Corrosion inhibitor for water quality of high salt and weak acid oil field with chloride ion content of more than 50,000 ppm

A technology with chloride ion content and high salt content, which can be used in drilling compositions, chemical instruments and methods, etc., and can solve problems such as research and fewer products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

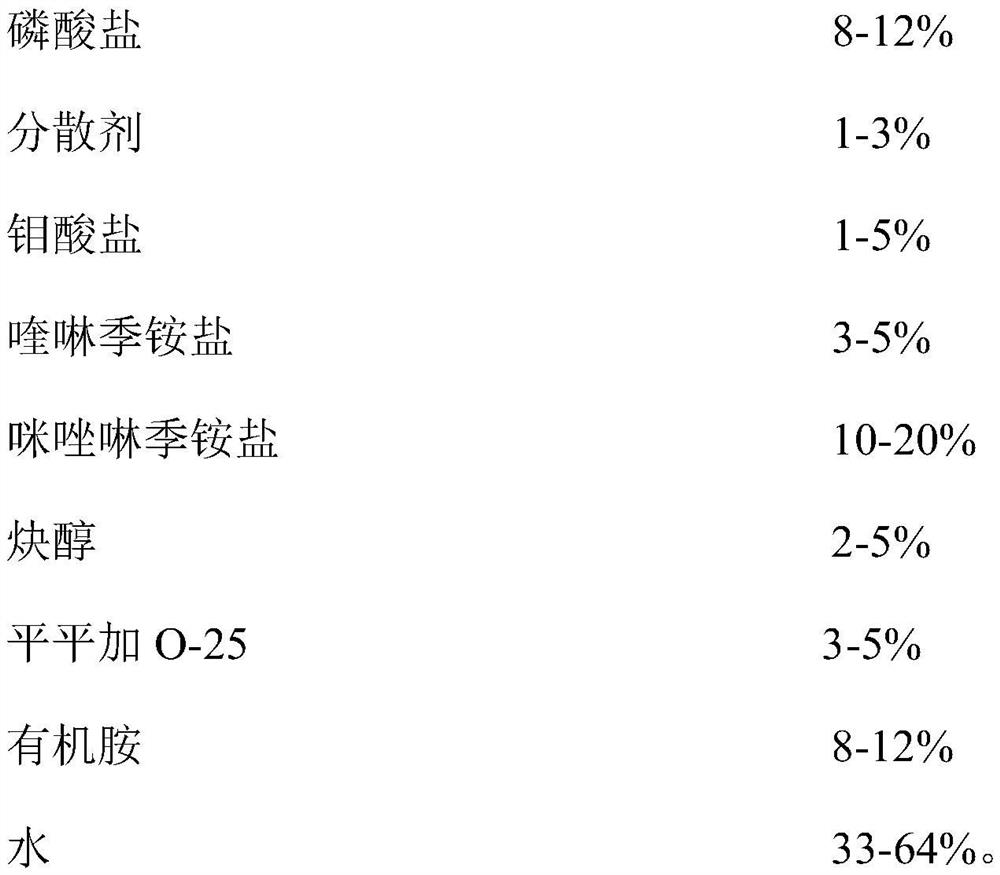

Image

Examples

Embodiment 1

[0016] Dissolve 5g of ammonium molybdate, 2g of disodium EDTA, and 8g of sodium hexametaphosphate in water to prepare a solution. The quinoline quaternary ammonium salt is a synthetic product of quinoline and chloroacetic acid, and the synthesis process is as follows: the mol ratio of quinoline and chloroacetic acid is 1: 1.05, and quinoline is added in the there-necked flask equipped with reflux condenser, agitator and thermometer, Then, under stirring, chloroacetic acid was added dropwise, and the temperature was raised to 110° C. and reacted for 4 hours. After the reaction, the temperature was lowered to obtain a crude product. Then, isopropanol was used as a solvent for recrystallization, and the quinoline quaternary ammonium salt product was obtained after filtration and drying. The imidazoline quaternary ammonium salt is a synthetic product of oleic acid, diethylenetriamine and chloroacetic acid, and the synthesis process is as follows: the molar ratio of oleic acid, diet...

Embodiment 2

[0018] Dissolve 3g sodium molybdate, 3g sodium gluconate and 12g disodium hydrogen phosphate in water to make a solution, then add 5g peregal plus O-25 and 3g propargyl alcohol and fully stir and dissolve, the quinoline quaternary ammonium salt For quinoline and chloroacetic acid synthesis product, the synthesis process is as follows: the mol ratio of quinoline and chloroacetic acid is 1: 1.10, in the there-necked flask equipped with reflux condenser, agitator and thermometer, add quinoline, then dropwise under stirring Chloroacetic acid was heated to 120° C. and reacted for 6 hours. After the reaction was completed, the temperature was lowered to obtain a crude product. Then, isopropanol was used as a solvent for recrystallization and filtration and drying to obtain a quinoline quaternary ammonium salt product. The imidazoline quaternary ammonium salt is a synthetic product of oleic acid, diethylenetriamine and chloroacetic acid, and the synthesis process is as follows: the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com