Anti-icing wire and manufacturing method thereof

A wire and anti-icing technology, applied in cable/conductor manufacturing, conductors, non-insulated conductors, etc., can solve the problems of affecting electrical conductivity, difficult construction, and high operating costs, and increase the area of the diversion interface without affecting the overall weight. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

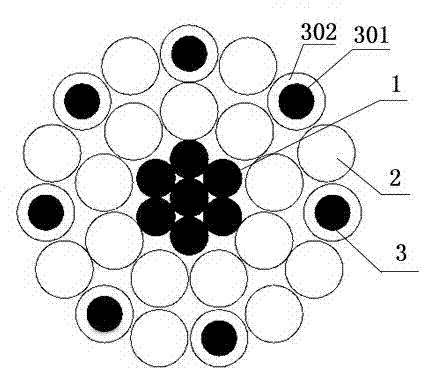

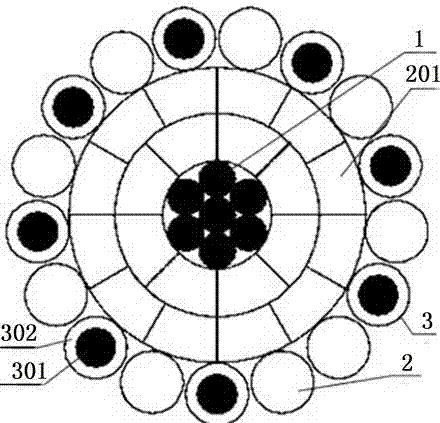

[0019] Such as figure 1 As shown, a kind of anti-icing wire, comprises the carbon fiber core 1 of inner layer, the annealed aluminum wire 2 of middle layer and outer layer, the low Curie point ferromagnetic material wire 3 of aluminum cladding, the round aluminum wire 2 of outer layer and cladding Aluminum low Curie point ferromagnetic material wires 3 are alternately arranged, and the aluminum-clad low Curie point ferromagnetic material wires 3 are made of a low Curie point ferromagnetic material inner layer 301 and coated on a low Curie point ferromagnetic material wire 301. The material inner layer 301 is composed of an aluminum clad layer 302 .

[0020] The preparation method of this anti-icing wire, its step is as follows:

[0021] 1. Use the aluminum cladding machine to melt the aluminum rod and extrude it on the low Curie point ferromagnetic material wire;

[0022] 2. Using a current generator, the output end of the current generator is connected to the low Curie poi...

Embodiment 2

[0025] Such as figure 1 Shown, a kind of anti-icing wire, its structure is the same as embodiment 1.

[0026] The preparation method of this anti-icing wire, its step is as follows:

[0027] 1. Use the aluminum cladding machine to melt the aluminum rod and extrude it on the low Curie point ferromagnetic material wire;

[0028] 2. Using a current generator, the output end of the current generator is connected to the low Curie point ferromagnetic material wire, and the aluminum extruded on the low Curie point ferromagnetic material wire is coated on the inner layer of the ferromagnetic material wire 301 An aluminum clad layer 302 is formed on it, and the current of the current generator is 600A and the voltage is 33V;

[0029] 3. Use carbon fiber 1 as the inner core, annealed aluminum wire 2 as the middle layer and outer layer, and arrange aluminum-clad low Curie point ferromagnetic material wires 3 between the outer annealed aluminum wires 2 at intervals for coaxial winding ...

Embodiment 3

[0031] Such as figure 1 Shown, a kind of anti-icing wire, structure is the same as embodiment 1.

[0032] The preparation method of this anti-icing wire, its step is as follows:

[0033] 1. Use the aluminum cladding machine to melt the aluminum rod and extrude it on the low Curie point ferromagnetic material wire;

[0034] 2. Using a current generator, the output end of the current generator is connected to the low Curie point ferromagnetic material wire, and the aluminum extruded on the low Curie point ferromagnetic material wire is coated on the inner layer of the ferromagnetic material wire 301 An aluminum clad layer 302 is formed on it, and the current of the current generator is 900A and the voltage is 30V;

[0035] 3. Use carbon fiber 1 as the inner core, annealed aluminum wire 2 as the middle layer and outer layer, and arrange aluminum-clad low Curie point ferromagnetic material wires 3 between the outer annealed aluminum wires 2 at intervals for coaxial winding , m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com