Drying and feeding all-in-one machine

An all-in-one and drying technology, applied in the field of all-in-one machines, can solve the problems of hot air not being effectively recycled, affecting the health of workers in the workplace, and not doing any return air treatment, etc., to achieve stable function, energy saving, and hot air circulation. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

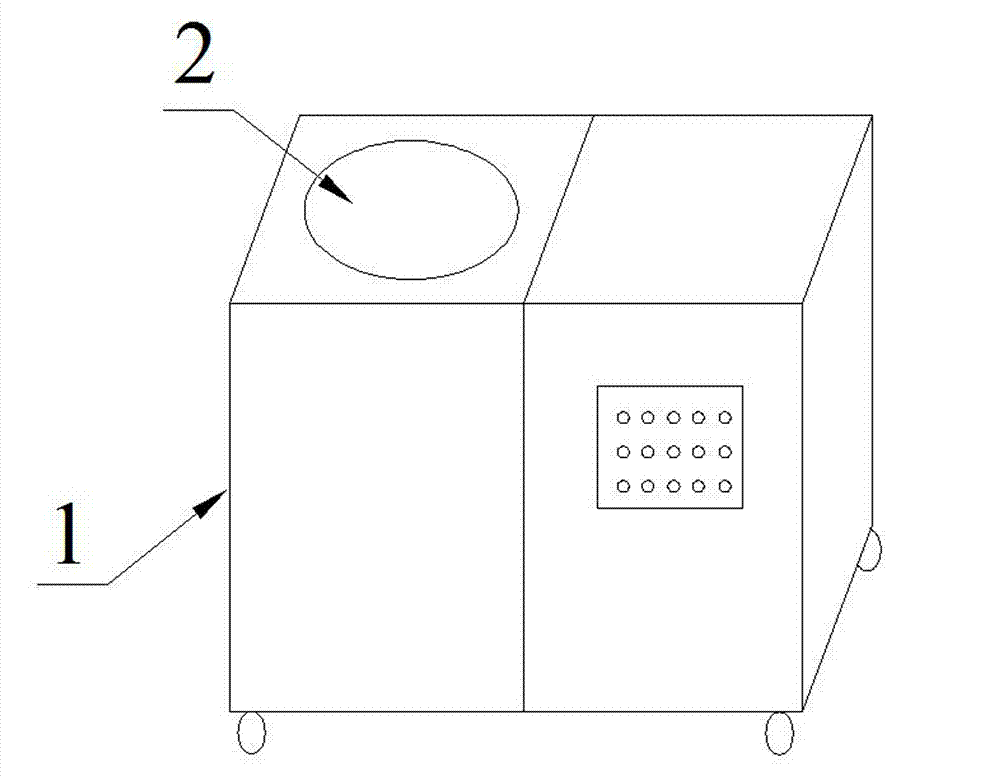

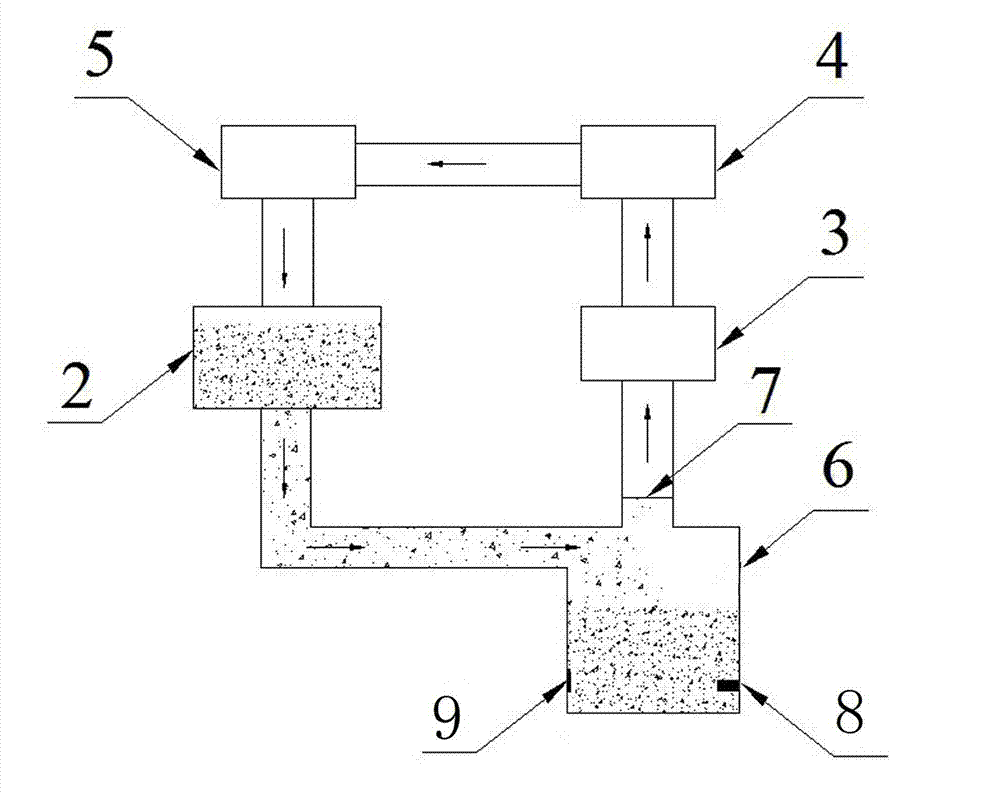

[0021] refer to figure 1 and figure 2 , The integrated drying and feeding machine of the present invention includes: a cabinet body 1, and various systems for realizing drying and feeding that are arranged in the cabinet body 1 . The above system includes: a material storage system for storing materials, a hot air circulation system for drying materials in the material storage system, a feeding system for outputting dry materials, and a material storage system, feeding system, A control system for intelligent control of the hot air circulation system. They are described as follows:

[0022] The material storage system includes a material storage tank 2, which is used to hold materials to be dried, and has an air inlet and an air outlet.

[0023] The hot air circulation system communicates with the material storage system through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com