Automatic production line technology and equipment for low-pressure casting of aluminum alloy

An automatic production line and low-pressure casting technology, which is applied in the field of metal casting equipment, can solve the problems of low production efficiency and low yield, and achieve the effects of improving production efficiency, small footprint, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

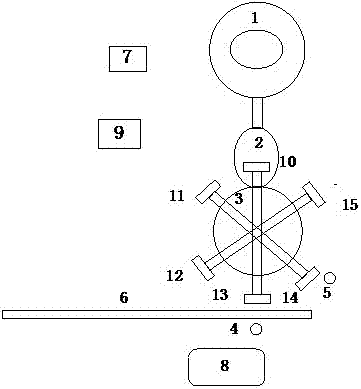

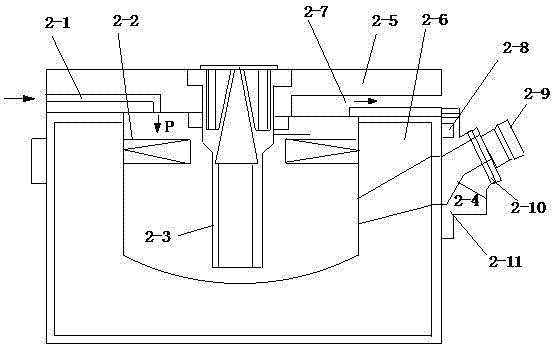

[0022] The raw material aluminum is dissolved in the smelting furnace, and the slag is removed and exhausted. The aluminum liquid automatically flows into the low-pressure holding furnace through the pneumatic liquid blocking mechanism. The low-pressure holding furnace is a melting pool type holding furnace with a fixed structure. figure 2 As shown, radiation heating, PID control, rated temperature range: 680-750°C, temperature control accuracy: ±5°C, the inflow channel is a closed structure that can be opened.

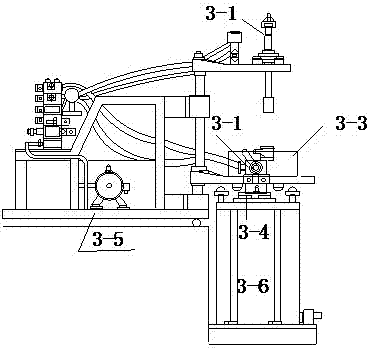

[0023] The closed low-pressure holding furnace is installed underground on one side of the wheel-type horizontal pouring machine, and the liquid is quantitatively discharged under the control of the liquid level pressurization device. There is a sealing plate at the liquid outlet that is in close contact with the metal cavity on the wheel-type multi-platform casting machine . After the injection port of the metal cavity of the wheeled horizontal pouring machine is al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com