Annular protection fluid corrosion inhibitor for oil and gas well, preparation method and use method

An annular protective fluid and corrosion inhibitor technology, applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve problems such as corrosion and perforation of oil pipelines, avoid corrosion under scale, slow release High efficiency, uniform and dense adsorption film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

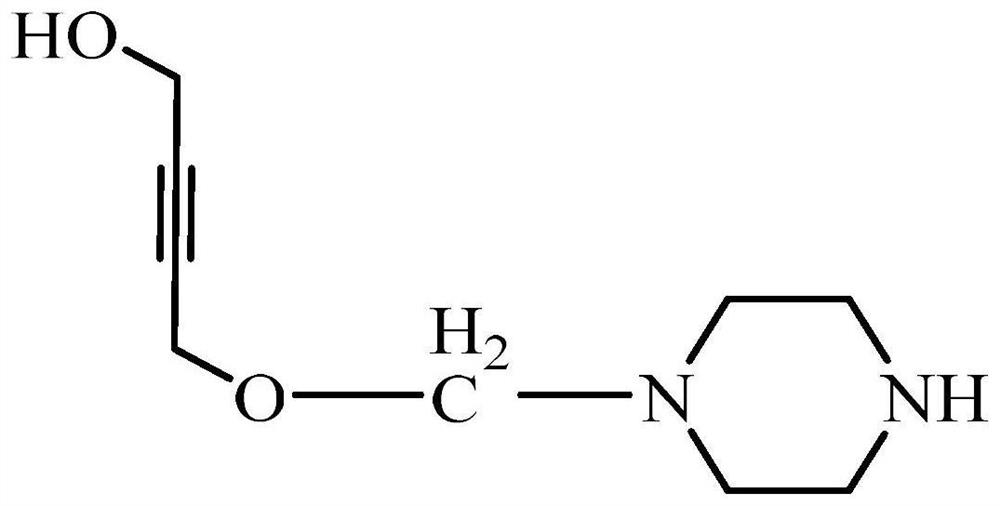

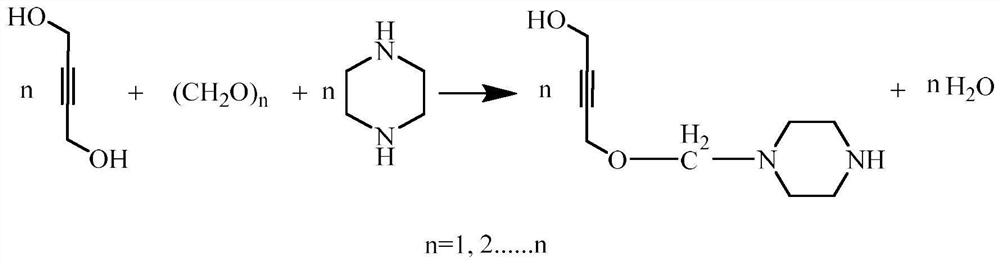

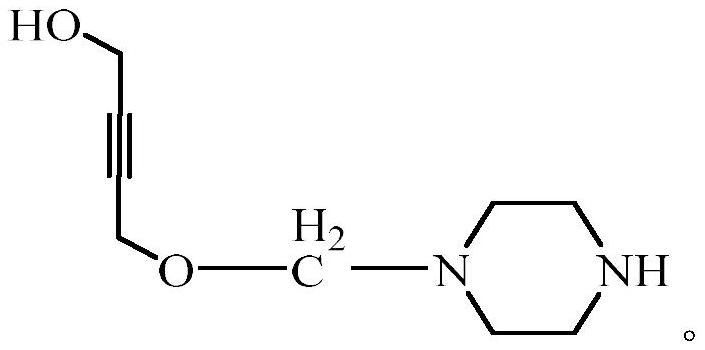

[0037] A kind of annulus protection fluid corrosion inhibitor for oil and gas wells, the preparation method of butynediols Mannich base comprises the following steps:

[0038] Step 1: Fully mix butynediol, paraformaldehyde, piperazine and solvent evenly to form mixture A; wherein the molar ratio of butynediol, paraformaldehyde and piperazine is 1:1.5~2.5:1.5~2.5 ;

[0039] Step 2: Adjust the pH value of the mixture A obtained in Step 1 to 2-3, heat up to the solvent reflux temperature, and keep it warm for 5 hours to obtain the required Mannich base. Hydrochloric acid with a mass percentage of 30 wt% was used as a reaction catalyst, and the pH value of the mixture A was adjusted.

[0040] A preparation method of annulus protection fluid corrosion inhibitor for oil and gas wells, comprising the following steps:

[0041] S11: Weigh each component raw material according to the weight percentage in claim 1;

[0042] S21: Fully stir the raw materials of each component at room te...

Embodiment 1

[0047] Follow the steps below to prepare annulus protection fluid corrosion inhibitor for oil and gas wells:

[0048] Step 1: butynediol, paraformaldehyde, piperazine are added in the there-necked flask, then add toluene and mix uniformly to form mixture A; wherein the mol ratio of butynediol, paraformaldehyde, piperazine is 1:2: 1.5;

[0049] Step 2: Adjust the pH value of the mixture A obtained in Step 1 to 2-3, heat up to the solvent reflux temperature, and keep it warm for 5 hours to obtain the required Mannich base. Hydrochloric acid with a mass percentage of 30 wt% was used as a reaction catalyst, and the pH value of the mixture A was adjusted.

[0050] Step 3: Weigh the raw materials of each component according to the following mass percentages:

[0051] Butynediol Mannich base 40%, glutaraldehyde 5%, polyaspartic acid 5%, polyacrylic acid 5%, octylphenol polyoxyethylene ether 5%, dimethylformamide 40%;

[0052] Step 4: Stir the components in step 3 and mix them well...

Embodiment 2

[0064] Follow the steps below to prepare annulus protection fluid corrosion inhibitor for oil and gas wells:

[0065] Step 1: butynediol, paraformaldehyde, piperazine are added in the there-necked flask, then add toluene and mix uniformly to form mixture A; wherein the mol ratio of butynediol, paraformaldehyde, piperazine is 1:1.5: 1.5;

[0066] Step 2: Adjust the pH value of the mixture A obtained in Step 1 to 2-3, heat up to the solvent reflux temperature, and keep it warm for 5 hours to obtain the required Mannich base. Hydrochloric acid with a mass percentage of 30 wt% was used as a reaction catalyst, and the pH value of the mixture A was adjusted.

[0067] Step 3: Weigh the raw materials of each component according to the following mass percentages:

[0068] Butynediol Mannich base 20%, formaldehyde 15%, polyaspartic acid 7.5%, polyacrylic acid 7%, octylphenol polyoxyethylene ether 7%, dimethylformamide 17%, ethanol 26.5% ;

[0069] Step 4: Stir the components in step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com