Anti-counterfeiting control system and anti-counterfeiting control method for warehouse logistics

A warehousing logistics and control system technology, applied in logistics, image data processing, instruments, etc., can solve problems such as control loopholes, uncontrollable, cargo batches, quantities, authenticity errors, etc., and achieve high operating efficiency and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

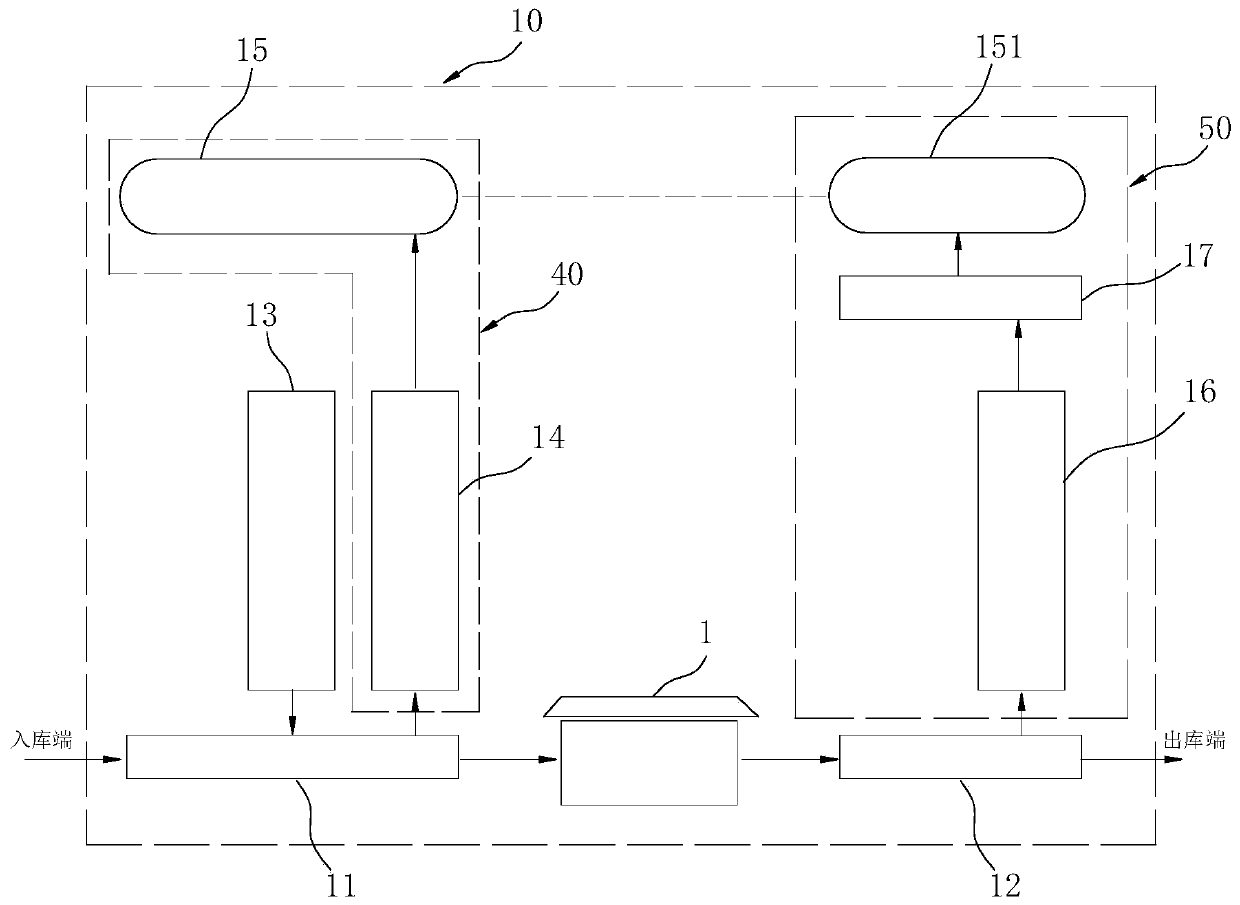

[0064] Please refer to figure 1 , is a schematic diagram of the first embodiment of the warehousing and logistics anti-counterfeiting control system of the present invention, as shown in the figure, the warehousing and logistics anti-counterfeiting control system of the present invention mainly includes a first-level system 10, and the first-level system 10 has a warehouse-in terminal and a warehouse-out terminal, further , the first-level system 10 includes: a first-level warehouse 1; a random texture production device 13, which is arranged at the storage end of the first-level warehouse 1, and is used to make and generate random texture patterns on the goods in the warehouse; the storage terminal collects and stores modules 40 , used to collect the random texture patterns formed on the incoming goods and store them as reference pattern data; the collection and determination module 50 is set at the outgoing end of the first-level warehouse 1, and is connected to the incoming e...

no. 2 example

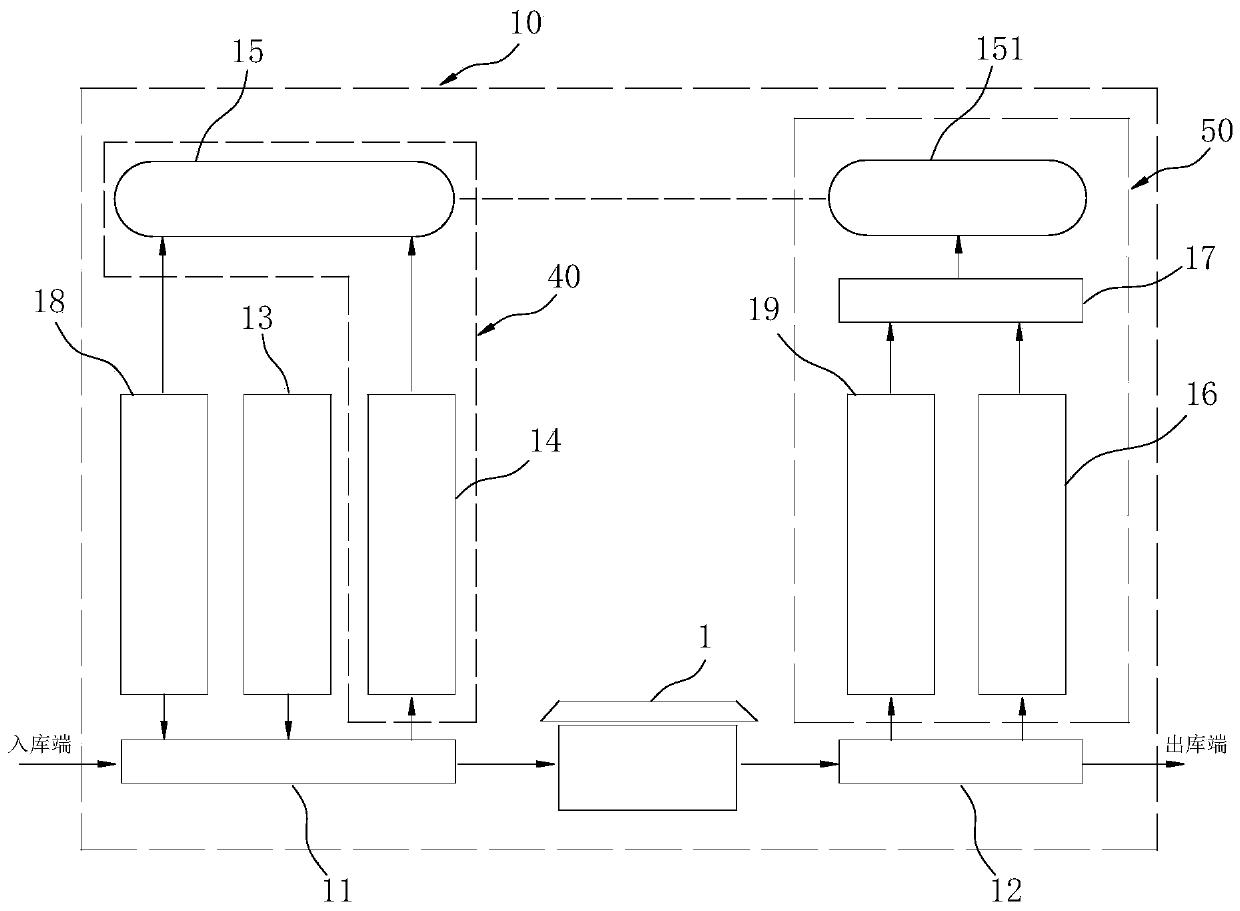

[0076] Please refer to figure 2 , is a schematic diagram of the second embodiment of the warehousing and logistics anti-counterfeiting control system of the present invention, as shown in the figure, the difference from the above-mentioned first embodiment is that the warehousing and logistics anti-counterfeiting control system of this embodiment also includes: a coding production device 18, which is set in The warehouse-in end of the first-level warehouse 1 is used to make and generate coding patterns on the goods in the warehouse, and the code making device 18 is connected to the reference pattern storage device 15 (collection and storage module of the warehouse-in terminal), and uploads the code patterns made to the reference pattern. The pattern storage device 15 is stored, and is paired with the random texture patterns generated on the same goods and stored in groups; the code recognition device 19 is arranged at the outbound end of the first-level warehouse 1, and is use...

no. 3 example

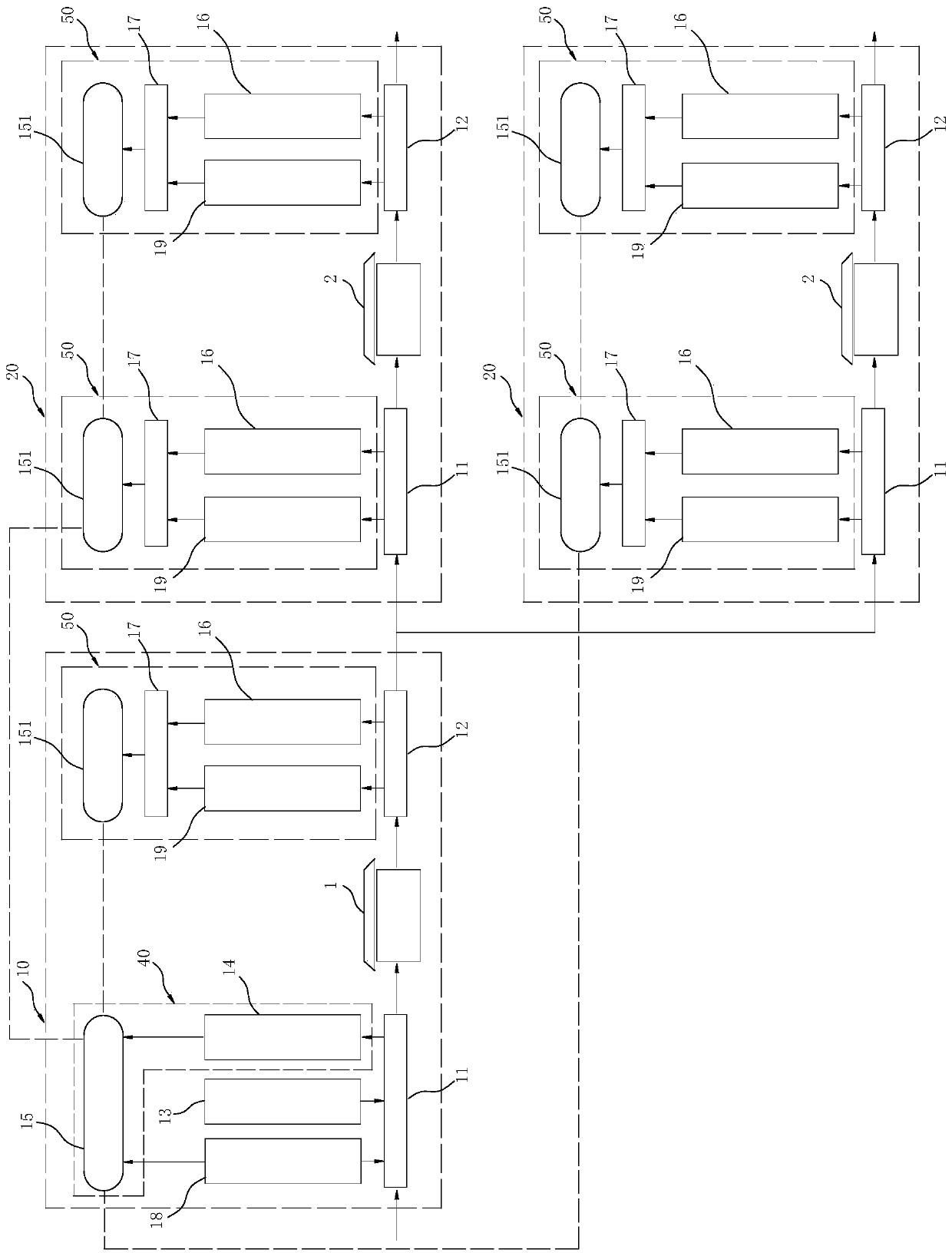

[0083] Please refer to image 3 , is a schematic diagram of the third embodiment of the warehousing logistics anti-counterfeiting control system of the present invention ( image 3 What is shown is actually a schematic diagram of the second implementation of the third embodiment, which can still be referred to here), as shown in the figure, the difference from the first embodiment above is that the warehousing and logistics anti-counterfeiting control system of this embodiment also includes : one or more secondary systems 20, each secondary system 20 includes a storage terminal and a storage terminal, the storage terminal of the secondary system 20 is connected to the storage terminal of the primary system 10, and the storage is carried out from the primary system The goods are transported to the secondary system 20 through logistics. Further, the secondary system 20 includes: a secondary warehouse 2, which has a warehouse-in terminal and a warehouse-out terminal; two collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com