Pipeline cleaning method and remote-controlled spin-washing type pipeline cleaning robot used

A pipeline cleaning and spin-washing technology, which is applied in the direction of cleaning methods and appliances, chemical instruments and methods, and cleaning hollow objects, etc., can solve the problems of increasing the speed of pipeline dirt, large application limitations, and high production costs, and reduce cleaning costs. The effect of high cost, high utilization rate and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

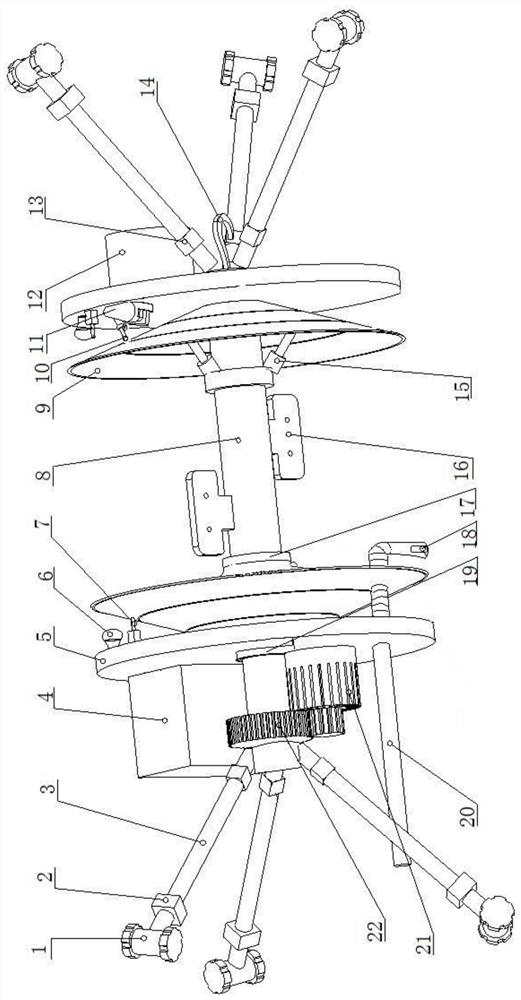

[0031] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

[0032] like figure 1 As shown in the figure, a pipeline cleaning method of the present invention seals the pipeline in sections inside the pipeline, firstly sprays high-pressure water / cleaning liquid to the inner wall of the pipeline in the sealed section, and then generates a swirling flow in the pipeline in the sealed section by agitating the blades. The dirt adhering to the inner wall of the pipe is vigorously removed by spraying, soaking, and swirling impact; the cleaning process will not cause any damage to the inner wall of the pipe.

[0033] The pipeline cleaning process specifically includes the following steps:

[0034]1) Use a remote-controlled spin-washing pipe cleaning robot for pipe cleaning, and each part of the remote-controlled spin-washing pipe cleaning robot is controlled by remote control;

[0035] 2) First, the travelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com