Patents

Literature

90 results about "Lathe faceplate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A lathe faceplate is a basic workholding accessory for a wood or metal turning lathe. It is a circular metal (usually cast iron) plate which fixes to the end of the lathe spindle. The workpiece is then clamped to the faceplate, typically using t-nuts in slots in the faceplate, or less commonly threaded holes in the faceplate itself.

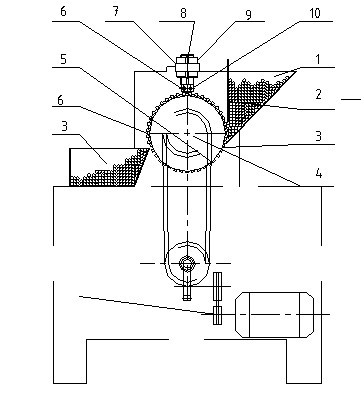

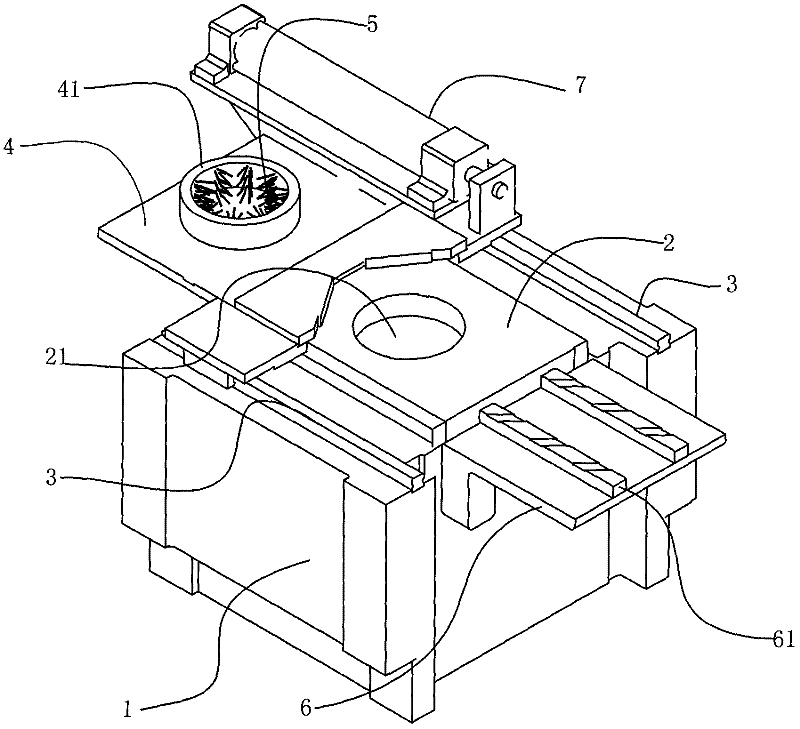

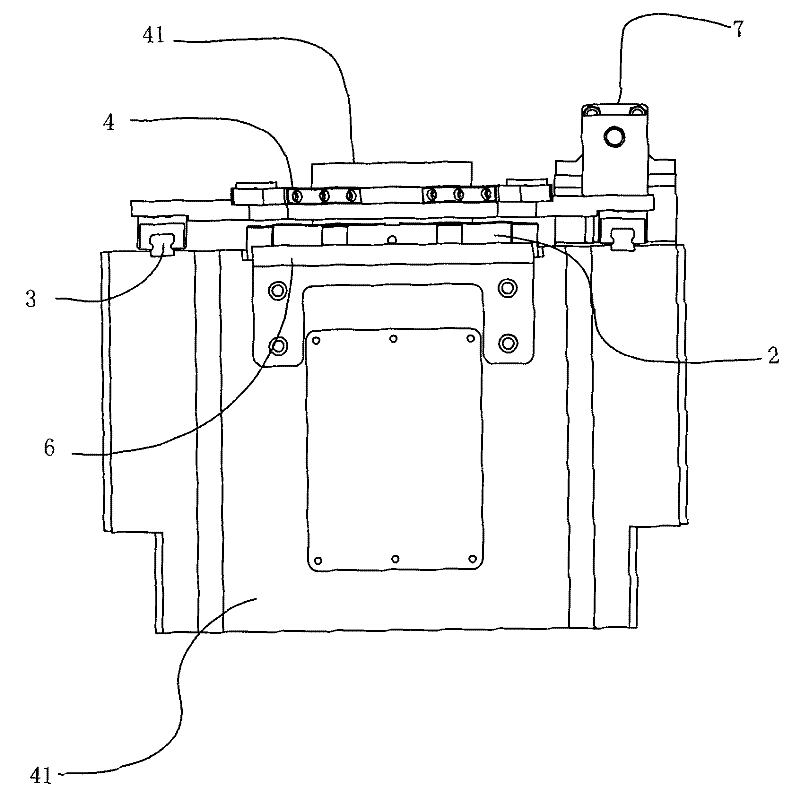

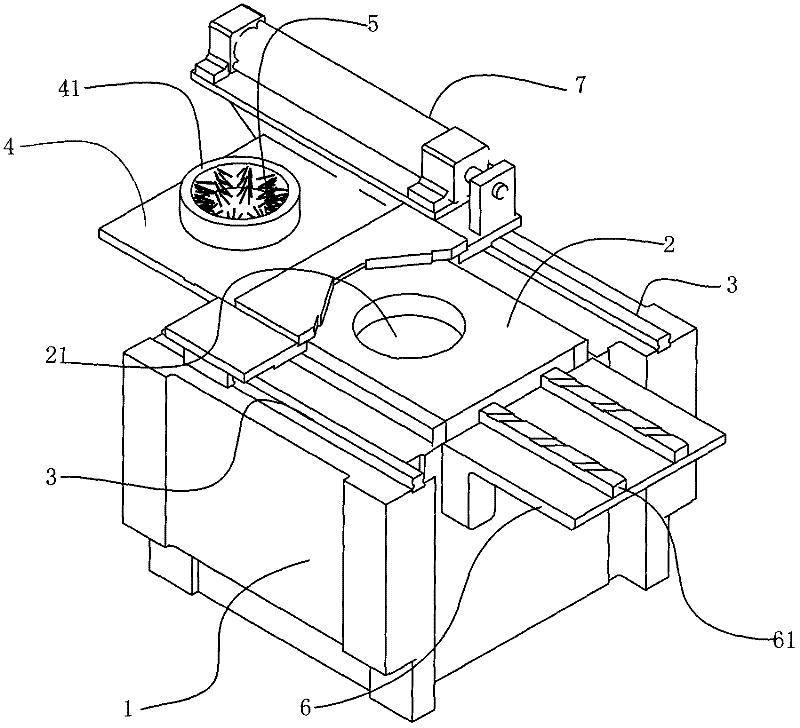

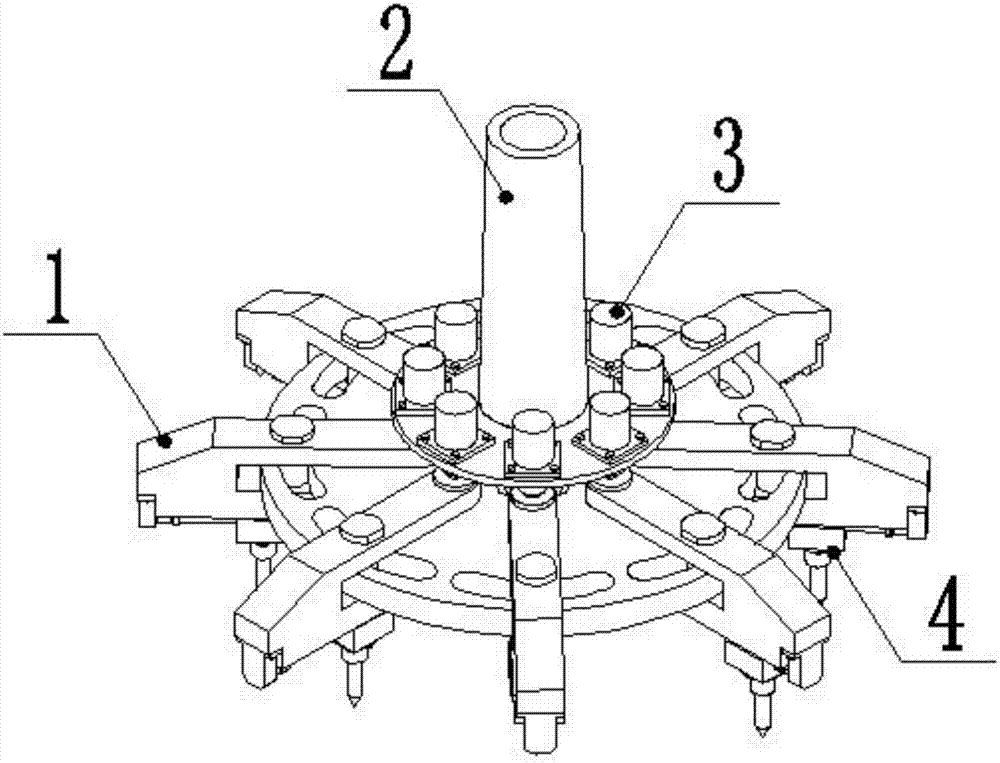

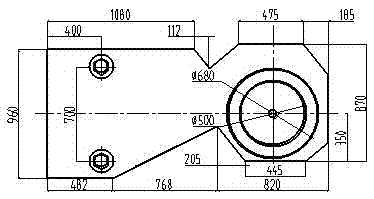

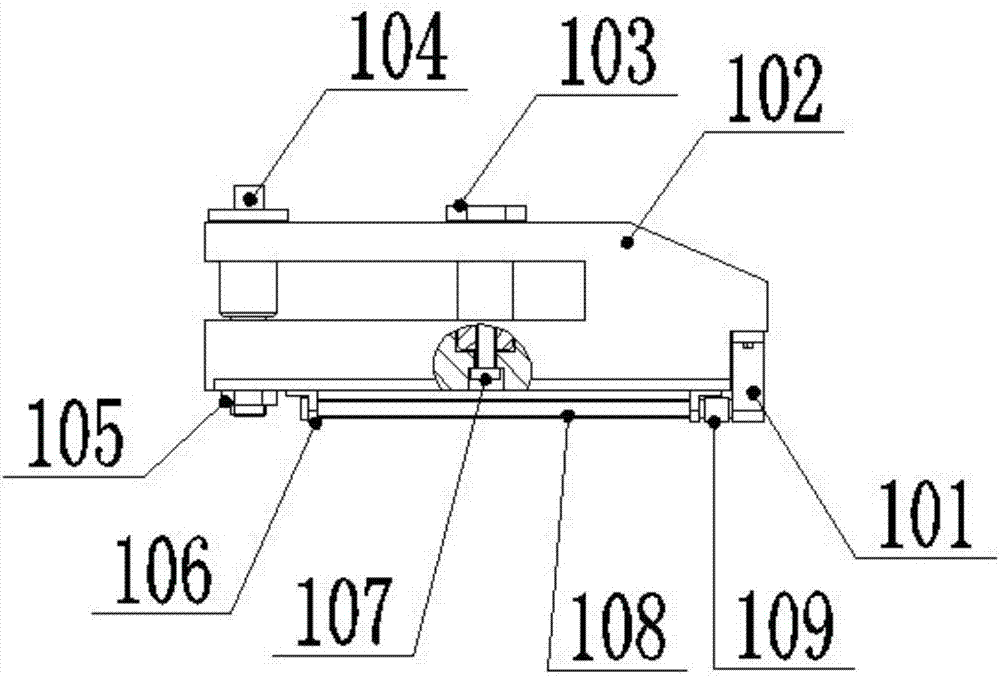

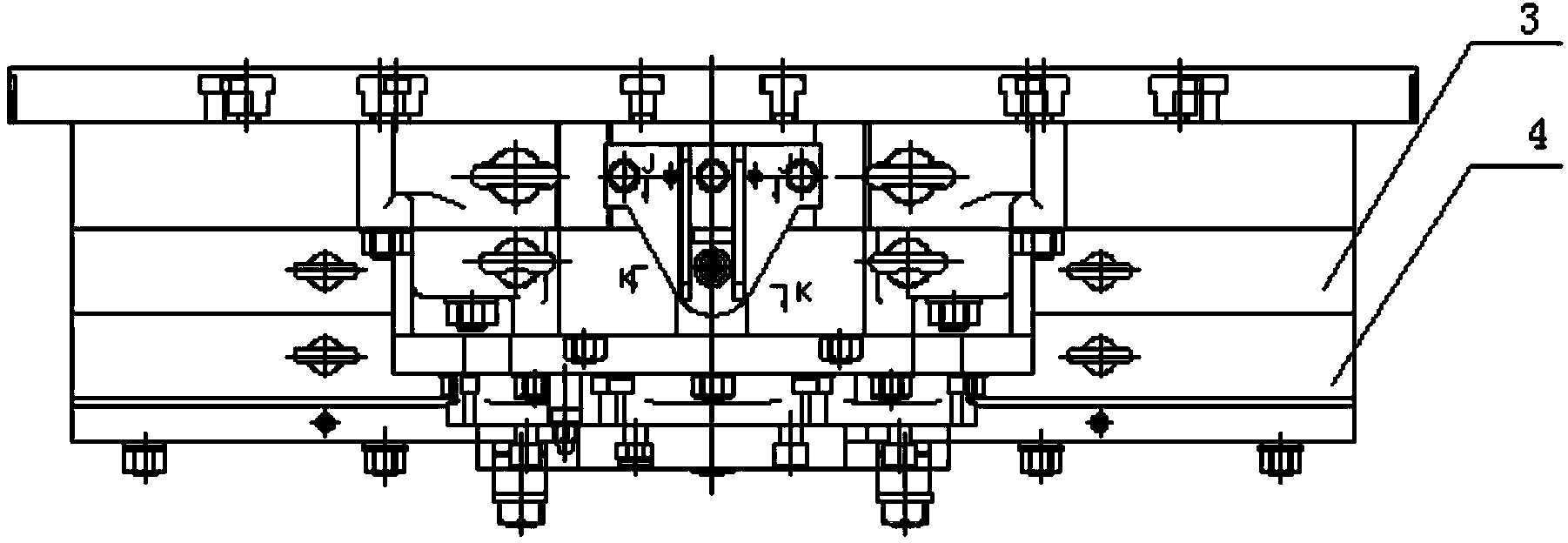

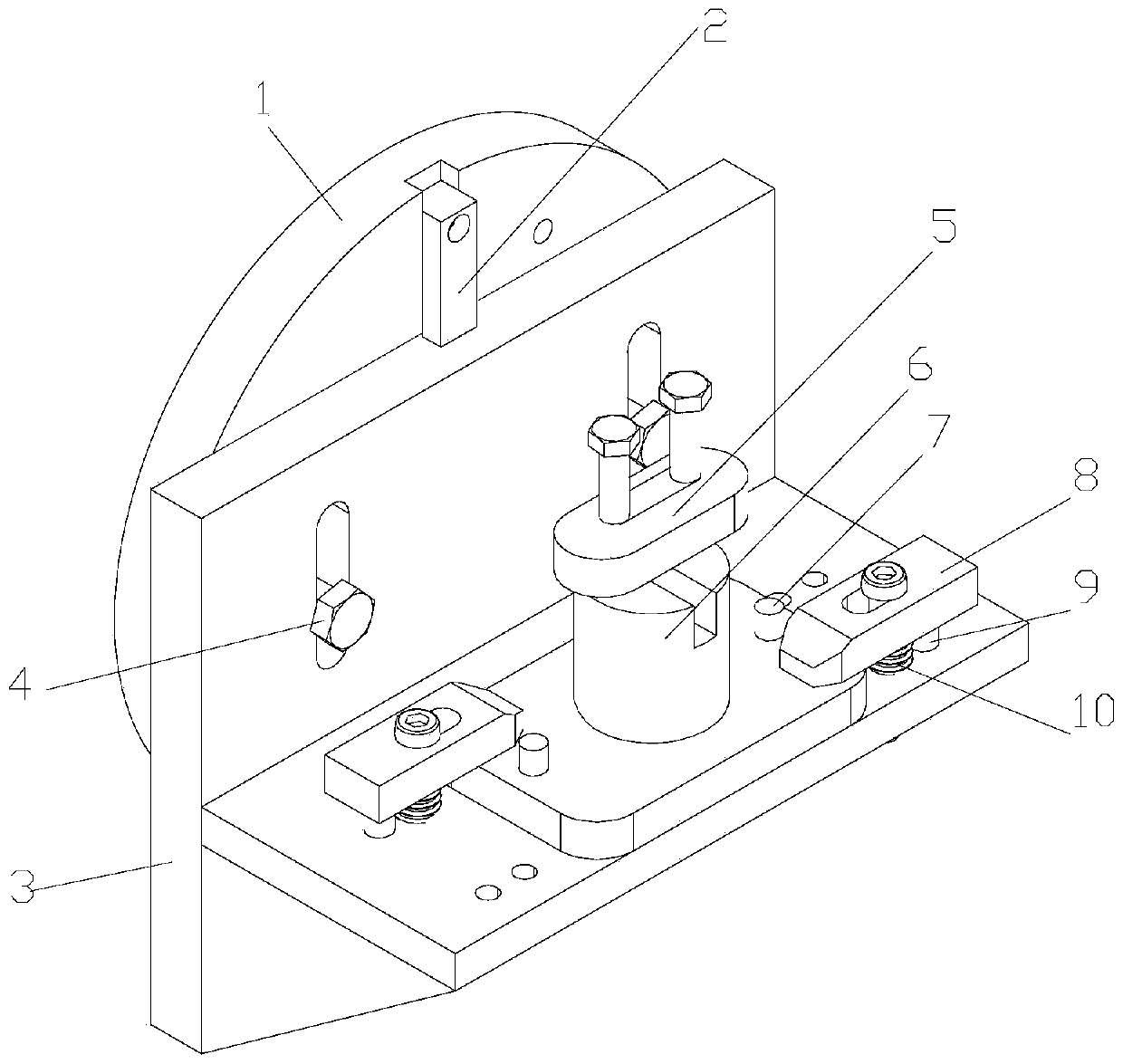

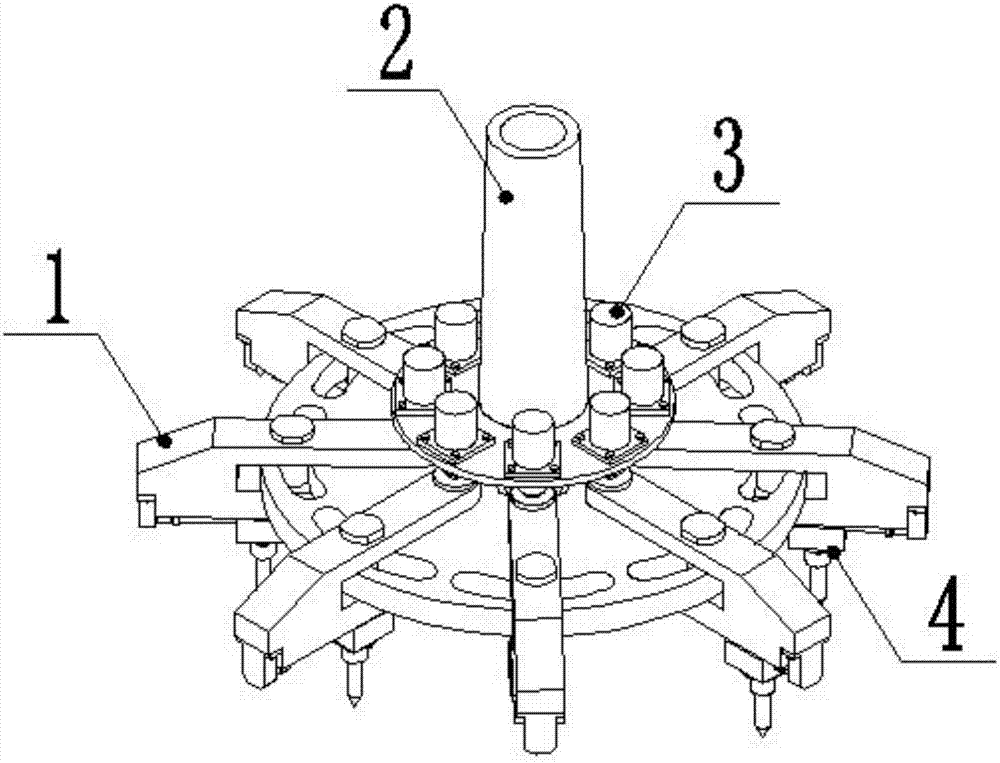

Self-centering clamping device of drill press workpiece

ActiveCN103801959AImprove processing efficiencyEasy to operateWork clamping meansFeeding apparatusLathe faceplateEngineering

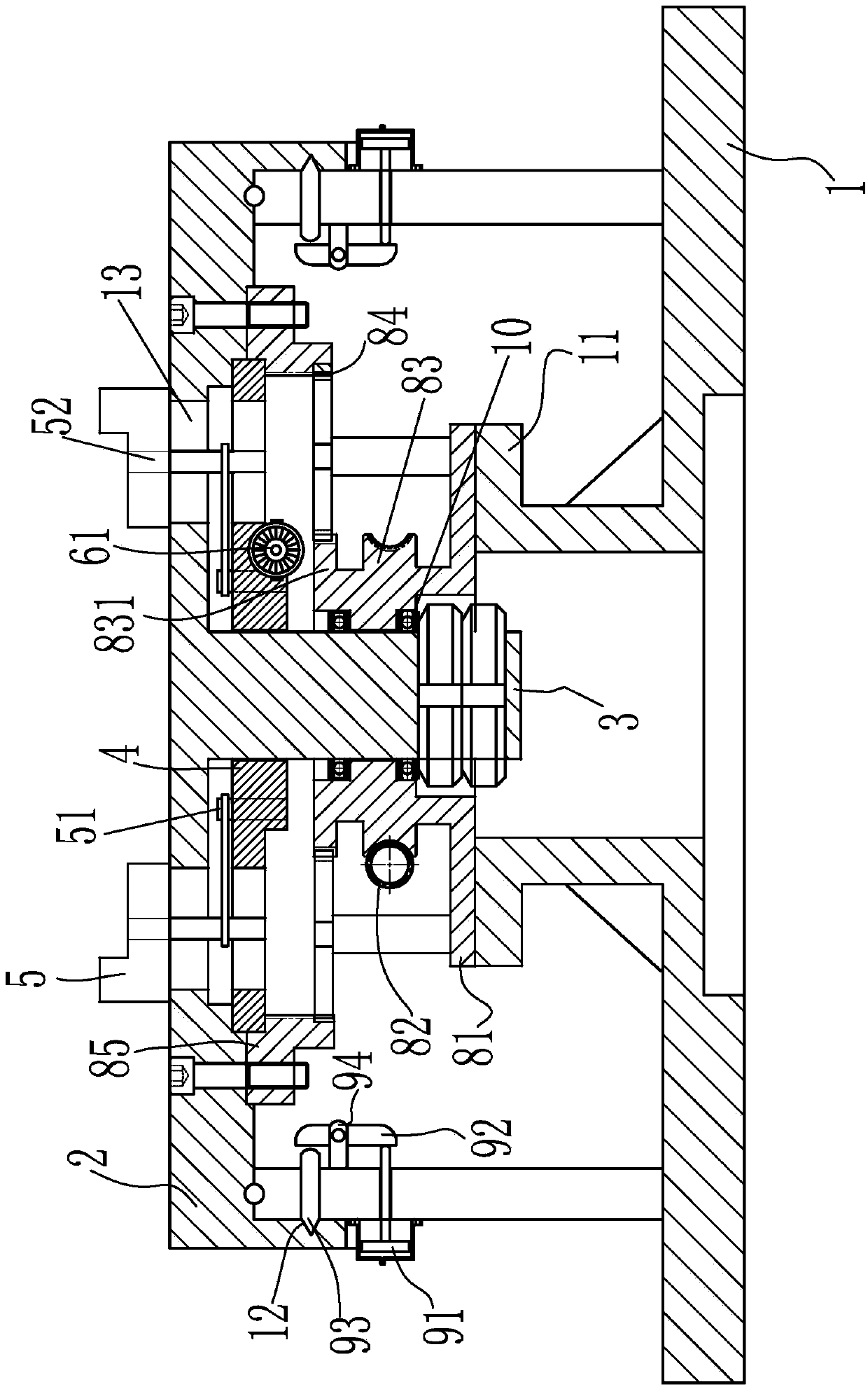

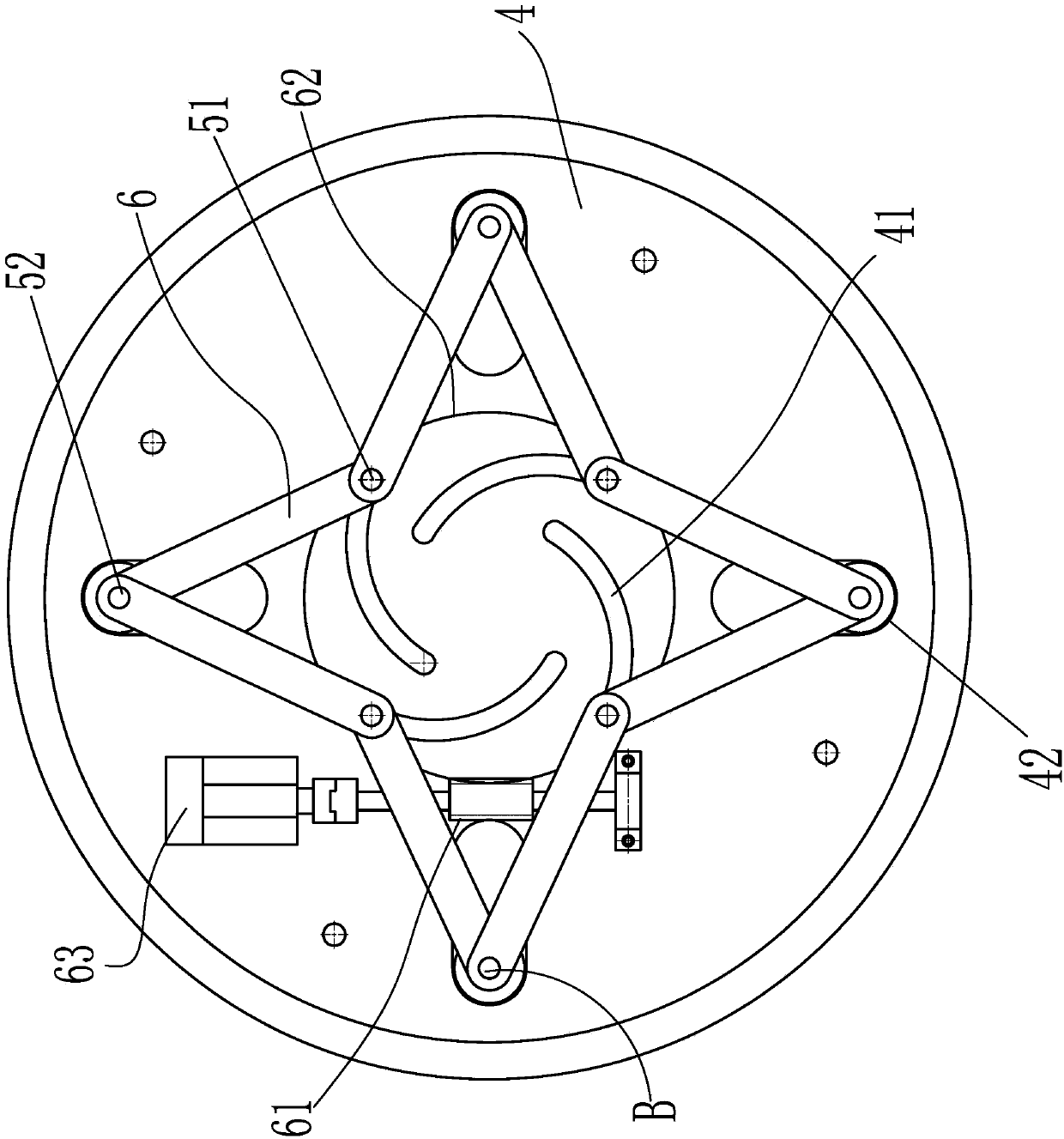

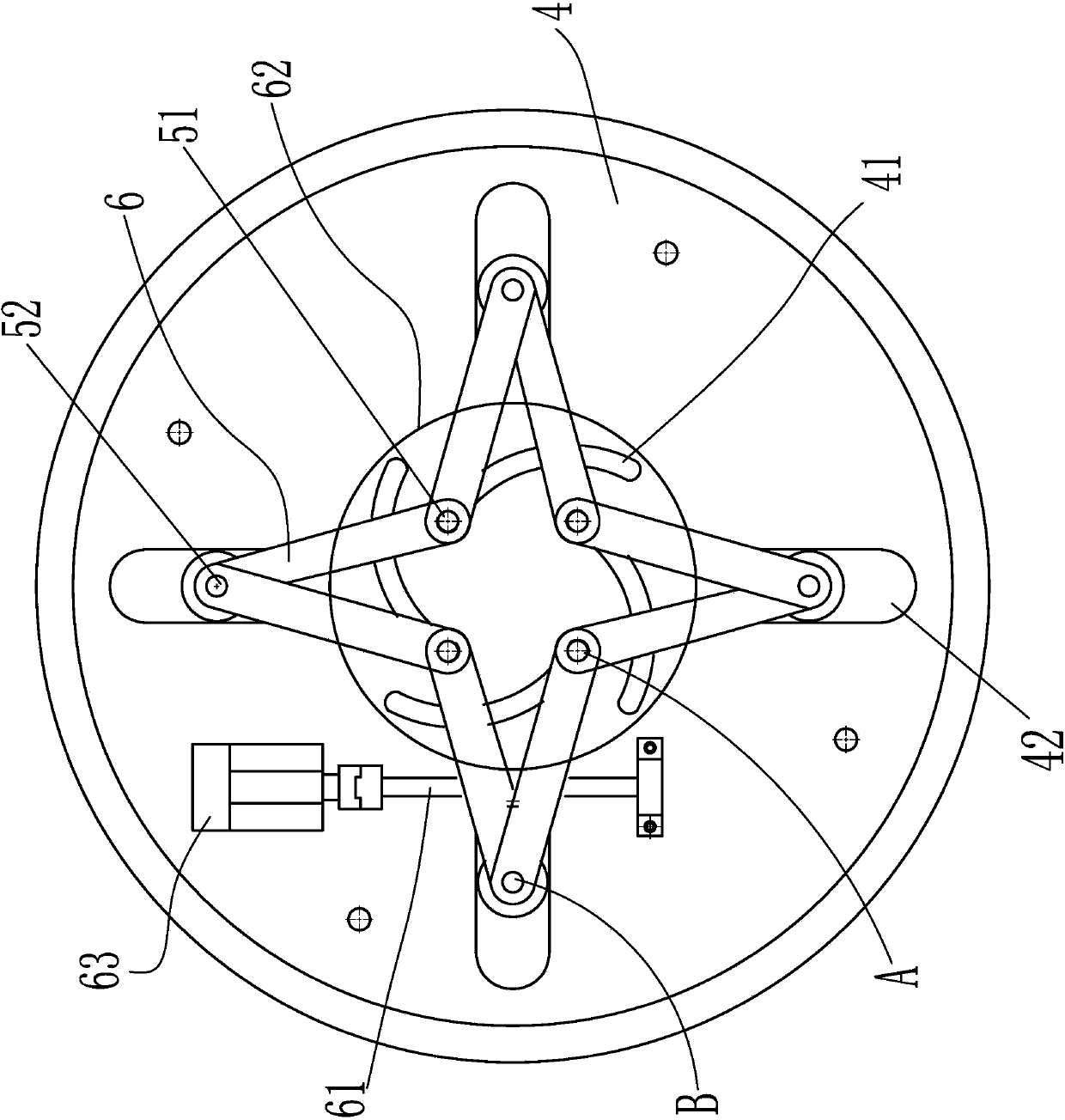

The invention provides a self-centering clamping device of a drill press workpiece. The device can realize the self-centering function for a workpiece. The device comprises a connecting base, a workbench rotary disc, a main shaft, a parabola self-centering flower disc, a plurality of connecting rods and a plurality of positioning pawls, wherein the workbench rotary disc can be arranged above the connecting base in a rotary way, the main shaft is fixedly arranged below the middle part of the workbench rotary disc, the parabola self-centering flower disc can be arranged below the workbench rotary disc on the main shaft by a transmission mechanism in a rotary way, arc-shaped gradually slotting grooves are uniformly formed in the parabola self-centering flower disc in the radial direction, the head of one connecting rod is hinged to the end of the other connecting rod, both ends of each of the connecting rods are respectively a first hinging end and a second hinging end, the first hinging ends are respectively hinged to the arc-shaped gradually slotting grooves on the parabola self-centering flower disc, long hinging grooves corresponding to the positions of the peripheral sides of the arc-shaped gradually slotting grooves are respectively formed in the parabola self-centering flower disc, the second hinging ends are respectively hinged to the long hinging grooves in a hinge way, and the positioning pawls are respectively arranged above the second hinging ends of the connecting rods.

Owner:HUHANG TECH GRP CO LTD

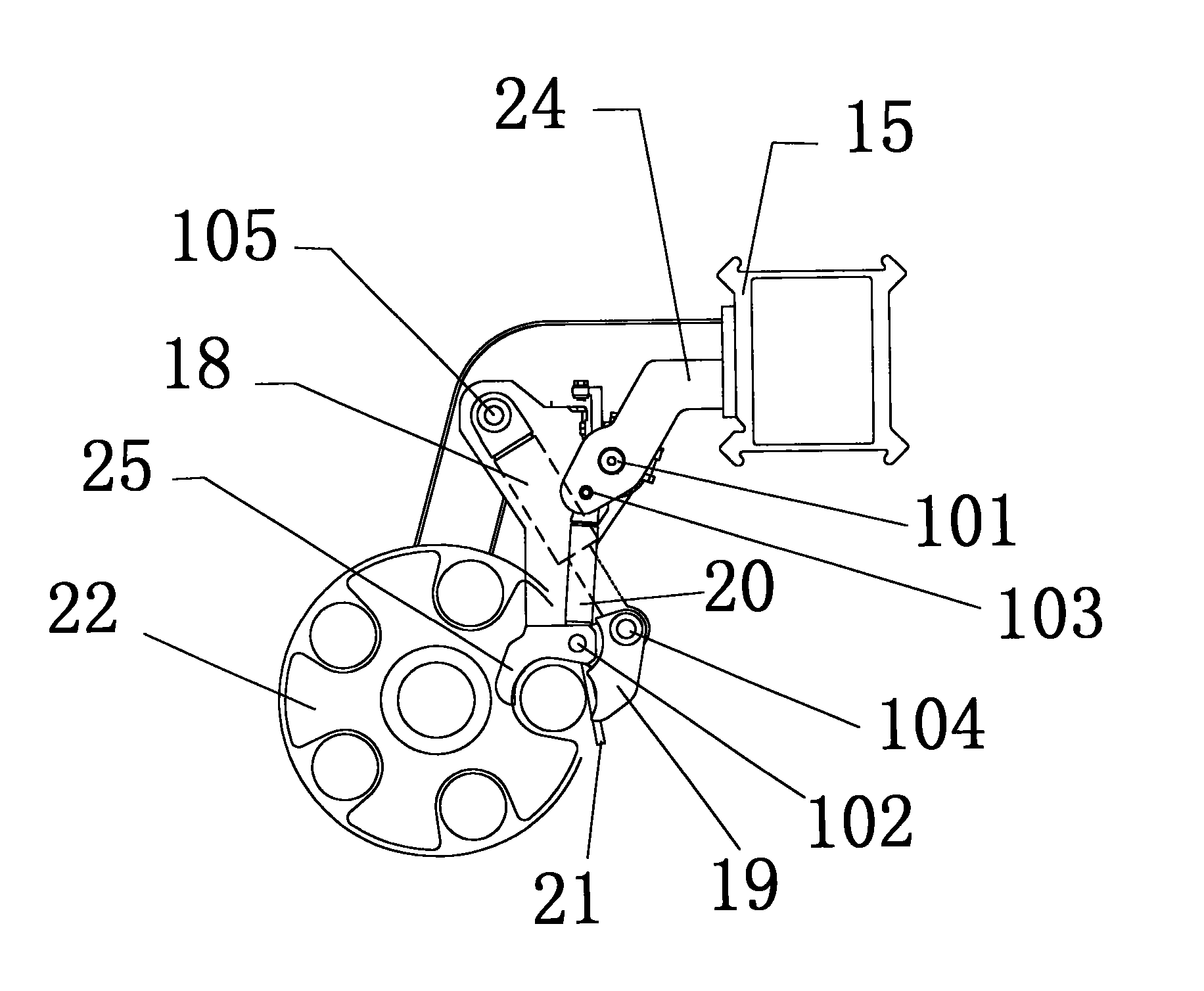

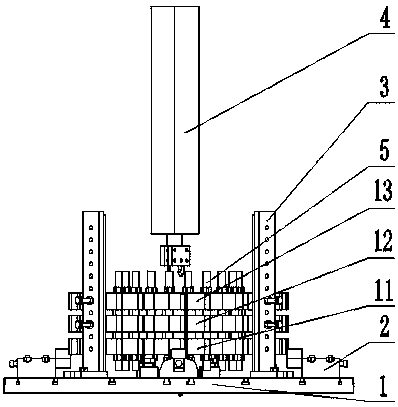

System for storing and fetching multiple drill rods

ActiveCN101988374AImplement automatic storageRealize automatic grippingDrilling rodsDrilling casingsLathe faceplateManipulator

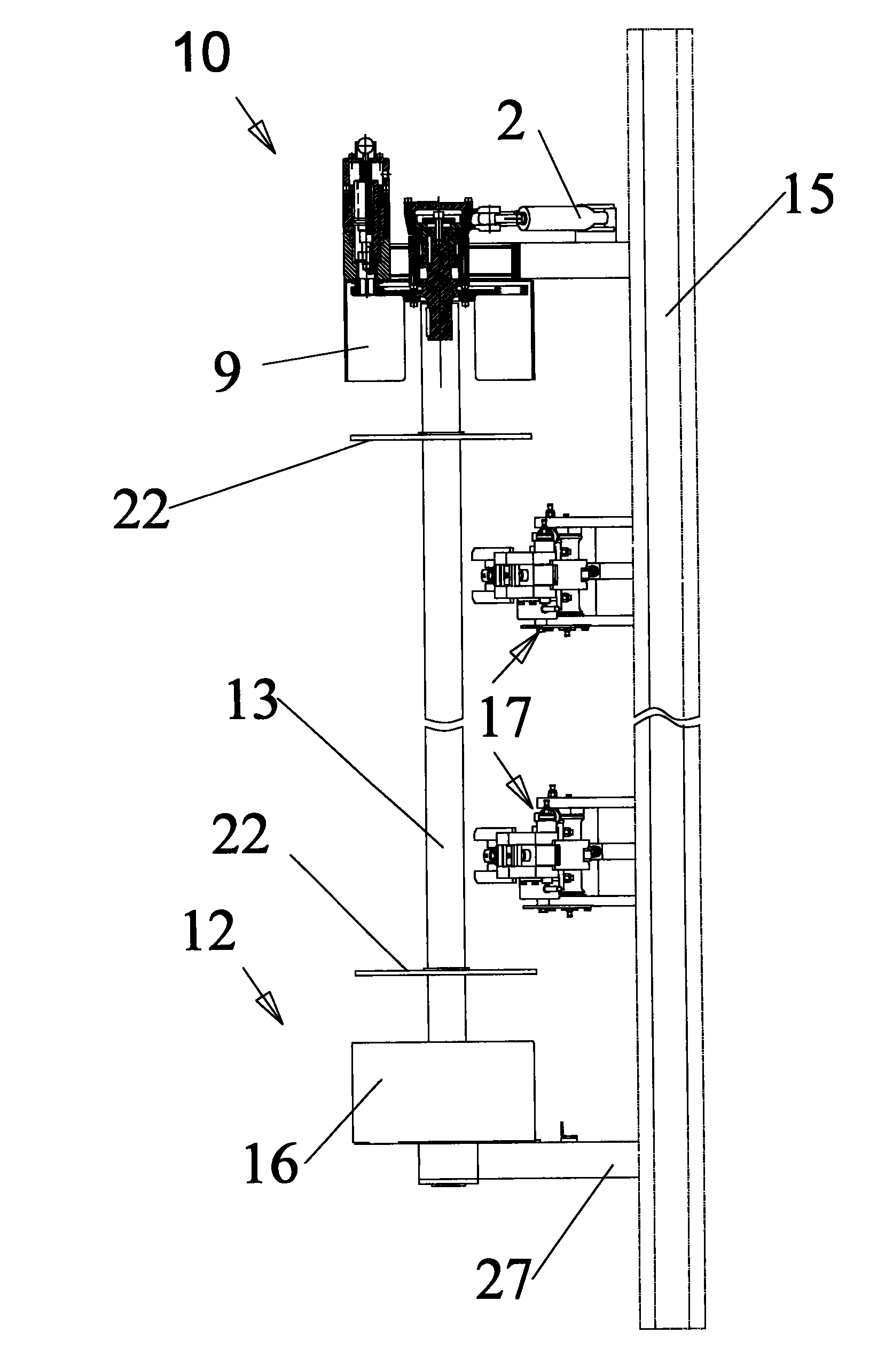

The invention provides a system for storing and fetching multiple drill rods, which comprises a drill rod warehouse, a plurality of manipulators and a pushing beam, wherein the drill rod warehouse is used for storing drill rods; the manipulators are used for clamping the drill rods; the pushing beam is used for installing the drill rod warehouse and the manipulators; the drill rod warehouse comprises a main shaft, an upper bracket and a lower bracket, the main shaft is parallel with the pushing beam and connected with the upper bracket and the lower bracket, the upper part and the lower part of the main shaft are respectively provided with a face plate perpendicular to the main shaft, a plurality of grooves are uniformly arranged at the periphery of each face plate, and the drill rods areclamped in the grooves of the face plates; the upper bracket and the lower bracket are internally and respectively provided with an upper drill rod box and a lower drill rod box used for storing the drill rods, and the upper bracket is also provided with a rotating positioning mechanism; and each manipulator comprises a manipulator seat frame, a swinging arm, a swinging arm oil cylinder, a fixed clamping jaw, a movable clamping jaw and a clamping jaw oil cylinder. Compared with the way of manual mounting and dismounting in the prior art, the invention realizes the storage and the automatic and continuous fetching of the multiple drill rods, reduces the labor intensity, improves the working efficiency and further enhances the operation safety through matching of the drill rod warehouse andthe manipulators.

Owner:ATLAS COPCO (NANJING) CONSTR & MINING EQUIP CO LTD

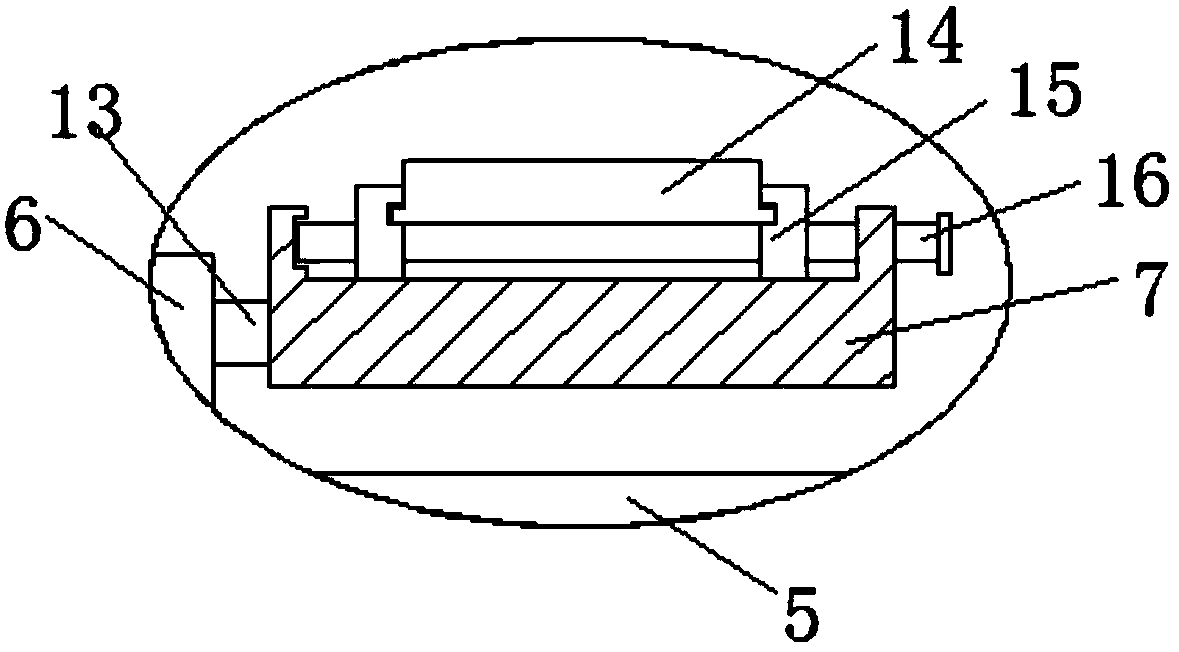

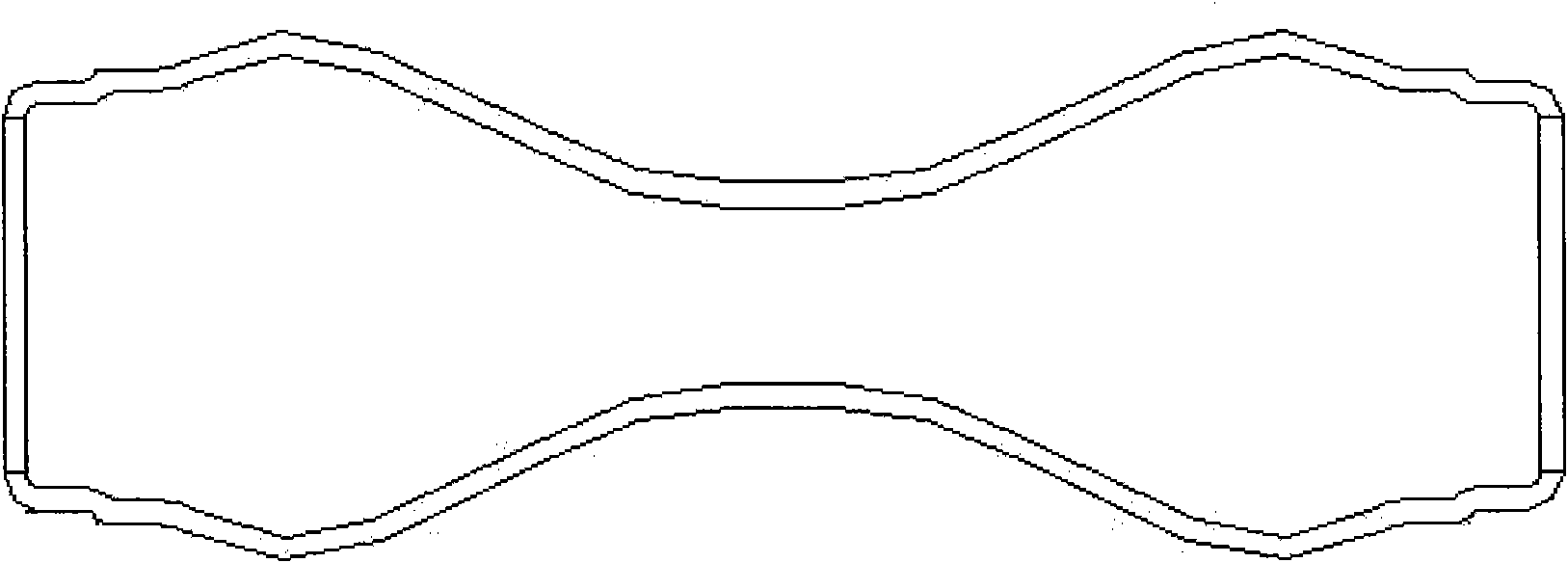

Roller drive plate clamping tool

ActiveCN102773774AEasy to installEasy to manufactureRevolution surface grinding machinesGrinding work supportsLathe faceplateCircular disc

The invention relates to a roller drive plate clamping tool. The roller drive plate clamping tool comprises a disc-shaped laminar driver disk, the outer circumference of the driver disk is provided with a drive pawl which is matched with a shifting fork arranged on a roller grinder main shaft, a drive hole which is matched with a roller drive handle is arranged in the middle of a circular disc, one ends of a plurality of supporting rods are uniformly distributed and fixedly connected on the end face of one side of the driver disk, the other ends of the supporting rods penetrate through a disc-shaped laminar support disk to arrange limit end sockets, springs are sleeved on the supporting rods, a flexible connector is mounted between the support disk and each of the supporting rods, and the support disk is connected with the roller grinder main shaft through a bolt. According to the roller drive plate clamping tool, the support disk and the supporting rods are used for connecting the driver disk on a main shaft face plate of a roller grinder in advance, by means of the elastically extending and retracting of the supporting rods, the clamping of a roller is convenient, simultaneously, a flexible connecting mechanism is arranged on the supporting rods, the support disk and the driver disk can relatively twist, and the problem of mutual interference is solved. The clamping tool has the advantages that the structure is simple, the usage is convenient, the work efficiency is increased, and the remarkable economic benefit can be achieved.

Owner:北京信泰德利华自动化科技股份有限公司

Automatic character rolling machine

The invention relates to an automatic character rolling machine comprising a rotating plate and a face plate which are driven by a motor to rotate synchronously, wherein the circumference of the face plate is provided with a circle of groove for holding workpieces; a storage hopper is arranged at the upper part of one side of the face plate, and a receiving hopper is arranged at the lower part of the other side of the face plate; and the right upper part of the face plate is provided with a typewriting head capable of moving vertically. In the character rolling process, the workpieces roll in the face plate so that the character rolling process is continuously carried out, the rolled handwritings are clear, and the service life of the typewriting head is 5-6 times of that of a reciprocating type character rolling machine; and after the character rolling machine is adopted, the character rolling efficiency is rather high and can be up to 130000-150000 for each shift, thus the labor is saved, and the problem of shortage of manpower is solved.

Owner:江苏万金工具有限公司

Eccentric shaft machining tool and method

InactiveCN103600270ASimple toolingTooling structure is simpleRevolution surface grinding machinesGrinding drivesLathe faceplateEngineering

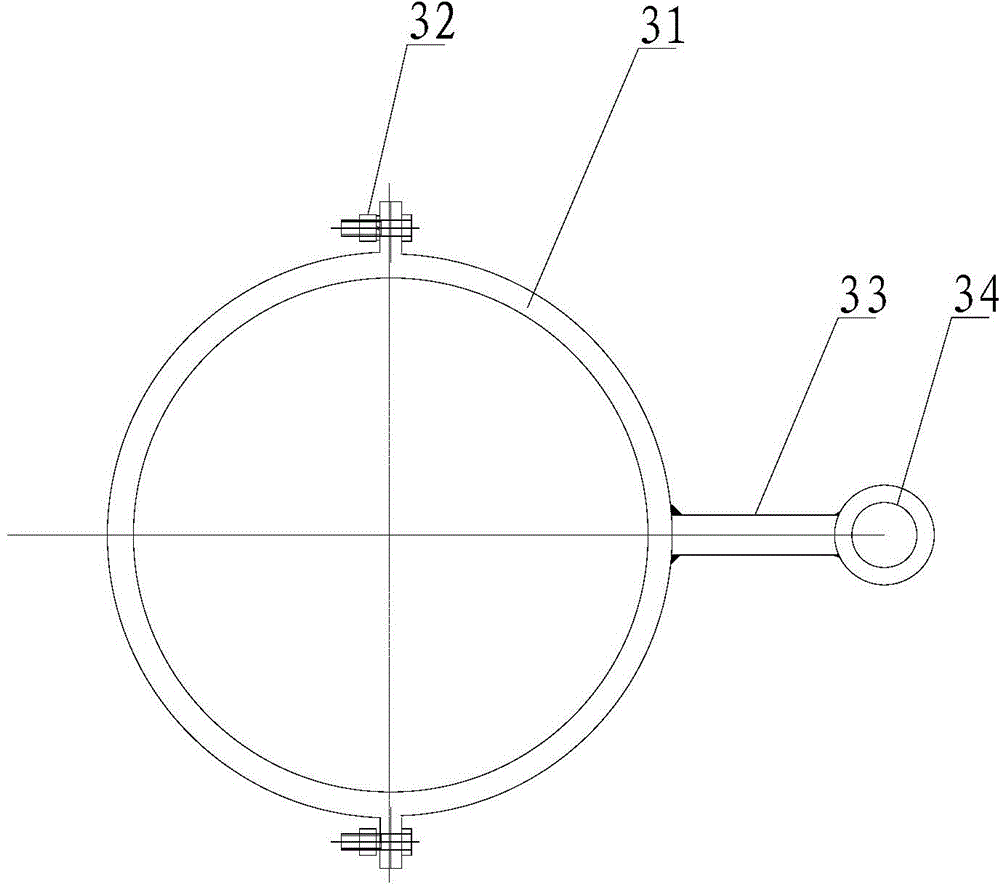

The invention provides an eccentric shaft machining tool and method. The eccentric shaft machining tool comprises a deflector rod assembly fixed on a machine tool, a hoop assembly fixed on the deflector rod assembly, a front grinder apex and a rear grinder apex, wherein the hoop assembly is used for fixing an eccentric shaft in the radial direction; the front grinder apex and the rear grinder apex are fixed on the machine tool and used for positioning the eccentric shaft in the axial direction; the deflector rod assembly is fixed on a disc chuck at the front end of the machine tool; the disc chuck drives the eccentric shaft to rotate for grinding through the deflector rod assembly and the hoop assembly in the rotating process. The eccentric shaft machining tool is simple in structure, low in cost, capable of being combined with a general machine tool for use, wide in application range and high in efficiency.

Owner:SANY AUTOMOBILE MFG CO LTD

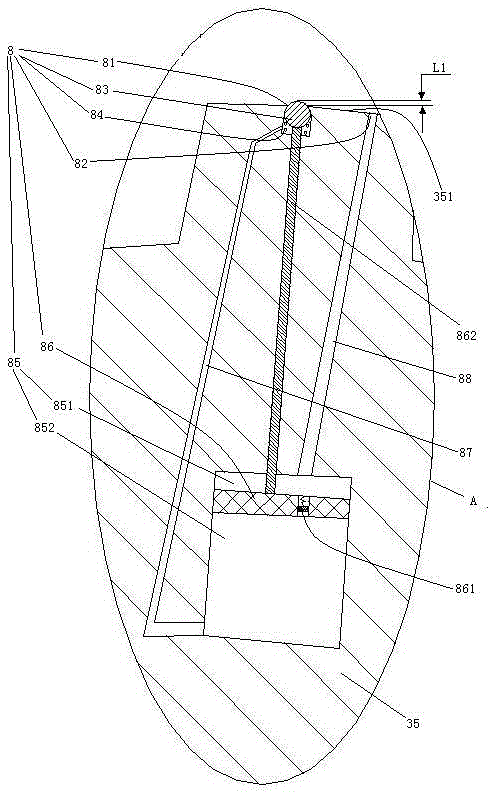

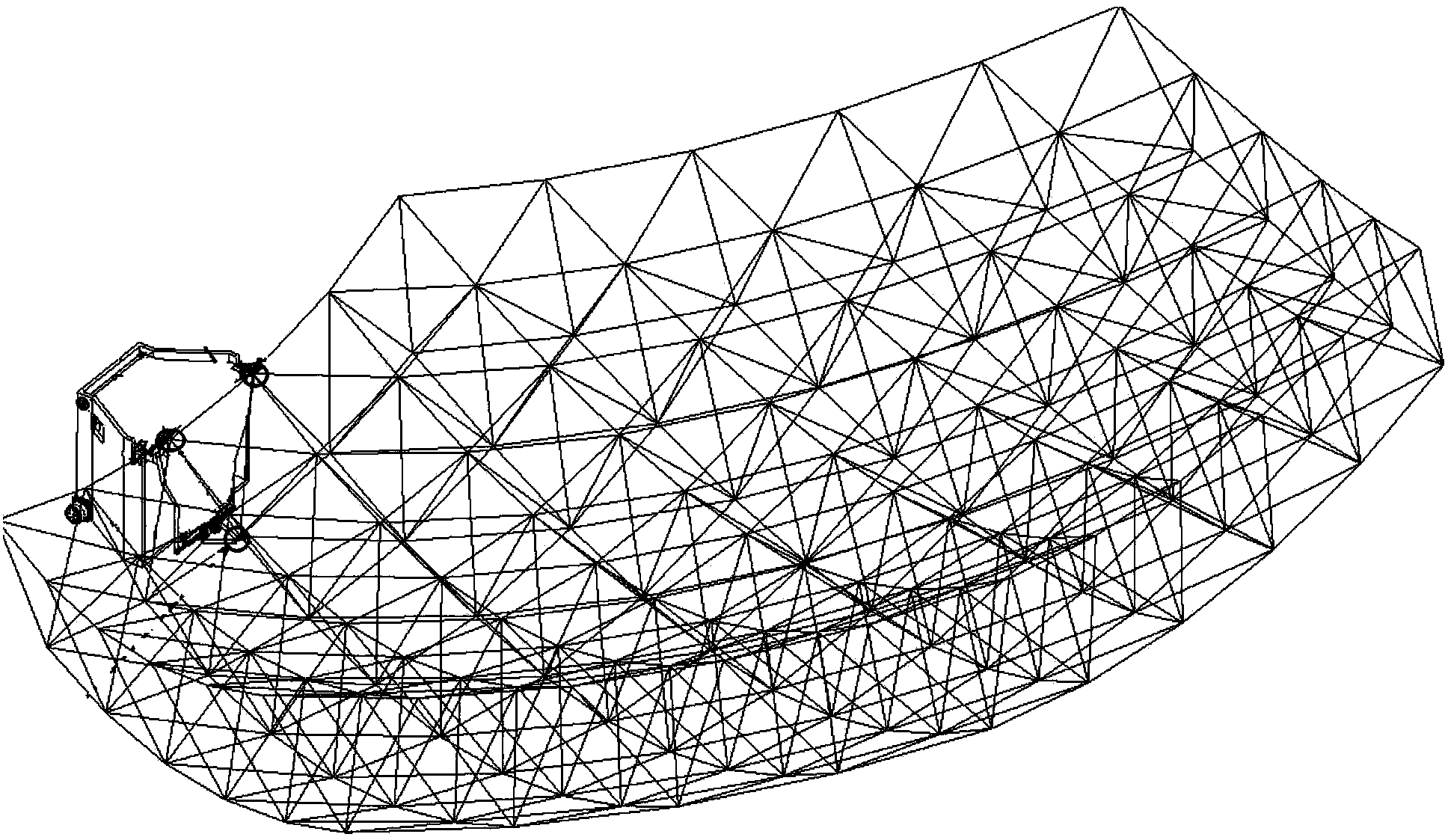

Scissors type hexagonal-prism-shaped extensible unit and space extensible mechanism formed by same

ActiveCN107331939ALarge shrink rateIncrease stiffnessPhotovoltaic supportsCollapsable antennas meansLathe faceplateStructural symmetry

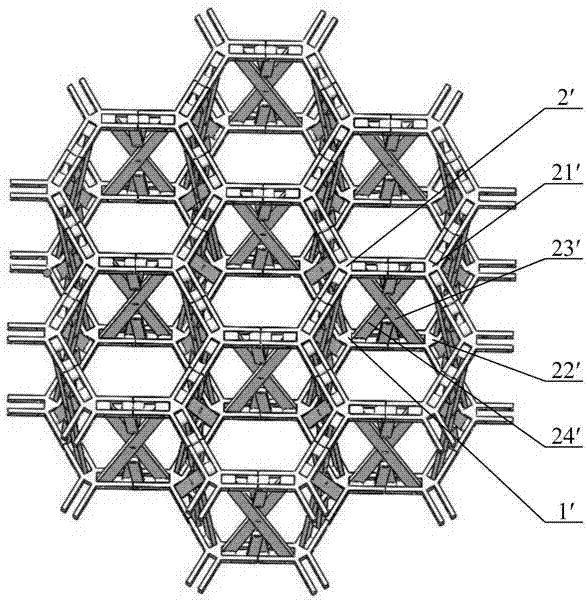

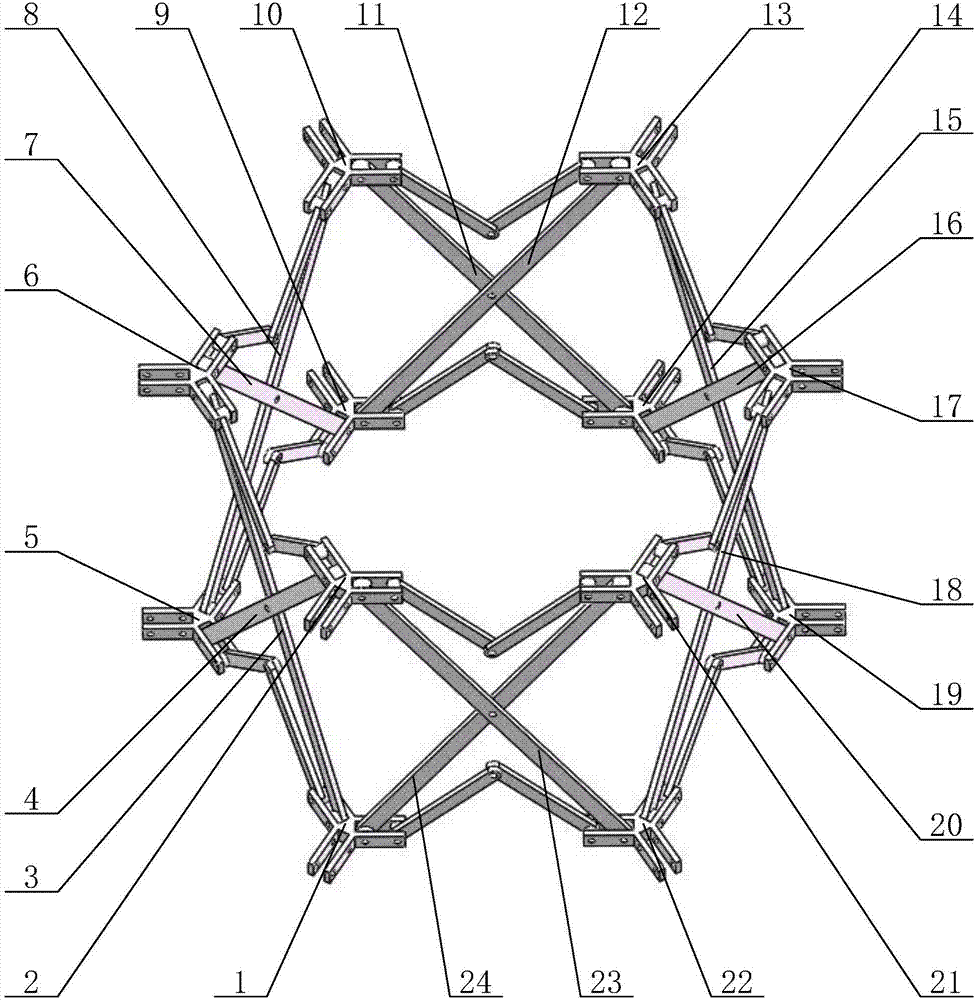

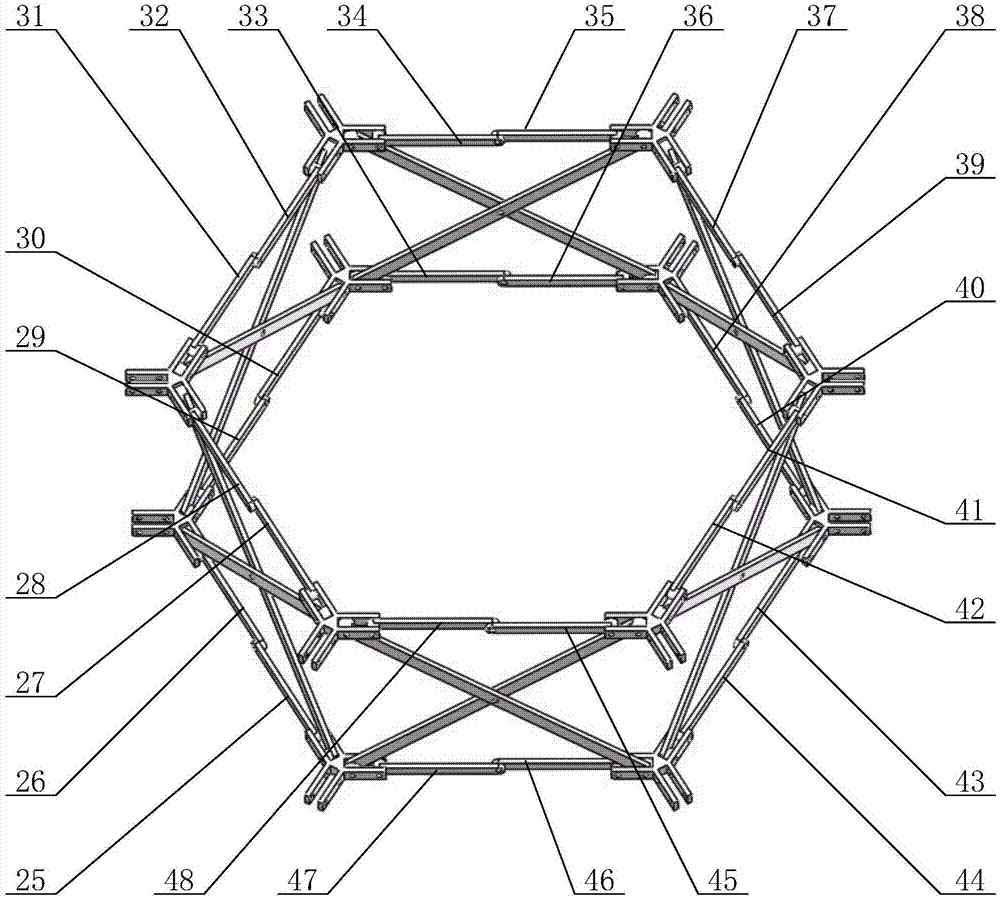

The invention relates to a scissors type hexagonal-prism-shaped extensible unit and a space extensible mechanism formed by the same. The scissors type hexagonal-prism-shaped extensible unit is a single-freedom-degree over-constrained hexagonal-prism-shaped basic extensible unit and comprises twelve faceplates, six groups of scissors type folding rods, and twelve groups of folding connecting rods. One group of folding connecting rods limits the extending degree of the basic extensible unit by the connecting rod lengths and the other eleven groups of folding connecting rods are over-constrained folding connecting rods, so that the rigidity of the basic extensible unit is improved effectively. Multiple basic extensible units are arranged closely and the adjacent basic extensible units can form a space extensible mechanism by sharing four faceplates, one group of scissors type folding rods and two groups of folding connecting rods; and the size of the pace extensible mechanism can be changed by changing the number of basic extensible units. The provided scissors type hexagonal-prism-shaped extensible unit has high structural symmetry; and different large-dimension space extensible mechanisms can be formed based on assembling of the multiple extensible units. Therefore, the scissors type hexagonal-prism-shaped extensible unit and the space extensible mechanism are suitable for constructing a space solar battery array bracket and a satellite planar reflecting antenna.

Owner:YANSHAN UNIV

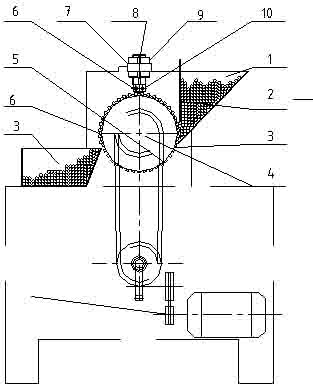

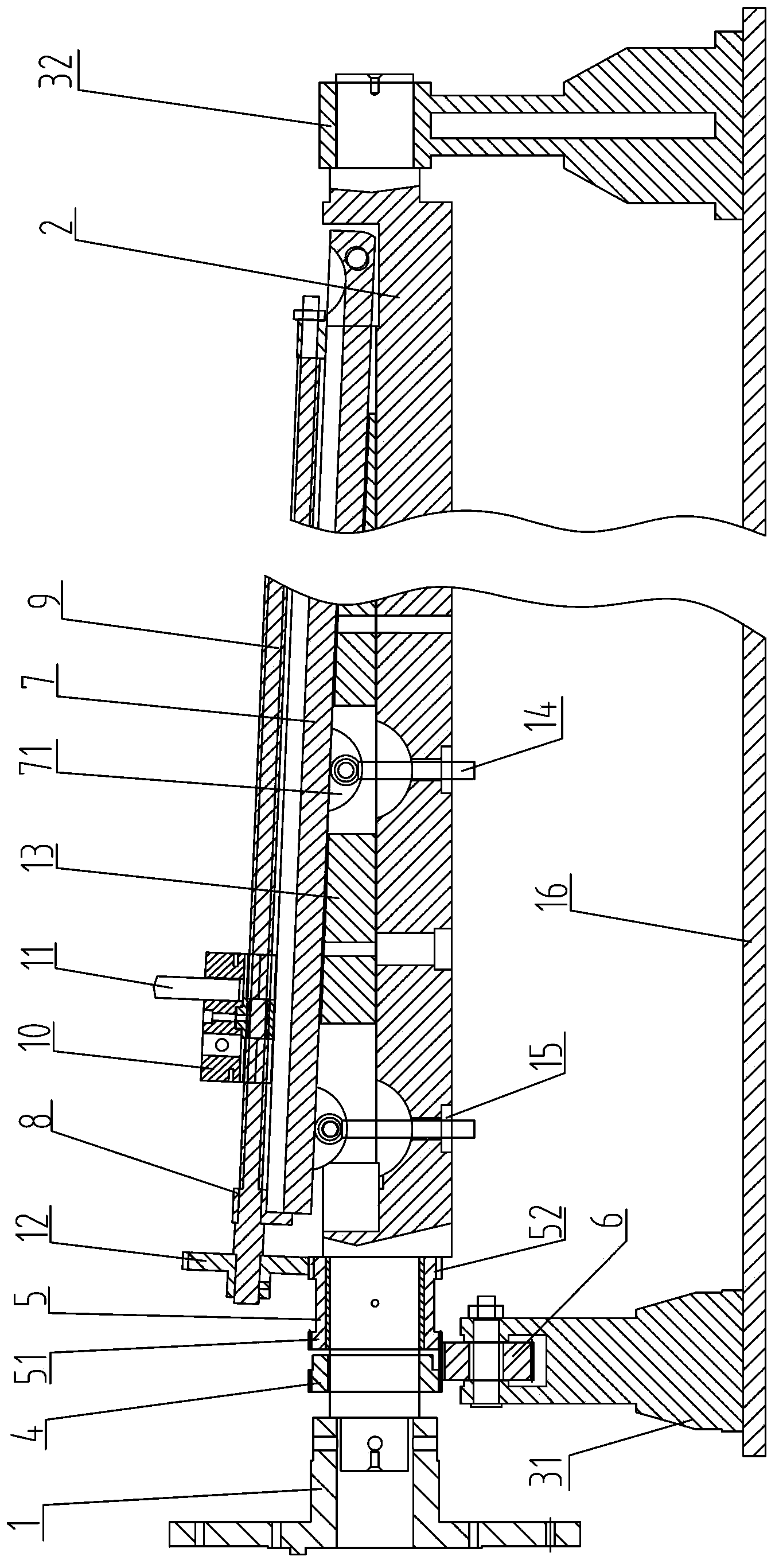

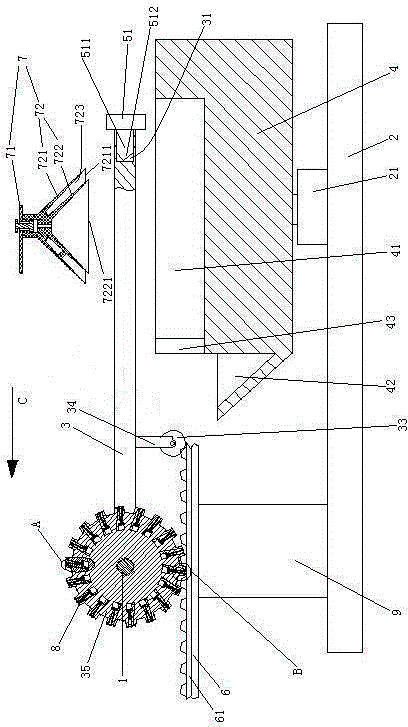

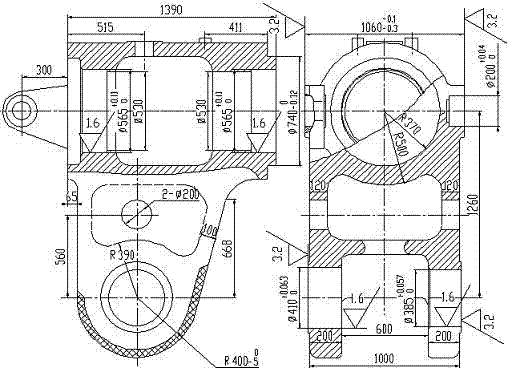

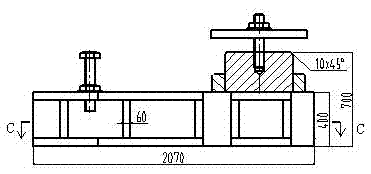

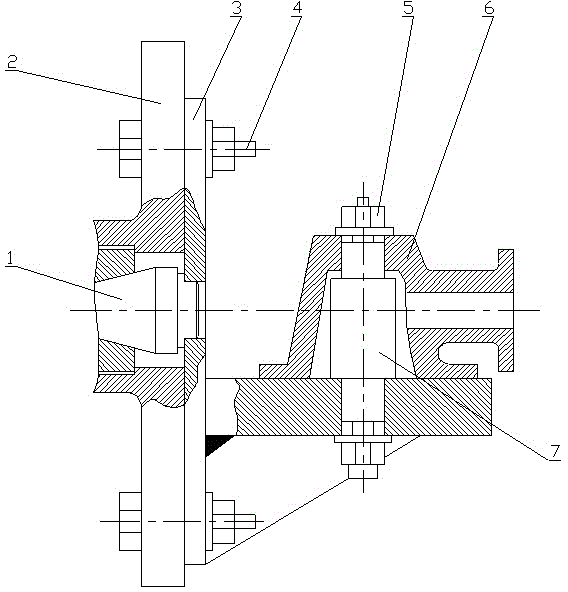

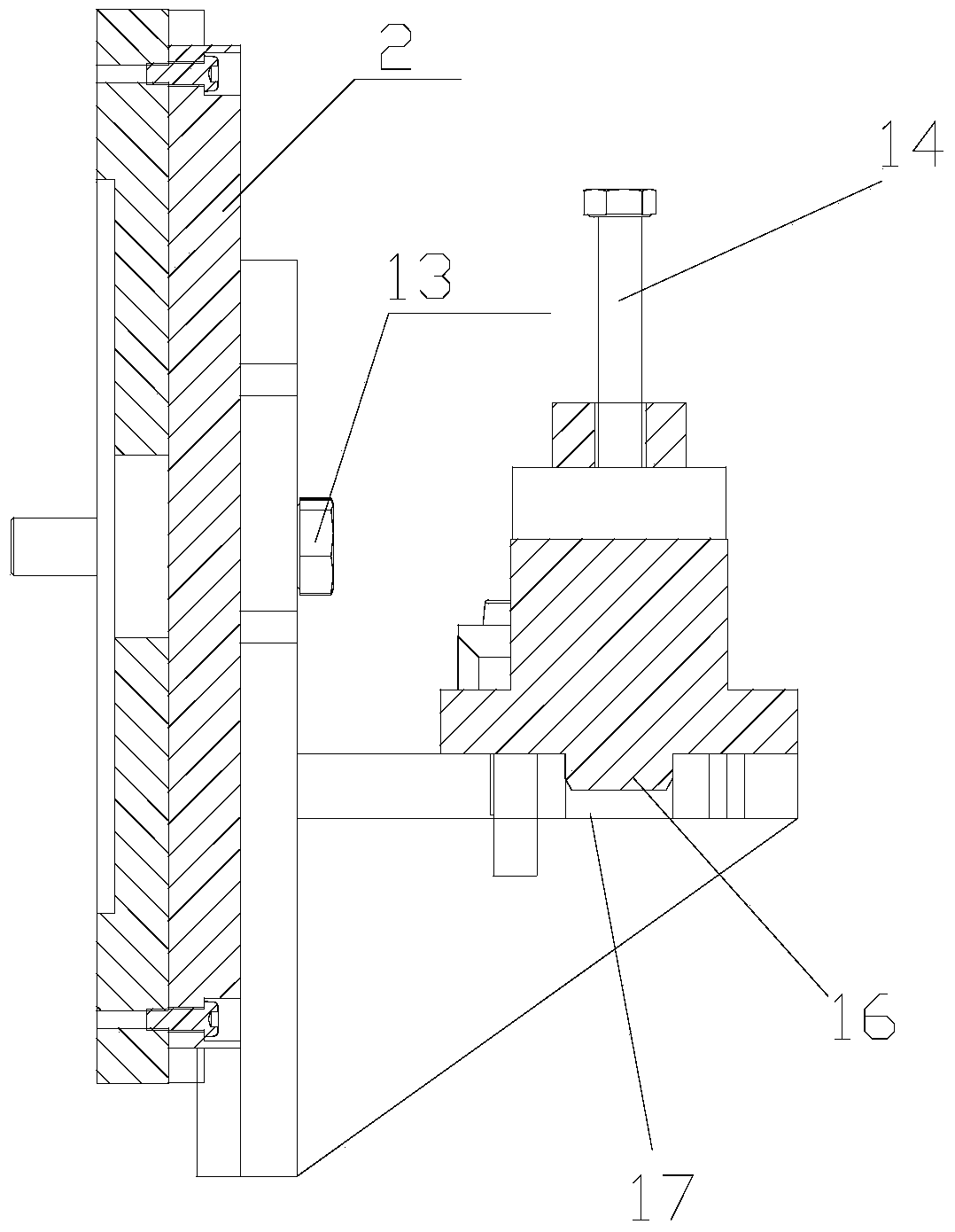

Device for assisting boring machine to process long conical through hole

ActiveCN104128639AGuaranteed axial feedGuaranteed taperFeeding apparatusBoring/drilling componentsLathe faceplateEngineering

The invention relates to a device for assisting a boring machine to process a long conical through hole. The device comprises a connecting base fixedly connected with a boring machine faceplate, a boring rod fixedly connected with the connecting base, a first bracket and a second bracket mounted on a boring machine stand and supported at the two ends of the boring rod, a driving gear coating at the shaft neck end, close to the boring machine faceplate, of the boring rod and fixedly connected with the boring rod, a duplex gear in clearance fit with the boring rod, a transition gear mounted on the first bracket and synchronously engaged to the driving gear and a first gear of the duplex gear, a guide plate having a certain included angle with the axis of the boring rod and fixed at one side of the boring rod, a lead screw rotationally connected to lead screw bases at the two ends of the guide plate, a cutter holder coating on the lead screw and capable of sliding along the guide plate, a cutter fixed on the cutter holder and outwards extending perpendicular to the guide plate, and a driven gear fixed on the lead screw and engaged to a second gear of the duplex gear, wherein the included angle of the lead screw and the axis of the boring rod is equal to the taper of a long conical hole of a workpiece; and the first gear of the duplex gear is fewer than the driving gear by one tooth.

Owner:中钢集团衡阳机械有限公司

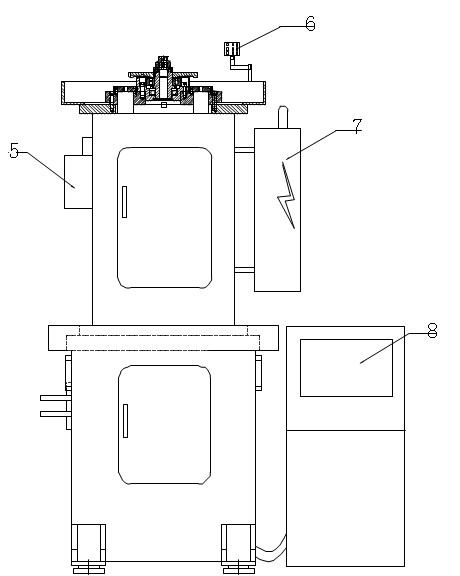

Roller type separator for cast grinding ball

ActiveCN107932301AImprove sanding effectMechanizationEdge grinding machinesPolishing machinesLathe faceplateEngineering

The invention discloses a roller type separator for cast grinding balls. The roller type separator comprises a base. The base is provided with two stand columns, a drive device and a collecting box. The collecting box is located between the stand columns. The drive device is provided with a supporting frame. A first rotation shaft penetrates the stand columns in an inserted manner. A roller penetrates the first rotation shaft in an inserted manner. The roller type separator is simple in structure and easy to operate; through the interaction of the drive device, the first rotation shaft, firstgears, second gears and other structures, face plates and the roller are driven to rotate, accordingly, the connected cast balls in the roller and casting heads are in collision and are successively separated under the action of centrifugal force, gravity and inertia, meanwhile, grinding plates are utilized for conducting grinding cleaning on adhering sand, splashing marks, protruding points and fractures on the surfaces of the cast balls, and cast ball production and separation procedure mechanization is achieved; and meanwhile, the cast ball grinding effect is improved, meanwhile, the production efficiency is improved, and the labor intensity of workers is relieved.

Owner:山东信开源科技创新发展有限责任公司 +1

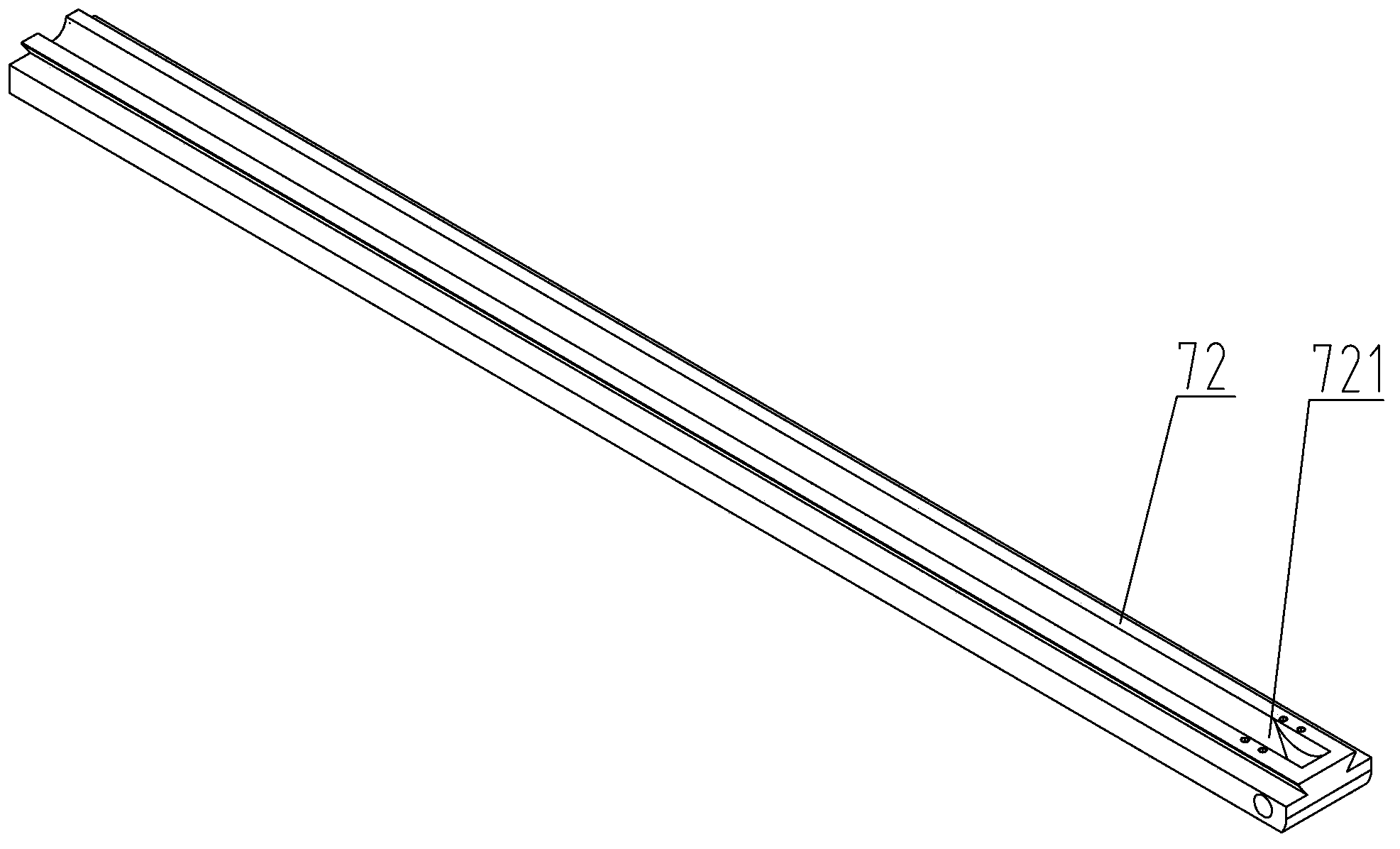

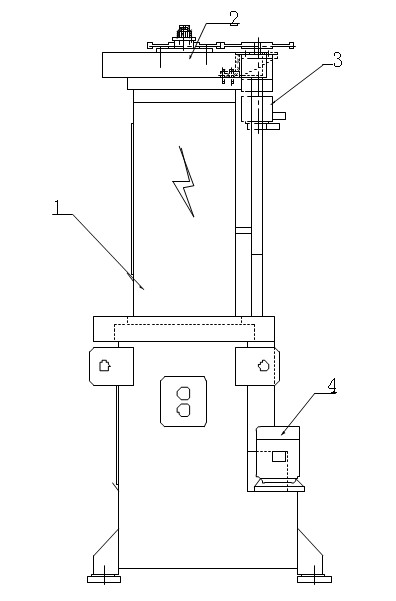

Workbench structure of a vertical inner broaching machine

ActiveCN102266976AAutomatically realize automatic unloadingAutomated cleanupPlaning/slotting machinesLarge fixed membersLathe faceplateReciprocating motion

The invention relates to a working table structure of a vertical internal broaching machine. The working table structure comprises a working table body and a flower disc which is positioned on the working table body and used for accommodating a workpiece to be machined, wherein the flower disc is provided with a through hole through which a broach passes; the working table structure is characterized in that: a bracket board which is abreast with or a little lower than the flower disc is arranged on the front side of the flower disc; guide rails are arranged on the working table body on both sides of the flower disc; a discharging board is arranged above the flower disc; the discharging board can do horizontal reciprocating motion along the guide rails so as to be covered above or on the rear side of the flower disc; a hole matched with the through hole of the flower disc is formed in the discharging board; and a circle of brush hairs are arranged on the inner circumferential surface of the hole. The working table structure can automatically discharge the machined workpiece and clean iron scraps on the broach during return of the working table, so that the structure is simple, the discharging time and the cleaning time of the broaching machine are saved, and the working efficiency of the broaching machine is improved.

Owner:ZHEJIANG CHR INTELLIGENT EQUIP

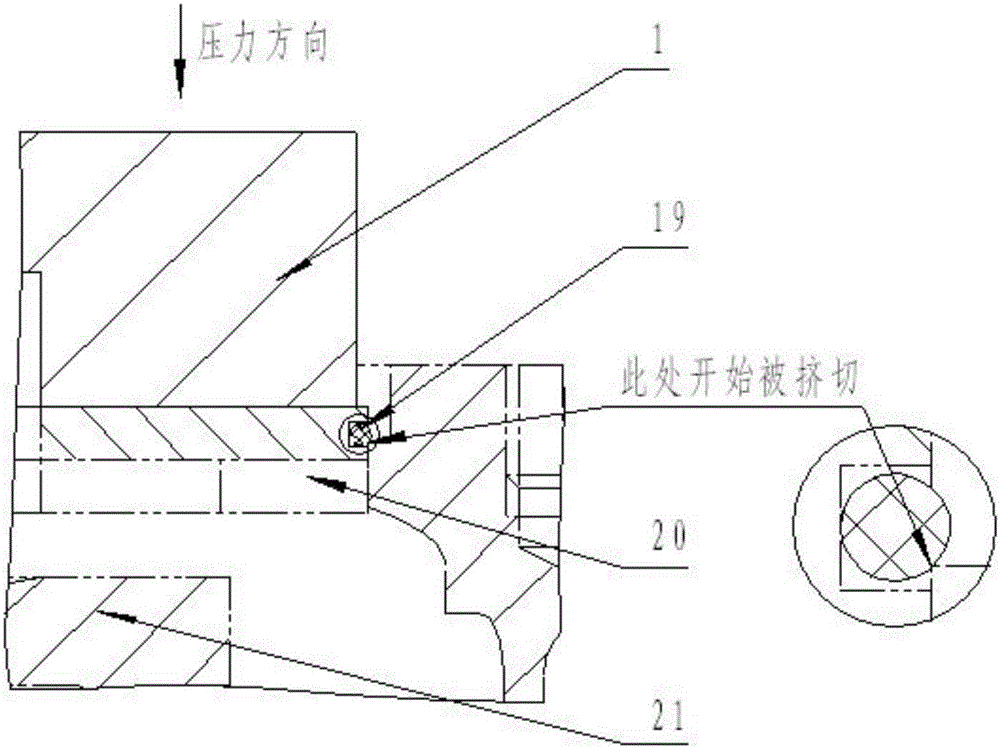

Method for preventing machining deformation of thin-walled work-piece

Disclosed is a method for preventing machining deformation of a thin-walled work-piece. The two ends of the machined work-piece are respectively provided with an installation edge, the installation edges are removed after the work-piece is machined to be of the required size, the work-piece is installed on a disc chuck or a chuck of a machine tool to be pressed tightly, point countering and alignment are carried out, the upper end face and outer circles or cone faces are machined in a rough mode, the work-piece turns around and aligns using the machined end face and the machined outer circles of the installation edges, the lower end face is pressed tightly, and deformation errors of the machined end faces are measured through a filler gauge; after a gasket or filler gauge of the equal error value is used for being plugged to the corresponding position of an error protrusion at the bottom face, the work-piece is pressed tightly by a handle board, then the other face is machined in a rough mode, the work-piece turns around, and semi-fine turning is carried out on the upper end and the outer circles or the cone faces; the semi-fine turning is carried out step by step, when the allowance for machining is 0.5-1mm, the work-piece is released and placed in a free mode, alignment is carried out again, point countering and alignment are carried out on the outer circles of the installation edges, and fine machining and semi-fine machining are the same in method. The method for preventing machining deformation of the thin-walled work-piece has the advantages that deformation of the workpiece in the machining process is avoided, and whether the dimensional accuracy, technical conditions and the like meet the requirements can still be measured accurately when the work-piece is located at the free state.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Wood plastic pavilion making method and wood plastic pavilion making tool

InactiveCN104908313AEasy to fixEasy to fix and stableGear lubrication/coolingSmall buildingsLathe faceplateSolid structure

The invention relates to the technical field of wood plastic product making, and relates to a wood plastic pavilion making tool and a wood plastic pavilion making method. The wood plastic pavilion making tool comprises a pedestal, a first workbench connected to the pedestal in a liftable manner, a pull bar, a second workbench and a fixing structure, the first workbench is provided with a spacing groove and a heating structure for heating the spacing groove, the fixing structure is positioned above the spacing groove, the second workbench is provided with tooth bars, one end of the pull bar is in threaded connection with the core of a bolt connecting bar, the other end is provided with walking gears and a motor for driving the walking gears to rotate, and the walking gears are engaged with the tooth bars. The making method comprises the following steps: making two floral discs, making the connecting bar with a negative pressure cavity through a wood plastic connecting floral disc making tool, and connecting the two floral discs to two ends of the connecting bar. Wood plastic pavilions with columns having the negative pressure cavity are made in the invention, and the disadvantage of the solid structure of the columns of present pavilions is overcome in the invention.

Owner:TAIZHOU QIFENG ENVIRONMENTAL PROTECTION MATERIAL

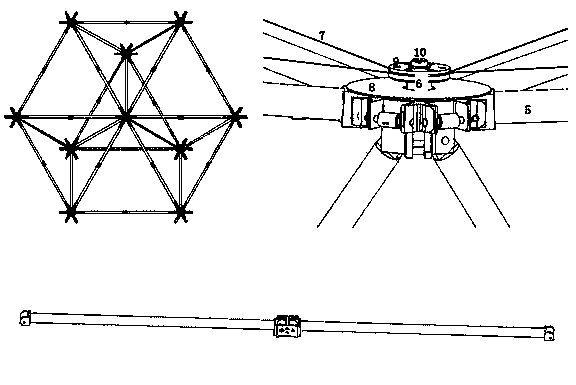

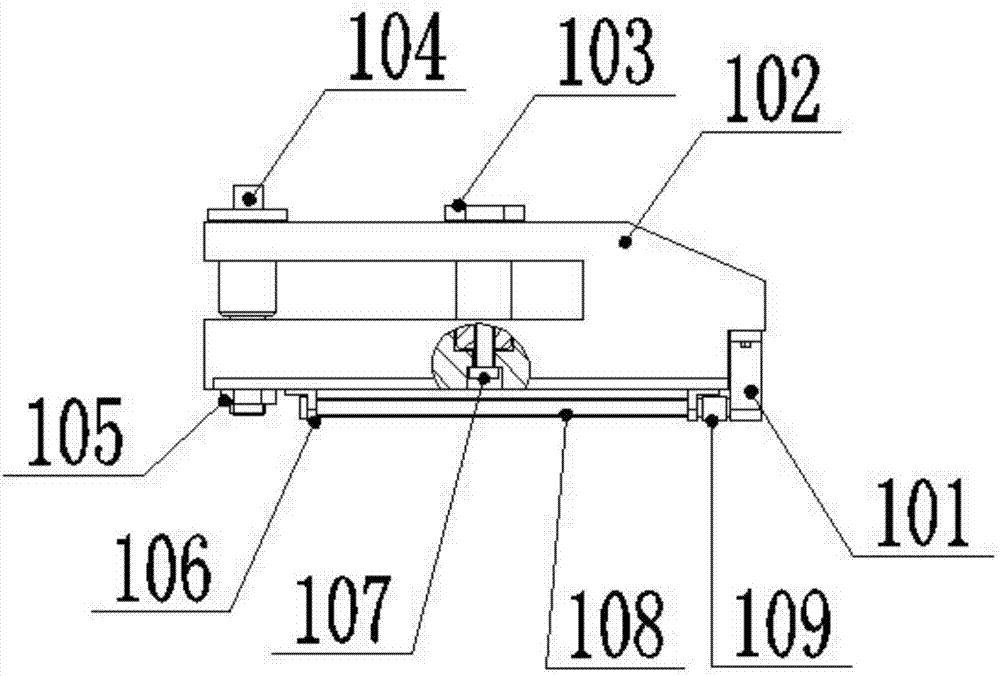

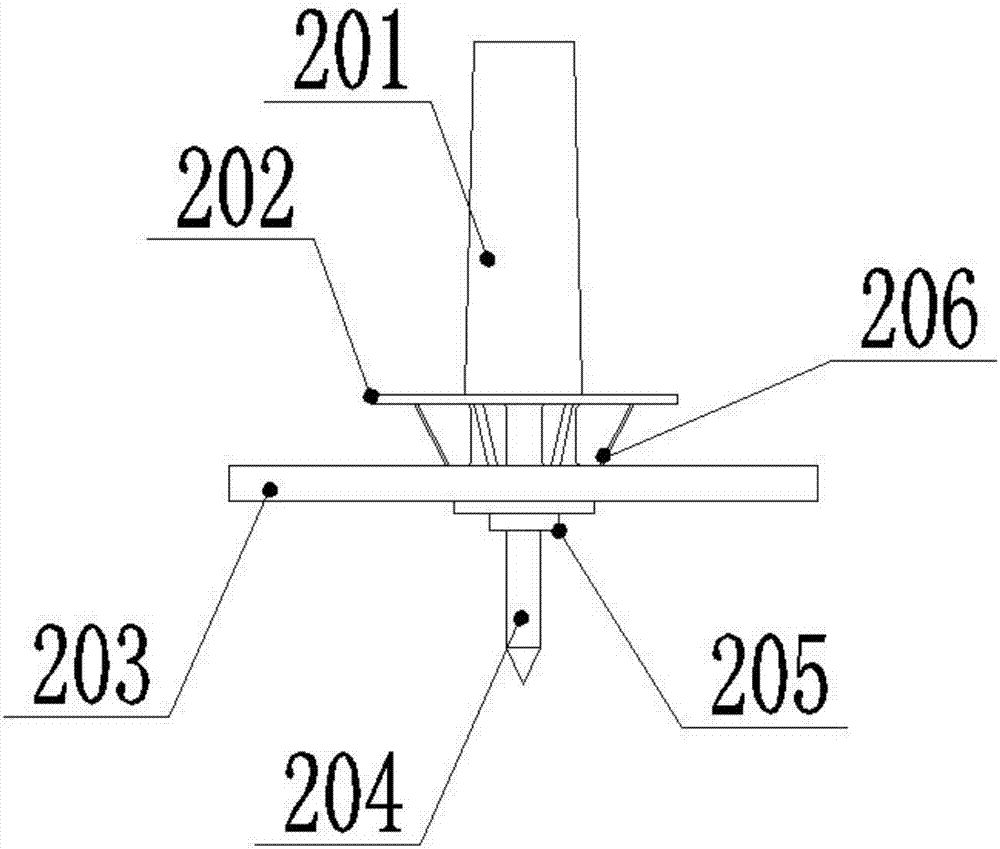

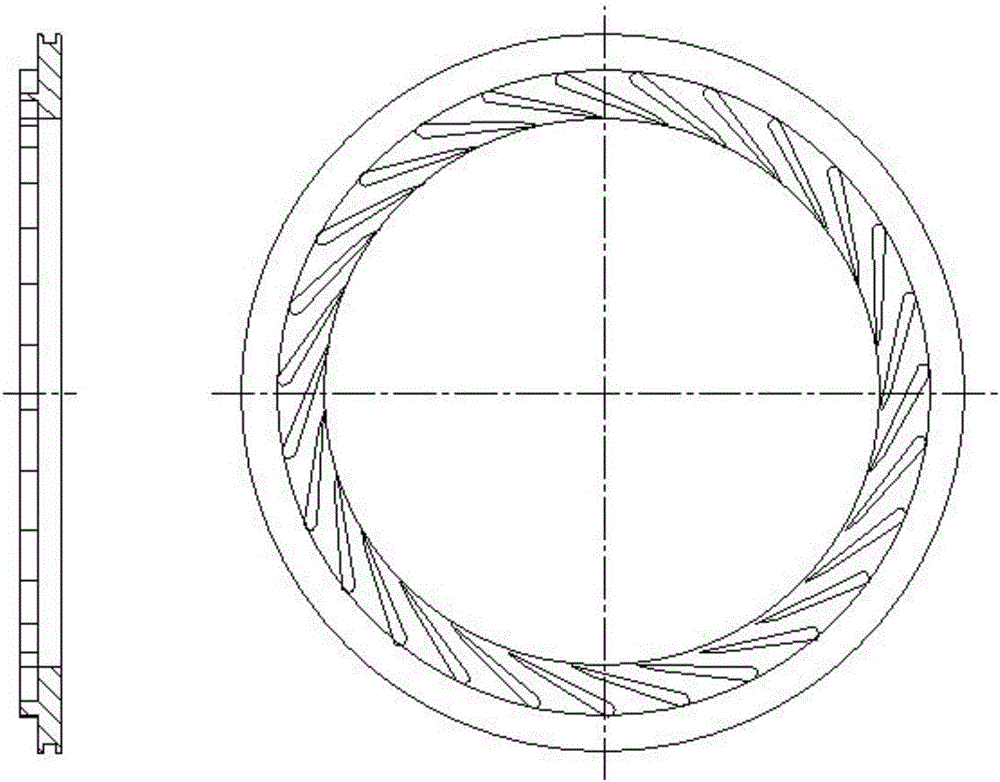

Framework type expandable reflector metal net paving method

ActiveCN104078772ASolve the anti-hook problemAchieve utilizationAntennasLathe faceplateCircular disc

The invention discloses a framework type expandable reflector metal net paving method which comprises the steps that (1) an assembled framework type expandable reflector profile is subjected to offset in the disc chuck normal direction, and an offset design profile is formed; (2) a net face hooking-preventing protecting piece is arranged, the net face hooking-preventing protecting piece is of a circular disc structure with a center circular hole, the center circular hole penetrates through a net pressing connector, the net face hooking-preventing protecting piece is placed between the net pressing connector and a disc chuck, and the net pressing connector is connected with the disc chuck; (3) a metal net is arranged on a reflector truss in a paving mode, pretension is exerted, a net pressing piece is placed on the net pressing connector and the metal net, the net pressing piece, the metal net and the net pressing connector are connected to the disc chuck through net pressing screws, and at the time, the net pressing screws cannot be completely arranged in a fastening mode; and (4) a net pressing wire is arranged in a folding rod direction of a reflector in a paving mode, the net pressing wire is wound on the net pressing screws, then the net pressing screws and the disc chuck are arranged in a fastening mode, and the metal net and the net pressing wire are sewn together.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

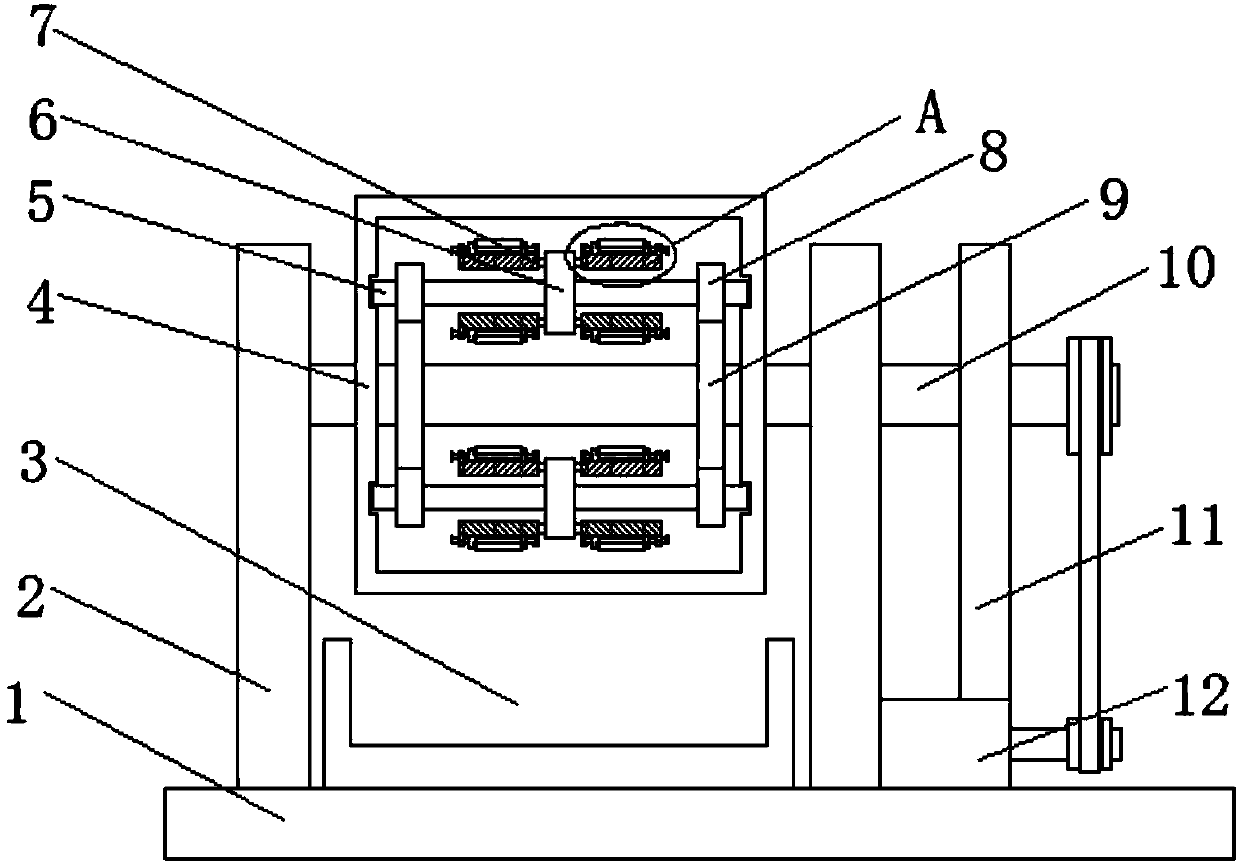

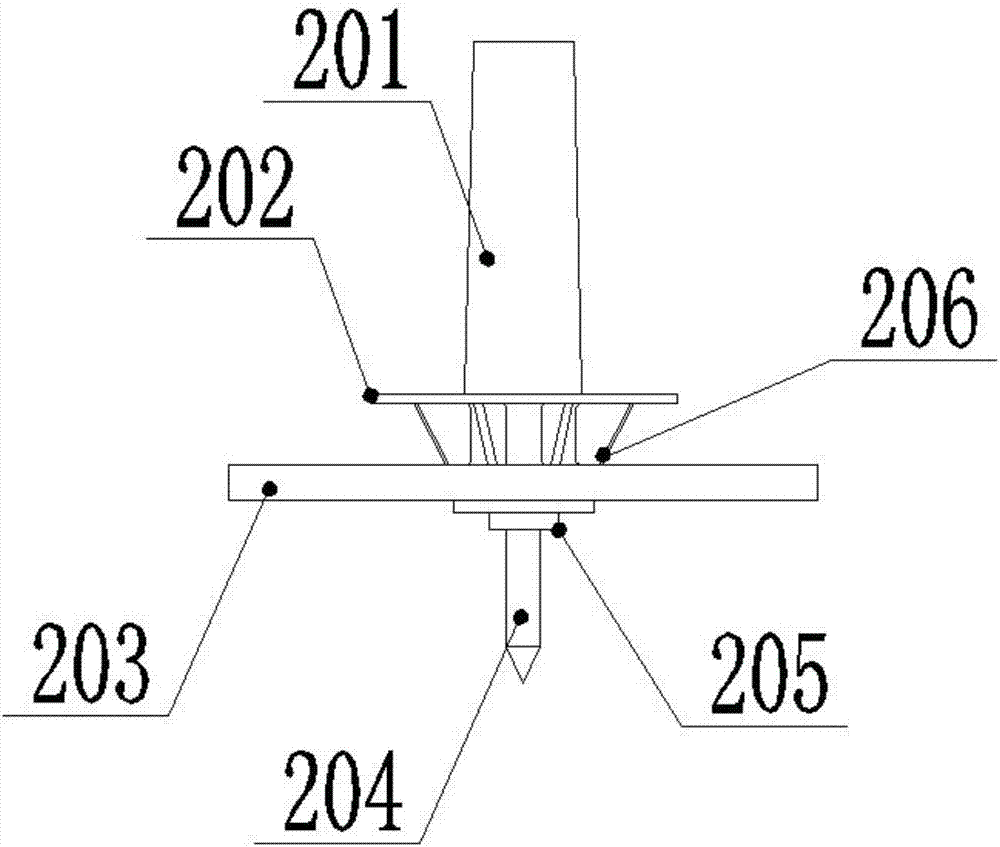

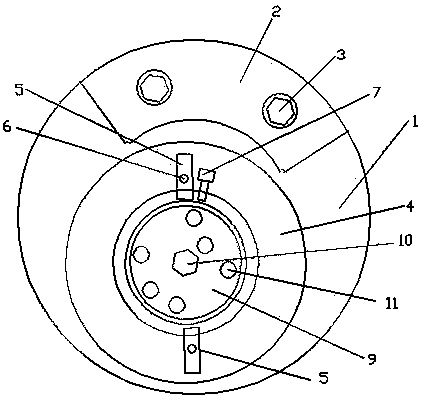

Multi-shaft drilling device for aluminum alloy hub PCD holes

InactiveCN107322043AImprove versatilityImprove transformation efficiencyWheelsBoring/drilling machinesLathe faceplateCoupling

The invention discloses a multi-axis drilling device for aluminum alloy wheel PCD holes, which includes a drill spindle, which includes a spindle pull rod, an upper faceplate, a lower faceplate, a center drill, a first electric spindle and a reinforcing rib, and eight supporting components. It includes the first motor, supporting block, rolling shaft, rotating shaft, lock nut, bearing seat, countersunk screw, ball screw and the first coupling, each supporting assembly has a drill slide, and each rotating shaft is connected to the first The two motors are connected. The invention has the advantages of simple connection, convenient operation and low modification cost, and can drill the center hole of the aluminum alloy wheel hub and up to eight PCD holes at the same time, which improves the processing efficiency, and can automatically change the relative angle and pitch circle diameter of the PCD hole drill bit, reducing the process The production and investment of equipment ensure the quality of PCD holes during porous processing.

Owner:沈金田

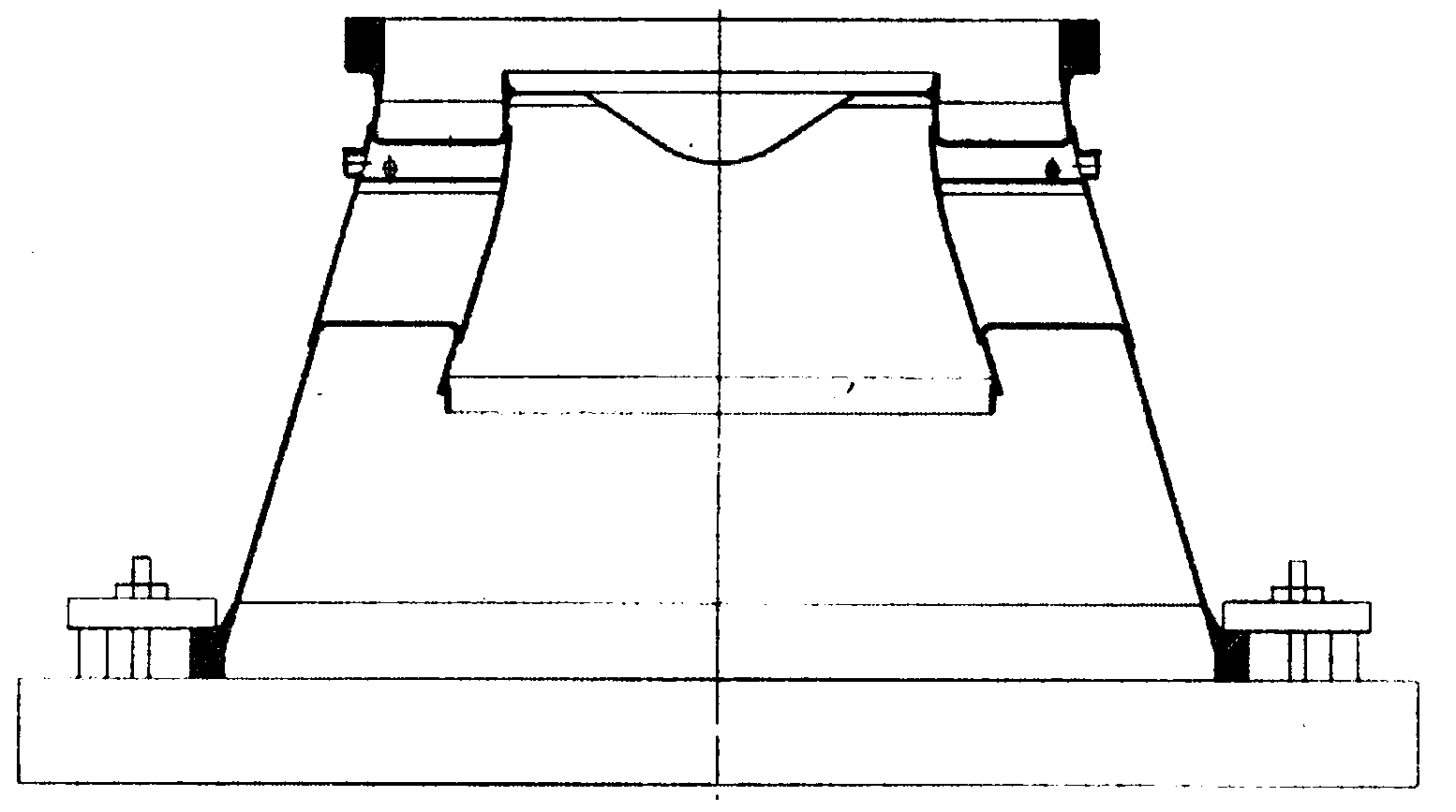

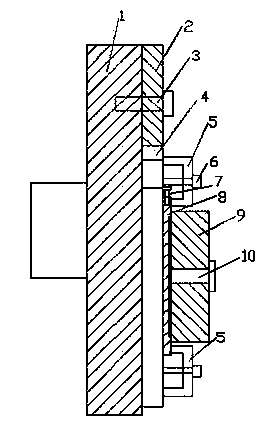

Vehicle lathe rough machining tool for upper rocker arm of vertical milled large-scale key part

InactiveCN105436959AImprove stabilityIncrease contactWork clamping meansPositioning apparatusLathe faceplateMachine tool

The invention discloses a vehicle lathe rough machining tool for an upper rocker arm of a vertical milled large-scale key part. The vehicle lathe rough machining tool comprises a tool base parallel to a vertical lathe faceplate. Tool clamping jaw clamping positions are arranged in one end of the tool base in the four directions respectively and used for allowing clamping jaws in the center of the faceplate to clamp and fix the tool base. A shaft hole positioning block is connected with the top face located at the end of the tool base. The shaft hole positioning block is further sleeved with a replaceable shaft hole positioning ring. The shaft hole positioning block and the shaft hole positioning ring are used for extending into an upper rocker arm shaft hole and supporting a first step of an inlet of the shaft hole through the shaft hole positioning ring. A height-adjustable pressing plate is further connected with the center of the top of the shaft hole positioning block through a tool pressing bolt and a nut. During usage, the pressing plate is tightly pressed on an inner cavity of the upper rocker arm shaft hole and position the shaft hole together with the shaft hole positioning block. Two height-adjustable supporting bolts and nuts are symmetrically installed on the other end top face of the tool base relative to the central axis of the other end face and used for supporting the long-arm end of the upper rocker arm. After usage, the production efficiency is remarkably improved, and the production cost is greatly reduced.

Owner:SINOMA TECH (XUZHOU) HEAVY MASCH CO LTD

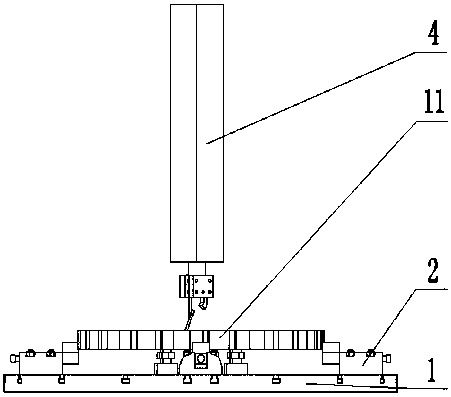

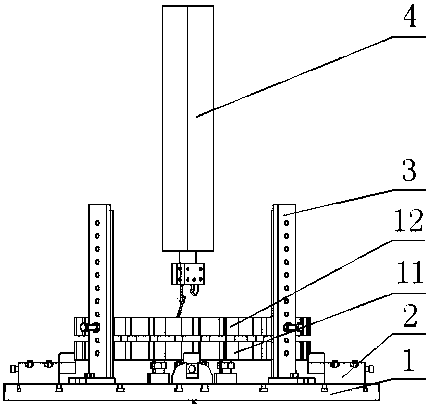

Multi-axle drilling device of aluminum alloy hub PCD holes

ActiveCN106984977AImprove versatilityImprove transformation efficiencyLarge fixed membersBoring/drilling machinesLathe faceplateProcess equipment

The invention discloses a multi-axle drilling device of aluminum alloy hub PCD holes. The device comprises a drill bit main shaft; the drill bit main shaft includes a main shaft pull rod, an upper face plate, a lower face plate, a center drill, a first electric main shaft and a reinforcing rib, and also includes eight support modules; each support module includes a first motor, a support block, a rolling shaft, a rotating shaft, a locking nut, a bearing base, a sunk screw, a ball screw and a first coupling; a drill bit slide base is below each support module; and each rotating shaft is connected with a second motor. The device is simple in connection, convenient to operate and low in transformation cost, can synchronously drill a center hole and at most eight PCD holes of an aluminum alloy hub to improve the machining efficiency, and can automatically change relative angles and pitch diameters of PCD hole drill bits to reduce the production and the investment of process equipment so as to guarantee the quality of the PCD holes during machining of multiple holes.

Owner:ANHUI HIGH TECH POWER TECH

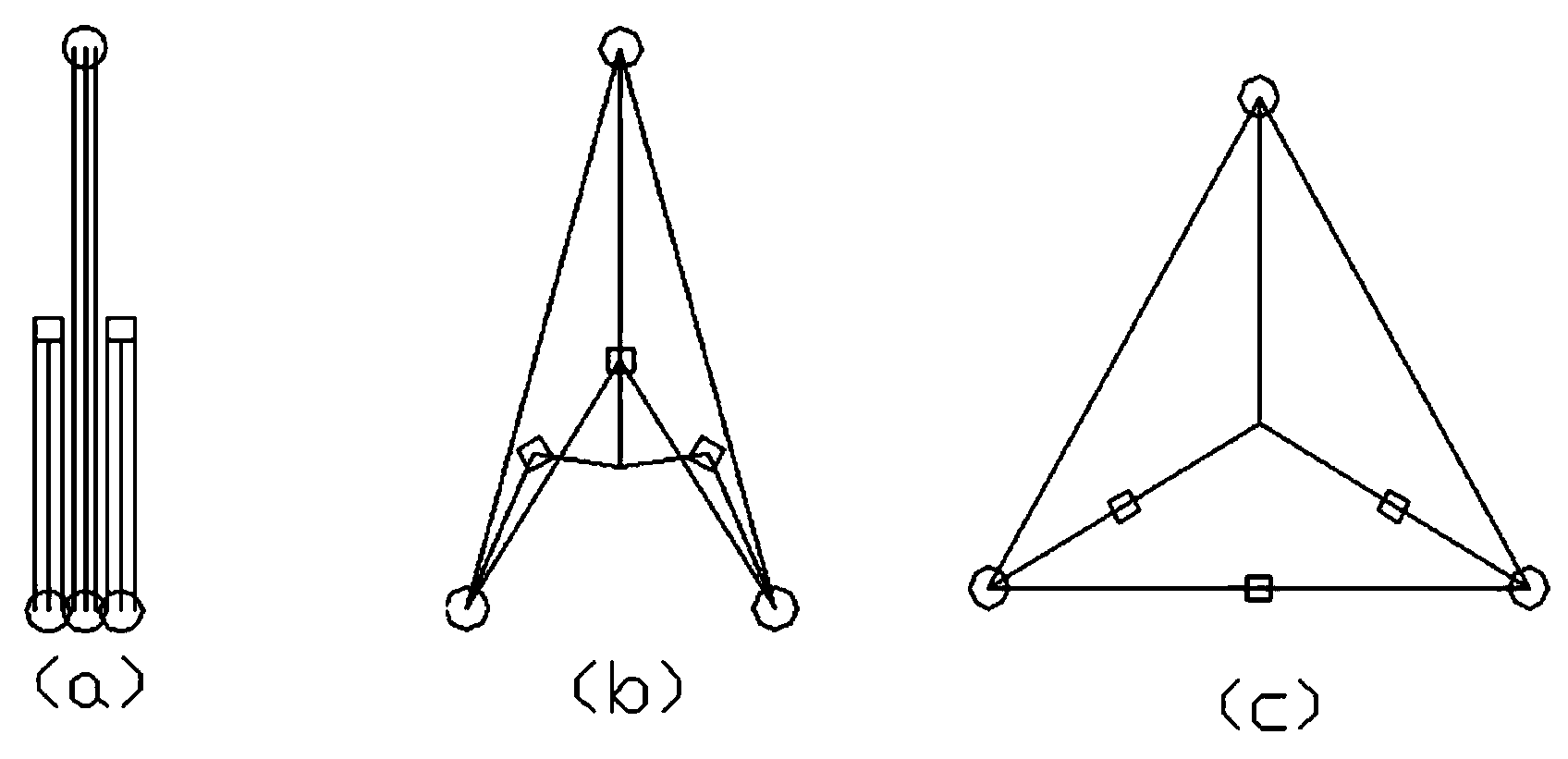

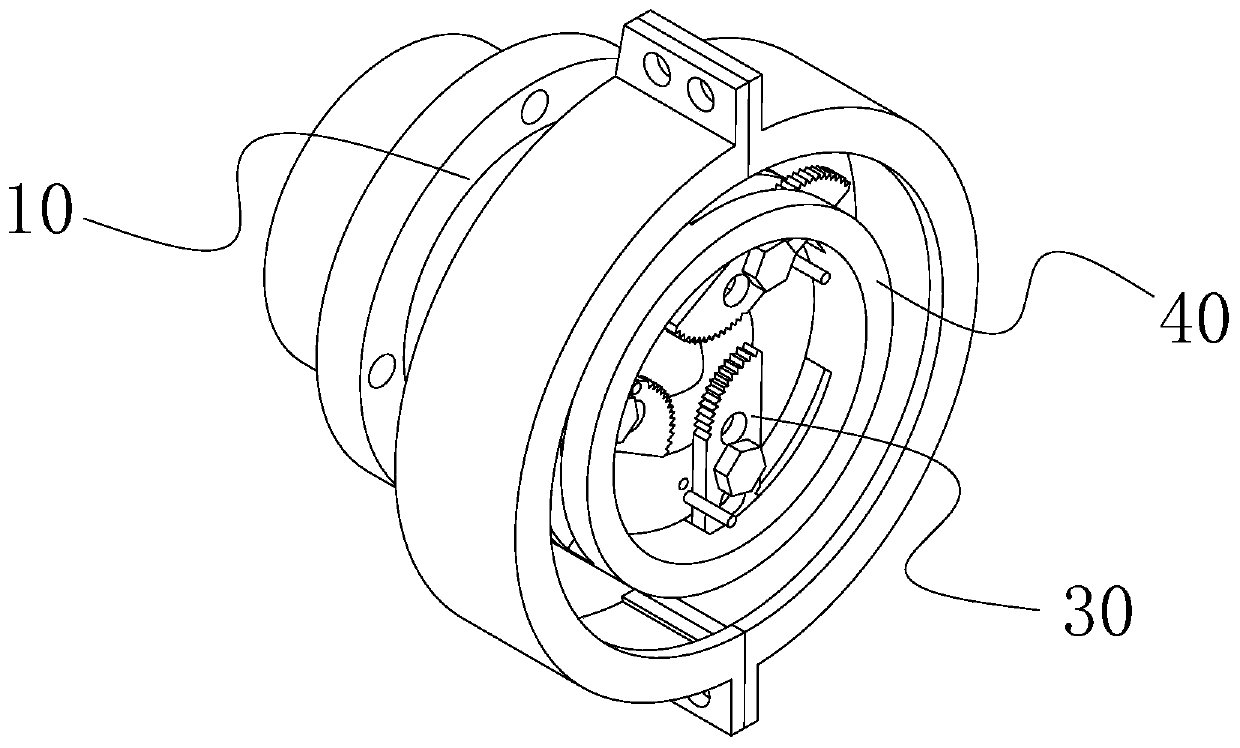

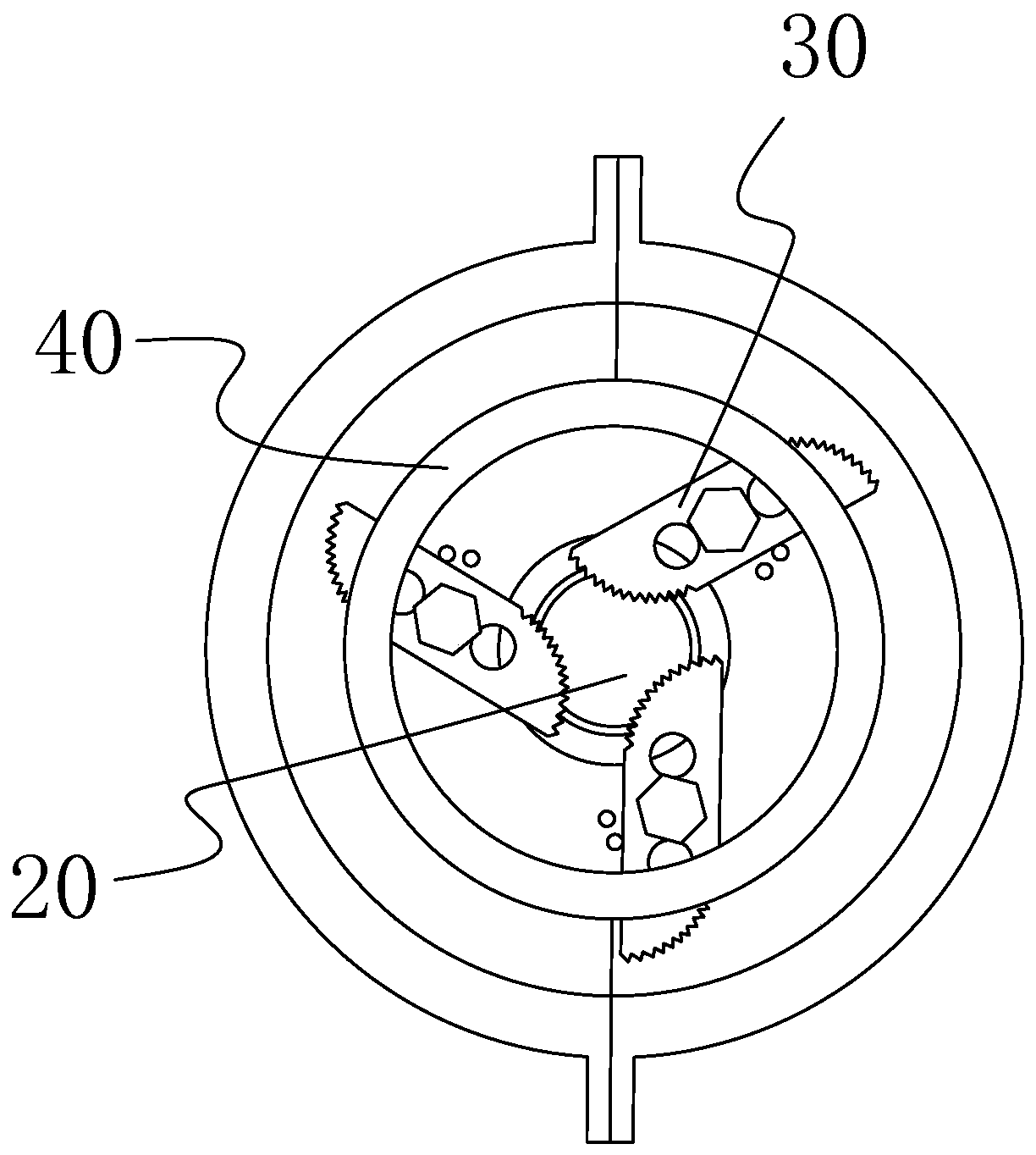

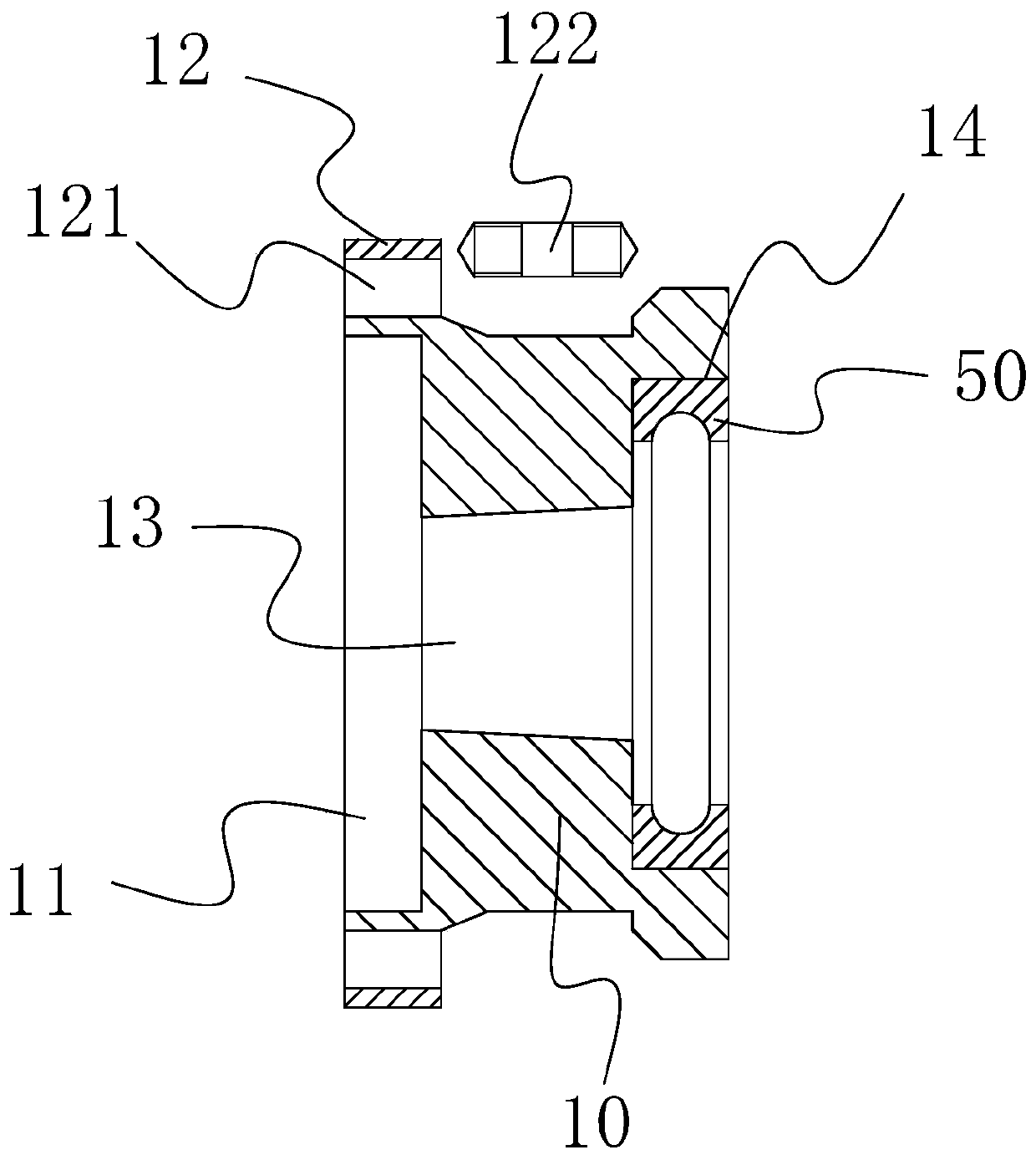

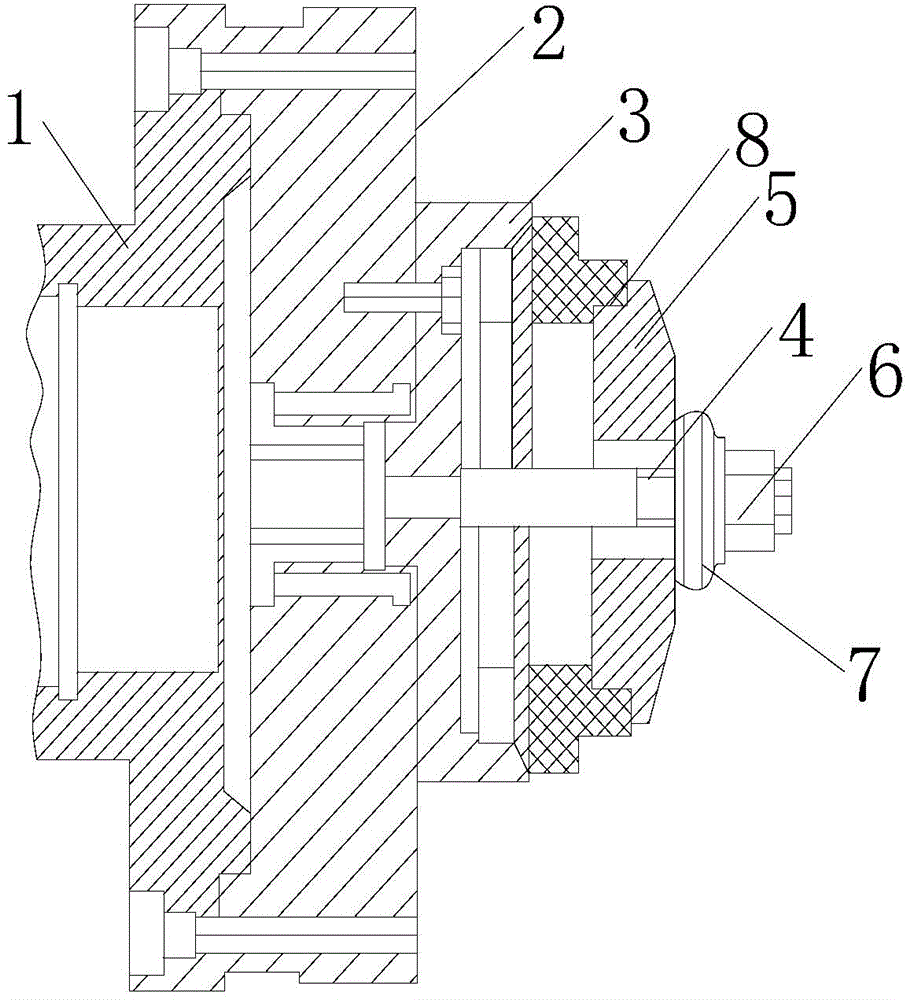

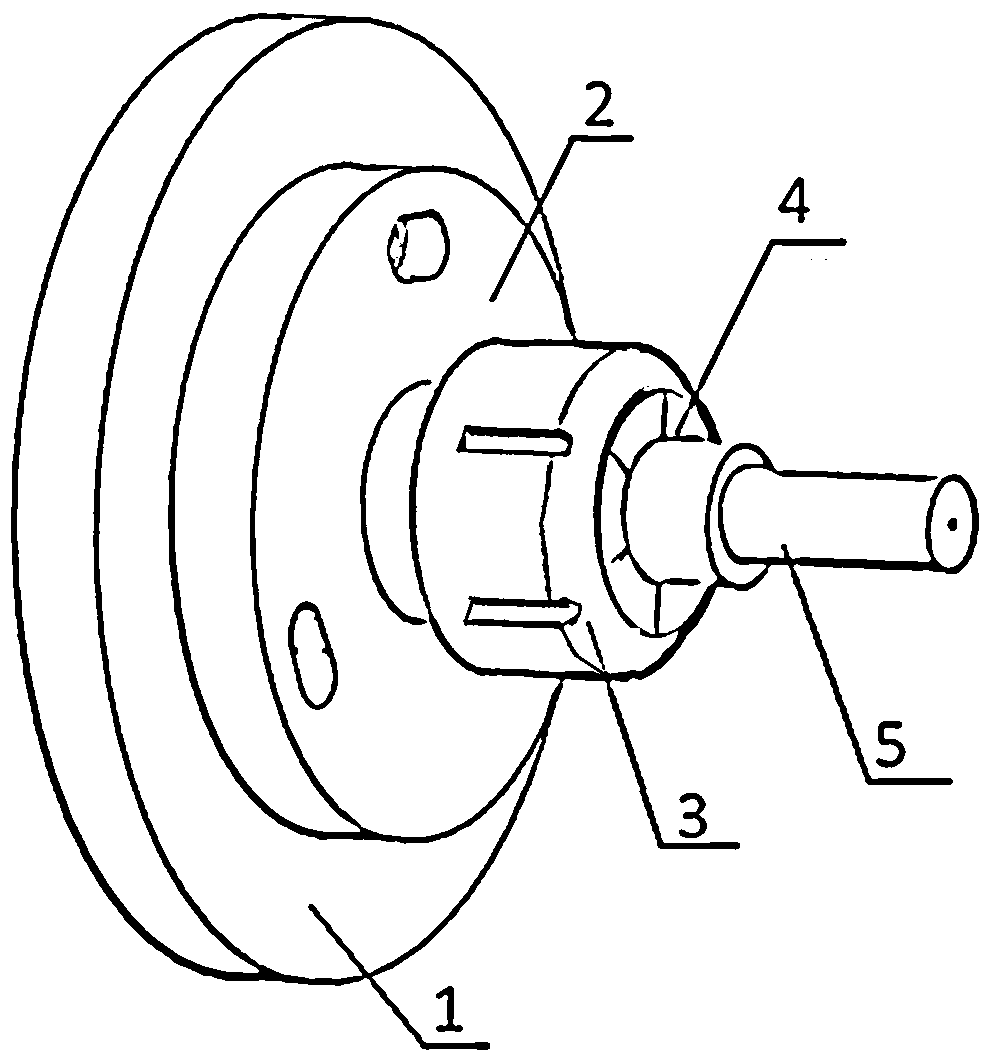

Shaft centrifugal type clamp

The invention discloses a shaft centrifugal type clamp. The clamp comprises a faceplate, a rotating center, a claw mechanism, a sliding seat and an annular fixing seat, wherein the faceplate is fixedon a lathe spindle, so that the faceplate can rotate along with the lathe spindle, the annular fixing seat is arranged on a fixing groove of the faceplate, and the sliding seat is connected in the annular fixing seat in a sleeved mode. Firstly, a workpiece passes through the centers between the rotating center and the center on the lathe tailstock, when the faceplate rotates, the annular fixing seat can be driven to rotate, the sliding seat can rotate relative to the annular fixing seat, meanwhile, the clamping jaw mechanism installed on the sliding seat is subjected to centrifugal rotation, so that the plurality of clamping jaws can fasten the workpiece under the action of centrifugal force, the purpose of clamping and fixing the workpiece is achieved, when the lathe spindle stops rotating, an extruded reset spring can stretch the sliding seat in the reverse direction of an annular reset groove, so that the plurality of claws rotate reversely to remove the workpiece, so that people can conveniently take down the workpiece, and the time for clamping the workpiece is saved.

Owner:NINGDE NORMAL UNIV +1

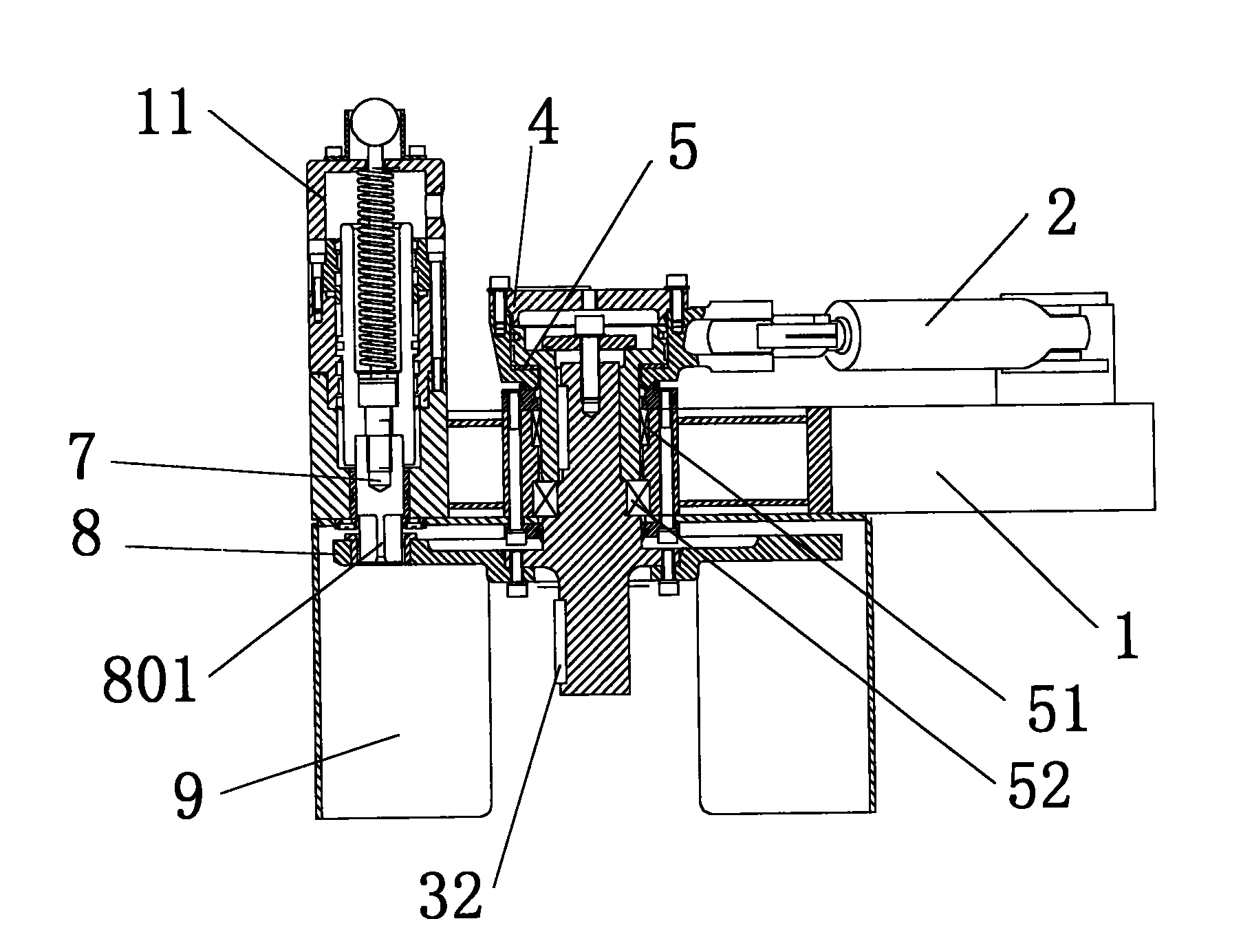

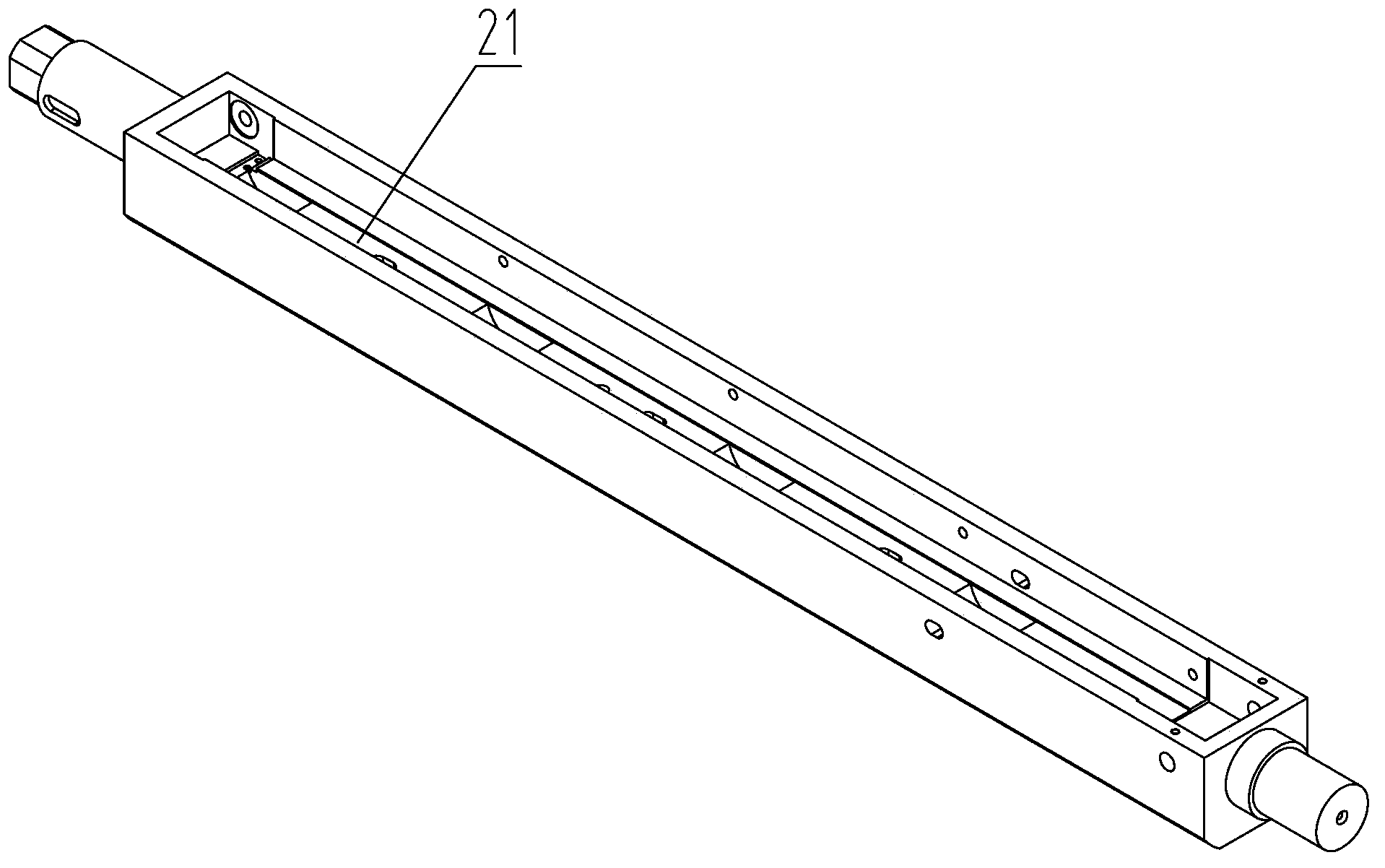

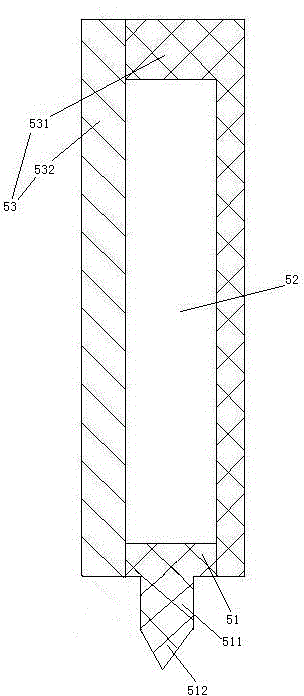

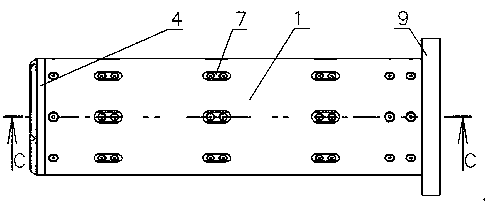

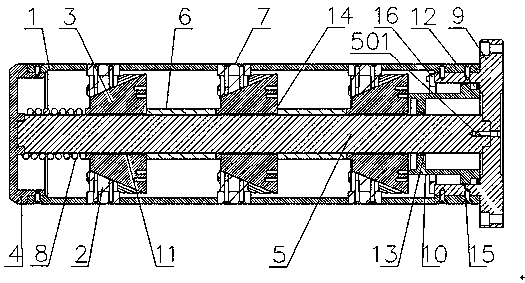

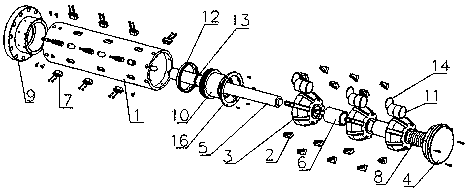

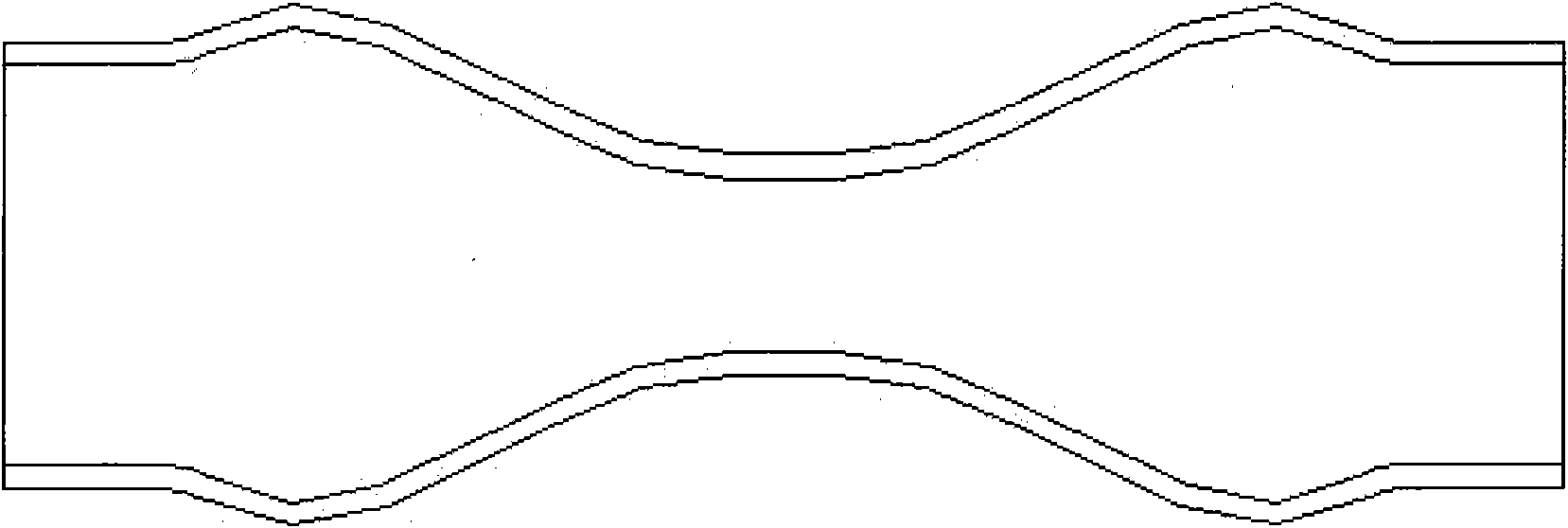

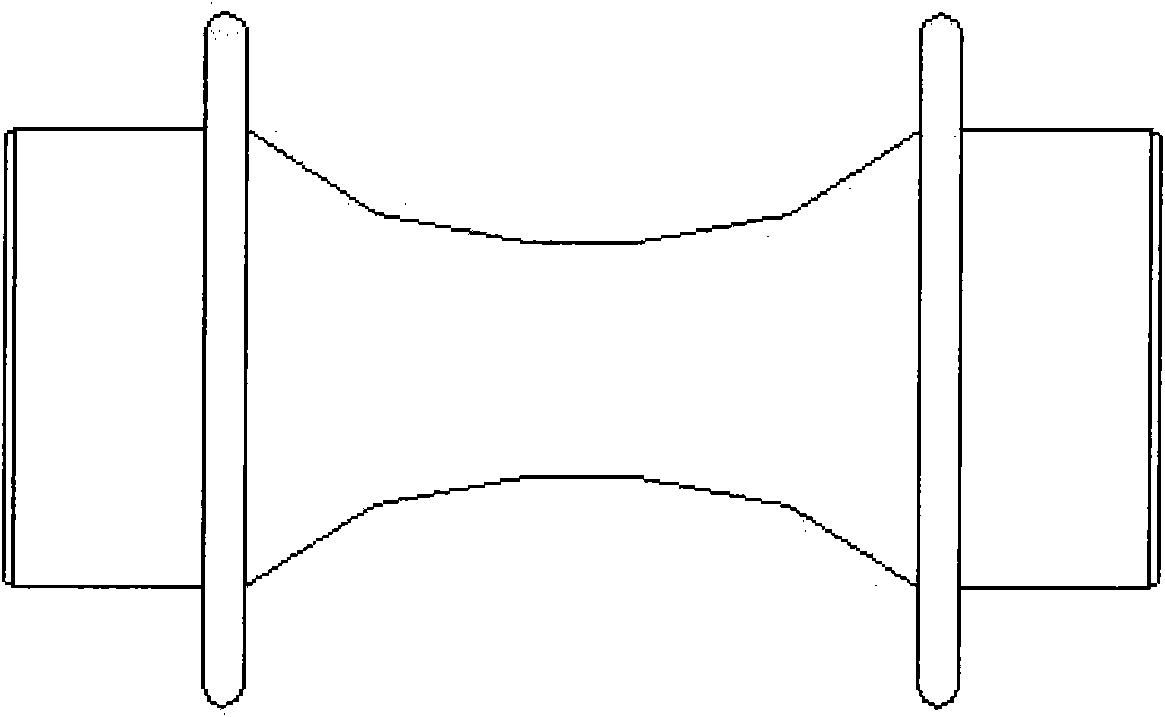

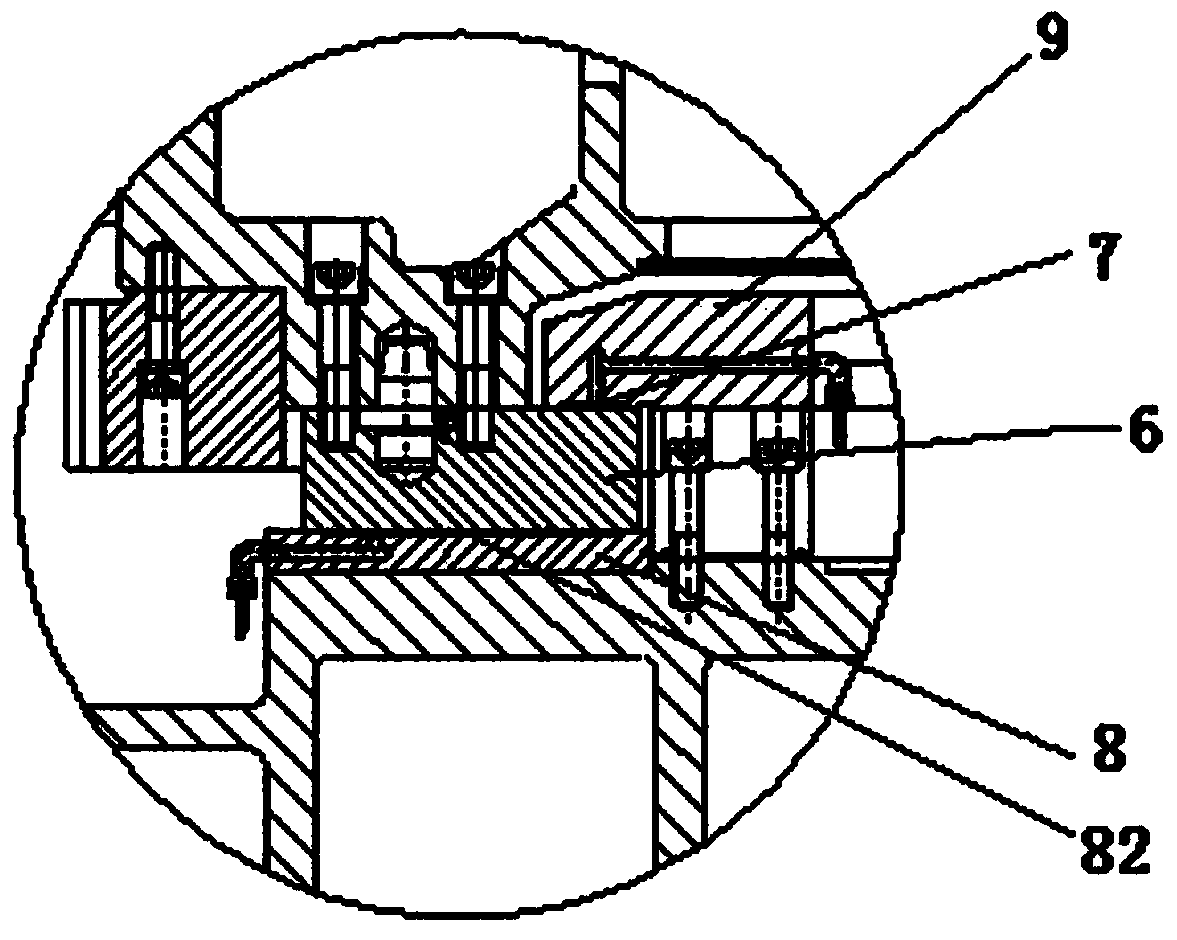

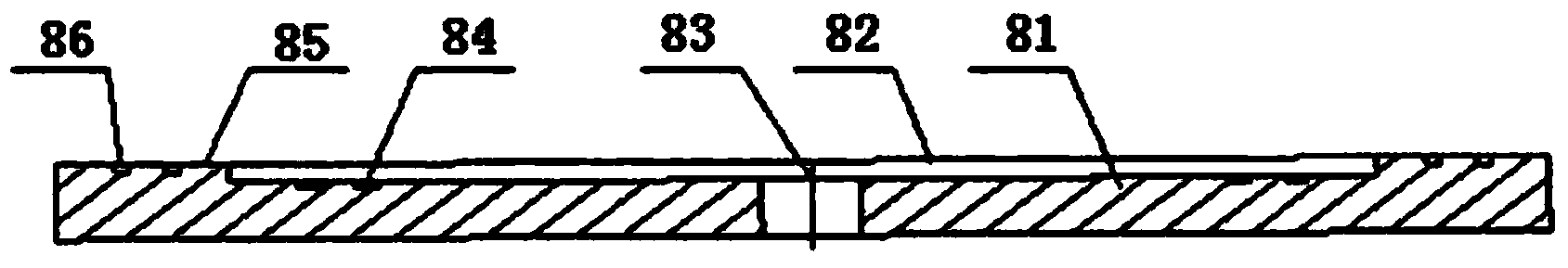

Mechanical air pressure expanding shaft used for winding and unwinding system on papermaking and printing packaging equipment

The invention discloses a mechanical air pressure expanding shaft used for a winding and unwinding system on papermaking and printing packaging equipment. The mechanical air pressure expanding shaft comprises a core shaft body; a boss at one end of the core shaft body is inserted into a round groove of a flange; a cylindrical stand of the flange is sleeved with one end of a shaft pipe; a thrust piston is sleeved with the cylindrical stand of the flange, sleeved with a sealing cover and fixedly connected to the end of the cylindrical stand of the flange through bolts; guiding bands are furtherdisposed in the contact position of the thrust piston and the inner wall of the cylindrical stand of the flange; the core shaft body is sequentially sleeved with a plurality of disc chucks through oiling copper sleeves; the portions, between the disc chucks, of the core shaft body are sleeved with spacer bushes; the portions, at the tail ends of the disc chucks, of the core shaft body are sleevedwith springs; a boss at the other end of the core shaft body is arranged in an inner round groove of an end socket in a sleeved mode; and an outer round ring of the end socket is arranged in the otherend of the shaft pipe in a sleeved mode and connected through screws. The mechanical air pressure expanding shaft used for the winding and unwinding system on the papermaking and printing packaging equipment is compact in structure, novel in idea, large in working stroke and bearing capacity, long in service life, easy to maintain and convenient to repair; and the using accuracy is high, a shaftbody is made of a seamless steel tube, and therefore the non-deformability is high.

Owner:安徽哲乐机电有限公司

Device for turning vertical cross holes in disc bending plate

InactiveCN104875060ASimple structureEasy to operatePositioning apparatusMetal-working holdersLathe faceplateMechanical engineering

Owner:NANJING AGRI UNIV GUANYUN MODERN AGRI EQUIP RES INST

Special clamp of irregular workpieces

InactiveCN104476222AEasy clampingImprove clamping efficiencyWork clamping meansPositioning apparatusLathe faceplateEngineering

The invention relates to the technical field of machine tool clamps, in particular to a special clamp of irregular workpieces. The special clamp comprises a transition plate, a face plate connected with the transition plate, and a clamping device connected with the face plate. The clamping device comprises a supporting sleeve with the left end sleeved in the face plate, a screw penetrating through the supporting sleeve, a pressing plate sleeved on the screw, and a nut and a gasket which are used for fastening the pressing plate. A pressing step portion fit with the step surfaces of workpieces is arranged at the left end of the pressing plate. The special clamp facilitates processing of annular parts with steps.

Owner:常州中远精密工具厂

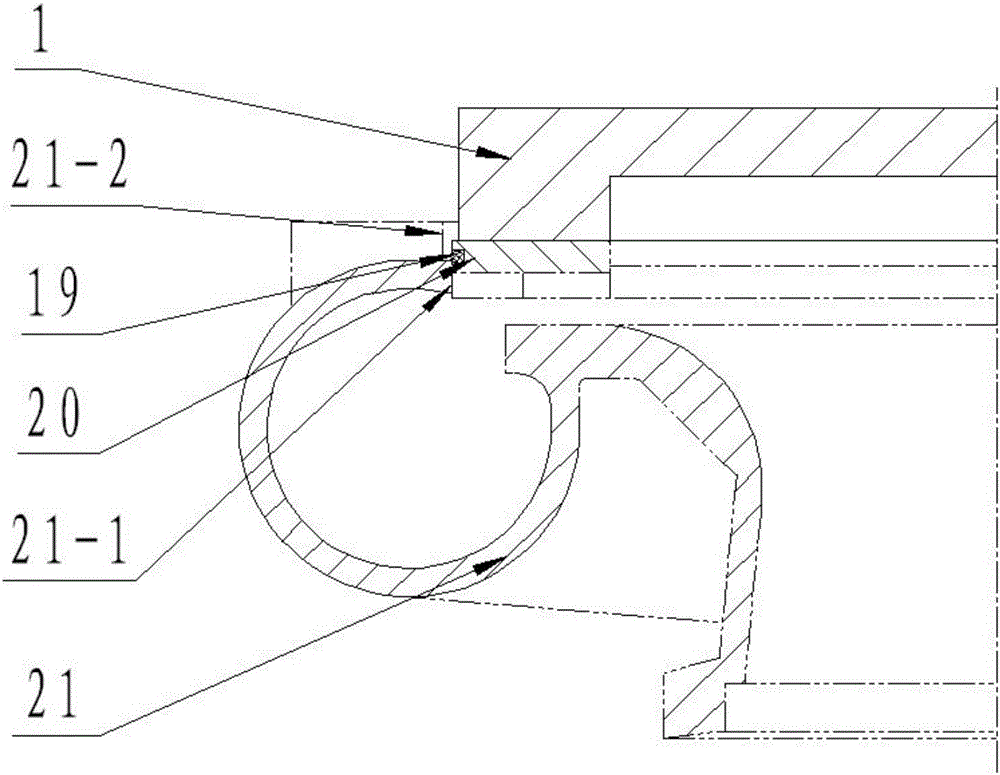

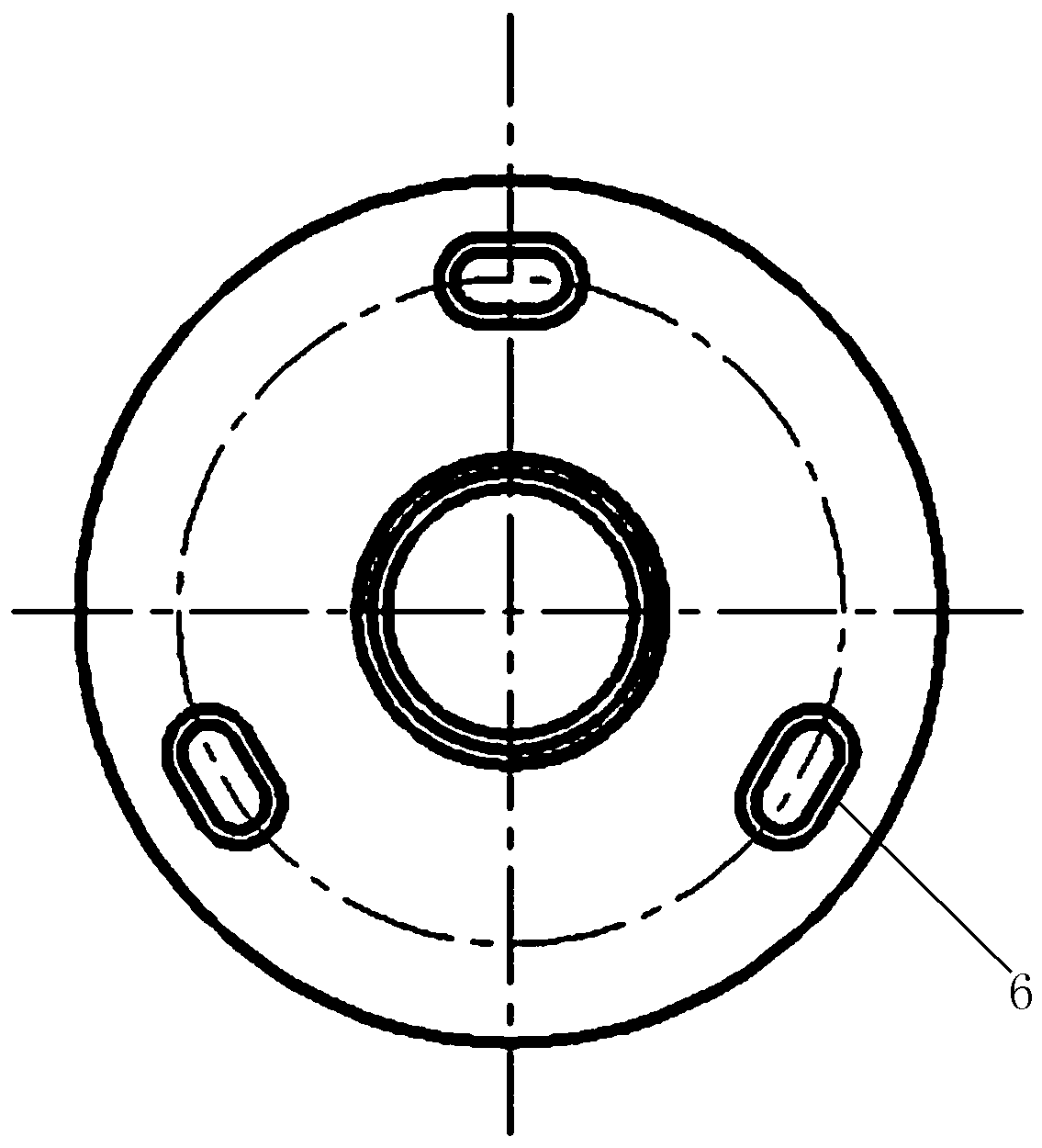

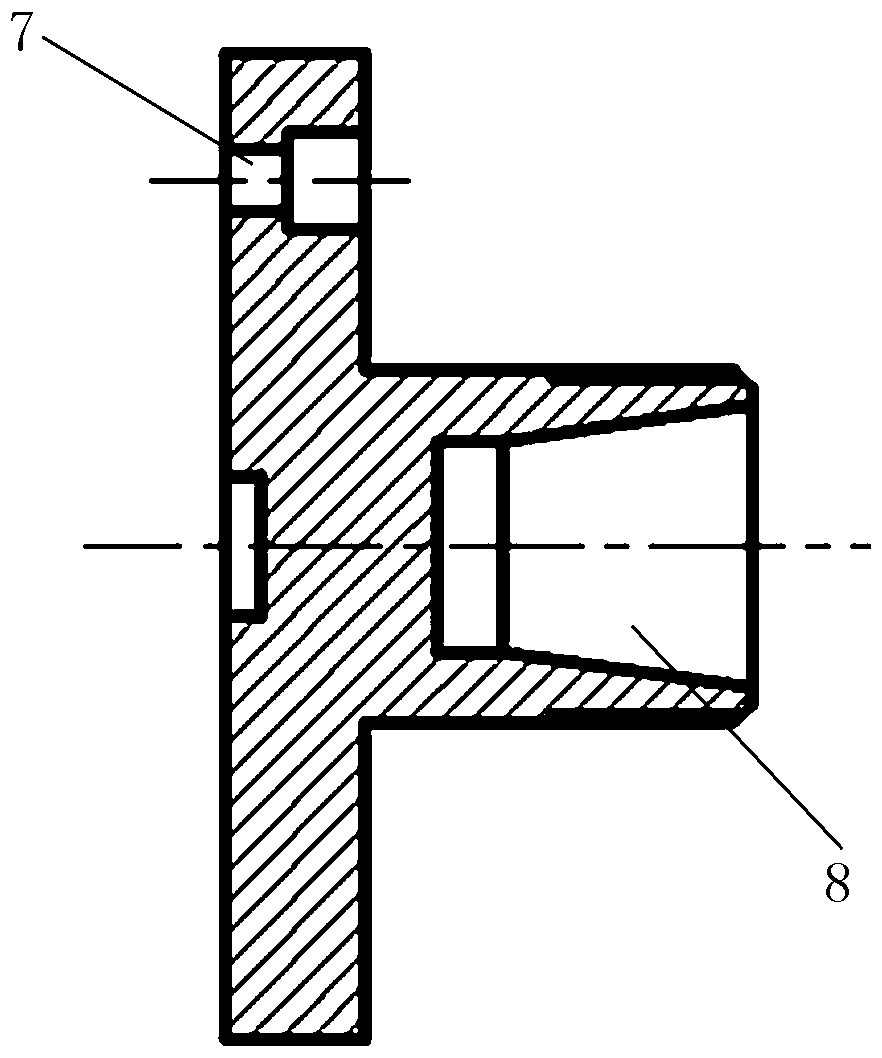

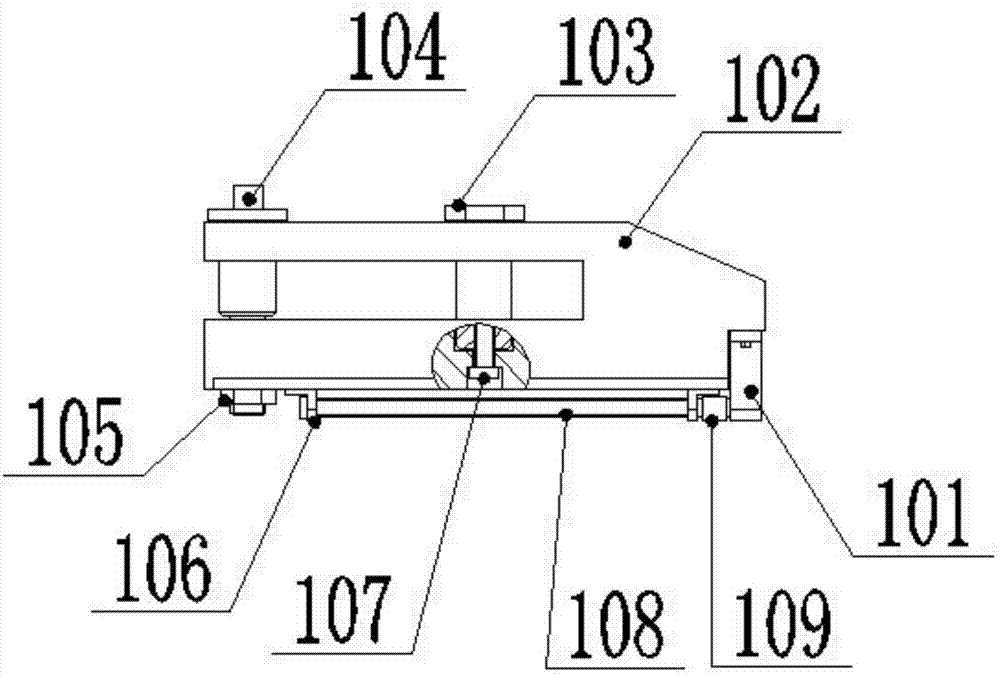

Press-mounting device for rectification window of aviation turbine cooler and press-mounting method

The invention discloses a press-mounting device for a rectification window of an aviation turbine cooler and a press-mounting method. The press-mounting device for the rectification window of the aviation turbine cooler comprises a base plate. Stand columns are inserted in the two sides of the top end of the base plate correspondingly. A cross beam is mounted at the top ends of the stand columns. A threaded hole is formed in the middle of the cross beam. A screw is inserted into the threaded hole. A ball is arranged at the bottom end of the screw. A guide piece is hinged to the ball and comprises a disc located in the middle, and a plurality of supporting arms are evenly arranged outside the disc. A rectangular groove is formed in the middle of each supporting arm. Pressing rods are inserted into the rectangular grooves. A disc chuck is mounted on the upper portion of the guide piece in a clamped mode and comprises a round disc body. A through hole is formed in the center of the disc body, arc-shaped grooves are formed in the disc body, and handles are fixedly connected to the edge of the disc body. The top ends of the pressing rods stretch out of the guide piece and are fixed through nuts at the top after penetrating through the arc-shaped grooves. By adoption of the press-mounting device for the rectification window of the aviation turbine cooler and the press-mounting method, the problems that in the prior art, when the rectification window of the aviation turbine cooler is mounted, a sealing ring is prone to cut damage, a sealing ring mounting groove is prone to being torn, stress is nonuniform, deflection occurs easily, and the mounting precision is poor can be solved.

Owner:GUIZHOU YONGHONG AVIATION MACHINERY

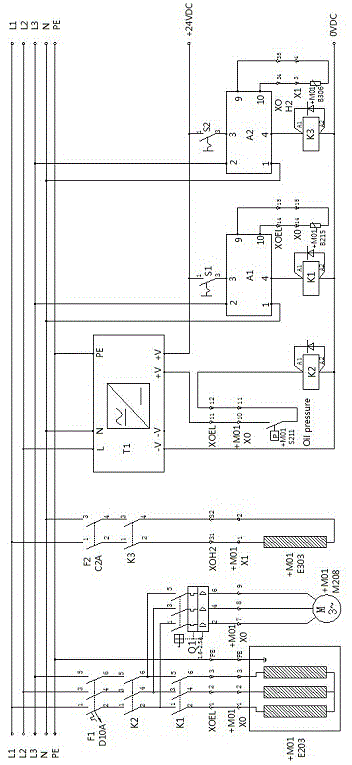

Lathe bed and disc chuck temporary heating control device for warp knitting machine

InactiveCN104133508AImprove application flexibilityReduce volumeAuxillary controllers with auxillary heating devicesLathe faceplateEngineering

The invention relates to the technical field of heating devices, in particular to a lathe bed and disc chuck temporary heating control device for a warp knitting machine. The lathe bed and disc chuck temporary heating control device comprises a three-phase power supply, a lathe bed heating device, a disc chuck heating device and a circuit control device. The circuit control device comprises a direct current 24V power supply, a lathe bed temperature controller and a disc chuck temperature controller. The lathe bed temperature controller controls the lathe bed heating device, the disc chuck temperature controller controls the disc chuck heating device, the lathe bed and disc chuck temporary heating control device does not need to be connected with a finished main electric cabinet or a matched cable, a lathe bed and a disc chuck can be heated, and application flexibility is high; the lathe bed and the disc chuck of the machine are independently heated and can be independently controlled to be heated; the lathe bed and disc chuck temporary heating control device can be hung on an external oil circulation heating device, and is small in size and convenient to move.

Owner:KARL MAYER CHINA

Six-hole gasket machining clamp

InactiveCN105081875AAccurate and reliableEasy to operatePrecision positioning equipmentLathe faceplateEngineering

The invention discloses a six-hole gasket machining clamp. The six-hole gasket machining clamp comprises a disc chuck, wherein the disc chuck is fixedly provided with a balance block and an indexing disc; the indexing disc is provided with a spring relative fixation pin; the disc chuck is provided with a rotating disc; the spring relative fixation pin is used for locating the relative position between the rotating disc and the indexing disc; a workpiece is fixedly arranged on the rotating disc and is located and fixed through a locating pin; the indexing disc is provided with a pair of pressing plates; the pressing plates are used for clamping and fixing the workpiece through locking screws. According to the six-hole gasket machining clamp disclosed by the invention, the bottom surface and an intermediate hole of the workpiece are used for positioning, locating and clamping are carried out by using an intermediate locating pin, an angle is located and controlled to rotate automatically by using the rotating disc and the spring relative fixation pin, and the machining of turning corresponding holes can be completed after the workpiece is installed and clamped for one time, so time and labor are saved by adopting the six-hole gasket machining clamp, the accuracy is reliable, the machining efficiency can be effectively increased, and the machining cost can be reduced.

Owner:CHENGDU XINGYU PRECISION CASTING

Numerical control hydraulic spiral vertical broaching machine

The invention discloses a numerical control hydraulic spiral vertical broaching machine which comprises a motor, a speed reducer, a workbench, a broaching tool and an encoder, and is characterized in that a servo motor is additionally arranged, the servo motor is used for driving the speed reducer, the speed reducer is connected with a gear and used for driving a flower disc, a PC (personal computer) is connected with the servo motor and used for controlling lead and adjusting rotation direction, the encoder arranged on the broaching machine is used for monitoring the broaching tool, and a position signal of the broaching tool is transmitted to the PC. The broaching machine based on the technical scheme can be applicable to large-batch production and small-batch broaching of splines with different leads, be suitable for broaching various splines with the different leads, and simultaneously enable the precision of broached products to be high.

Owner:盐城市大丰区生产力促进中心

Novel process for manufacturing bicycle axle hub

The invention relates to a novel process for manufacturing a bicycle axle hub. The process comprises the following steps of: performing automatic spin forming on a steel pipe and cutting the steel pipe according to a required length; putting a half-finished product into a spinning machine again to automatically plain an end, chamfer and deburr; polishing the prepared half-finished product and putting the prepared half-finished product into a two-head extruding machine to extrude and form a face plate; threading (the step is saved for a front wheel spindle); after electroplating, installing steel cups at two ends by pressing; automatically spraying butter or grease; installing steel beads, a small bearing and a main shaft at one end; installing the steel beads and the bearing at the other end; and after pressing dustproof covers into two ends, installing a spacer and screwing a nut. The process has the advantages of effectively overcoming the defects, reducing material loss of finished products, greatly improving the production efficiency of the products, along with simple process.

Owner:李良有

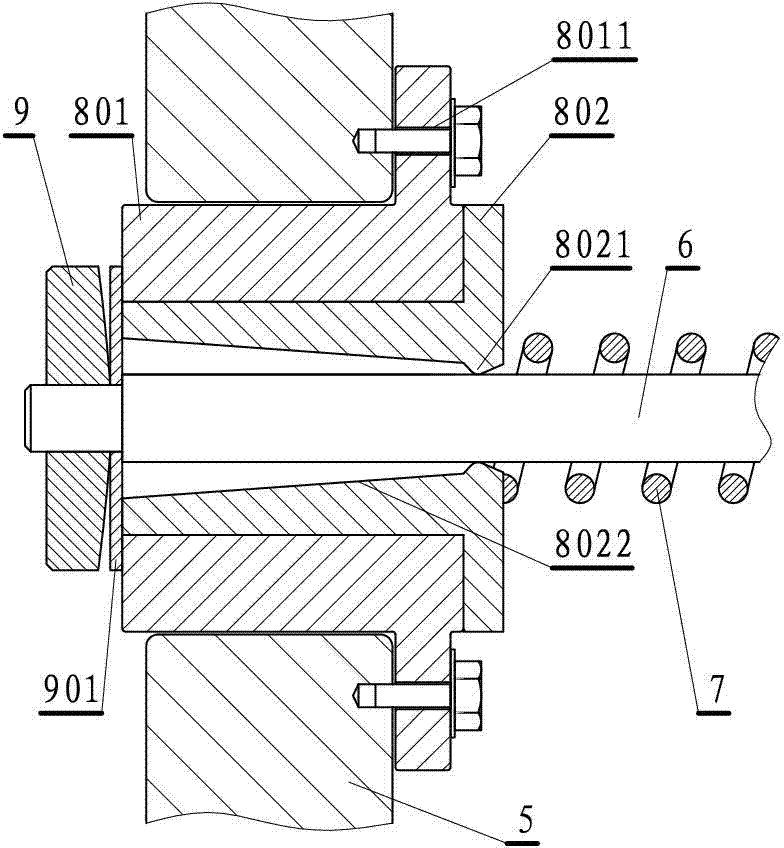

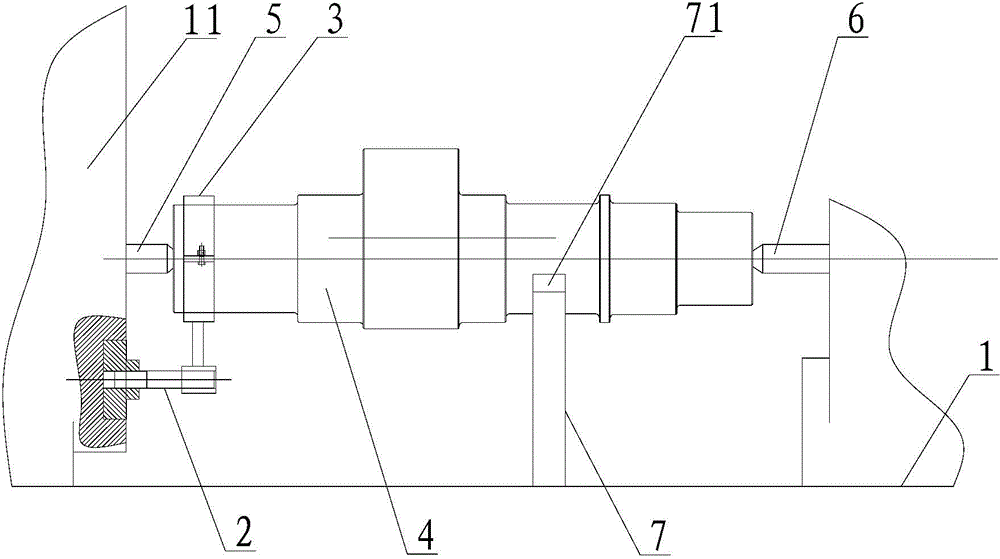

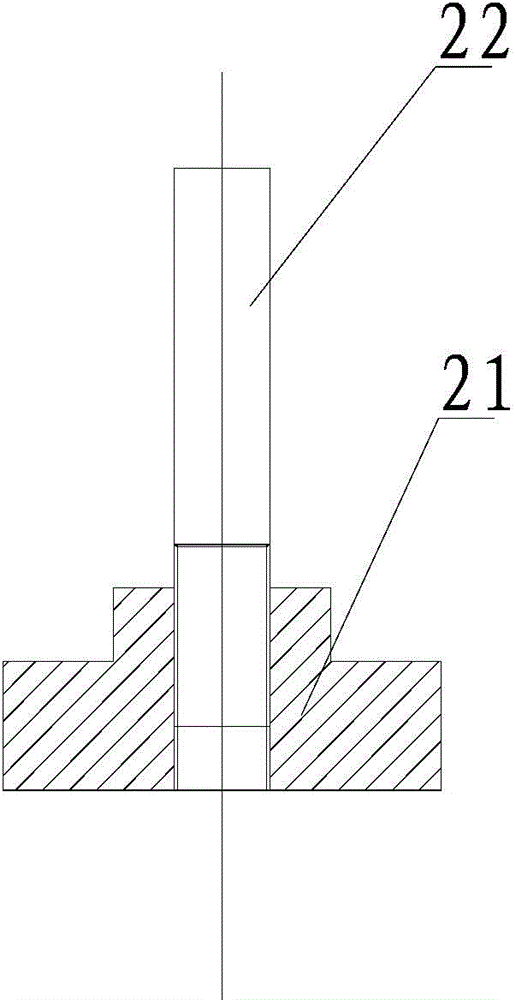

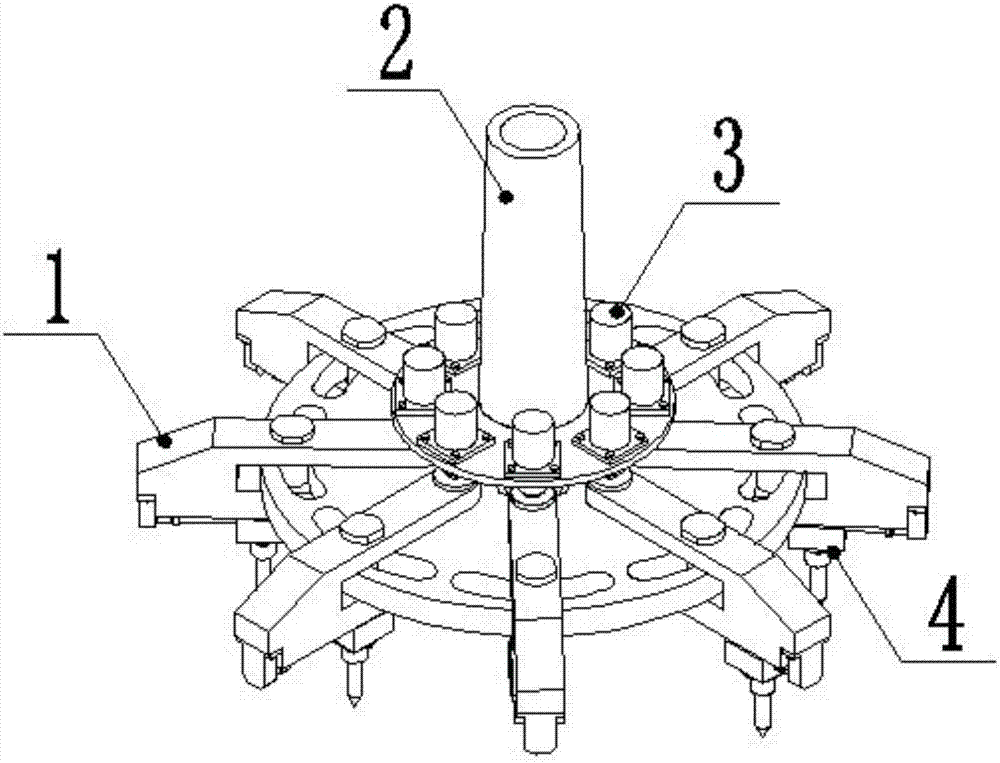

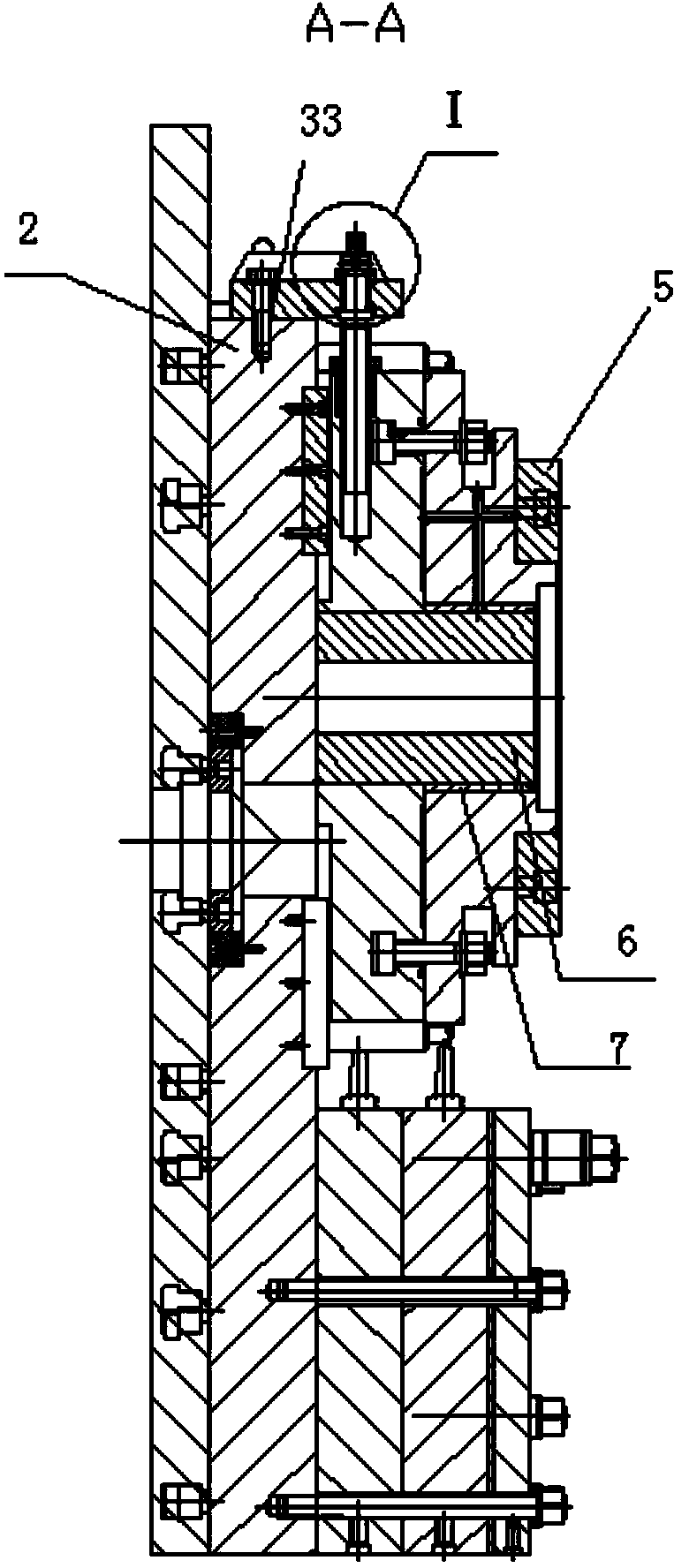

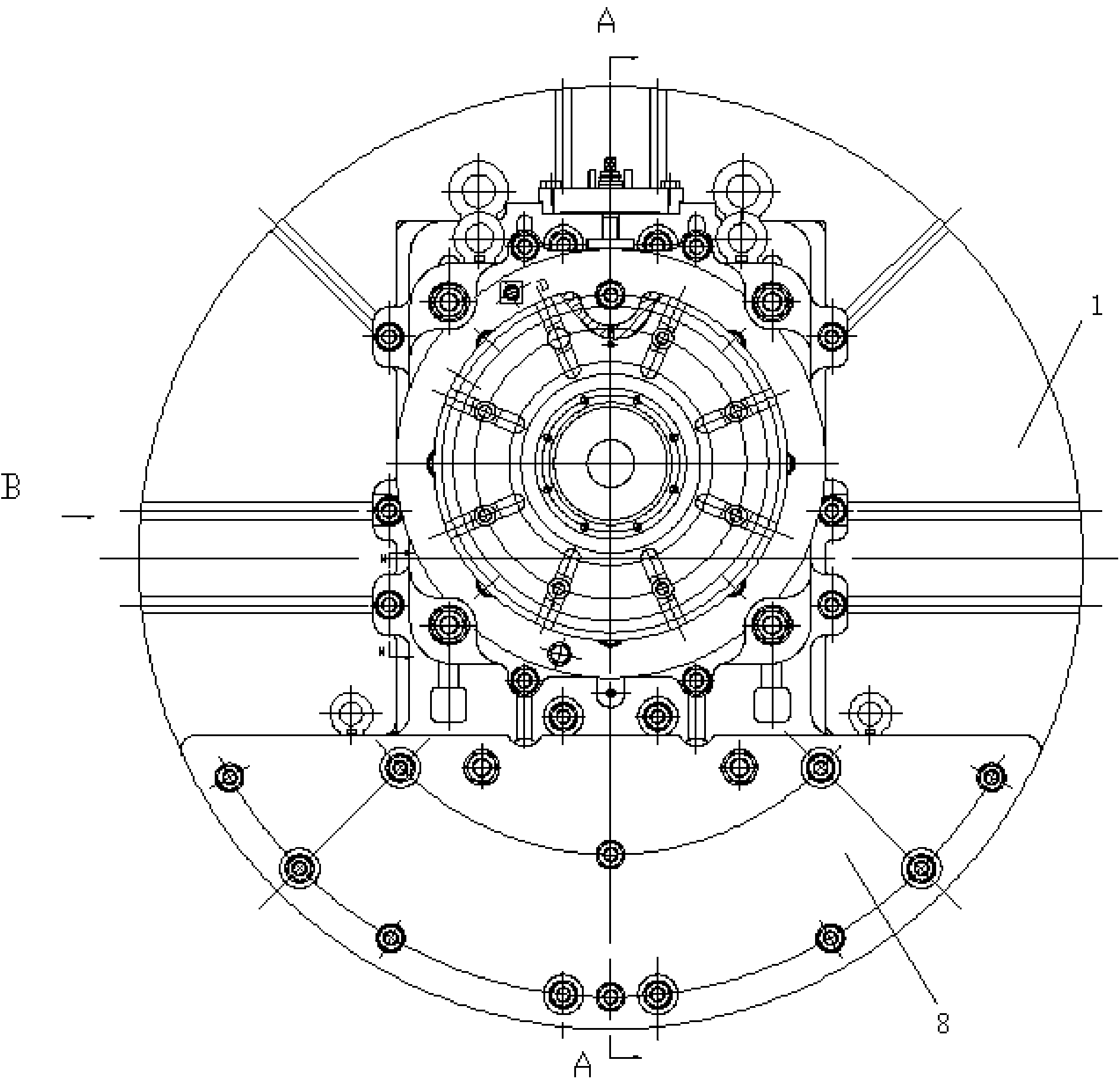

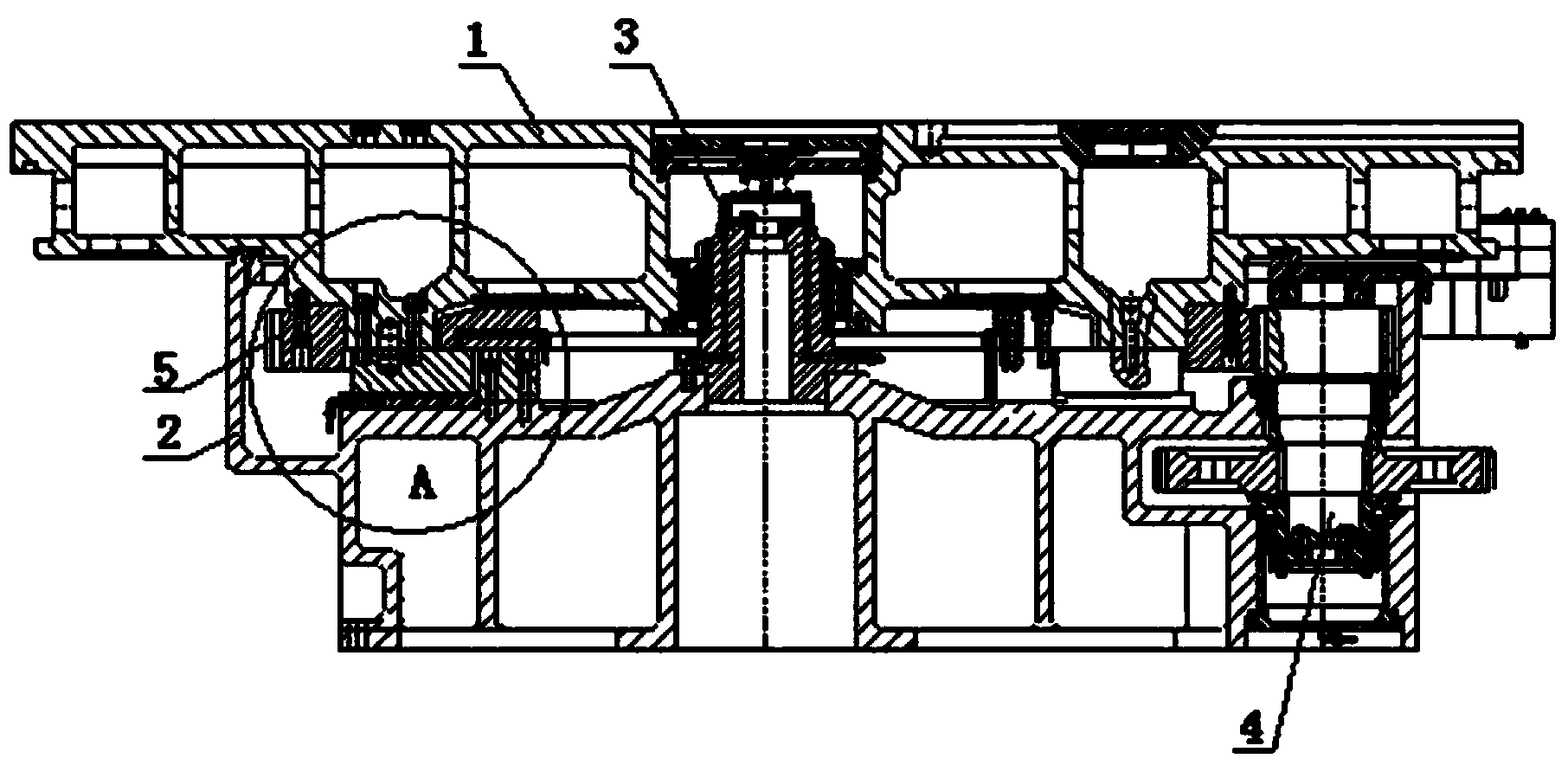

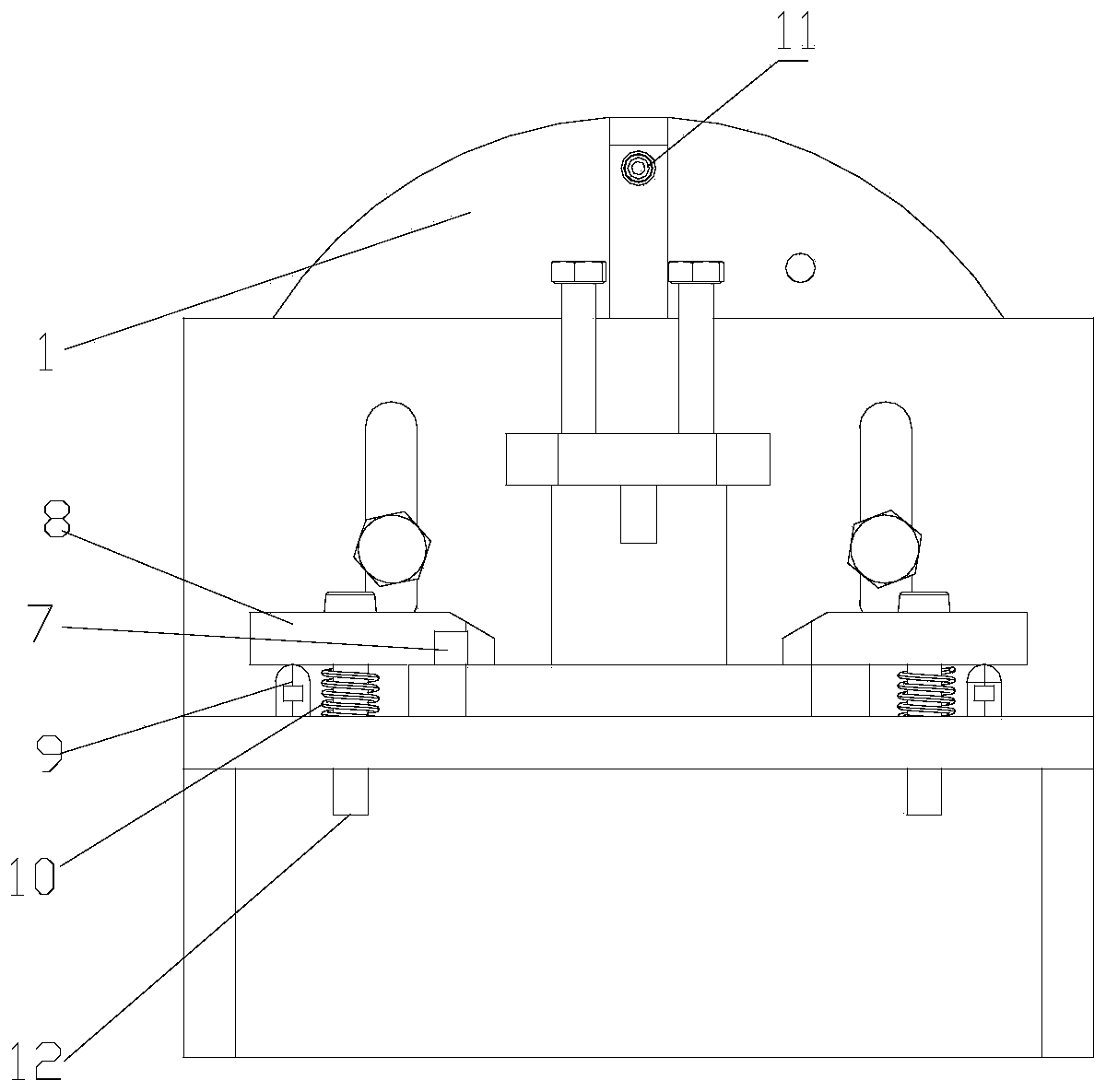

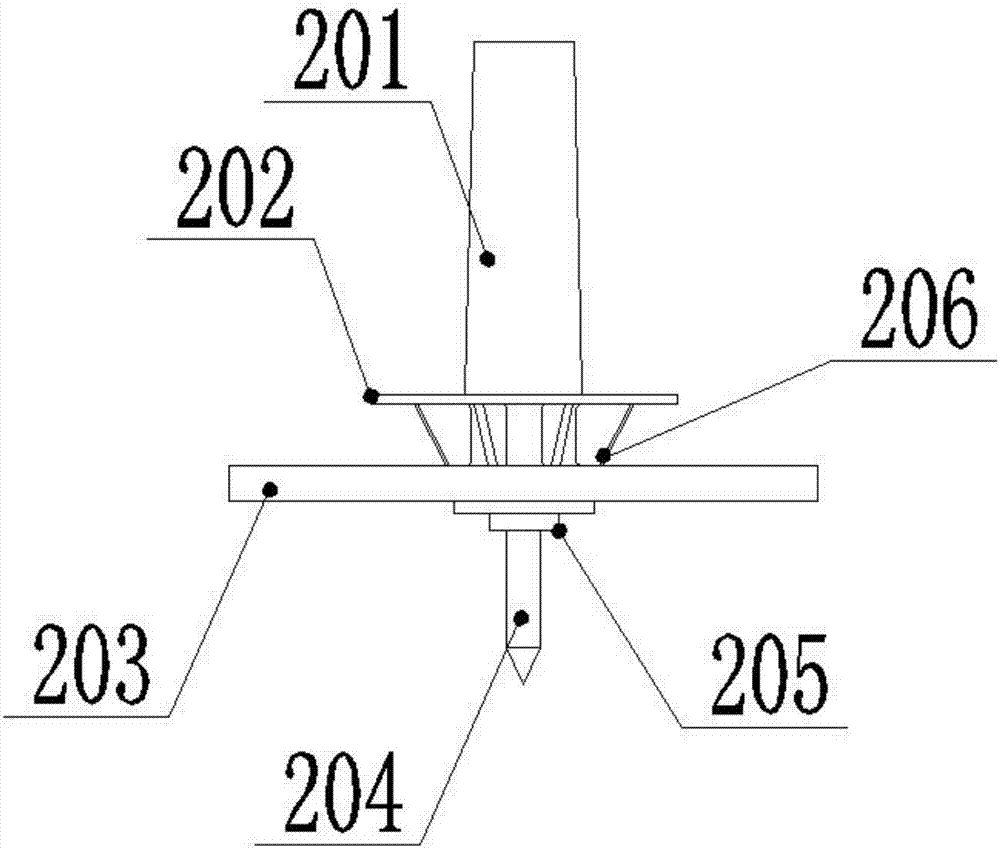

Crankshaft eccentricity tool

ActiveCN104043996AEasy to adjustGood accuracy retentionWork clamping meansPositioning apparatusLathe faceplateEngineering

The invention relates to a crankshaft eccentricity tool. The tool comprises a lathe disc chuck (1), a head axe disk (2), an eccentricity adjusting assembly, a workpiece connecting assembly, an eccentric positioning assembly and a balance plate assembly in a split structure, wherein the head axe disk (2) is fixed on the lathe disc chuck (1); the eccentricity adjusting assembly, the workpiece connecting assembly and the eccentric positioning assembly are connected into a part for adjusting the eccentricity of a crankshaft of the tool through a connecting component, and are fixed on one side of the head axe disk (2); the balance plate assembly is fixed on the other side of the head axe disk (2) through a connecting component. Compared with the prior art, the crankshaft eccentricity tool has the advantages of accuracy in positioning, convenience in assembling and disassembling, convenience and rapidness in replacement, convenience in transformation, convenience and flexibility in overall structure, low manufacturing cost and the convenience in manufacturing by adopting a split structure, positioning through a positioning pin and connecting through a positioning plate and bolts.

Owner:SHANGHAI DALONG MACHINE FACTORY CO LTD

Closed hydrostatic workbench of heavy-duty vertical milling machine

The invention relates to the field of rotary workbenches and particularly relates to a closed hydrostatic workbench of a heavy-duty vertical milling machine. The closed hydrostatic workbench comprises a base, a main shaft, a guide rail, a pressing plate, a disk chuck, a driving shaft and a tooth ring, wherein the main shaft is arranged at the center of the base, and the disk chuck is mounted on the main shaft; the driving shaft is arranged at the side edge of the base and is in linkage connection with the disk chuck through the tooth ring clung to the outside of a bottom ring of the disk chuck, the guide rail and the pressing plate are arranged between the disk chuck and the base, the pressing plate is located at an inner ring of the disk chuck and is located on the guide rail, an upper hydrostatic oil cavity is arranged below the pressing plate, an oil pad is arranged between the guide rail and the base, and a lower hydrostatic oil cavity is formed between the oil pad and the guide rail. Due to the adoption of the structure, the carrying capacity is larger, the accuracy is higher, and the performance is more stable.

Owner:CFHI SHAOXING HEAVY MACHINE TOOL

Valve body shaft hole machining clamping mould

InactiveCN110900273APrecise positioningEasy to processWork clamping meansMetal working apparatusLathe faceplateEngineering

The invention discloses a valve body shaft hole machining mould which comprises a T-shaped positioning plate assembled with a lathe faceplate through a guide rail, a rotating body of a T-shaped structure is installed on the plane portion of the T-shaped positioning plate, and the rotating body is provided with a cylindrical portion matched with a valve body to be machined and a bottom plate connected with the cylindrical portion. A lower protruding column assembled together with an upper round hole of the plane part in a rotating fit mode is formed at the bottom of the bottom plate, a rotatingbody pressing plate is arranged on the plane part so as to press the rotating body on the plane part to be fixed, and a valve body fixing plate is installed at the upper end of the rotating body through a bolt in a connected mode. The positions of the bottom plate and the plane part of the rotating body are positioned through positioning pins. According to the valve body shaft hole machining clamping mould, through the technical scheme, a corresponding valve body can be conveniently positioned, so that shaft holes in the two sides of the valve body are conveniently machined, the structure issimple, and use is convenient.

Owner:TIANJIN GALAXY VALVE

Fast changing fixture for six-axis air floating grinding machine

PendingCN109333353AAchieve installationGuaranteed accuracy requirementsGrinding work supportsLathe faceplateMachine parts

The invention relates to a fast changing fixture for a six-axis air floating grinding machine. According to the structure of the fast changing fixture, a machine tool spindle and a disc chuck clamp are connected in a fastened mode through bolts to fix the position of the disc chuck clamp; a back cap is connected with the disc chuck clamp through threads;the back cap and a clamping spring are fixedin a clearance fit mode; and a machined part and a clamping spring inner hole are fixed in a clearance fit mode. By adjusting and disassembling the connecting bolts between the disc chuck clamp and the machine tool spindle, fast installation, alignment and replacement of the machined part and the machine tool spindle are guaranteed.

Owner:SHENYANG AEROSPACE XINGUANG GRP

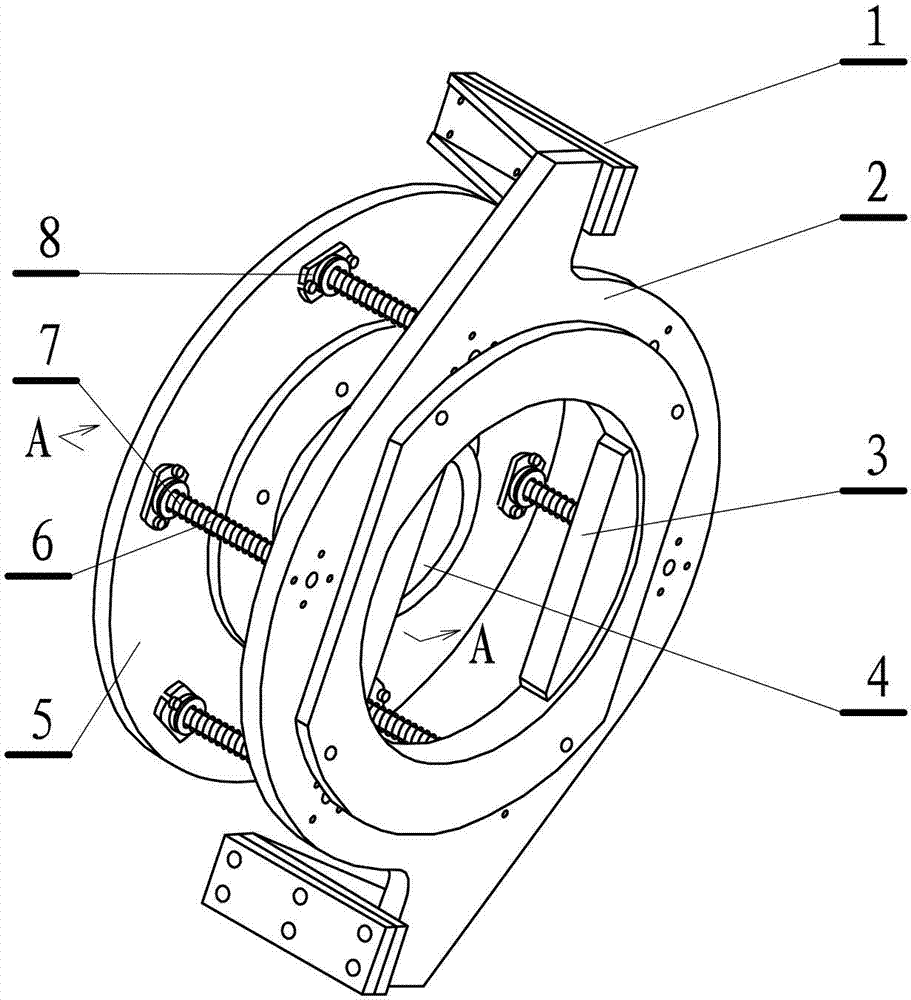

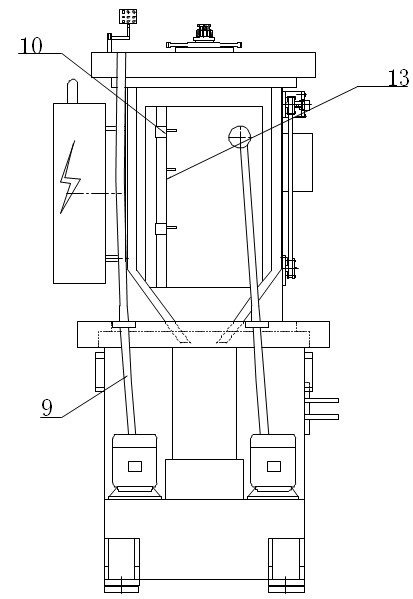

Integrated shrink fit technology for multiple magnet yokes of hydro-generator rotor

InactiveCN107742959AGood effectIncrease productivityManufacturing stator/rotor bodiesLathe faceplateMagnet

The invention discloses an integrated shrink fit technology for multiple magnet yokes of hydro-generator rotor. The technology includes a centering tool and a shrink fit technical method. The centering tool comprises a vertical lathe faceplate, a centering device, the magnet yokes, supporting limiting strips, a centering detector and a process screw rod. The shrink fit technical method includes the following steps that firstly, the first magnet yoke A is installed on the centering tool in an aligned mode; secondly, the second magnet yoke B and the third magnet yoke C are installed on the centering tool in an aligned mode; thirdly, the first magnet yoke A, second magnet yoke B and the third magnet yoke C are axially combined and fixed into a whole through the process screw rod and are rechecked; fourthly, the first magnet yoke A, second magnet yoke B and the third magnet yoke C are slowly and axially tightened through the process screw rod one by one; fifthly, a main shaft is sleeved with the combined magnet yokes to form a combined element, and the whole combined element is subjected to baking and shrink fit; sixthly, after shrink fit is conducted for a preset period of time, the combined element is taken out to be thoroughly cooled. The technology has the advantages that the work efficiency is high, the production cost is low, and the production period is short.

Owner:成都金英荟科技有限公司

Multi-axis drilling method of PCD holes of aluminum alloy hub

InactiveCN107363280AQuality assuranceAvoid automatic changesBoring/drilling machinesLathe faceplateProcess equipment

Owner:沈金田

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com