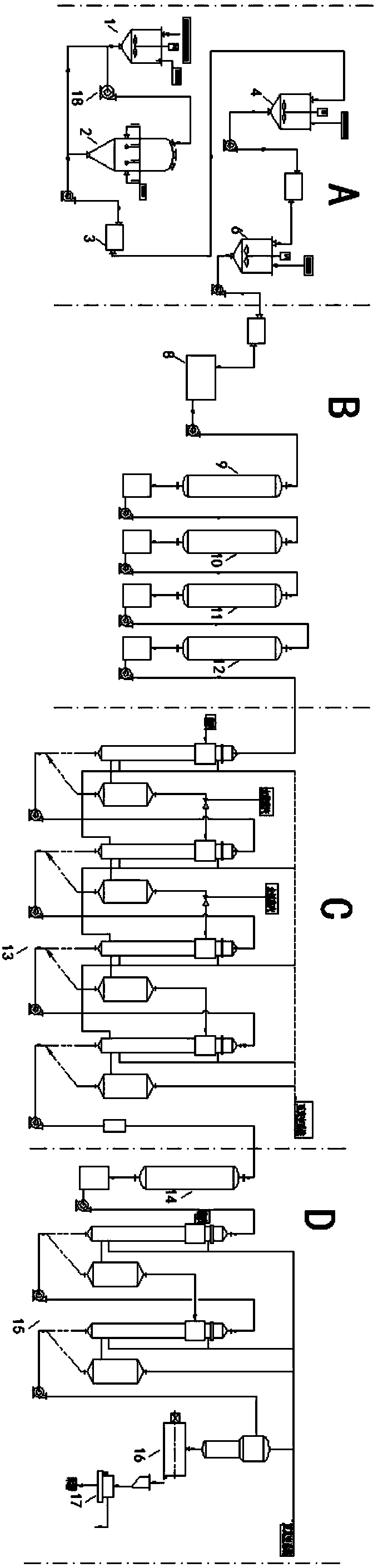

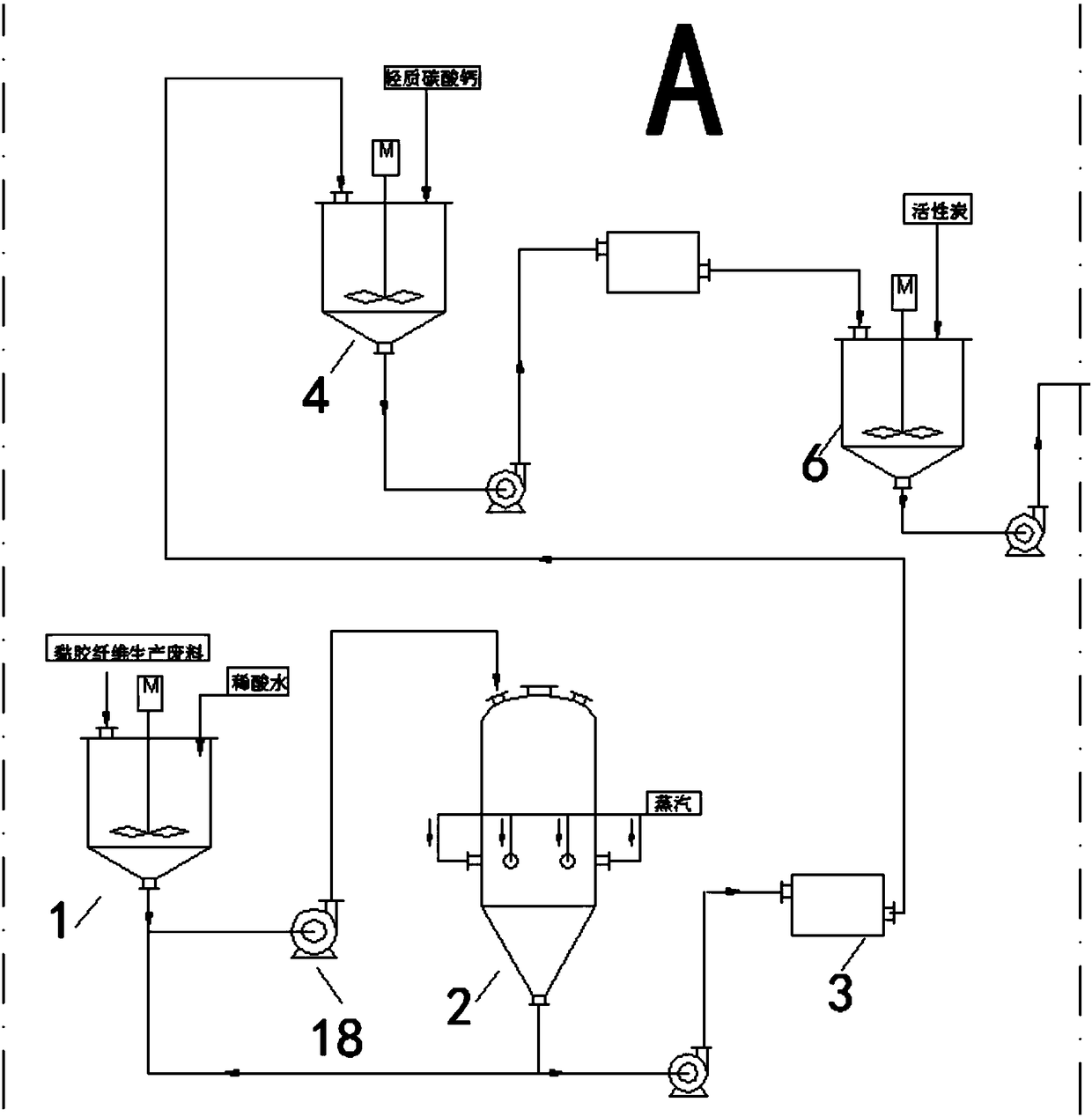

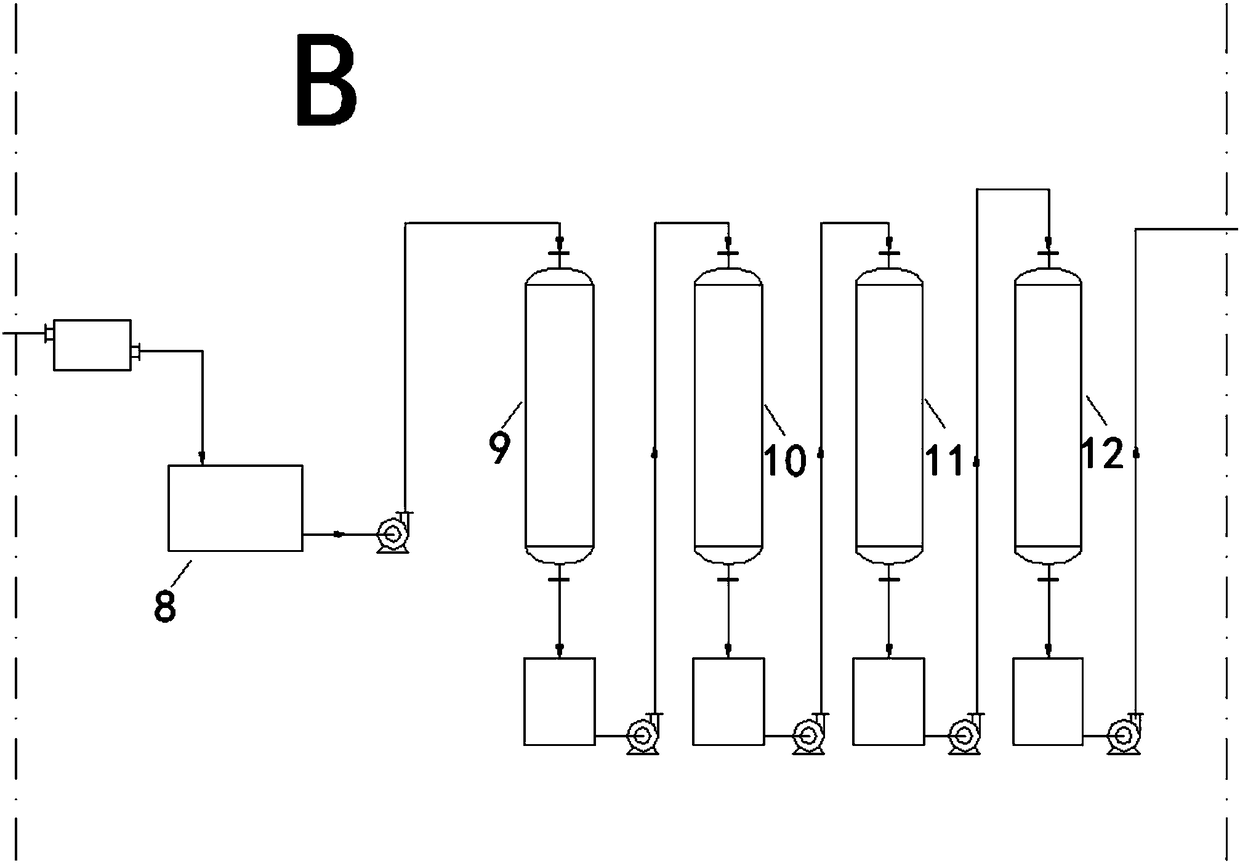

[0049] Such as Figure 1-5 Shown, a kind of method extracting xylose from viscose waste material, comprises the steps:

[0050] Step (1) pulping

[0051] Add dilute sulfuric acid in the mixing tank 1, then slowly add the solid viscose fiber waste into the mixing tank 1, and keep stirring to make it mix evenly with the dilute sulfuric acid. The mass ratio of solid waste in the mixing tank 1: sulfuric acid: water is 15:3:82;

[0052] Step (2) Hydrolysis

[0053] The slurry obtained in step (1) is injected into the hydrolysis pot 2 through the circulating pump 18, and steam is continuously fed into the hydrolysis pot 2 to heat up, and the temperature in the hydrolysis pot 2 is controlled at 110±5°C, and the pressure in the hydrolysis pot 2 is controlled at 0.08MPa , the hydrolysis time was controlled at 2 hours, and the circulating pump 18 was started during the hydrolysis process to extract and enter the slurry circulation from the hydrolysis pot 2;

[0054] Step (3) neutral...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com