Six-hole gasket machining clamp

A sheet processing and fixture technology, applied in the field of positioning fixtures for six-hole gasket processing, can solve the problems of difficult clamping, difficult to ensure diagonal angles, difficult positioning, etc., to achieve convenient operation, reduce processing costs, and save time for fixtures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings.

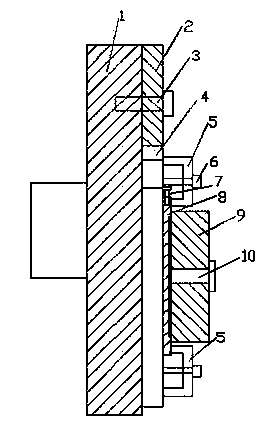

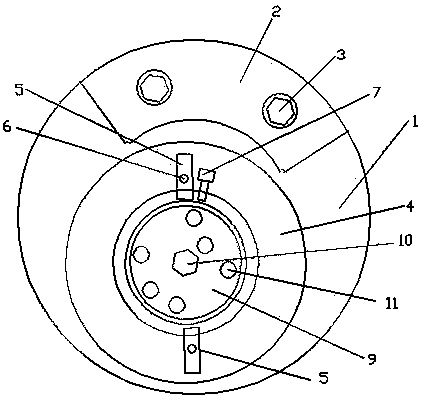

[0010] refer to figure 1 , is a six-hole gasket processing fixture, including a face plate 1, a balance weight 2 and an index plate 4 are fixedly installed on the face plate 1, a spring pair fixed pin 7 is arranged on the index plate 4, and the face plate 1 is provided with a rotating disk 8, and the relative position between the rotating disk 8 and the indexing disk 4 is positioned by the spring to the fixed pin 7. The positioning is fixed, and the index plate 4 is provided with a pair of pressing plates 5, and the pressing plates 5 clamp and fix the workpiece 9 through the locking screws 6.

[0011] The fixture is mainly controlled by the indexing plate 4, the rotating plate 8 on the faceplate 1, the positioning pin 10 and the spring pair fixed pin 7 to realize the transformation of the angle; the indexing plate 4 is fixed on the faceplate 1 with bolts 3, and the fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com