Process for treating oil-containing waste water for ship

A waste water treatment and ship technology, applied in the direction of water/sewage multi-stage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the inconvenience of installation, use and maintenance, poor pollutant removal ability, equipment Complex structure and other issues, to achieve the effect of long service life, small volume and high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

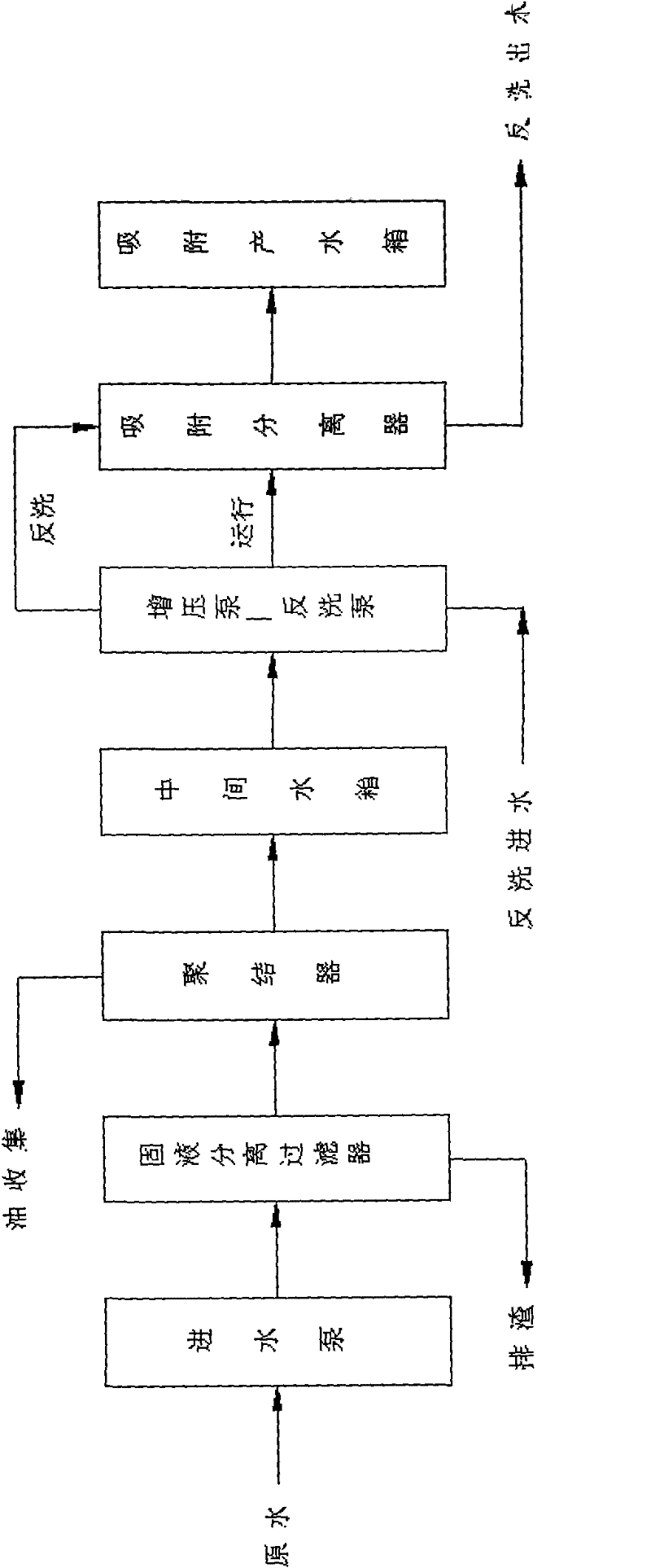

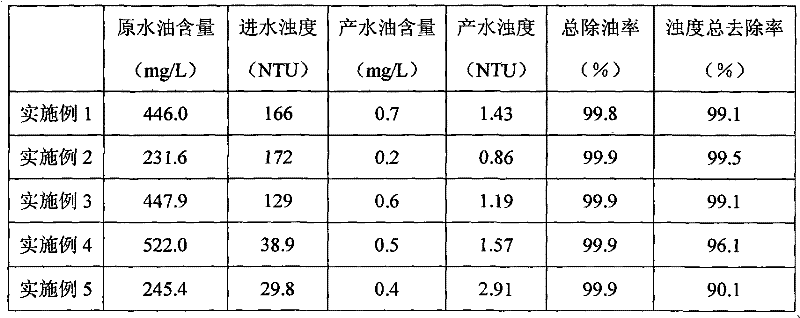

[0039] according to figure 1 In the shown ship oily wastewater treatment process, the raw water is ship oily wastewater with an oil content of 446.0mg / L and a turbidity of 166NTU.

[0040] 1. Primary filtration treatment

[0041] The pretreated oily wastewater is pumped into the upper water inlet of the filter through the water inlet pump and flowmeter. The filter is composed of a shell and a 10μm filter element. The water inlet flow rate is 15m3 / hr, and the water inlet pressure is 0.25MPa; the empty bed filtration speed 4m / h.

[0042] 2. Coalescing and filtering

[0043] After the primary filter, the oily wastewater enters the horizontal coalescing filter, and after treatment, it enters the intermediate water tank. The coalescing filter consists of a housing, an oil sump and a coalescing filter element. There are 5 coalescing filter elements installed in the coalescing filter. The inner diameter of the coalescing filter element is Φ50mm, the outer diameter is Φ80mm, and t...

Embodiment 2

[0048] according to figure 1 In the shown ship oily wastewater treatment process, the raw water is ship oily wastewater with an oil content of 231.6mg / L and a turbidity of 172NTU.

[0049] The influent flow rate of the primary filtration treatment is 25m3 / hr, the water inlet pressure is 0.3MPa; the filtration speed is 5m / hr, and the others are the same as in Example 1.

[0050] The residence time of the coalescing filter unit during the coalescing and filtering process is 15 minutes, and the others are the same as in Example 1.

[0051] The flow rate of the organic adsorption filtration separation treatment is 6m / hr, and the water inlet pressure is 0.2Mpa. Others are the same as in Example 1.

Embodiment 3

[0053] according to figure 1 In the shown ship oily wastewater treatment process, the raw water is ship oily wastewater with an oil content of 447.9mg / L and a turbidity of 129NTU.

[0054] The primary filtration treatment influent flow rate is 50m3 / hr, the water inlet pressure is 0.35Mpa, and the filtration speed is 7.5m / hr, the others are the same as in Example 1.

[0055] The residence time of the filter unit during the coalescing filtration process was 25 minutes, and the others were the same as in Example 1.

[0056] The flow rate of the organic adsorption filtration treatment is 8m / hr, and the pressure of the water is 0.4Mpa. Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com