Thermal simulation test auxiliary device for round bar metal forged piece and using method thereof

An auxiliary device, thermal simulation technology, applied in the direction of measuring device, testing material strength with one impact force, instrument, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

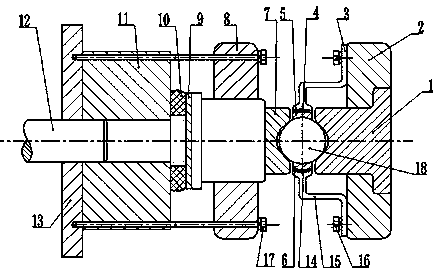

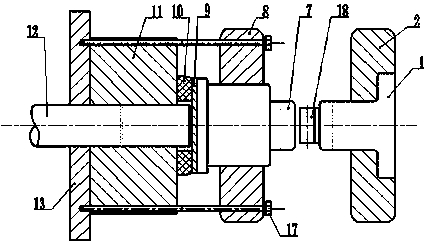

[0025] The embodiment of the present invention will be described in detail in conjunction with the accompanying drawings. This embodiment is based on the technical solution of the present invention, and provides detailed implementation and specific operation process, but the scope of protection of the present invention is not limited to the following embodiments.

[0026] According to the accompanying drawings, it can be known that it is an auxiliary device for thermal simulation test of a round bar-shaped metal forging. The auxiliary device is installed on a thermal simulation testing machine 13 to conduct a forging deformation test on a sample 18. , moving anvil head 7, fixed seat II8, and pushing mechanism; said fixed seat I2 and said fixed seat II8 are all installed on said thermal simulation testing machine 13, and said fixed seat II8 is installed on the thermal simulation testing machine by locking screw II17 On the testing machine 13, the fixed anvil head 1 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com