Arc runner stirring tank

An arc-shaped flow channel and mixing tank technology, which is applied to cement mixing devices, clay preparation devices, chemical instruments and methods, etc. Transporting ready-mixed concrete and other issues, to ensure the quality of transported concrete, facilitate heat dissipation, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

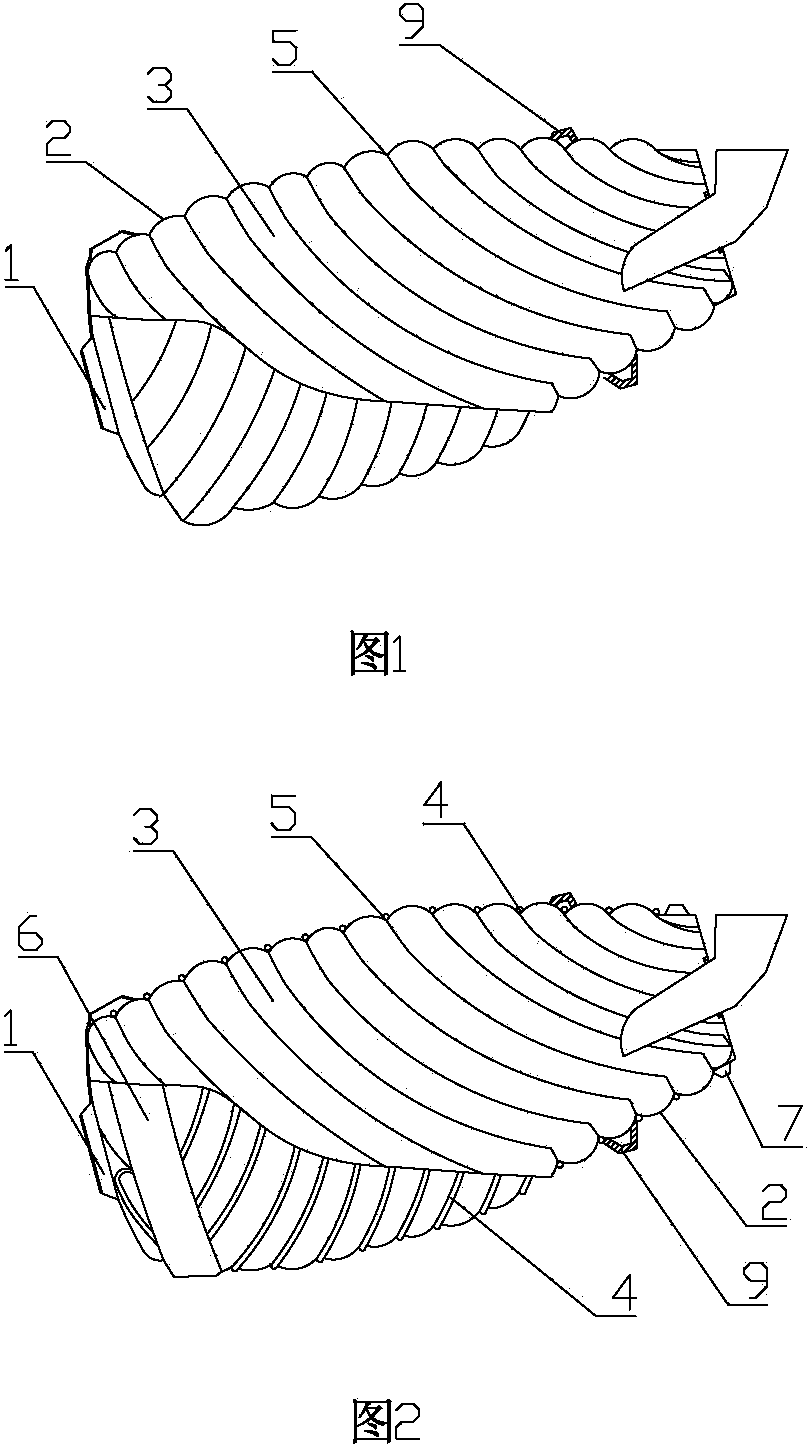

[0026] Embodiment 1: as attached figure 1 As shown, the agitation tank body with arc-shaped flow channel includes a driving flange 1 and a tank body 2 with an opening facing to the right. The left end of the tank body 2 is fixedly installed with a driving flange 1 capable of driving the tank body 2 to rotate; At least three agitation and diversion grooves 3 are arranged adjacent to each other along the circumference in a spiral shape from left to right, and the bottoms of the agitation and diversion grooves 3 all have smooth fillet transitions. When in use, the discharge funnel can be loaded from the opening of the tank body 2, and the tank body drive motor of the concrete tank truck and the drive flange 1 are connected together, so that the tank body 2 can be driven to rotate by the drive motor, and During the rotation process, the concrete can be exported along with the rotation of the tank body 2 through the stirring diversion groove 3; since the bottom of the stirring d...

Embodiment 2

[0028] Embodiment 2: as attached figure 2 As shown, there is a groove 5 spiraling to the right on the outer wall of the tank body 2 , and a circulation pipe 4 is wound and installed in the groove 5 . During use, the two ends of the circulation pipe 4 can be respectively communicated with the liquid inlet and the liquid outlet of the existing known water heating device or water cooling device, and the water heating device or water cooling device is fixedly installed on the outside of the tank body 2, Then a circulating water pump can be provided in the water heating device or water cooling device, thereby realizing the process of heat preservation or cooling through the circulating water pump; the circulating pipe 4 can also be wound along the same direction of the tank body 2, and then the water heating device or water cooling device is fixed on the tank Outside the main body 2, the hot water or cold water in the water heating device or the water cooling device can be circu...

Embodiment 3

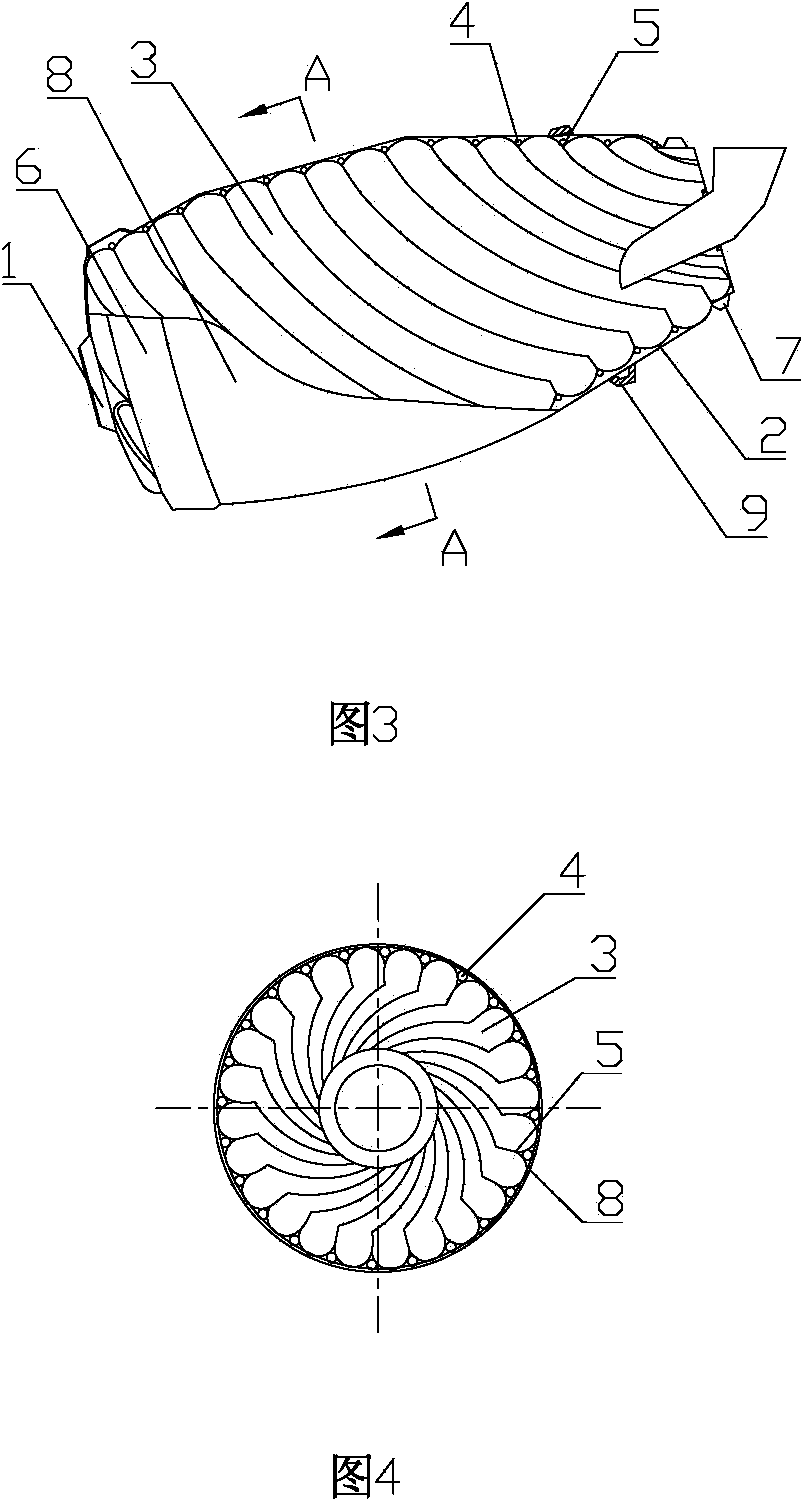

[0034] Embodiment 3: as attached image 3 As shown, the exterior of the tank body 2 is provided with a tank insulation layer 8 that wraps the groove 5 and the circulation pipe 4 . The tank body insulation layer 8 can reduce the heat loss of the tank body 2 and has a good thermal insulation effect; when the outside of the tank body 2 is equipped with a jacket, the outside of the tank body 2 is provided with a tank body insulation layer that wraps the jacket 8.

[0035] as attached figure 1 , 2 As shown in .

[0036] as attached figure 1 , 2 , 3, the outer side of the tank body 2 is fixedly installed with an annular tank rotating raceway 9. The tank body rotating raceway 9 can make it easy to install with the rotating parts; when the tank body insulation layer 8 is added, the tank body rotation raceway 9 is fixedly installed on the outside of the tank body insulation layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com