Pipeline surface pit repair tool

A technology for pits and pipes, applied in the field of pit repair tools on the surface of pipes, can solve the problems of metal pipes that cannot be repaired, require fire, and unfavorable pit repairs, etc., and achieve broad promotion prospects and practical use significance, easy to carry and operate convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

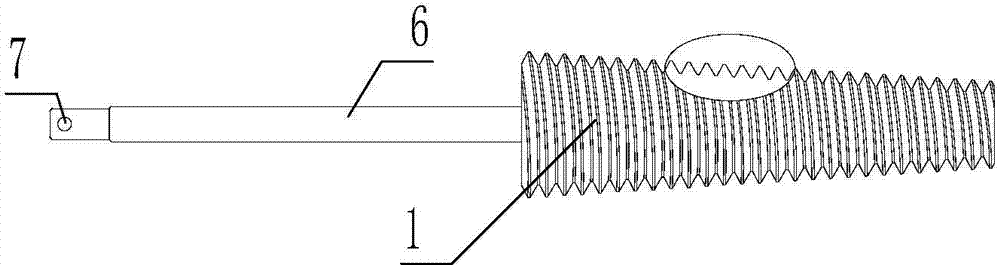

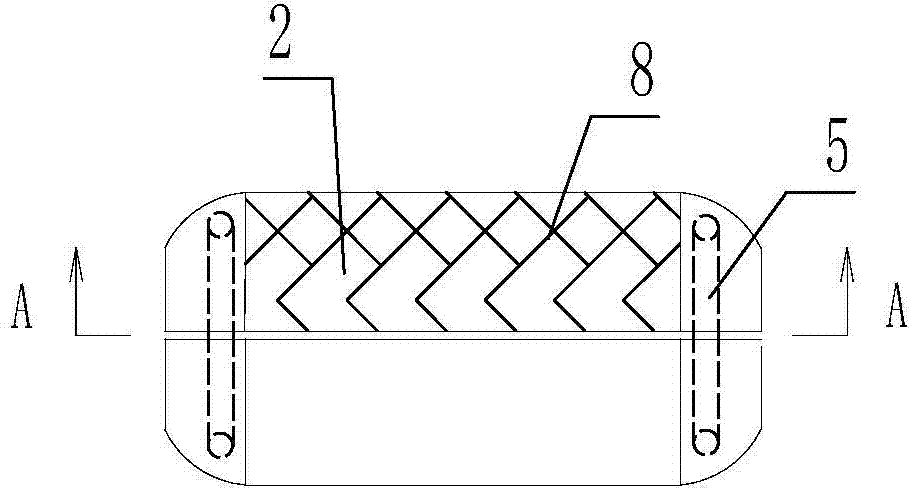

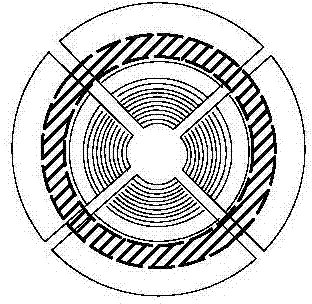

[0029] A tool for repairing pits on the surface of pipes, comprising a tapered screw and an annular tapping head;

[0030] The ring-shaped tapping head is a cylindrical body with a cylindrical outer surface. A tapered threaded hole is arranged along the axis of the cylindrical body at the center of the inner cavity of the cylindrical body. The cylindrical cylindrical body is composed of several pieces. It is formed by embracing each other, and the columnar body is divided into several pieces along the axis direction, and the several pieces of columnar bodies are bound by elastic bodies;

[0031] The tapered screw rod is matched with the threaded hole in the inner cavity of the ring tapping head.

[0032] The tapered lead screw 1 is a conical external thread, which adopts a special 60° metric tapered thread with a taper of 1:16. It is made of high-quality steel and has excellent wear resistance after special heat treatment. The large end of the tapered screw 1 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com