High-temperature electric resistance furnace used for fretting wear tests

A technology of fretting wear and high temperature, applied in the direction of furnace, furnace type, lighting and heating equipment, etc., can solve the problems of slow heating and uncontrollable temperature of high-temperature electric furnace, and achieve slow heating, uncontrollable temperature and increase heating speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

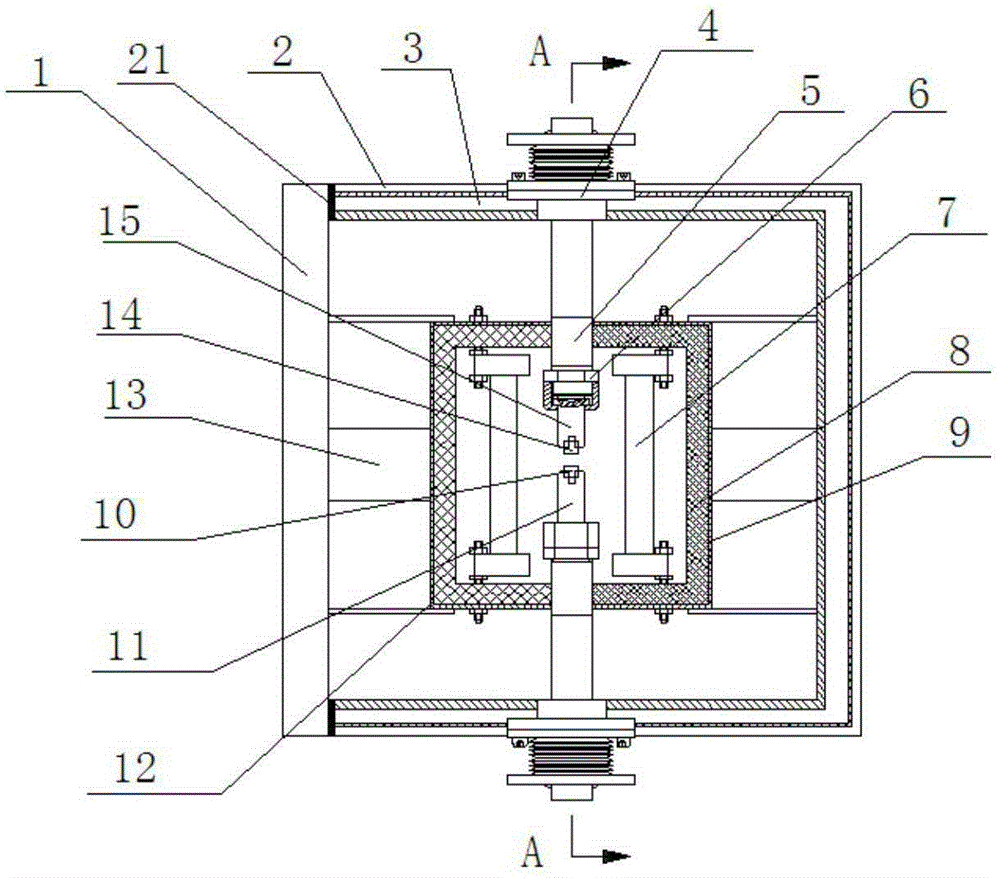

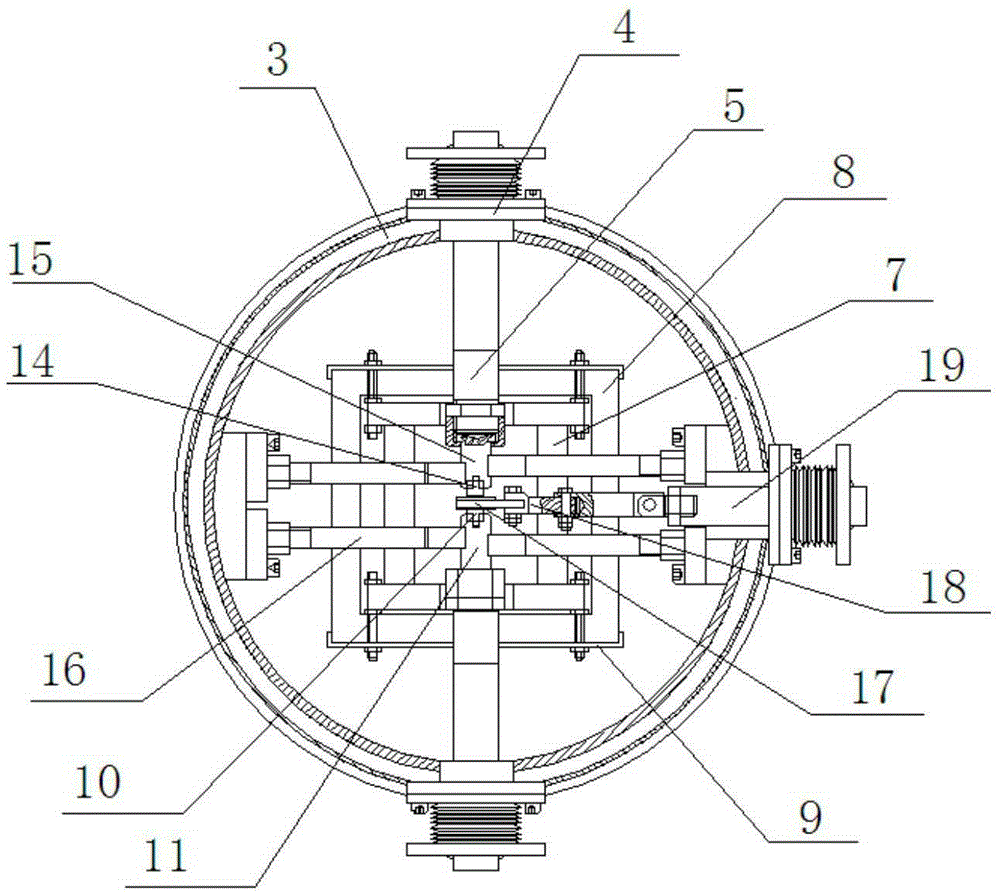

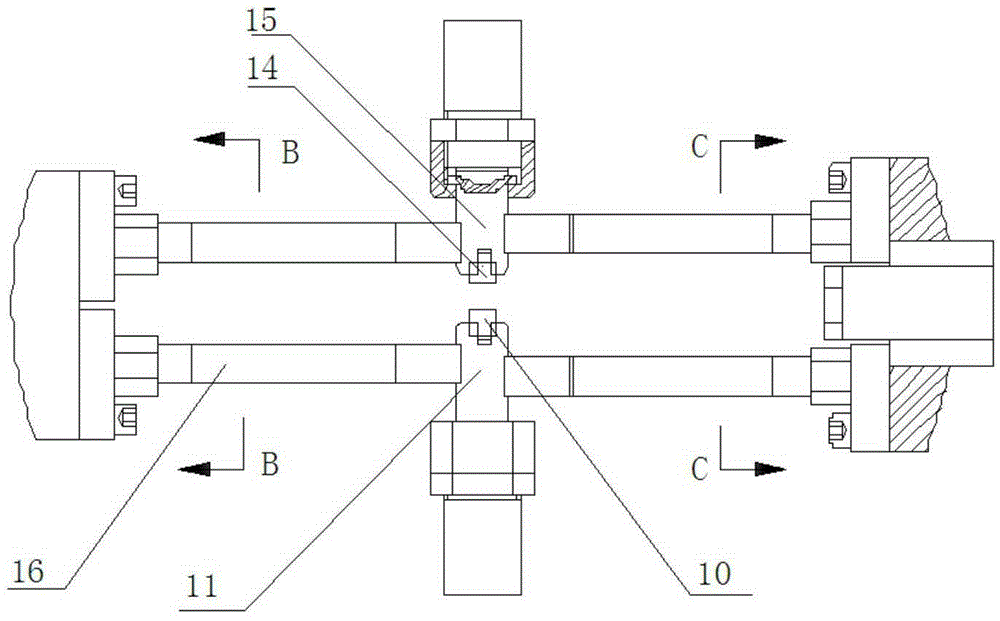

[0022] Such as Figure 1~6 A high-temperature electric furnace for fretting wear test is shown, which includes an end cover 1, a furnace body 2, a bellows assembly 4, a high-temperature connecting rod 5, a heating device 7, a lower sample 10, a lower sample seat 11, an upper Sample 14, upper sample holder 15, moving sample 17, moving sample holder 18 and transmission rod 19, a heating device 7 is fixedly arranged in the furnace body 2; Sample 14 and lower sample 10, the upper sample 14 is installed on the high temperature connecting rod 5 through the upper sample seat 15, and the lower sample 10 is fixedly installed on the high temperature connecting rod 5 through the lower sample seat 11, so The high temperature connecting rod 5 is installed on the side wall of the furnace body 2 through the bellows assembly 4; the moving sample ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com