Patents

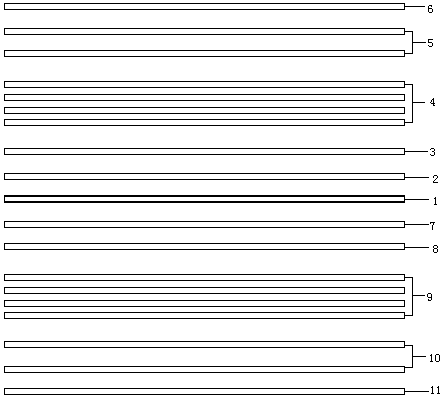

Literature

140results about How to "Strong antifouling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

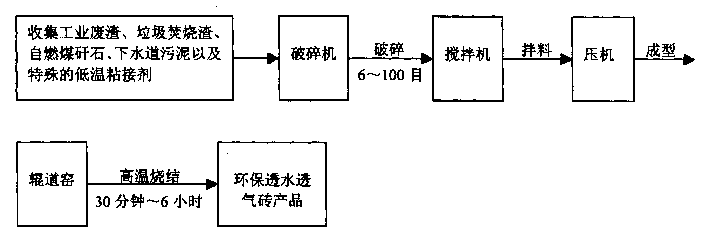

Fast baking process of environment protecting water and air permeable brick in roller kiln

InactiveCN1436750AReduce the temperatureStable water tableSolid waste managementSolid waste disposalEnvironmental resistanceCooking & baking

Owner:广东唯美新技术实业有限公司

Light glazed ceramic tile with anion function and low water absorption and production method thereof

The invention discloses a light glazed ceramic tile with anion function and low water absorption and a production method thereof. The formula of the glazed ceramic tile is as follows: fancy glaze containing 0.1-90 portions of stamp powder, 0.0-190 portions of pigments, 100-200 portions of stamp-pad ink and 0.01-15 portions of anion material; a green body containing 10-45 portions of ceramic shraff, 15-20 portions of clay, 10-20 portions of feldspar, 30-50 portions of sandstone, 30-50 portions of water, 0.0-0.3 portion of lignin, and 0.0-1.0 portion of sodium tripolyphosphate; and conventionalcover glaze. The production method comprises the following steps: stirring and screening the fancy glaze materials to obtain the fancy glaze; conducting ball-milling, screening and pelleting after materials of the green body are mixed, and then conducting compression moulding and drying, glazing, embossing, and sintering for 50-55 minutes at the temperature of 1195-1205 DEG C, thus obtaining the product. The ceramic tile has the characteristics of being light, low in water absorption, high in mechanical strength, small in coefficient of thermal conductivity, strong in antifouling capability and the like, can continuously release anions with the number of more than 500 / cm3 in space, and can be widely applied to decoration of building outer walls and home furnishing spaces.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD +2

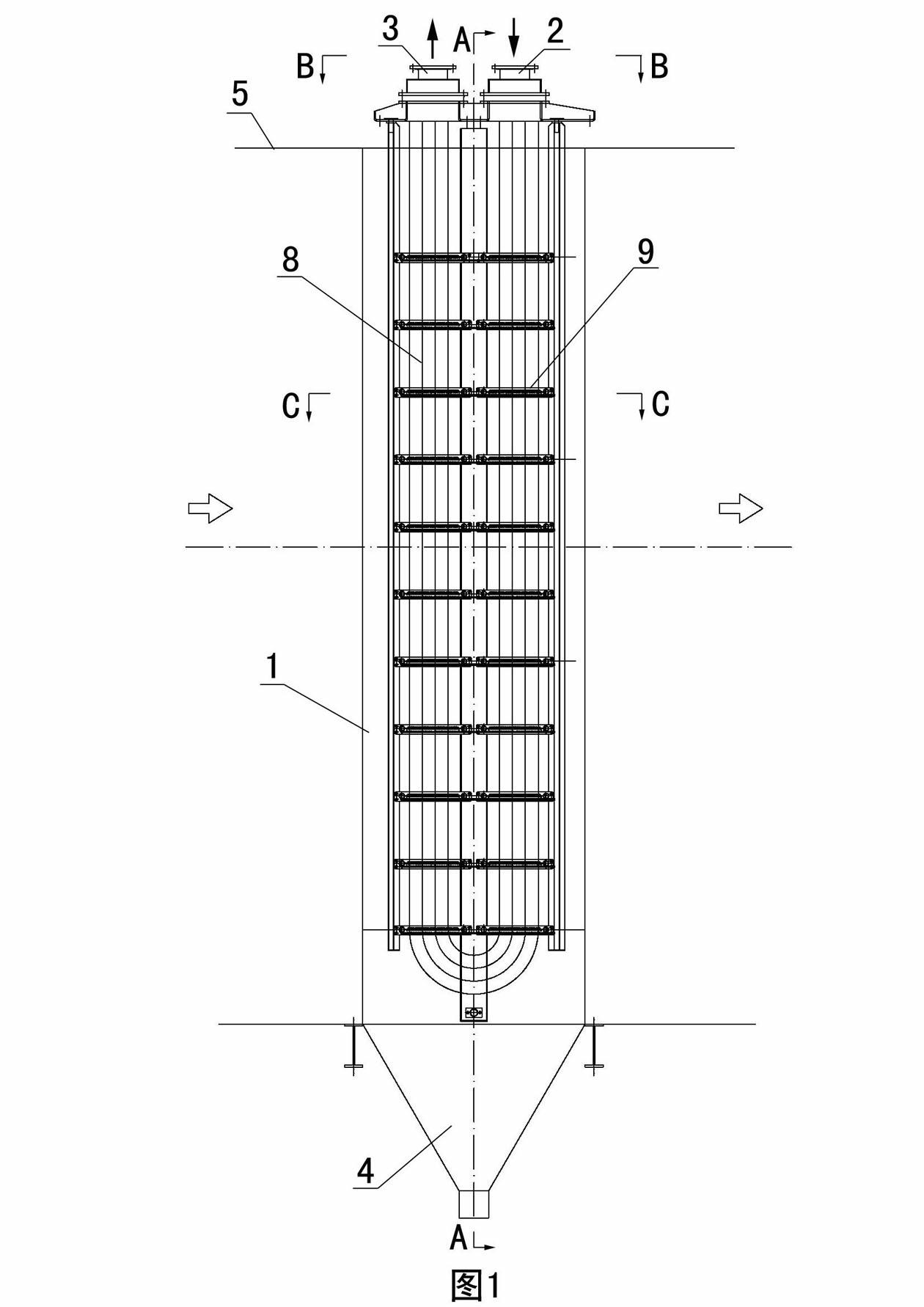

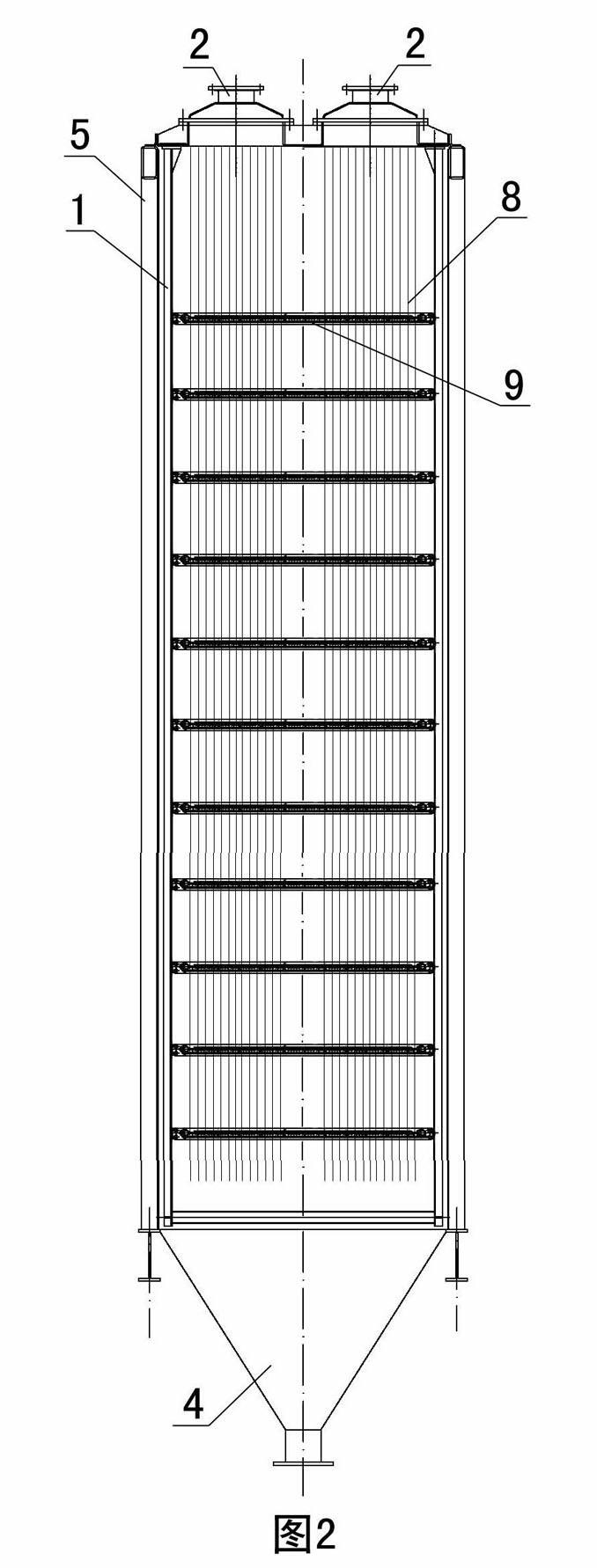

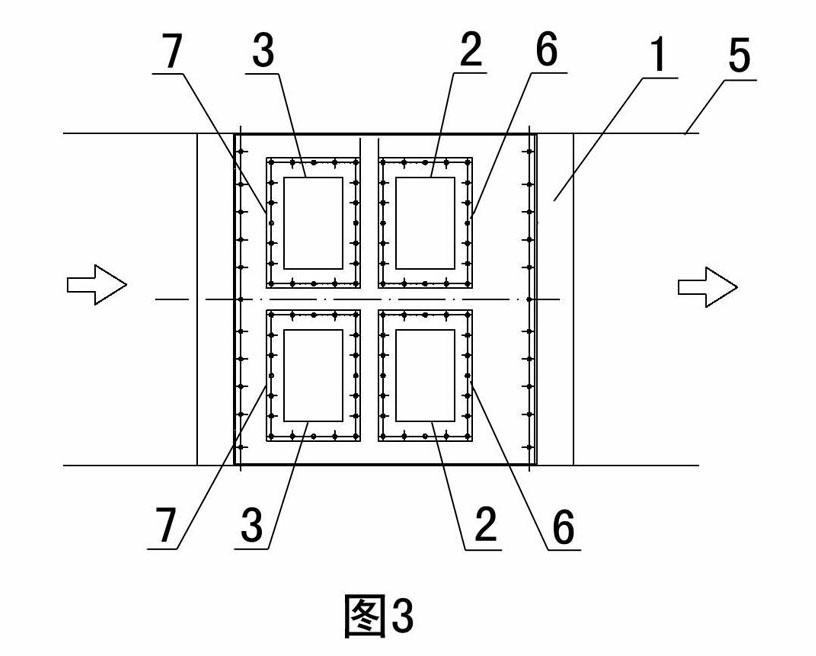

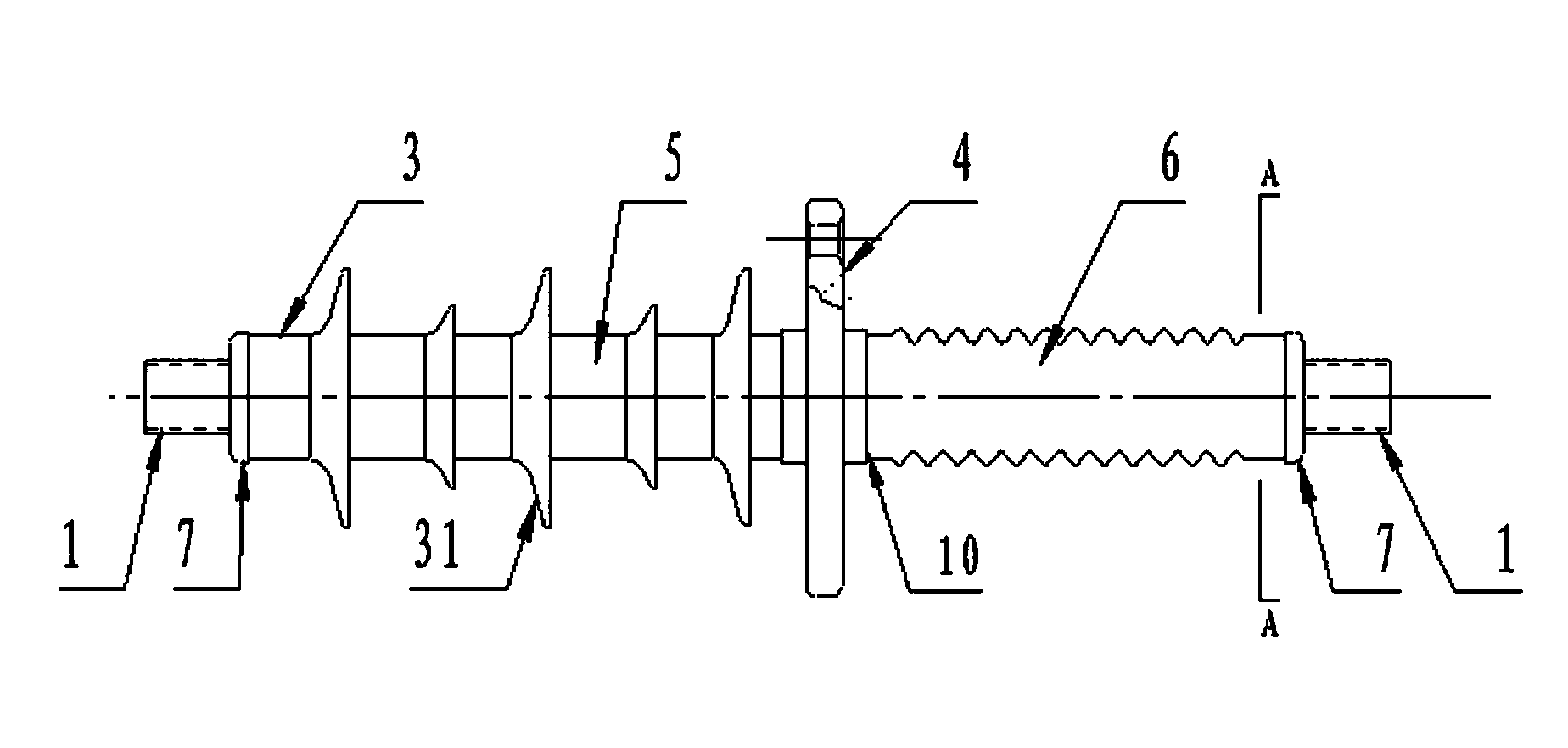

Module type flue gas heat exchanger with fluorine plastic pipes

ActiveCN102607299ALow temperature corrosion resistanceStrong antifoulingHeat exchanger casingsStationary tubular conduit assembliesFlue gasEngineering

A module type flue gas heat exchanger with fluorine plastic pipes comprises a heat exchanger casing and a heat exchange pipe, wherein the upper end of the heat exchanger casing is provided with water inlets and water outlets, and the lower end of the heat exchanger casing is provided with a drain outlet. A water inlet end plate is detachably connected to the position of the water inlets and provided with water inlet holes, and a water outlet end plate is detachably connected to the position of the water outlets and provided with water outlet holes. The heat exchange pipes are U-shaped fluorine plastic heat exchange pipe bundles, water inlet ends of the fluorine plastic pipes in the fluorine plastic heat exchange pipe bundles are communicated with the water inlet holes, water outlet ends of the fluorine plastic pipes in the fluorine plastic heat exchange pipe bundles are communicated with the water outlet holes, and positioning nets are parallelly distributed in the heat exchanger casing from top to bottom at intervals. Module type design is adopted by the flue gas heat exchanger, equipment utilizing rate of the flue gas heat exchanger is greatly improved, the positioning nets are used by the flue gas heat exchanger at a fixed interval so as to fix the fluorine plastic pipes in the fluorine plastic heat exchange pipe bundles, and shaking deformation of the flexible fluorine plastic pipes caused by flowing impact of flue gas can be avoided.

Owner:北京新世翼节能环保科技股份有限公司

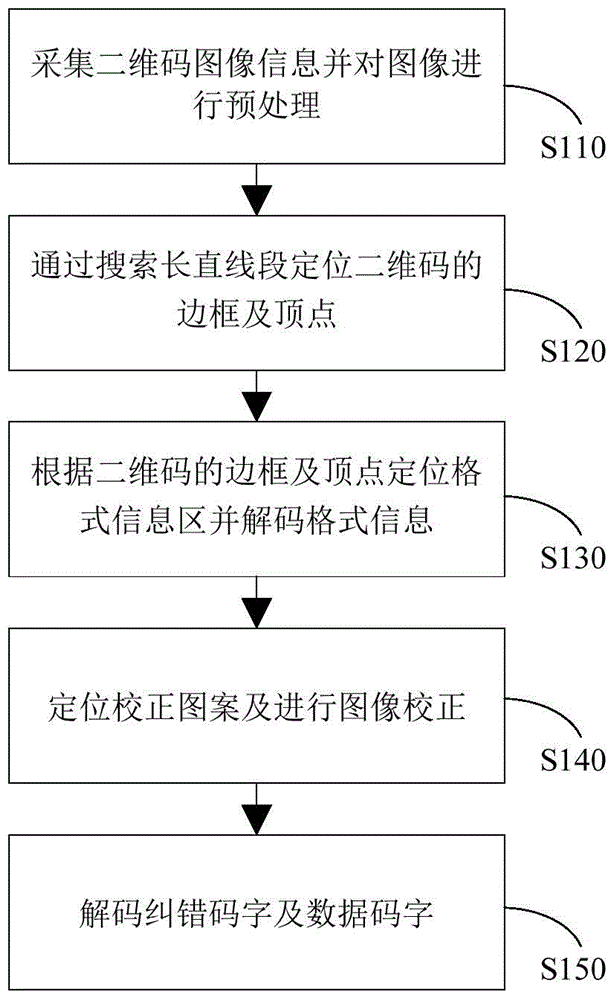

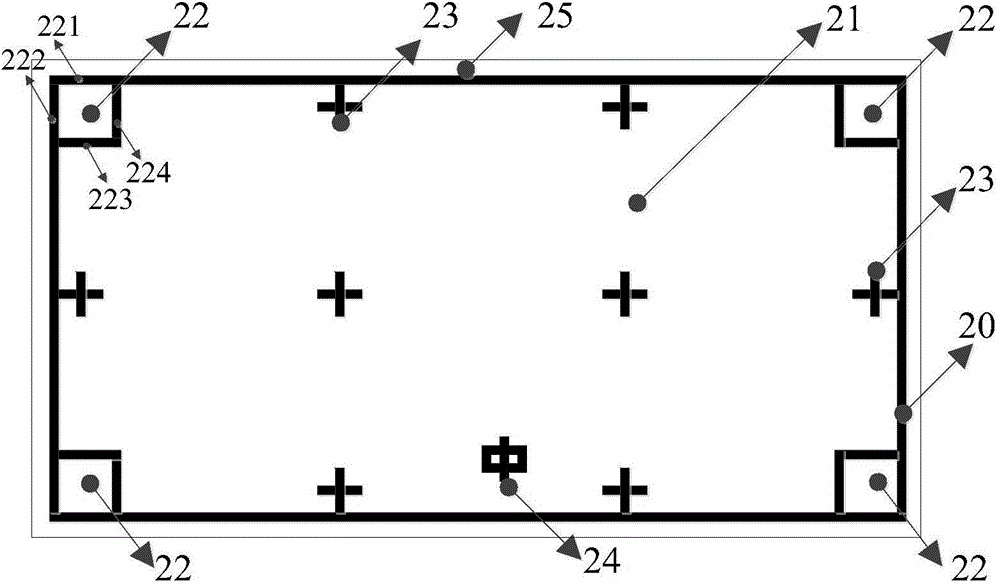

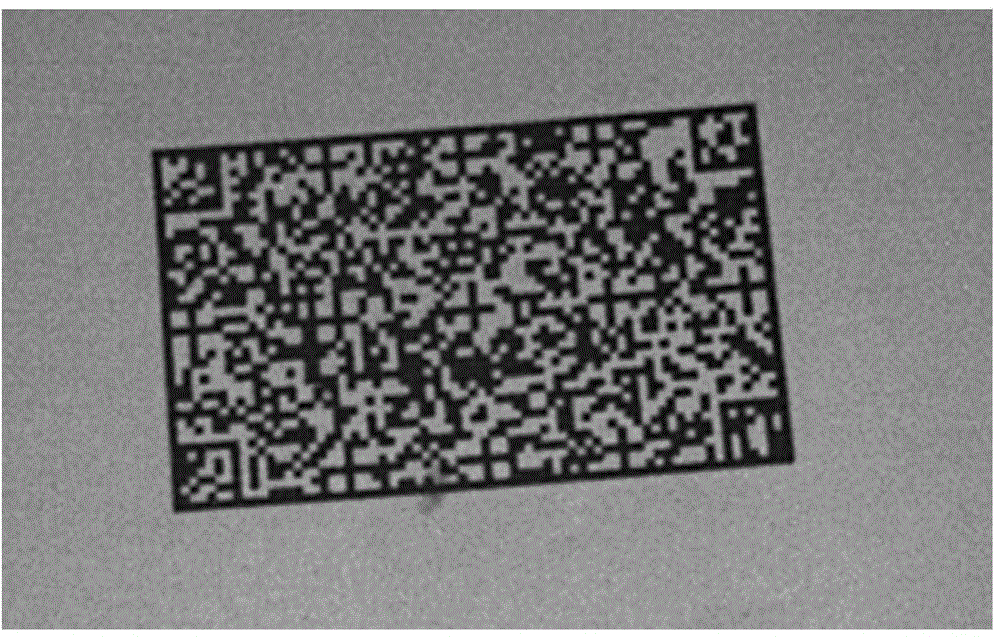

Identification method of two-dimensional code and apparatus thereof

ActiveCN105989317AQuickly locate and obtainFast recognitionSensing by electromagnetic radiationComputer hardwareRapid identification

The invention discloses a method and device for identifying a two-dimensional code. The method includes that the two-dimensional code includes a data coding area, a format information area, a correction pattern, and surrounds the data coding area, the format information area and the The frame of the correction pattern is described, and the specific steps are to collect the two-dimensional code image information and preprocess the image; locate the frame and apex of the two-dimensional code by searching for a long straight line segment; locate the format information area according to the frame and apex of the two-dimensional code and Decoding format information; locating correction patterns and performing image correction; decoding error correction codewords and data codewords. The recognition method can quickly locate and obtain the matrix information of the two-dimensional code, and has the advantages of fast recognition speed, strong anti-fouling and anti-distortion capabilities, and a wide range of applications.

Owner:BEIJING D9ING INST OF INFORMATION ENG CO LTD

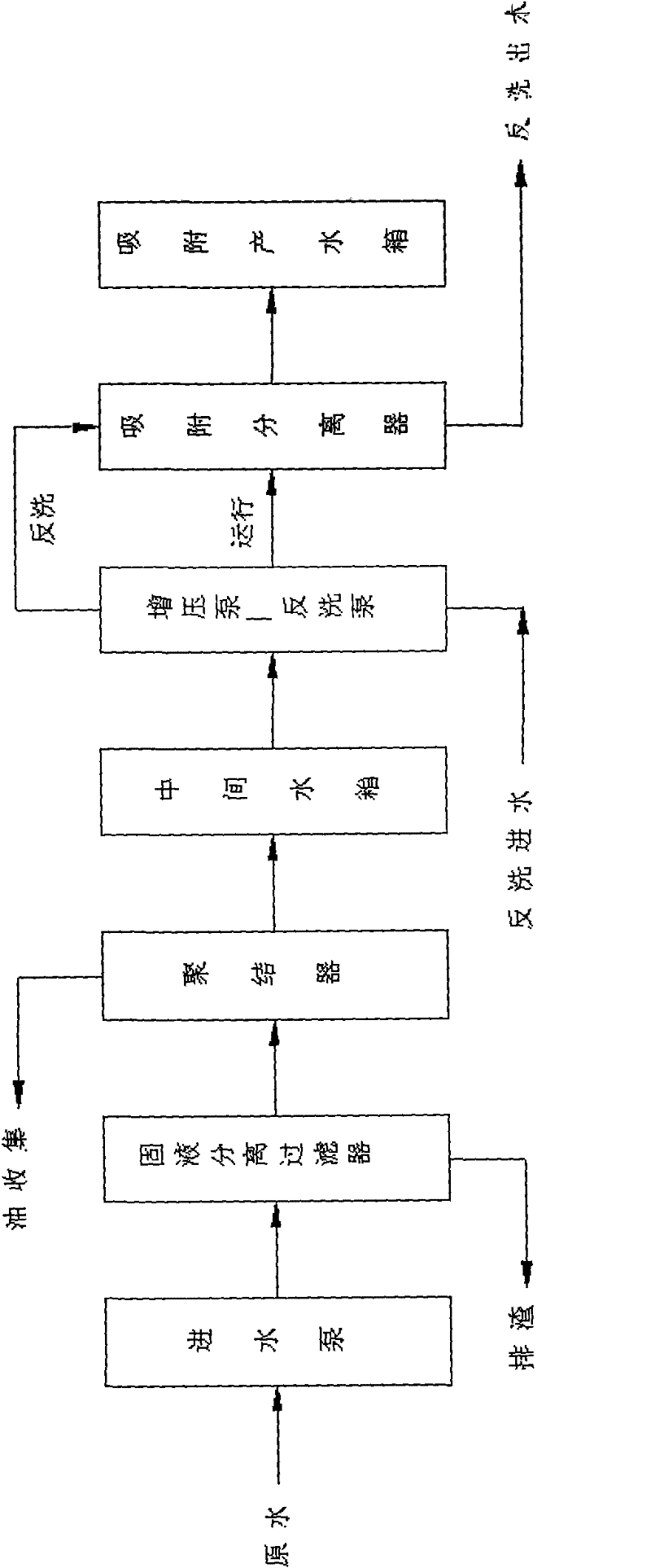

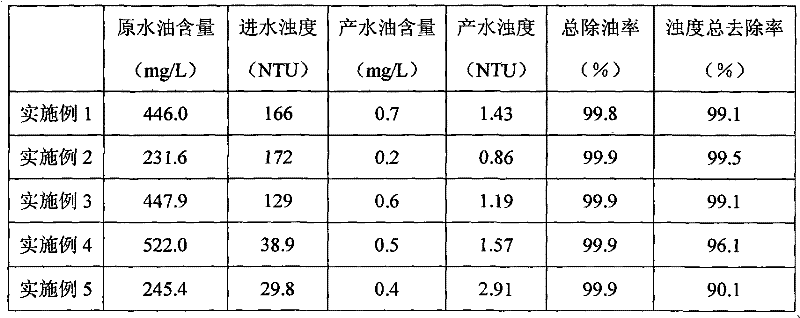

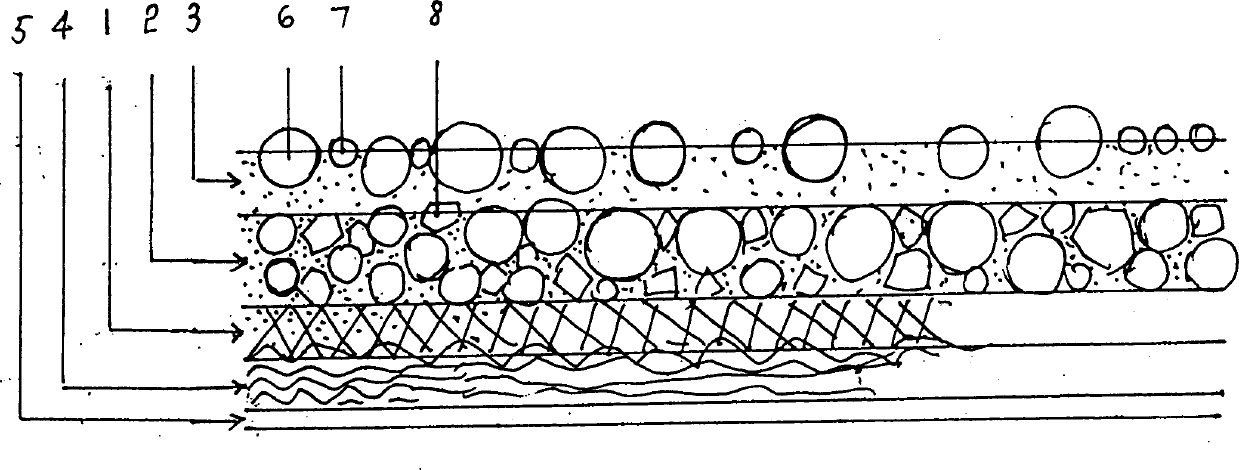

Process for treating oil-containing waste water for ship

InactiveCN102464413AHigh adsorption capacityReduce volumeMultistage water/sewage treatmentWater/sewage treatment by sorptionChemistryOil content

The invention relates to a process for treating oil-containing waste water for a ship. The process comprises the following technical steps of: performing solid and liquid separation, coalescing separation treatment, adsorbing separation treatment and the like on pretreated ship oil-containing waste water sequentially. When the oil content in supplied water is less than or equal to 500 mg / L and the turbidity of the supplied water is less than or equal to 200 NTU, the oil content in discharged water quality is less than or equal to 1 mg / L and the turbidity of the discharged water quality is less than or equal to 5 NTU; and the national standard of the Integrated Pollutant Discharge Standard GB8978-1996 can be met. The method is high in treatment capacity of purifying the oil-containing waste water, namely the waste water treatment amount is up to 10 to 100 m<3> / hr, and is high in purifying efficiency, namely the oil removal rate is more than 99 percent and the turbidity removal rate is more than 90 percent. The process for treating the oil-containing waste water for the ship can be also applied to various types of oil-containing waste water, such as oil-field reinjected water, oil-base oil-containing waste water, metallurgical oil-containing waste water, steel factory oil-containing waste water, machined oil-containing waste water and the like, so that the treated oil-containing waste water can be treated until reaching the standard, and waste oil resources can be recycled.

Owner:浙江瑞普环境技术有限公司

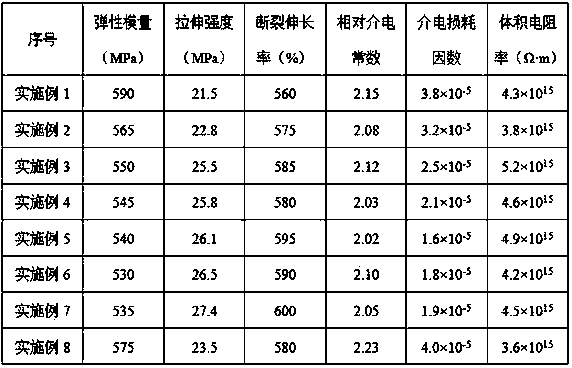

Heatproof antifouling superhigh voltage insulation material and preparation method thereof

InactiveCN105367870AGood compatibilityImprove dispersionPlastic/resin/waxes insulatorsChemistryMagnesium

The invention relates to a heatproof antifouling superhigh voltage insulation material and a preparation method thereof. The material contains the components, by weight, 100 portions of low density polyethylene, 15-20 portions of fluorine silicon resin, 20-30 portions of polytetrafluoroethylene, 5-15 portions of a room temperature vulcanized silicone rubber, 1-5 portions of nano montmorillonite, 0.1-1 portion of sodium dodecyl sulfate, 10-30 portions of distilled water, 5-15 portions of a mixture of nano boron nitride, nano magnesium oxide and nano zinc oxide, 0.8-6 portions of a compatible agent, 1-5 portions of a flame retardant, 0.5-2.5 portions of an antioxidant, and 0.5-5 portions of a crosslinking agent. The heatproof antifouling superhigh voltage insulation material prepared by the invention can effectively restrain space charge accumulation in the cable insulation material, and has the advantages of good mechanical, electrical, thermal and physical properties.

Owner:STATE GRID HENAN ELECTRIC ZHOUKOU POWER SUPPLY

Traffic marking belt of water solube reflecting nano-paint and its making process

InactiveCN1399036ASo as not to damageImprove lane splitting effectTraffic signalsCoatingsExhaust gasPaper sheet

The present invention is prefabricated traffic marking belt comprising base material, reflecting nano-material, nano emulsion, back adhesive, release paper, glass beads with refractive index greater than 1.5 and wear resisting material. The said traffic marking belt has powerful antifouling capacity and high reflecting effect, and can be adhered to road instantaneously and released without producing damage to road. Under sunlight, the traffic marking belt can decompose NOx in tail gas and purify air.

Owner:深圳市夜明珠高新技术有限责任公司

Colored heat insulation anti soak coating material

An insulating color paint resisting water immersion is prepared from white jade powder, nano calcium carbonate, light calcium carbonate, water, talc powder, mica-Ag-Pt powder, water pigment, silicic propylene emulsion, F-C emulsion and assistant through sequentially mixing and reaction. Its advantages are exellent heat insulating and dissipating performance, high resistance to ultravidet ray and dirt, and high weatherability.

Owner:NANXING COATING MATERIAL SCI & TECH GAOMING

Spray type mildew-proof leather polishing agent and preparation method thereof

The invention discloses a spray type mildew-proof leather polishing agent which is characterized by comprising the following components in parts by weight: 5-15 parts of aloe fibroin collagen humectant, 30-50 parts of carnauba wax, 5-7 parts of castor oil, 5-20 parts of dimethyl silicon oil, 0.1-0.5 part of mildew preventive, 0.5-2 parts of cationic surfactant, 0.01-0.1 part of essence and 20-30 parts of water. The spray type mildew-proof leather polishing agent is simple and convenient to use, and the cleaning, maintenance and polishing are finished at one time; the spray type mildew-proof leather polishing agent has strong antifouling ability, does not generate static electricity and prevents dust; the spray type mildew-proof leather polishing agent is neutral and phosphorus-free, contains a benzoic acid preservative and can suppress mildew reproduction; the spray type mildew-proof leather polishing agent resists ultraviolet under strong light and prevents aging and cracking; and with natural aloe component, the spray type mildew-proof leather polishing agent can keep the fullness, elasticity and gloss of leather for long time.

Owner:SUZHOU XIELU NETWORK TECH

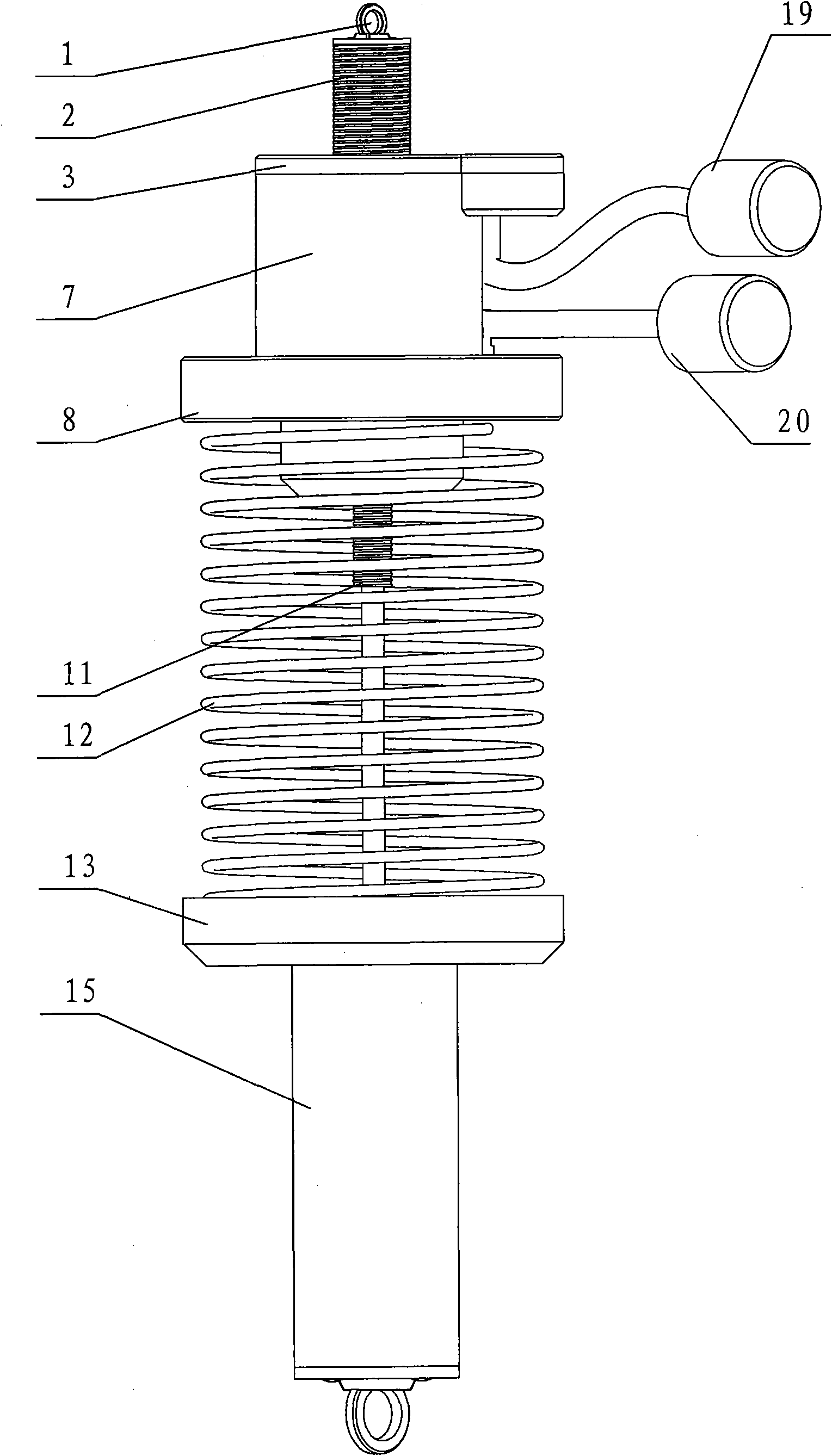

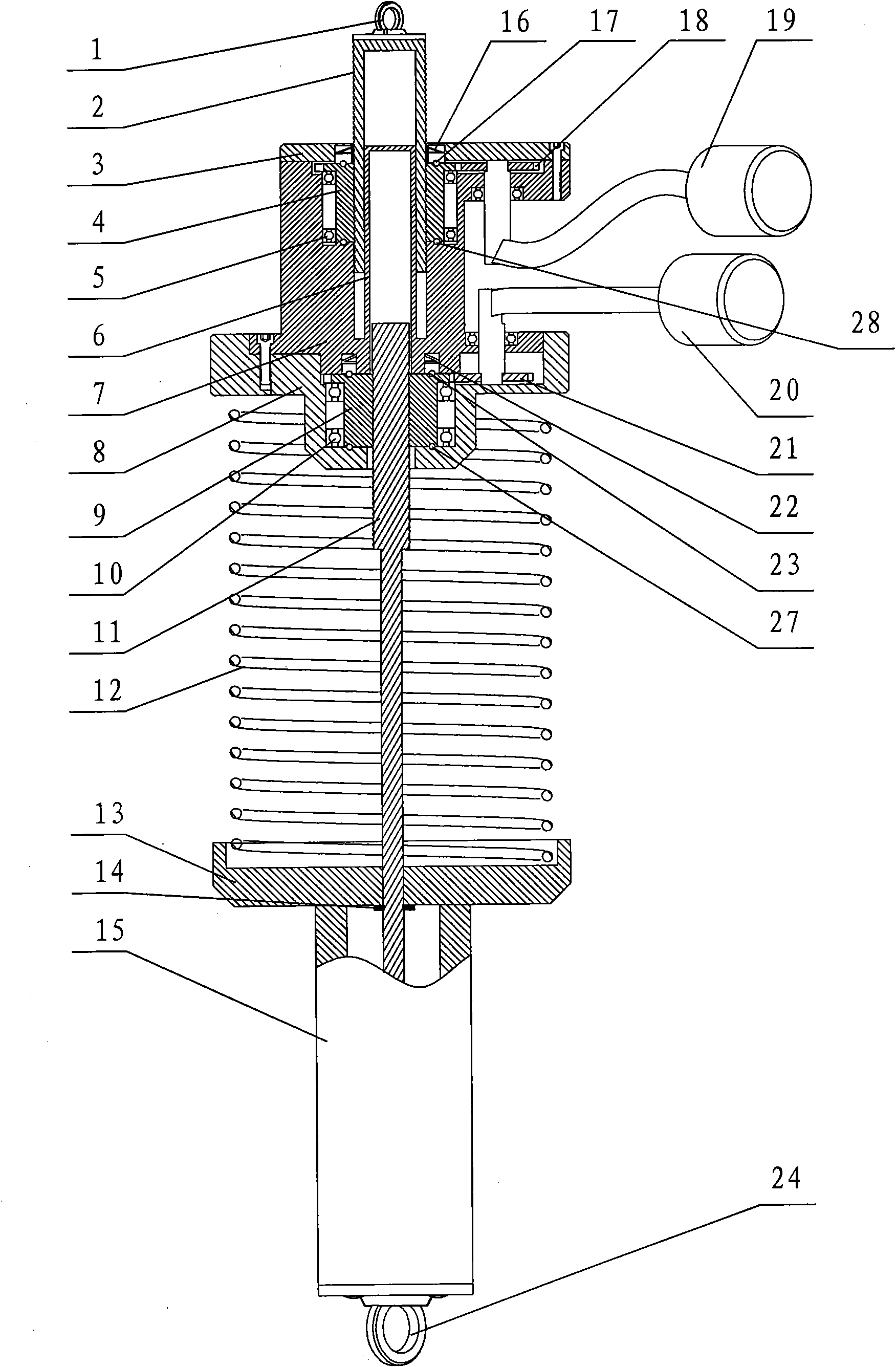

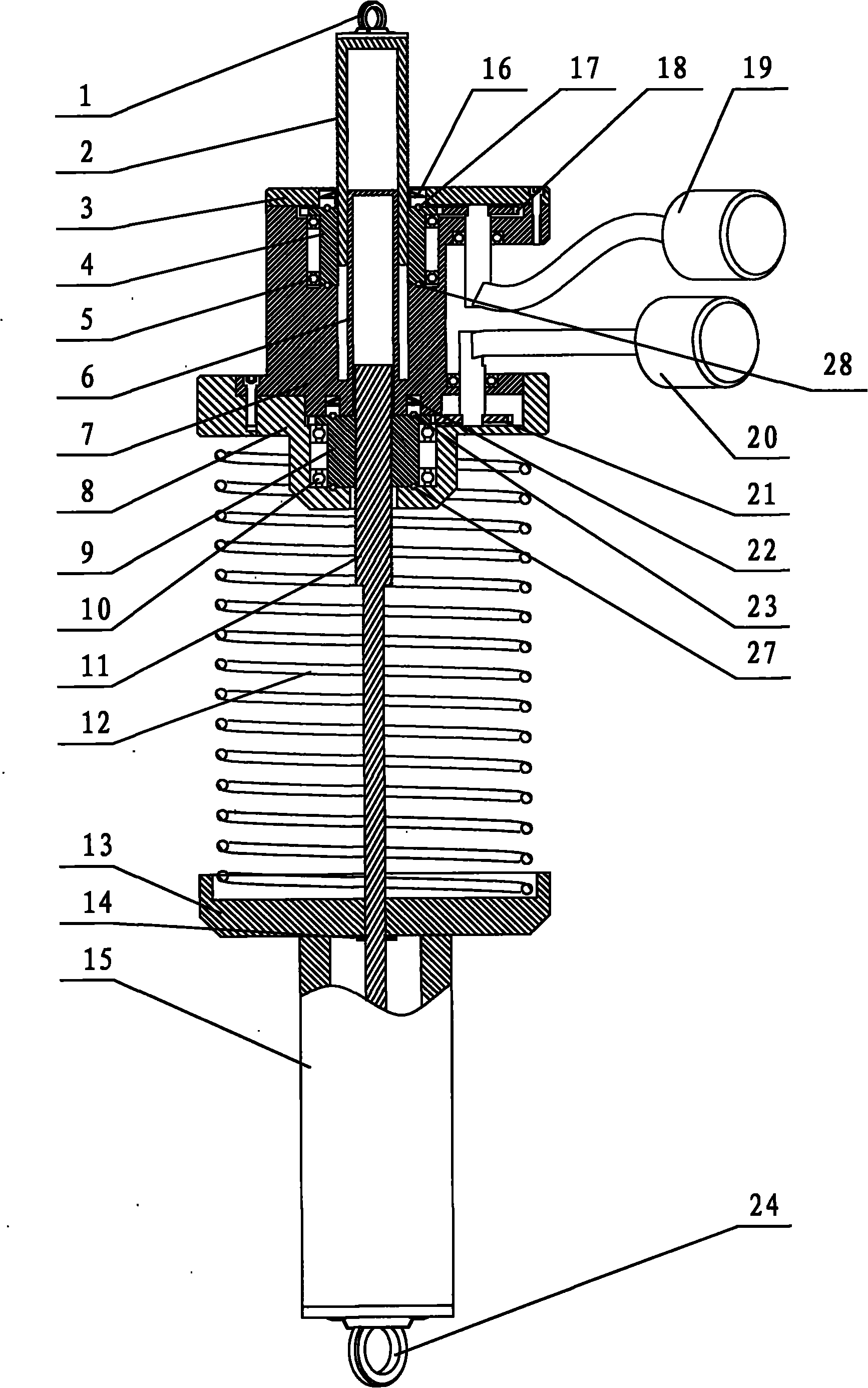

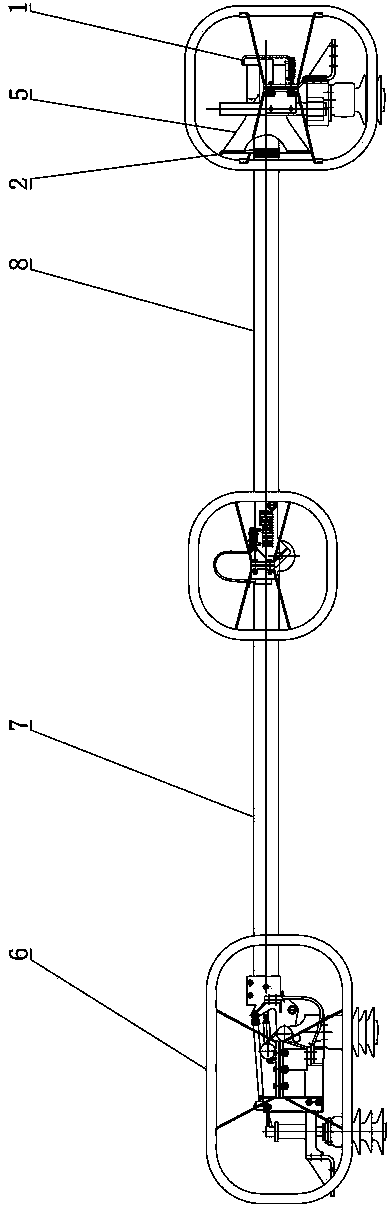

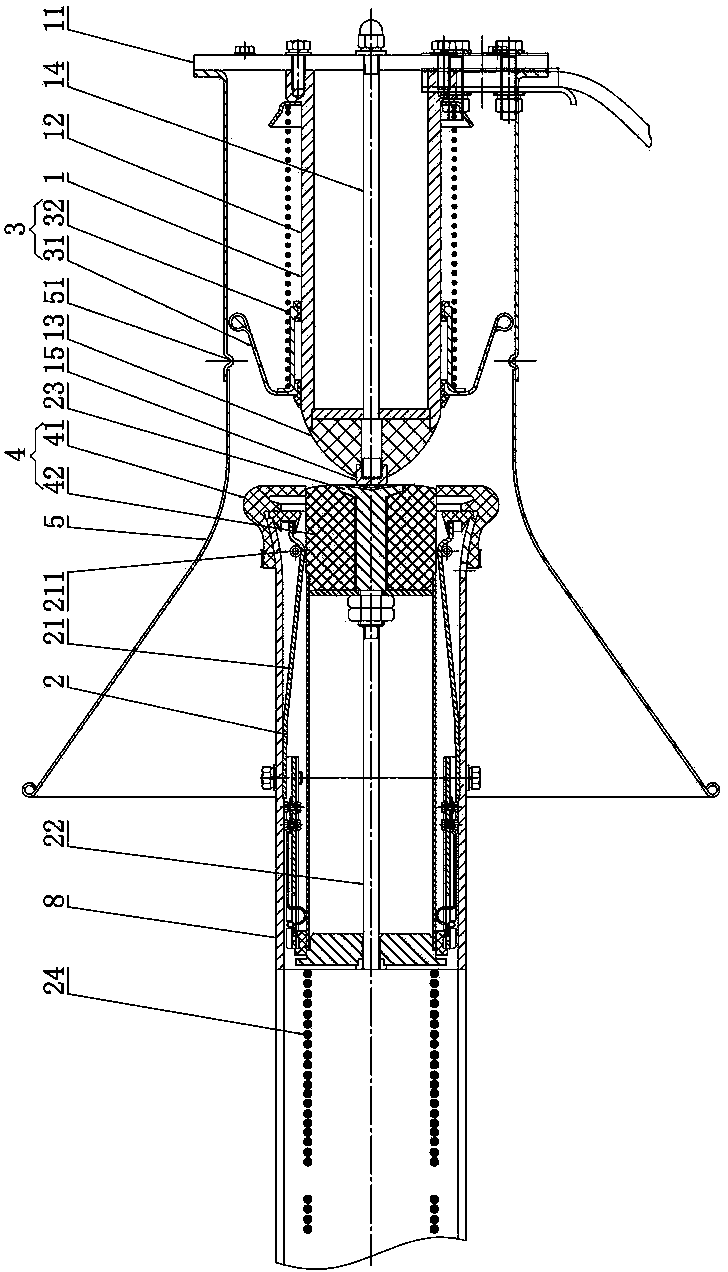

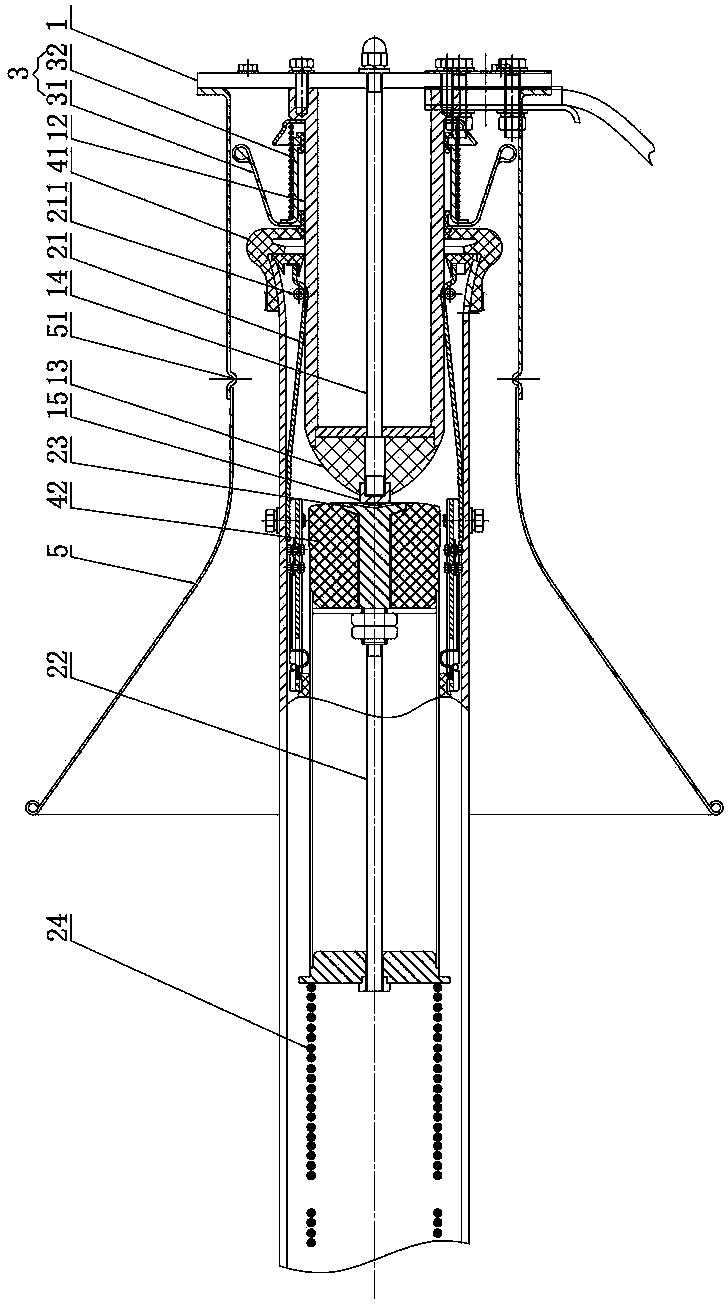

Active type coil spring suspension

The invention discloses an active type coil spring suspension which comprises a spring pre-tightening force regulating device, a suspension height regulating device and a shock absorber (15), wherein the spring pre-tightening force regulating device comprises an upper spring seat (8), a coil spring (12), a lower spring seat (13), a pull rod (11), a pre-tightening driven gear (9) and a pre-tightening power device; the pre-tightening driven gear (9) is rotatably arranged on the upper spring seat (8) through upper and lower bearings (10); the pull rod (11) is connected with the pre-tightening driven gear (9) through thread fit and passes through the upper spring seat (8), the coil spring (12) and the lower spring seat (13); the lower end of the pull rod (11) is provided with a limit clamping piece (14); and the pre-tightening power device is matched with the pre-tightening driven gear (9). After adopting the structure, the coil spring suspension has the advantages of simple structure, light weight, small volume, low failure rate, low production cost, convenient maintenance, good stability, active regulation capability of the spring pre-tightening force and the suspension height, and the like.

Owner:游建春 +1

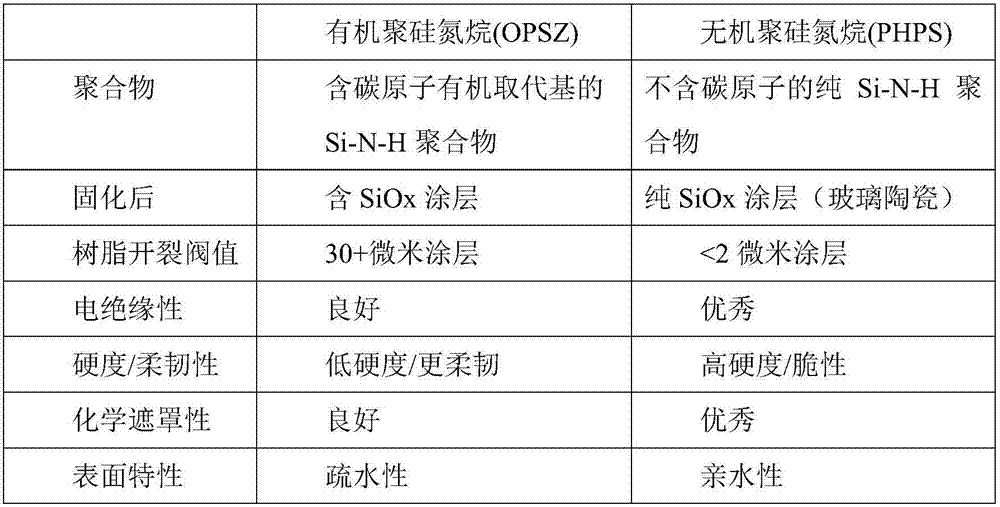

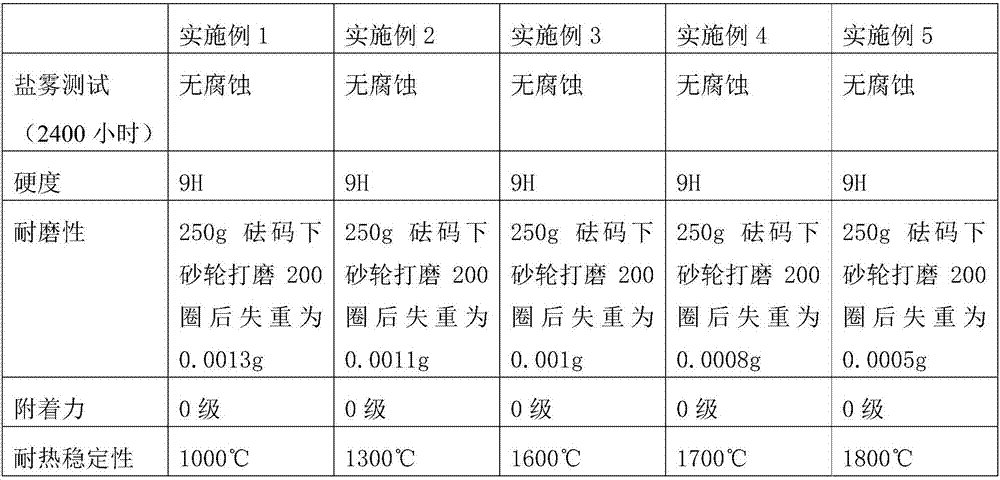

Application of polysiloxane used as coating on kitchen utensil

InactiveCN107307745AImprove performanceHas non-stick propertiesCooking-vessel materialsCoatingsHeat resistanceHardness

The invention provides an application of polysiloxane used as a coating on a kitchen utensil. The inner surface and / or the outer surface of the kitchen utensil is coated with Polysiloxane, and the polysiloxane is used as one or more kinds of a non-stick coating, a hydrophobic and oleophobic coating, a mar-proof coating, a high temperature resistance coating and a stain resistance coating. A formed polysiloxane coating is transparent, accordingly, the coated kitchen utensil not only has aesthetic property, safety and excellent performance, but also has higher heat resistance, the maximum heat resistance temperature can reach 1800 DEG C, and the use process is safe; the coated kitchen utensil has ultrahigh rigidity, the rigidity can reach 9 H+, and the coated kitchen utensil is mar-proof, high in antifouling ability, easy to clean and excellent in anti-corrosion performance; a coated pot cover has hydrophobic property and oleophobic property, and people can better observe the cooking condition of the food in a pot; the method that the polysiloxane is applied to the kitchen utensil is simple and easy to operate, the sanding process of the common coating method can be omitted, the production efficiency is improved, and the problems of environmental pollution and noise caused by the sanding process are further reduced.

Owner:GUANGDONG UNIV OF TECH +1

Switching-on mechanism of high-voltage isolation switch

ActiveCN104282451ASimple structureAntifoulingContacts enclosures/screensAir-break switch detailsEngineeringHigh pressure

The invention discloses a switching-on mechanism of a high-voltage isolation switch. The switching-on mechanism comprises a static contact component and a moving contact component, the static contact component comprises a current-conducting plate and a static contact, and one end of the static contact is fastened on the current-conducting plate. The moving contact component comprises an annular moving contact, the annular moving contact is arranged on the inner wall of an upper conductive tube of the isolation switch, and the outer wall of the static contact is sleeved with the annular moving contact under the motion of the upper conductive tube to achieve switching on. The static contact component and the moving contact component are each provided with a sealing component, and the sealing components enable the static contact component and the moving contact component to be isolated from the outside air. The switching-on mechanism of the high-voltage isolation switch is simple in structure and reliable in motion and has the contamination and freezing prevention functions.

Owner:CHANGGAO ELECTRIC GROUP CO LTD

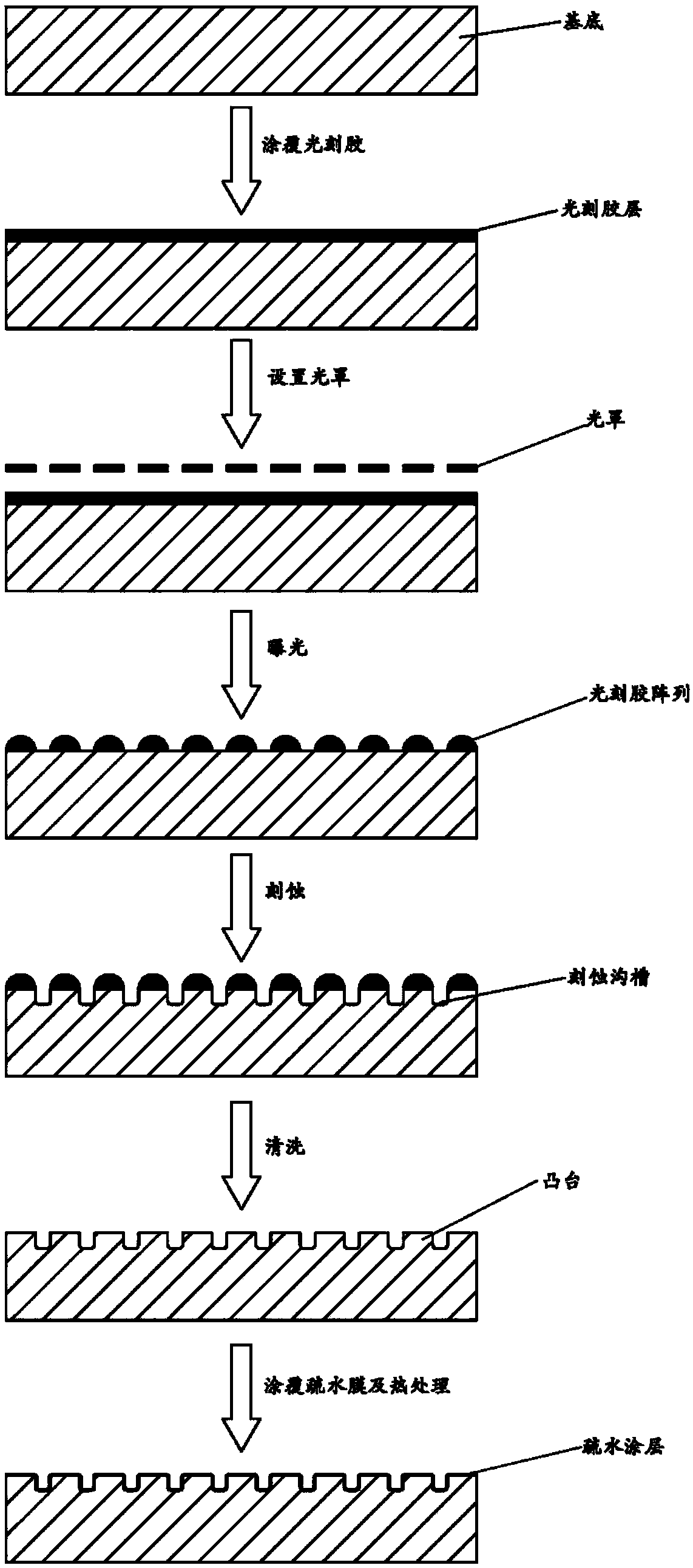

Anti-fouling substrate and preparation method thereof

InactiveCN107564865AImprove wear resistanceAccurate and controllable sizeSemiconductor/solid-state device detailsSolid-state devicesWear resistanceSubstrate surface

The invention discloses an anti-fouling substrate, which comprises a substrate. The surface of the substrate at least has one function region. At least a part of the function region has a coating layer. The function region has a plurality of bumps. The average height of the bumps is 10-2000 nm; the average upper surface area of the bumps is 78-1.964*10<5> nm<2>; and the average interval between adjacent two bumps is 7-5000 nm. The coating layer is made of a hydrophobic material. The invention also discloses a preparation method of the anti-fouling substrate. The prepared anti-fouling substratehas higher anti-fouling performance and abrasion resistance, and the substrate has multiple choices; the anti-fouling substrate can realize etching on the substrate surface directly, so that the problem of poor surface abrasion resistance can be solved; meanwhile, by controlling surface etching depth, sample surface appearance can be controlled; and the preparation method of the anti-fouling substrate is low in production cost, simple in process and can realize large-scale batch production.

Owner:CHAOZHOU THREE CIRCLE GRP

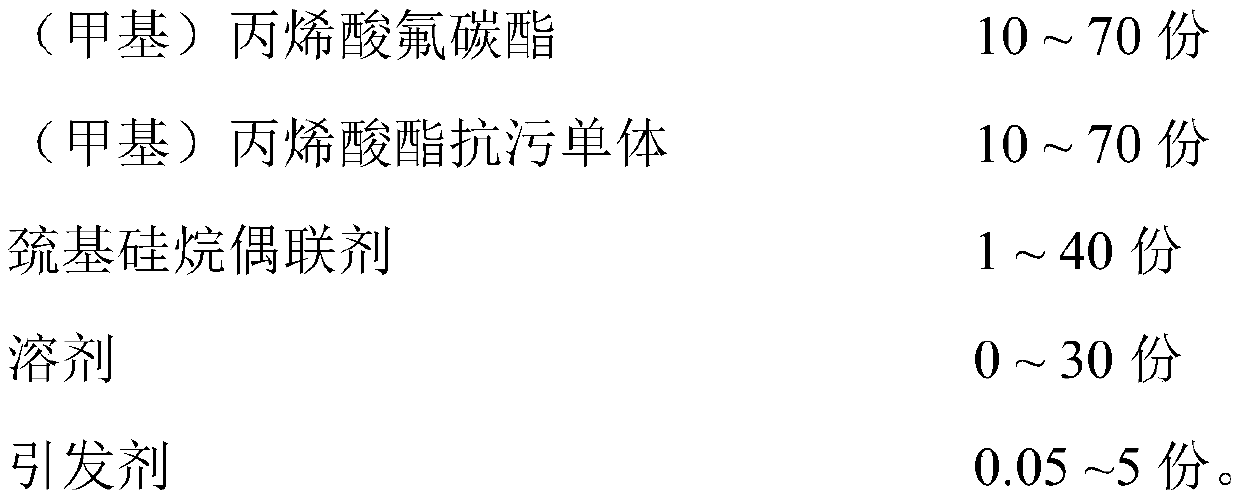

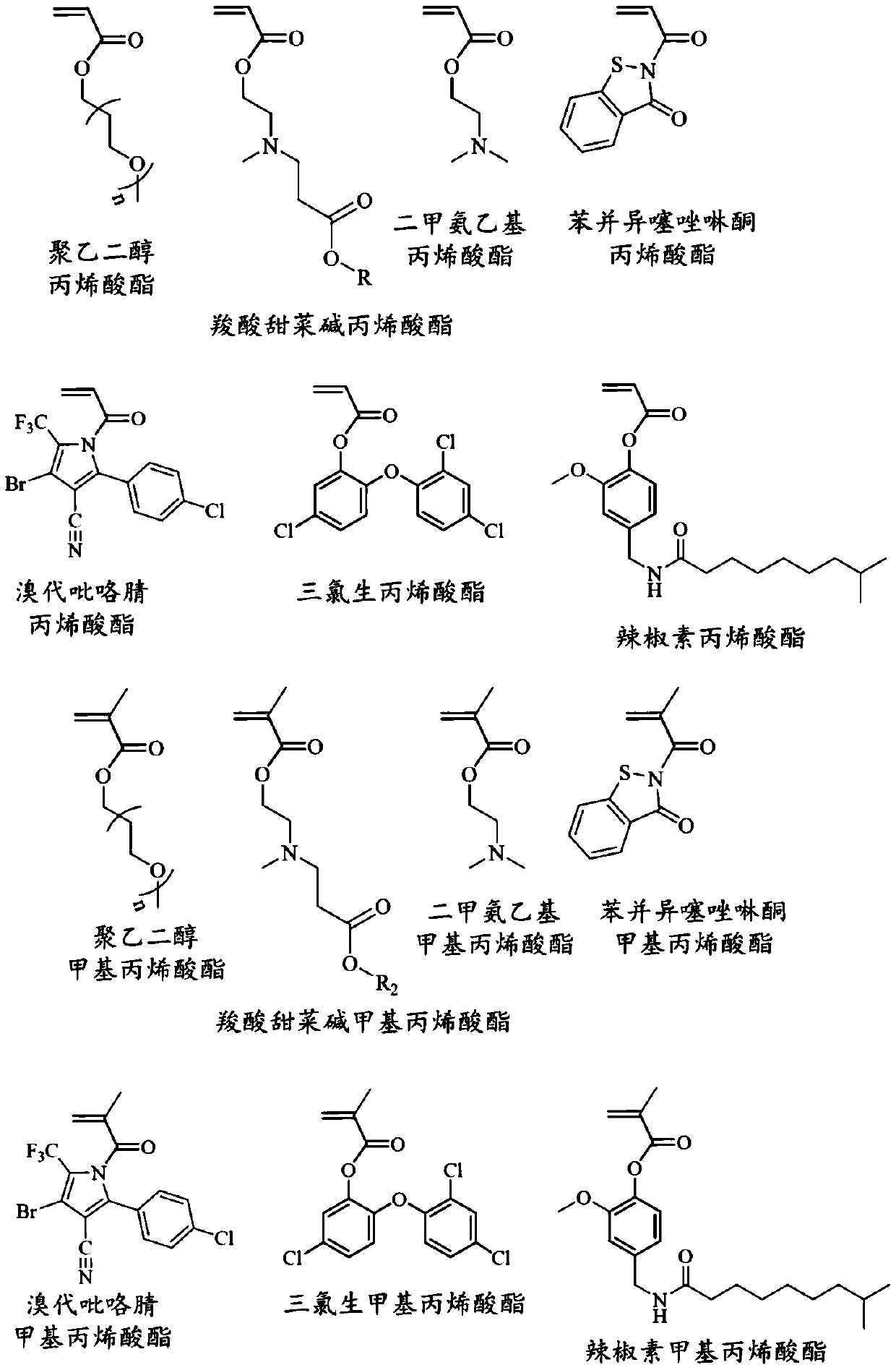

Static anti-fouling self-layering organosilicon coating and preparation method and application thereof

ActiveCN110218519APersistent fouling resistanceStrong antifouling abilityAntifouling/underwater paintsPaints with biocidesSolventChemistry

The invention discloses static anti-fouling self-layering organosilicon coating and a preparation method and application thereof. The coating includes an A component and a B component, wherein the A component includes 50-90 parts of silanol-terminated polydimethylsiloxane, 1-40 parts of a fluorocarbon ester-anti-fouling monomer telomer, 0.1-10 parts of a catalyst, and 0-30 parts of a solvent; theB component is 5-20 parts of silicate ester; the fluorocarbon ester-anti-fouling monomer telomer is prepared from (meth)acrylate fluorocarbon ester, a (meth)acrylate anti-fouling monomer, a mercapto silane coupling agent, an initiator and a solvent. The coating can form self-layering coatings with anti-fouling functional groups being enriched on surfaces of the coatings, thus endowing a material with excellent fouling resistance. Through the organosilicon, the coating has good decontamination ability. The self-layering material can meet anti-fouling requirements of ships with low speeds, offshore oil platforms and other facilities, and has excellent drag reduction performance.

Owner:SOUTH CHINA UNIV OF TECH

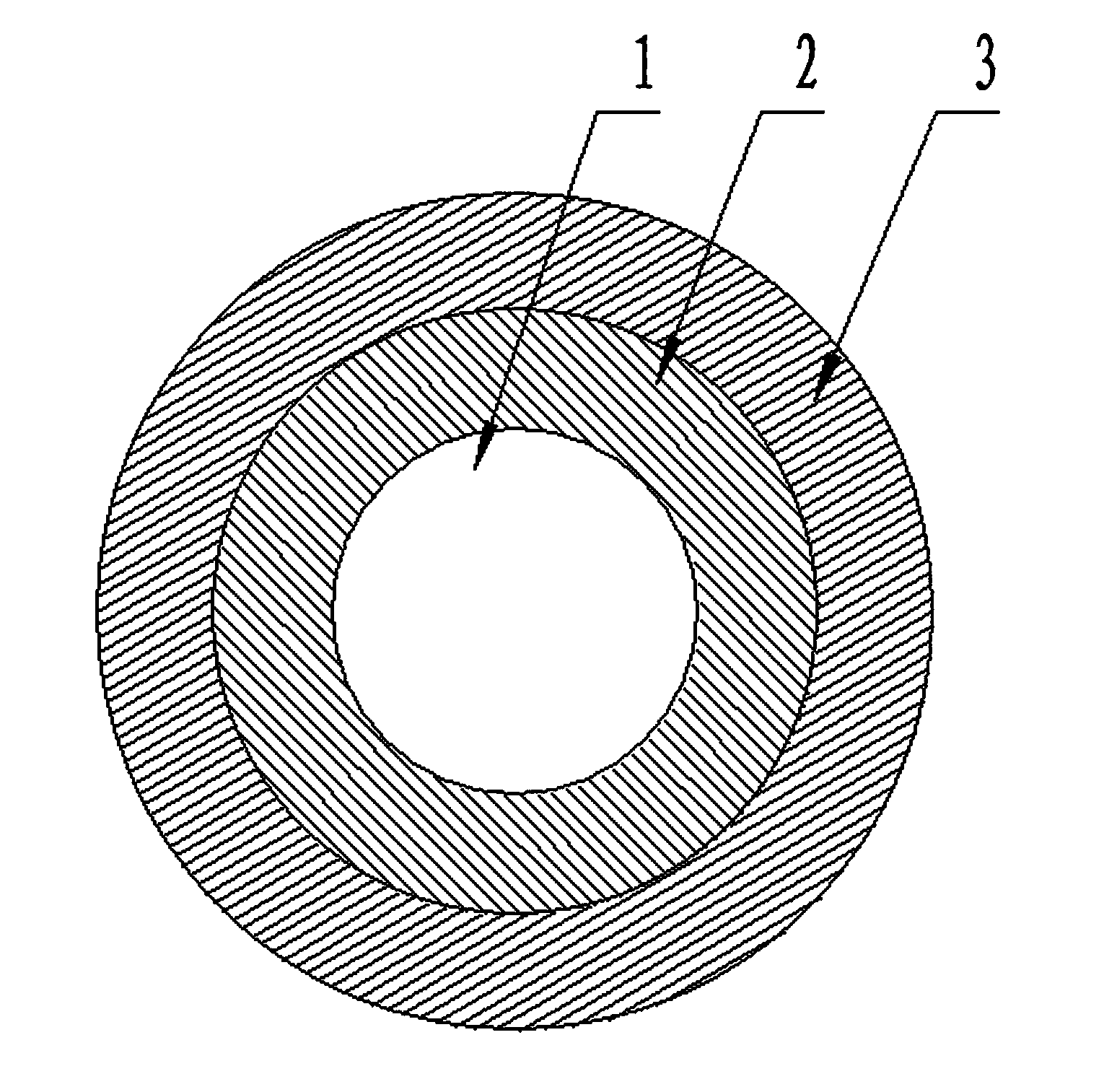

Fan-shaped rotary film separation device

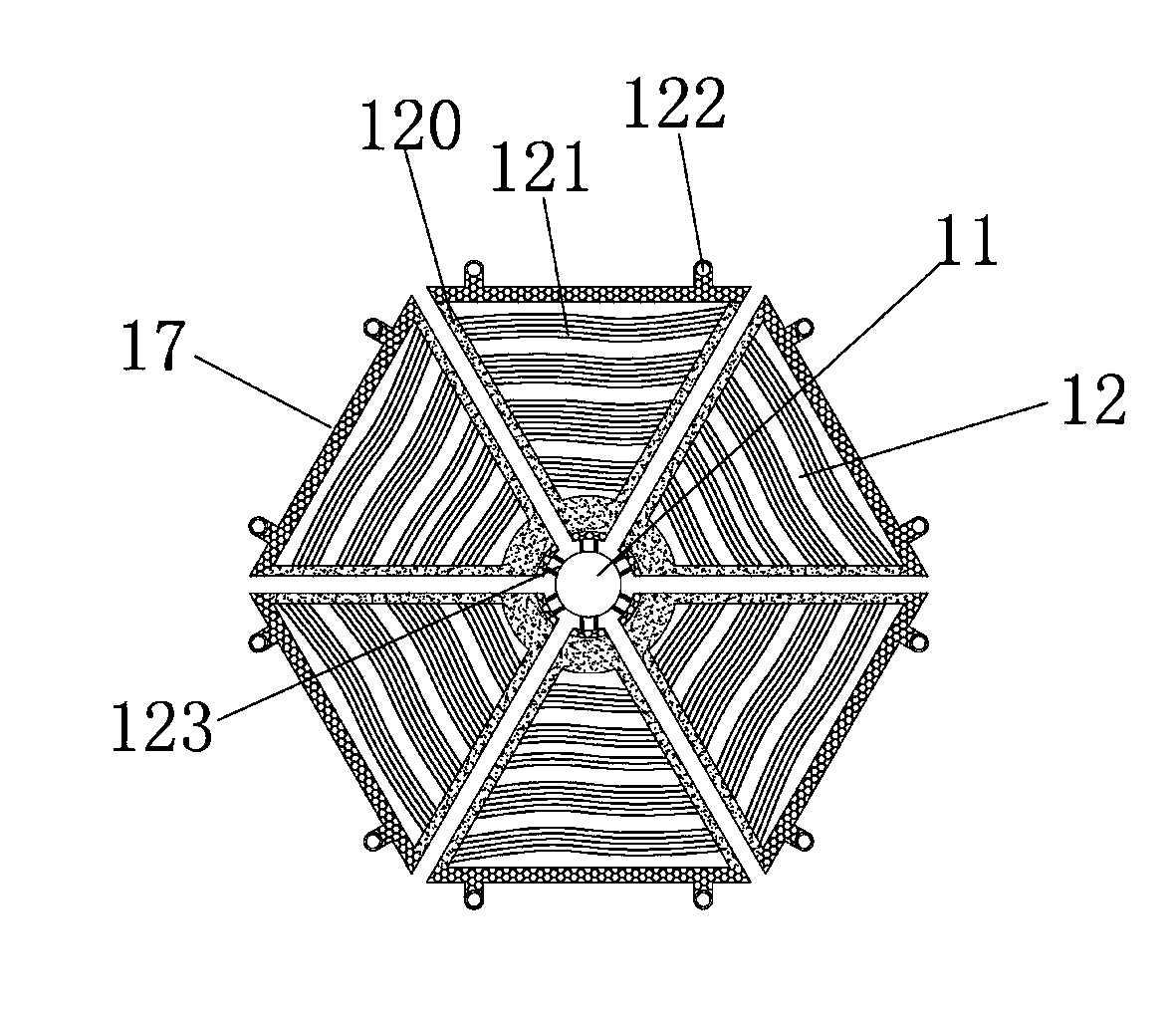

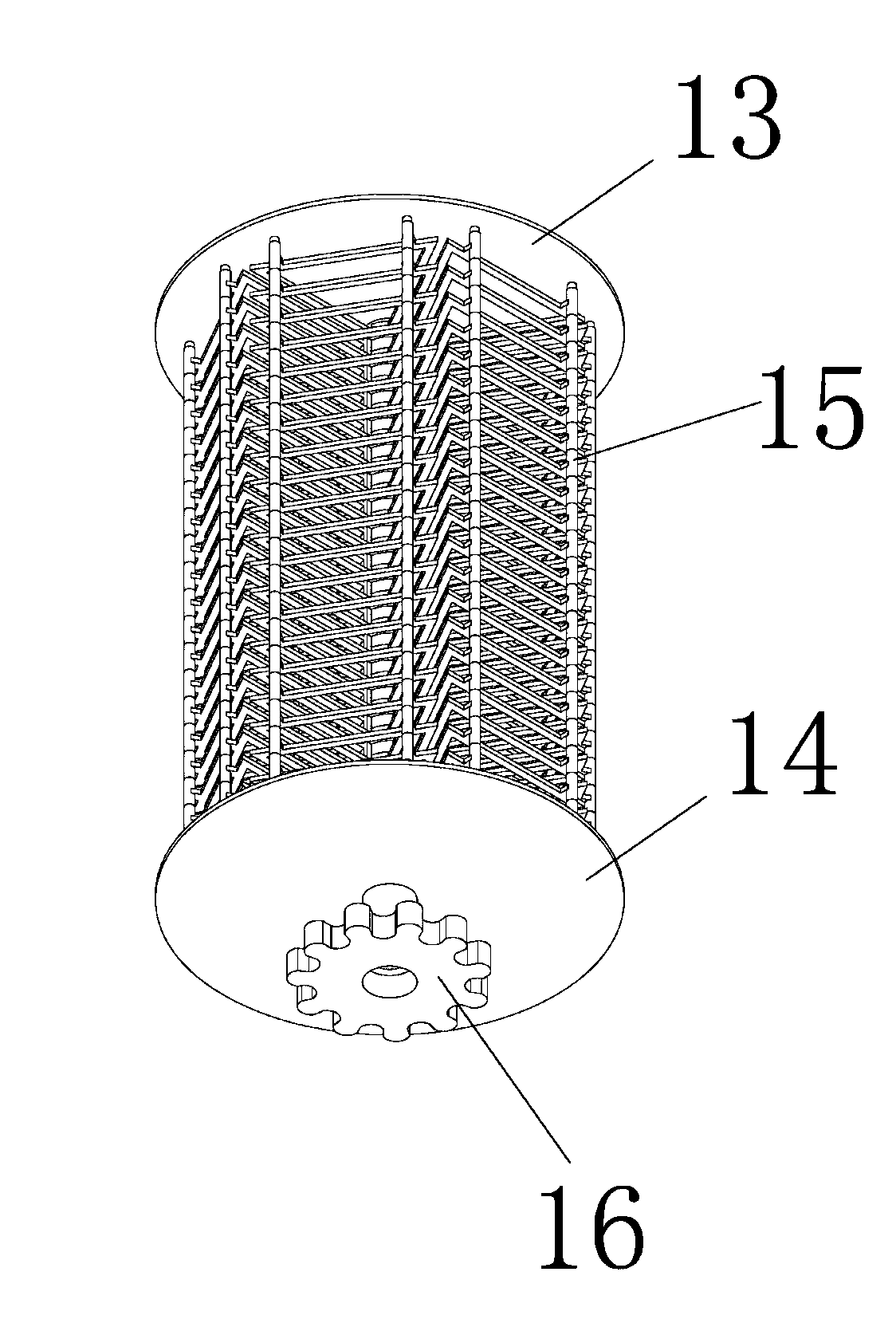

ActiveCN103316591AIncrease packing densityImprove filtration throughputSemi-permeable membranesPipingEngineering

The invention discloses a fan-shaped rotary film separation device which comprises a central water-collecting pipe, an upper tray and a lower tray, wherein a transmission gear is arranged at one end of the central water-collecting pipe; the fan-shaped rotary film separation device is characterized in that multiple turntables are distributed between the upper tray and the lower tray, each turntable consists of at least three fan-shaped film components; water collecting pipes are arranged on two sides and the inner sides of the fan-shaped film components; hollow fiber film filaments are filled in the fan-shaped film components; water outlets are formed in the inner sides of the fan-shaped film components; the water outlets are connected with the central water-collecting pipe; fixing holes are formed in the outer sides of the fan-shaped film components; multiple fixing posts are arranged on the outer circumferences of the upper tray and the lower tray; the fixing holes are fixedly formed in the fixing posts. Compared with other rotary film devices, the fan-shaped rotary film separation device has the advantages of high filling density, high filtration flux and the like; moreover, a film is conveniently replaced, and the aim of replacing the film can be fulfilled by replacing a fan-shaped film components only.

Owner:VISBE XIAMEN ENVIRONMENT TECH CO LTD

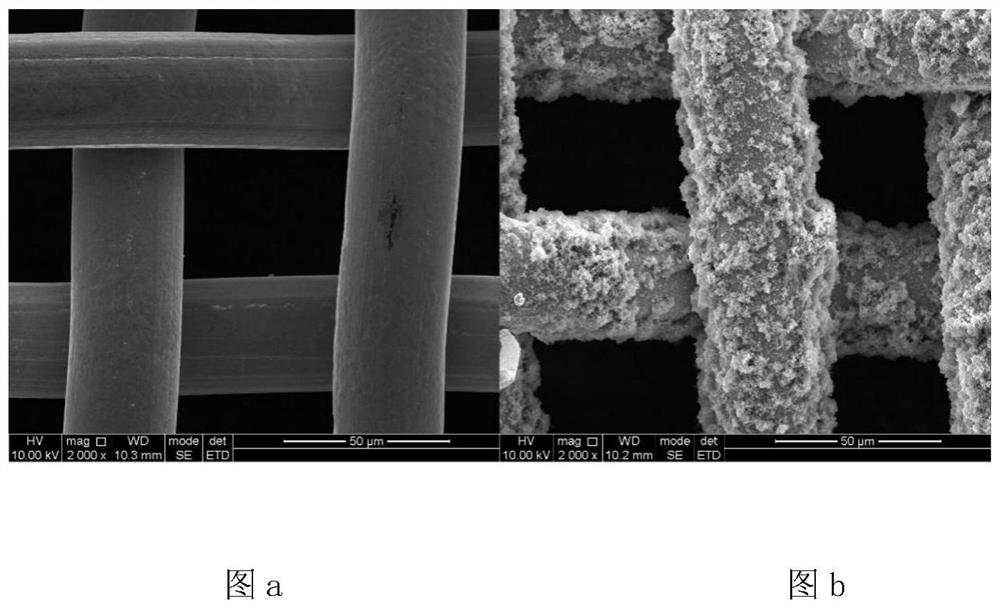

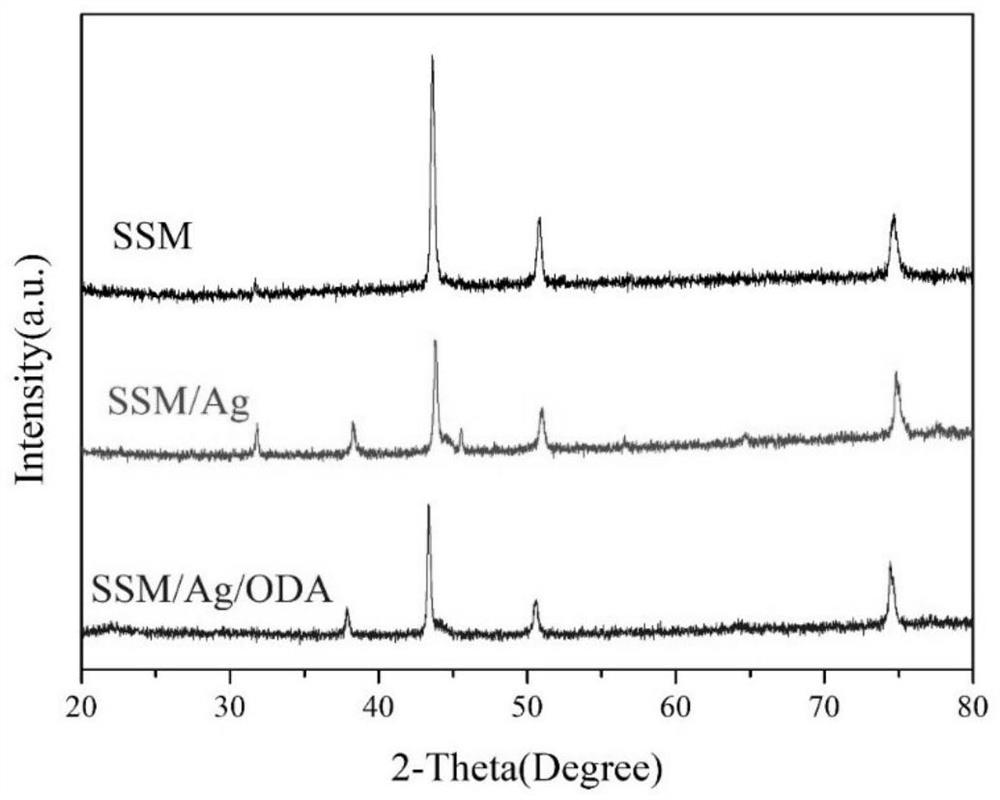

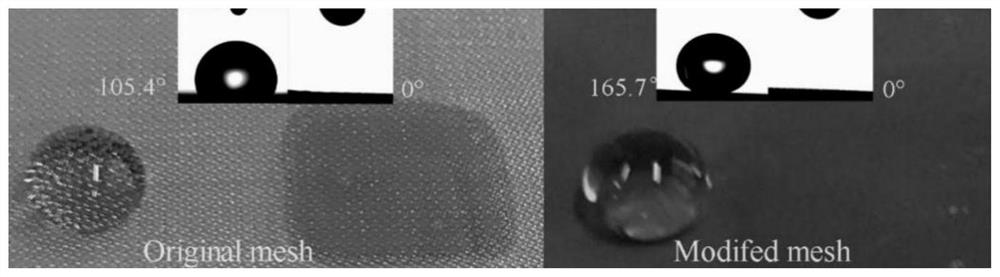

Super-hydrophobic metal net based on bionic mussels as well as preparation method and application of super-hydrophobic metal net

PendingCN111871003AStrong stabilityGood toleranceLiquid separationNanoclustersEnvironmental chemistry

The invention discloses a super-hydrophobic metal net based on bionic mussels as well as a preparation method and application of the super-hydrophobic metal net, and belongs to the technical field ofoil-water separation materials. The preparation method comprises the following steps: pretreating a metal net to remove oxides and grease on the surface; immersing the metal net in a dopamine solution, a metal salt solution and a long-chain amino compound solution with certain concentrations in sequence for reaction, and finally drying. The preparation method provided by the invention is simple, environment-friendly, low in energy consumption, low in cost and beneficial to large-scale production; the metal wire mesh is covered with a layer of rough metal nanoclusters, has high acid resistance,alkali resistance, salt resistance, organic solvent resistance and antibacterial performance, can achieve efficient separation of heavy oil and light oil mixtures in the oily wastewater under the action of gravity, is applied to treatment of the oily wastewater, and has the separation efficiency as high as 99.8%.

Owner:SOUTHWEST PETROLEUM UNIV

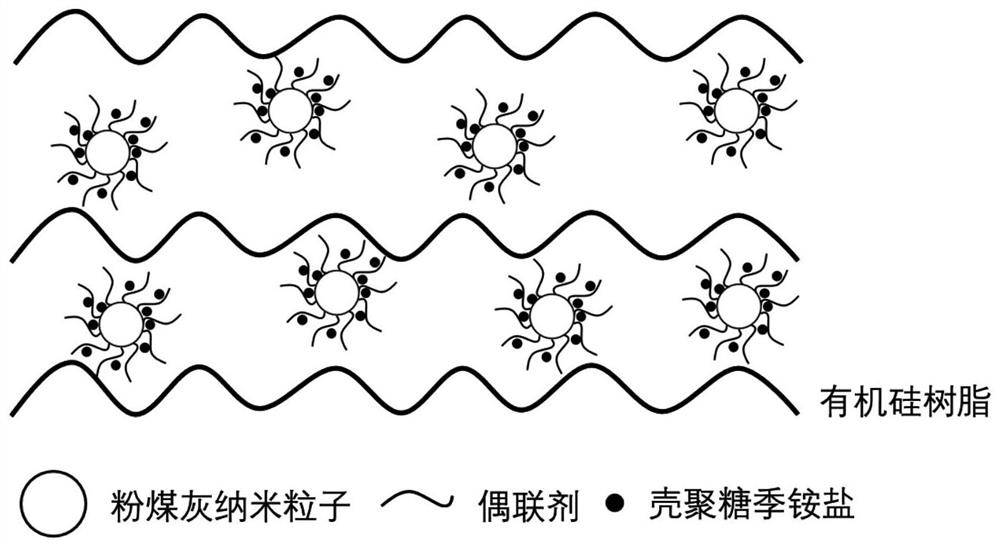

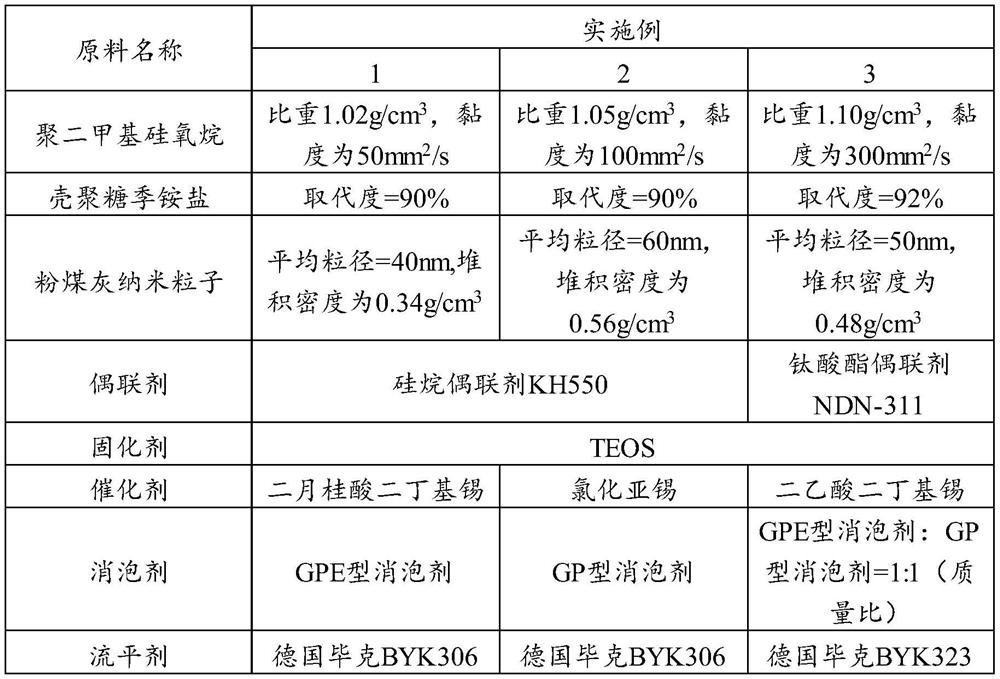

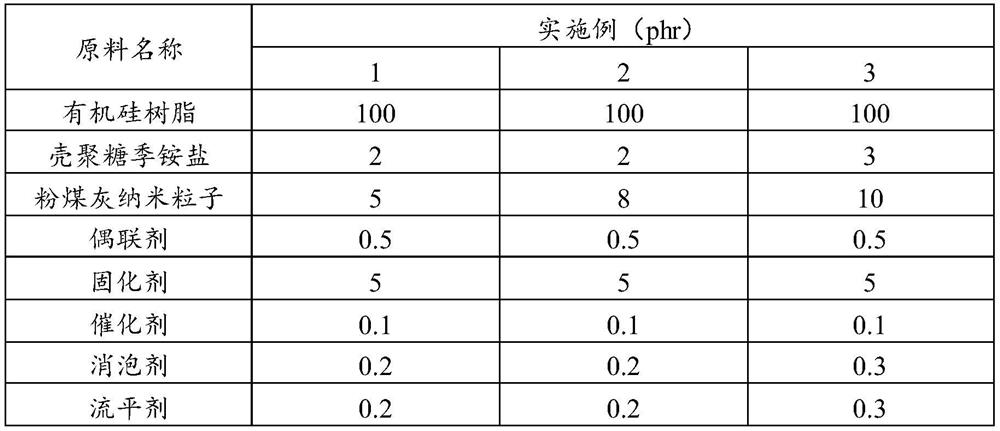

Non-toxic marine ship antifouling coating material and preparation method thereof

ActiveCN111793431AHigh strengthIncrease elasticityAntifouling/underwater paintsPaints with biocidesOrganosolvFirming agent

The invention provides a non-toxic marine ship antifouling coating material, which is prepared from the following raw materials in parts by mass: 100 parts of organic silicon resin, 1 to 3 parts of achitosan quaternary ammonium salt, 5 to 10 parts of fly ash nanoparticles, 0.5 to 1 part of a coupling agent, 3-5 parts of a curing agent, 0.01 to 0.1 part of a catalyst, 0.2 to 0.5 part of an antifoaming agent, and 0.2 to 0.5 part of a leveling agent. According to the invention, organic silicon resin is used as a matrix, nano fly ash is used as a carrier, and a chitosan quaternary ammonium salt loaded on the surface is used as a main antifouling agent, wherein the chitosan quaternary ammonium salt has good solubility and antibacterial property, has biocompatibility, and is safe and non-toxic,the fly ash nanoparticles have strong alkalinity, and the organic silicon is also a low surface energy material; by using a hydrophilic chitosan quaternary ammonium salt as a main antibacterial material, so that the use of a large amount of organic solvents is avoided, the cost is low, and less waste liquid is generated; and fly ash nanoparticles are activated to promote the self-polymerization of organic silicon resin molecules to form a layered structure with certain orientation so as to enhance the strength and elastic modulus of the coating material.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Pretreatment filling liquid applied to artificial inorganic stone and pretreatment method and application thereof

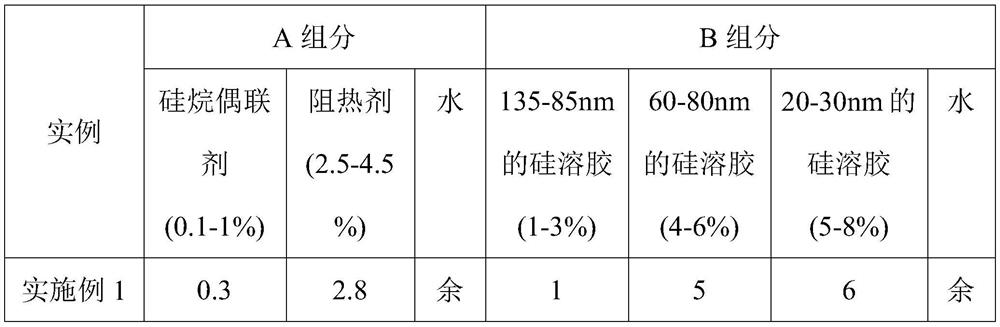

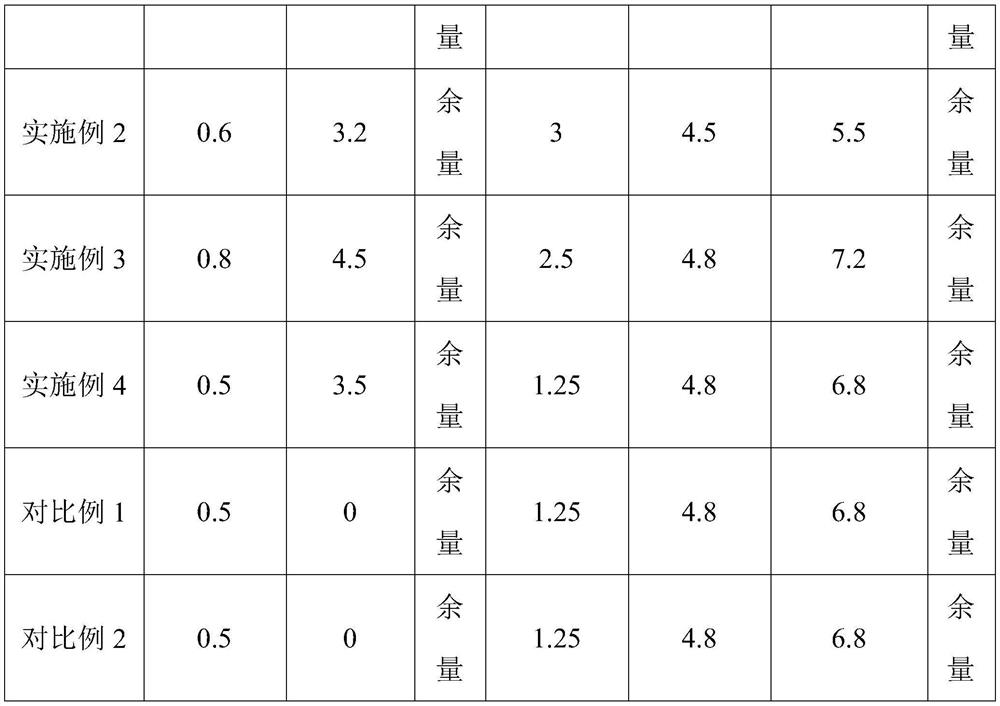

ActiveCN112680114AExcellent ring white repair abilityStrong antifoulingPolishing compositions with abrasivesGrinding/polishing apparatusPretreatment methodPhysical chemistry

The invention discloses a pretreatment filling liquid applied to artificial inorganic stone and a pretreatment method and application thereof, the pretreatment filling liquid comprises a component A and a component B, and the component A comprises 0.1-1% by mass of a silane coupling agent; and the component B is composed of a plurality of silica sol fillers with different particle sizes, and specifically comprises the following components in percentage by mass: 1-3% of silica sol with the particle size range of 135-85 nm, 4-6% of silica sol with the particle size range of 60-80 nm and 5-8% of silica sol with the particle size range of 8-30 nm. According to the pretreatment filling liquid disclosed by the invention, all the components are compounded, and meanwhile, a grinding and polishing process is improved, so that the produced artificial stone can achieve excellent effects in the aspects of ring white repairing capability, antifouling capability and glossiness.

Owner:GUANGDONG NADE NEW MATERIALS CO LTD

Antifouling, antistatic and water-based graphene-silicon-modified fluoroacrylic resin paint and preparation method thereof

InactiveCN109627896AHigh hardnessImprove anti-static effectAntifouling/underwater paintsPaints with biocidesWater basedDimethyl siloxane

The invention relates to antifouling, antistatic and water-based graphene-silicon-modified fluoroacrylic resin paint. The paint is prepared from, by weight, 50.0-70.0 parts of graphene-silicon-modified fluoroacrylic resin, 3.0-6.0 parts of dipropylene glycol butyl ether, 5.0-25.0 parts of pigments and fillers, 4.0-10.0 parts of an auxiliary agent and 10.0-20.0 parts of deionized water, wherein thegraphene-silicon-modified fluoroacrylic resin is prepared by a reaction of a hard acrylate monomer, a soft acrylate monomer, a fluoroolefin monomer, dimethylolpropionic acid, polytetrahydrofuran ether diol, hydroxypropyl-terminated polydimethylsiloxane, secondary distilled water, polyisocyanate, graphene, hydroxyethyl acrylate, anhydrous methanol and a neutralizing agent. The antifouling, antistatic and water-based graphene-silicon-modified fluoroacrylic resin paint prepared by the method has the advantages of high hardness, good antistatic property, high crosslinking density, great corrosionresistance, low surface tension, excellent antifouling capability, superior acid and alkali resistance and the like. The paint can be used as wood paint, metal paint, marine paint and the like.

Owner:UNION FOSHAN CHEM +1

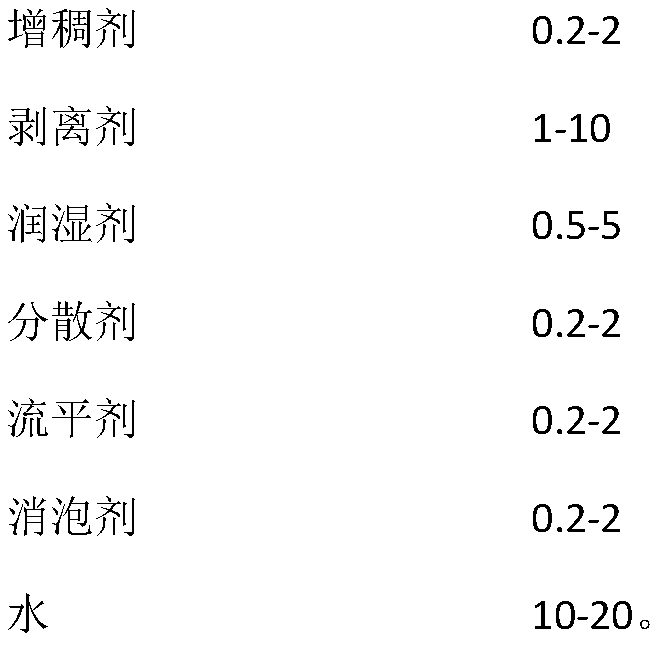

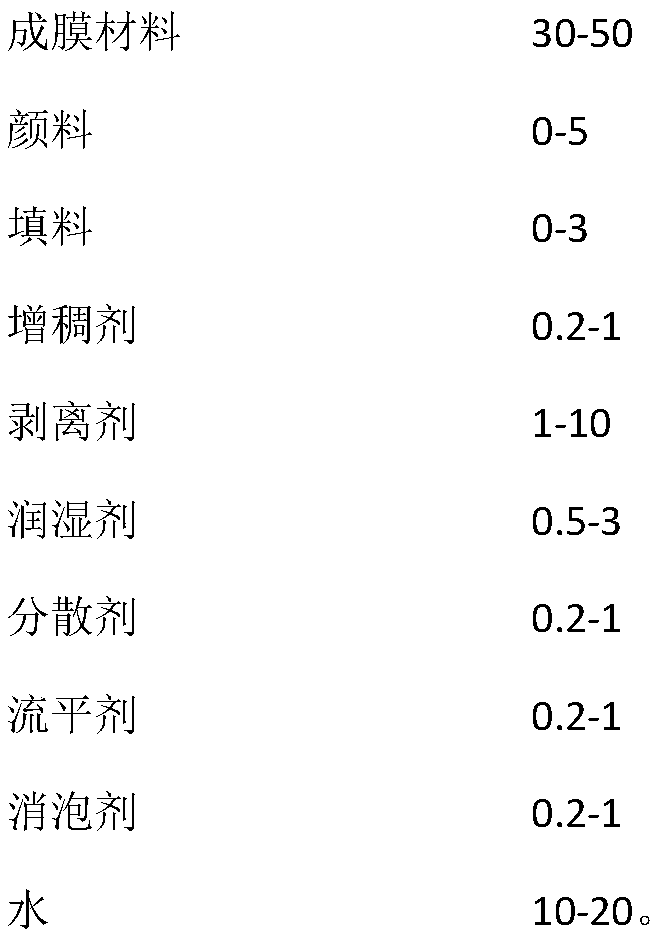

A kind of water-based peelable coating and preparation method thereof

ActiveCN107828322BExcellent peelabilityStrong cohesionPolyurea/polyurethane coatingsDefoaming AgentsRaw material

Owner:上海韦奇化工有限公司

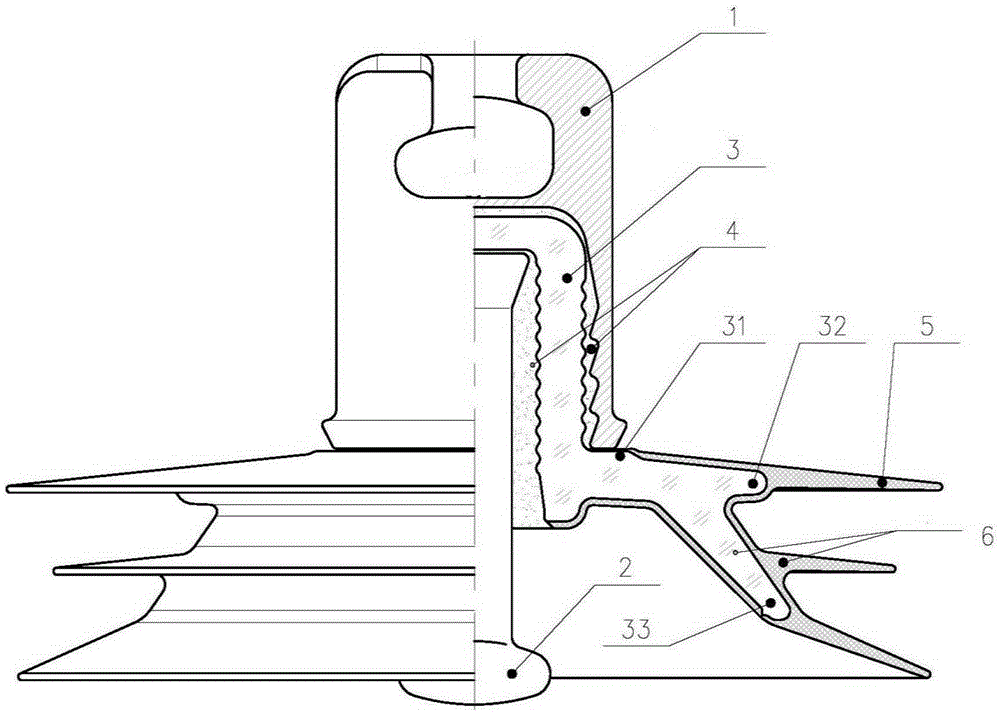

Glass composite insulator and manufacturing method therefor

ActiveCN105355340AStrong antifoulingBalance stressSuspension/strain insulatorsSupporting insulatorsRubber materialGlass composites

A manufacturing method for a glass composite insulator is disclosed. The manufacturing method comprises the following steps: a skeleton umbrella edge structured glass part is moulded; a silicone rubber umbrella cover is covered and wrapped with the glass part; an assembling mold integral injection mode is adopted; due to the use of the assembling mold, the silicone rubber umbrella cover (with multiple umbrella skirts) is integrally molded, so that the molded silicone rubber umbrella cover is attractive in appearance, high in efficiency, and less in interfaces, the electrical performance of the product is improved; a multi-point symmetrical type adjustable glue injection technology is adopted to be matched with a mold cavity pressure control scheme in the molding process in order to balance the stress conditions of each point on the glass part to prevent the glass part from being crushed; the mold cavity is integrally subjected to vacuumizing processing to reduce the generation of rubber material bubbles; iron caps and steel caps are cemented with insulating parts through cement adhesive, so that the influence on the cement adhesive performance caused by the high temperature of the molds is avoided, and the mechanical property dispersion of the product is greatly reduced; the cement adhesive is not covered with the silicone rubber, so that the product completely follows the zero self-destruction characteristic of the glass insulator; and the influence on the umbrella cover molding caused by the central straightness of caps generated by cement adhesive fittings is avoided.

Owner:南京电气绝缘子有限公司

Colorful color-changing mobile phone shell with anti-counterfeiting and anti-scratching functions and manufacturing method thereof

InactiveCN104191759AAvoid scratchesInhibit chafingSynthetic resin layered productsTelephone set constructionsEngineeringPet substrate

The invention provides a colorful color-changing mobile phone shell with anti-counterfeiting and anti-scratching functions. A complex adhesive layer is used for pasting a colorful color-changing PET (PET (Poly Ethylene Terephthalate) substrate layer on an insulation plastic layer; the anti-scratching layer is arranged on the upper surface of the colorful color-changing PET substrate layer; the anti-counterfeiting layer is arranged on the upper surface of the anti-scratching layer. The manufacturing method of the mobile phone shell comprises the following steps: extruding by virtue of a twin-screw extruder to form the insulation plastic layer, coating the upper surface of the insulation plastic layer with the complex adhesive layer, pasting the colorful color-changing PET substrate layer on the upper surface of the complex adhesive layer; curing the upper surface of the colorful color-changing PET substrate layer by virtue of an UV device to obtain the ant-scratching layer; and finally pasting anti-counterfeiting labels made from anti-counterfeiting ink on the upper surface of the anti-scratching layer or directly spraying codes on the upper surface of the anti-scratching layer by virtue of the anti-counterfeiting ink so as to obtain the anti-counterfeiting layer. The mobile phone shell is capable of effectively preventing objects such as fingers, pendants and the like from scratching and rubbing the mobile phone shell; the manufacturing method of the mobile phone shell is simple, easy to operate and suitable for industrial production.

Owner:TAICANG OURUI INTELLIGENT ENG

Method of stone-like surface treatment for glass-ceramic surface

InactiveCN102079628AWith three-dimensional effectImprove the decorative effectGrainstoneRoom temperature

The present invention discloses a method of the stone-like surface treatment for a glass-ceramic surface, which comprises the following steps: 1. cleaning the surface to be treated and drying; 2. putting gelatin into water to be dissolved for later use; 3. coating the obtained glue on the surface to be treated, and controlling the thickness of the glue layer within 0.5-3 millimeters; 4. placing for more than 3 hours at the room temperature, and then placing for more than 4 hours within the temperature range of 50 DEG C-80 DEG C; and 5 cleaning the surface after the layer bursts. The core technology of the method is the control of the drying process and by using different drying curves of several preferred programs to get different styles of surface effects. The glass-ceramic surface has the same random three-dimensional effects as the surface texture of the natural stones like white marble; and besides, compared with the materials without processing the invention, has better functions of decoration, soil resistance and skid resistance.

Owner:骆水根

Antifouling treatment technology for soft light tile

The invention relates to the technical field of architectural ceramics, and concretely relates to an antifouling treatment technology for a soft light tile. The technology comprises the following steps: 1, polishing: a tile body enters a polishing line and is polished, wherein the optimal arrangement method of a plurality of abrasive blocks is as follows: 16 groups of 150-mesh elastic abrasive blocks, 8 groups of 240-mesh elastic abrasive blocks, 5 groups of 230-mesh elastic abrasive blocks, 10 groups of 400-mesh elastic abrasive blocks, 8 groups of 600-mesh elastic abrasive blocks, 3 groups of 180-mesh carbon brush abrasive blocks, 13 groups of 240-mesh fiber abrasive blocks and 9 groups of 320-mesh fiber abrasive blocks; 2, the polished tile body undergoes ultra-clean and ultra-bright treatment; and 3, the treated tile body undergoes antifouling treatment by using a nano-liquid, wherein the mass proportion of the nano-liquid is adjusted according to the luminosity and glaze requiredby the surface of the tile and the size of fired capillary pores. The soft light tile with a high quality, a strong antifouling capability and a good soft light effect can be produced through the antifouling treatment technology for the soft light tile.

Owner:山东狮王陶瓷有限公司

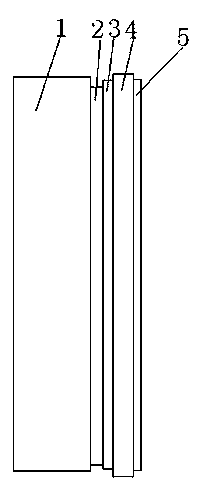

Composite sleeve penetrating through cabinet

InactiveCN103545765AIncrease the insulation withstand voltageImprove installation convenienceInsulating bodiesEngineeringElectric power

The invention discloses a composite sleeve penetrating through a cabinet. The composite sleeve comprises a power bus pipe composed of an electric conduction copper bar core, wherein the electric conduction copper bar core is at least wrapped by a composite silicone rubber layer, a flange plate is arranged in the middle of the power bus pipe, the power bus pipe is divided into a first power bus pipe section and a second power bus pipe section through the flange plate, and umbrella skirts are arranged on the outer surface, located on the first power bus pipe section, of the composite silicone rubber layer. The composite sleeve has the advantages of being long in creepage distance, capable of resisting oxidation, high in pollution resistant capacity and convenient to install, and the service life of the high-voltage switch cabinet can be effectively prolonged.

Owner:安徽宇宝电气有限公司

Wear-resistant oil-resistant leather special for automobile headrest

InactiveCN105132603AWith layers of protectionStrong antifoulingLeather surface mechanical treatmentLeather surface finishingWaxWear resistant

The invention relates to the technical field of leather production, in particular to wear-resistant oil-resistant leather special for an automobile headrest. Soft leather is obtained and then is sequentially subjected to bottom coating, rolling finishing, middle coating, top coating, lustring and throwing swelling treatment, and then the wear-resistant oil-resistant leather special for the automobile headrest is obtained. In the step of bottom coating, rolling coating treatment achieved by dissolving a penetrating agent and color-changing wax in water and spraying treatment achieved by dissolving positive ion acrylic resin and a positive ion wax agent in water are used. In the step of rolling finishing, a tumbling barrel is used for rolling finishing. In the step of middle coating, spraying treatment is conducted after dye and leather grease are dissolved in water. In the step of top coating, spraying treatment is conducted after a feeling agent and nitrocotton mist gloss oil are dissolved in water. The finished leather obtained through the method is high in oil resistance and does not need to be washed frequently, the service life of the leather is prolonged, and the original gloss of the leather is maintained to the maximum extent; the wear-resistant oil-resistant leather is high in anti-pressure capacity and not prone to damage in use.

Owner:HAINING SENDE LEATHER

Colorful color-changing mobile phone shell with anti-counterfeiting and anti-scratching functions

InactiveCN104191758AAvoid scratchesInhibit chafingSynthetic resin layered productsTelephone set constructionsPet substrateMobile phone

The invention provides a colorful color-changing mobile phone shell with anti-counterfeiting and anti-scratching functions. The colorful color-changing mobile phone shell comprises an insulation plastic layer, a complex adhesive layer, a colorful color-changing PET (Poly Ethylene Terephthalate) substrate layer, an anti-scratching layer and an anti-counterfeiting layer, wherein the complex adhesive layer is used for pasting the colorful color-changing PET substrate layer on the upper surface of the insulation plastic layer; the anti-scratching layer is arranged on the upper surface of the colorful color-changing PET substrate layer; the anti-counterfeiting layer is arranged on the upper surface of the anti-scratching layer. According to the mobile phone shell, UV reactive fluorine surfactant is added into light-cured resin, so that the mobile phone shell has relatively high antifouling property; the anti-scratching capability is controlled between 3H and 6H; the anti-scratching layer formed after being cured by the light is capable of effectively preventing objects such as fingers, pendants and the like from scratching and rubbing the mobile phone shell; a manufacturing method of the mobile phone shell is simple, easy to operate and suitable for industrial production.

Owner:TAICANG OURUI INTELLIGENT ENG

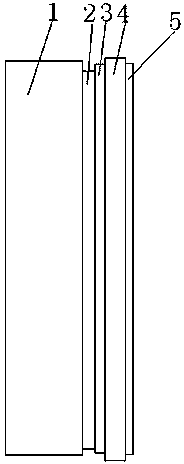

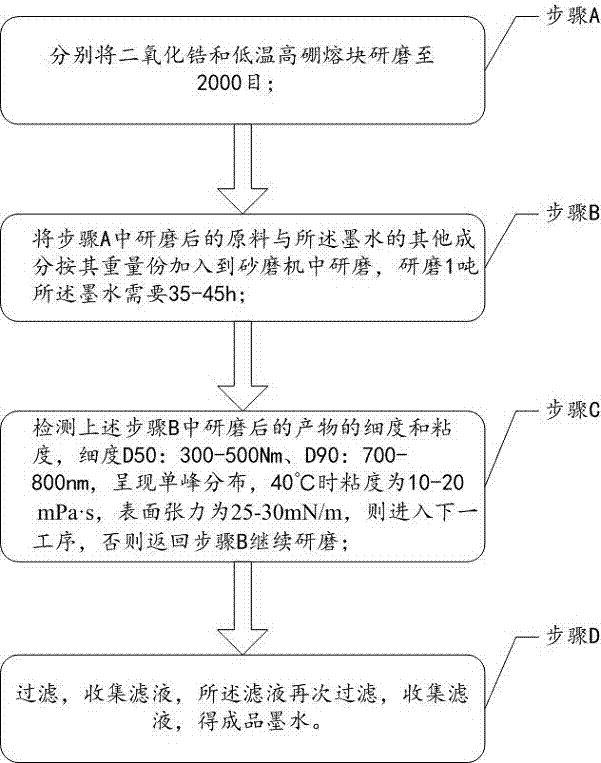

Ceramic white ink and preparation method thereof

The invention discloses ceramic white ink and a preparation method thereof. The ink comprises the following components in parts by weight: 30-40 parts of zirconium dioxide, 5-10 parts of low-temperature high-boron frit, 5-10 parts of a dispersing agent, 10-20 parts of an ester compound, 25-45 parts of a solvent, 0.5-1 part of organic dye and 0.5-1 part of a defoamer. By the synergistic effect of the various components, the opacity of the ink is high, the applicable temperature range is wide, and the ceramic white ink has certain storage stability. The fineness of the ink D90 prepared by the preparation method is controlled in a range of 700-800 nm, at the temperature of 40 DEG C, the viscosity of the ink is 10-20 mPa s, and the surface tension is 25-30 mN / m; and ink particles of the ink in a spray ink printing process can be arranged within the shortest time by the most effective stacking structure, the sink is firmly attached to a blank, and therefore, the sintered ink layer is high in sintering degree and stable in coloration.

Owner:佛山市华力达材料科技有限公司

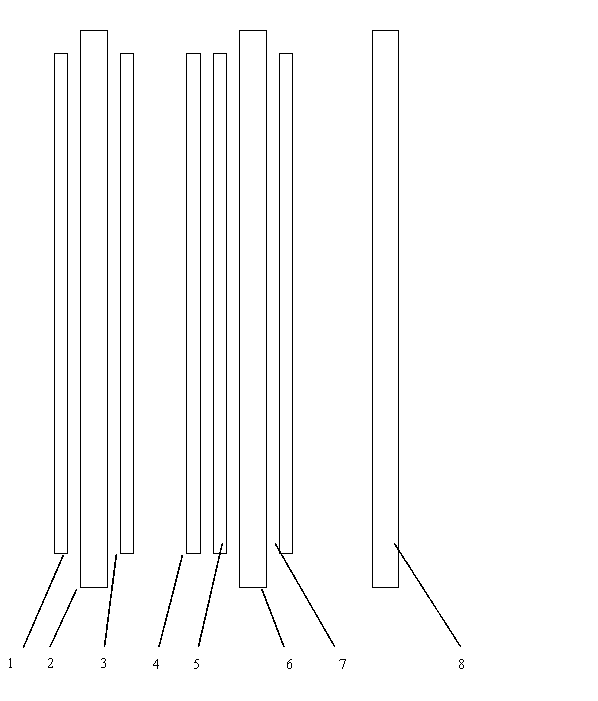

Scratch-resistant stain-repellent solar heat insulation membrane

InactiveCN103507370AWith anti-fouling functionEasy to prepareSynthetic resin layered productsArchitectural glassPolyurethane adhesive

The invention discloses a scratch-resistant stain-repellent solar heat insulation membrane. The main structure of the scratch-resistant stain-repellent solar heat insulation membrane comprises a scratch-resistant stain-repellent layer, a first optical thin film layer, a polyurethane adhesive layer, an ultraviolet infrared ray isolated strengthening layer, a metal or metal oxide layer, a second optical thin film layer, a mounting adhesive layer and a release film. The invention also discloses a making method of the scratch-resistant stain-repellent solar heat insulation membrane. The scratch-resistant stain-repellent solar heat insulation membrane provided by the invention is easy to mount, no adhesive residue is left on a screen surface after the scratch-resistant stain-repellent solar heat insulation membrane is removed, and the scratch-resistant stain-repellent solar heat insulation membrane has the functions of scratching resistance, excellent abradability, stain repellence and the like, and can be widely applied to installation and use of automobile glass and construction glass. The making method of the scratch-resistant stain-repellent solar heat insulation membrane provided by the invention is simple, is easy to operate and suitable for industrial production.

Owner:SUZHOU XILIN OPTOELECTRONICS TECH IND

Manufacturing method of goggle lens

InactiveCN104199198AEffective barrierHigh average barrier rateOptical partsOptical elementsWear resistantColor intensity

The invention provides a manufacturing method of a goggle lens. The manufacturing method comprises the following steps: (a) preparing a raw material mixture; (b) injecting the raw material mixture into a goggle lens mold; (c) performing a curing process; (d) coating to manufacture the lens, wherein the raw material mixture comprises the following components in parts by weight: 1,000+ / -0.1 parts of B-magicOG, 10+ / -0.1 parts of M-22, 3+ / -0.01 parts of UV-1, 20+ / -0.01 parts of T-13 and 1.8+ / -0.01 parts of V-65. The lens manufactured by the method effectively blocks the harmful blue light being 400-440nm, relieves the soreness and swelling of eye muscles, fight fatigue, enhances the color intensity, realizes soft and clear vision, has wear-resistant and durable effects and has an extremely strong antifouling property.

Owner:季叶俊

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com