Patents

Literature

58results about How to "Strong freeze-thaw resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

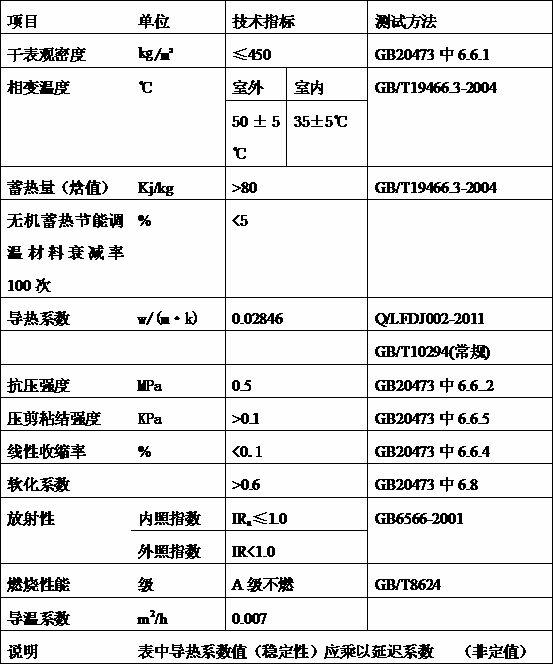

Phase-change and heat-storage heat preservation material and production method thereof

ActiveCN101613592ALow thermal conductivityLarge heat storage energyHeat-exchange elementsThermal energyParaffin wax

The invention relates to a phase-change and heat-storage heat preservation material and a production method thereof. The production method comprises the following steps: mixing paraffin wax, synthetic fatty acid, adipic acid, montan wax, crystal wax of heat storage materials accounting for 60 percent of the total weight in stirring and heating conditions according to a certain weight part ratio; raising the temperature to a certain value in atmospheric pressure; sequentially adding fire retardant, moisture repel, pour point depressant, stain control agent, mildew preventive and cement enhancer of adjustment materials accounting for 40 percent of the total weight under continuously stirring for reaction in a certain time; and keeping the temperature for 3 to 6 hours under continuously stirring, raising the temperature to 300 to 320 DEG C, keeping the temperature for few minutes, coating the materials to be finished goods when the temperature drops to be suitable for coating. The phase-change and heat-storage heat preservation material can become liquid phase so as to store heat energy when being heated (heat sources of sunlight, and the like) to achieve the saturation temperature; and when external temperature is lower than a set temperature, the phase-change and heat-storage material releases the heat energy, the phase-change material becomes solid phase from the liquid phase when the heat energy release is completed, and the process is repeated again and again for cycle.

Owner:阿尔派新能源(广东)集团有限公司 +1

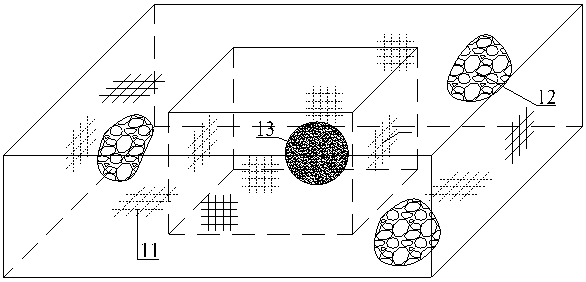

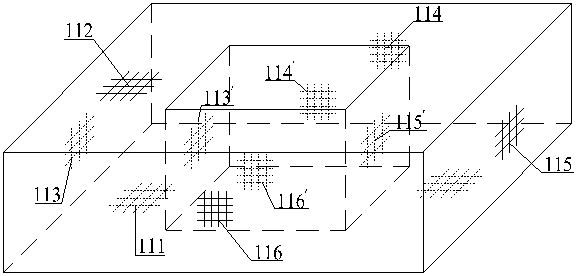

Arrangement method of ecological gabion chamber revetment type

InactiveCN102704441ARestoring Biodiversity TraitsRestoring Diversity TraitsCoastlines protectionReceptacle cultivationRiver routingEngineering

The invention relates to an arrangement method of an ecological gabion chamber revetment type, and belongs to a revetment structure type in river training works. A stepped sandstone cushion layer is laid on the revetment of a river; a sinuous ecological gabion chamber is arranged on the stepped sandstone cushion layer; and plants are planted in the sinuous ecological gabion chamber. The arrangement method has the advantages of novel structure, reliable operation, wide application range, capabilities of improving the engineering safety and favorably improving water eco-environments of rivers and lakes and great application prospect.

Owner:CHINA WATER NORTHEASTERN INVESTIGATION DESIGN & RES

Foamed coal ash geopolymer outer-wall thermal-insulation board and manufacturing process thereof

InactiveCN103214263AStrong freeze-thaw resistanceLow thermal conductivityCement productionCeramicwarePolymer scienceThermal insulation

The invention belongs to the technical field of material engineering and relates to a foamed coal ash geopolymer outer-wall thermal-insulation board and a manufacturing process thereof. The coal ash and mineral powder are foamed and maintained into a foamed coal ash geopolymer outer-wall thermal-insulation board under the excitation of alkali activator by utilizing cinerite activity of the coal ash and the mineral powder. The foamed coal ash geopolymer outer-wall thermal-insulation board comprises the following materials in percentage by weight: 60%-95% of coal ash, 4%-30% of mixed activator X, 0.01%-30% of superfine slag powder, 0.01%-30% of fine aggregate and 0.3%-10% of foam stabilizer. The fine aggregate refers to the materials including nanometer calcium carbonate, grinded kaolin, silica powder, silica fume and the like. And the mixed activator x is an alkali mixed solution containing a plurality of irons and active materials. The foamed coal ash geopolymer outer-wall thermal-insulation board has the characteristics of being strong in freeze-shaw resistance, low in heat conduction coefficient, as long as the service life of the building, and good waterproofness. Moreover, the industrial waste including waste coal ash, superfine slag powder and the like can be utilized.

Owner:德州先科地质聚合物研究所

Coal ash geopolymer self-thermal-insulation building block and manufacturing technology thereof

InactiveCN103224350AStrong freeze-thaw resistanceLow thermal conductivityCement productionCeramicwareManufacturing technologyPolymer science

The invention belongs to the technical field of material engineering, and relates to a coal ash geopolymer self-thermal-insulation building block and a manufacturing technology thereof. The technical scheme of the technology is characterized in that the coal ash geopolymer self-thermal-insulation building block is made through foaming and maintaining under the excitation of an alkali excitation agent by utilizing the cinerite activities of coal ash and mineral powder. The coal ash geopolymer self-thermal-insulation building block is composed of 60-95% of coal ash, 4-30% of a mixed excitant excitation agent X, 0.01-25% of mineral slag micropowder, and 0.3-5% of a foam stabilizer. The mixed excitant excitation agent X is an alkaline mixed liquid containing a plurality of ions and active materials. The coal ash geopolymer self-thermal-insulation building block has the characteristics of strong freezing and thawing resistances, low thermal conduction coefficient, same life with a building, good water resistance and high strength, and utilizes industrial wastes comprising waste coal ash, the mineral slag micropowder and the like. There is no waste discharge in the production process of a coal ash geopolymer exterior-wall self-thermal-insulation building block, so the building block is a very environmentally-friendly thermal insulation material.

Owner:张书源

Curing agent and its preparing method

InactiveCN1782022AImprove water tightnessLow water absorptionOrganic fertilisersSoil conditioning compositionsSlagPotassium

The curing agent consists of two parts: water solution preparation and powder preparation. The water solution preparation is compounded with saturated solution of sodium chloride, sodium carbonate, magnesium chloride, sodium silicate, potassium chloride, sodium hydroxide, calcium chloride and ammonium chloride; and the powder preparation is prepared through mixing iron ore slag, silica, magnesia, calcium sulfate, magnesium chloride and coal powder. The cured matter formed with the curing agent has high water tightness, low water absorption, low water penetration, powerful waterproof performance, high freeze-thaw resistance, high heat resistance and sustained compression strength enhancement. The curing agent of the present invention may be used in road environment, water engineering, building engineering, environment protection engineering, etc.

Owner:汤疆胜

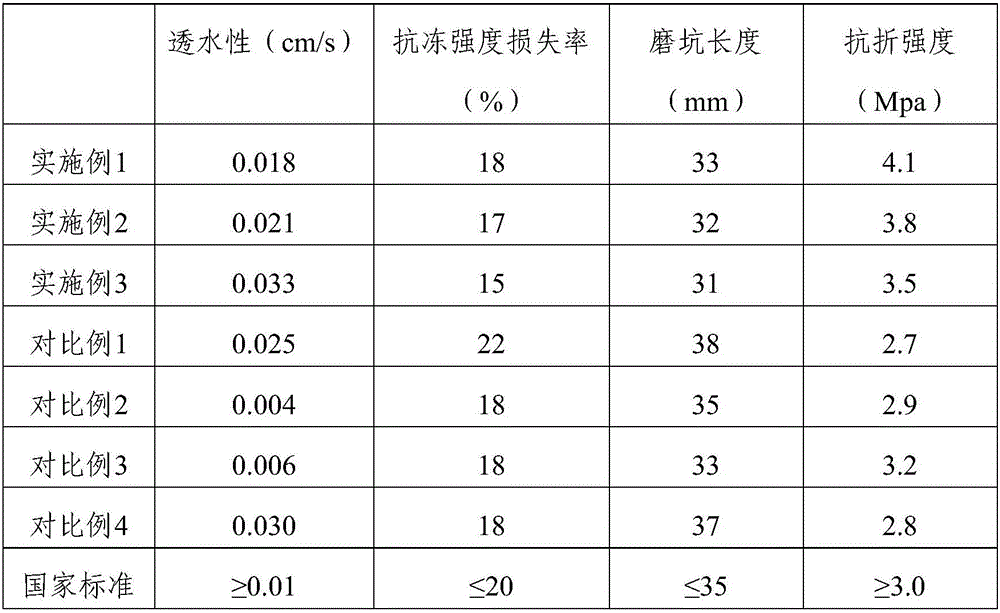

Sintered water permeable brick prepared by taking ceramic waste material as main material and preparation method thereof

InactiveCN106278365AGood water permeabilitySimple compositionCeramic materials productionCeramicwareBrickRoom temperature

The invention belongs to the technical field of building materials and in particular relates to a sintered water permeable brick prepared by taking a ceramic waste material as a main material and a preparation method thereof. The sintered water permeable brick is prepared from the following raw materials in parts by weight: 40 to 60 parts of the ceramic waste material, 25 to 55 parts of ceramic polishing dreg and 5 to 15 parts of kaolin. The preparation method of the sintered water permeable brick comprises the following steps: (1) adding water and mixing the ceramic waste material, the ceramic polishing dreg and the kaolin to obtain a mixture; (2) transferring the mixture treated by the step (1) into a brick pressing machine, and pressing and molding to form a water permeable brick blank; (3) drying the water permeable brick blank obtained by the step (2) to control the moisture content of the water permeable brick blank to be lower than 3 percent; (4) transferring the water permeable brick blank treated by the step (3) into a kiln and sintering; cooling to room temperature along the kiln to obtain the sintered water permeable brick. The water permeable brick is simple in composition and low in cost; the preparation method is simple and the problems that the comprehensive utilization efficiency of the ceramic waste material is low and the environment is polluted are solved.

Owner:PEKING UNIV

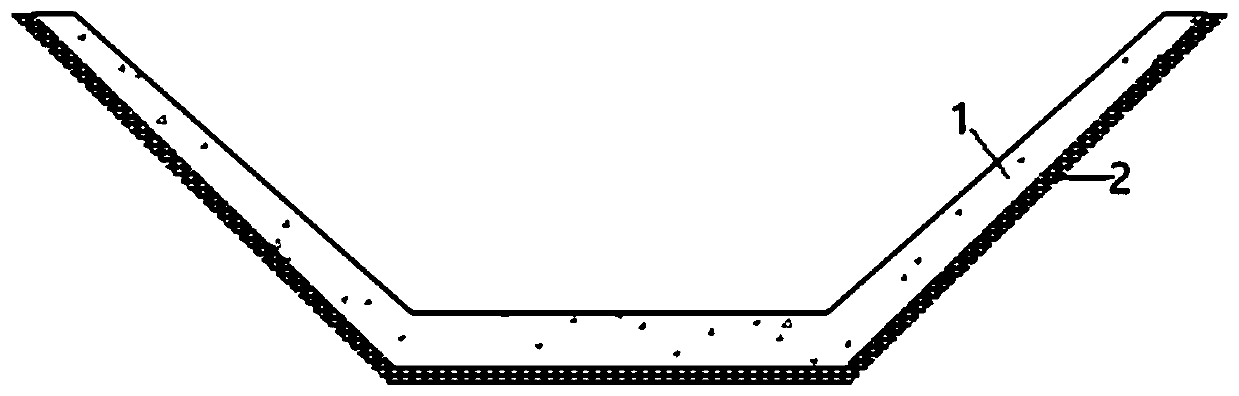

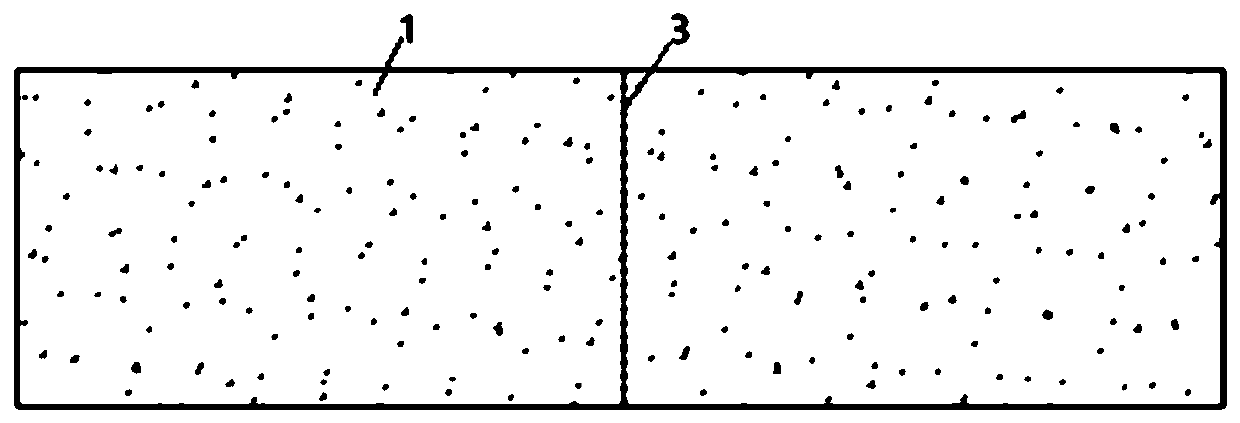

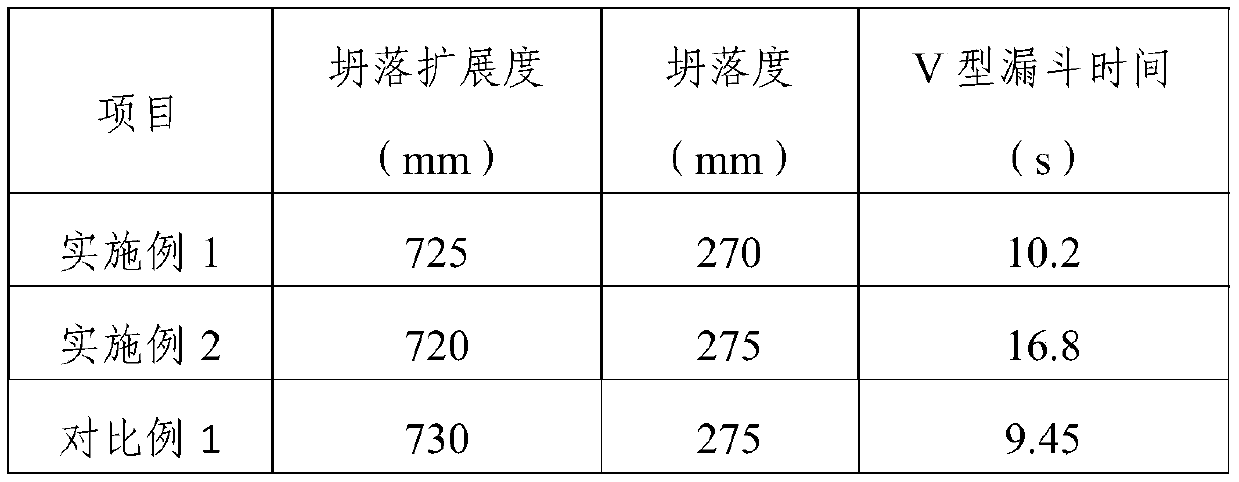

Self-compaction rubber concrete canal lining and preparation method therefor

ActiveCN110698127AImprove ductilityImprove impermeabilityArtificial water canalsFreeze thawingStructural engineering

The invention relates to a self-compaction rubber concrete canal lining and a preparation method therefor. The self-compaction rubber concrete canal lining comprises a canal lining main body, whereinthe canal lining main body is prepared from self-compaction rubber concrete. The lining material provided by the invention can be used for effectively improving high brittleness and low compliance ofthe conventional concrete linings and effectively improving the ductility, impervious waterproofing performance, salt corrosion resistance, freeze-thaw resistance and surrounding soil mass deformationadaptability of lining structures. In addition, the lining material can be filled and compacted in a lining die without bumping down in a poured-in-place process, so that construction steps are simplified, and the schedule of construction is accelerated. The self-compaction rubber concrete canal lining provided by the invention has better popularization and application prospects.

Owner:CHINA AGRI UNIV

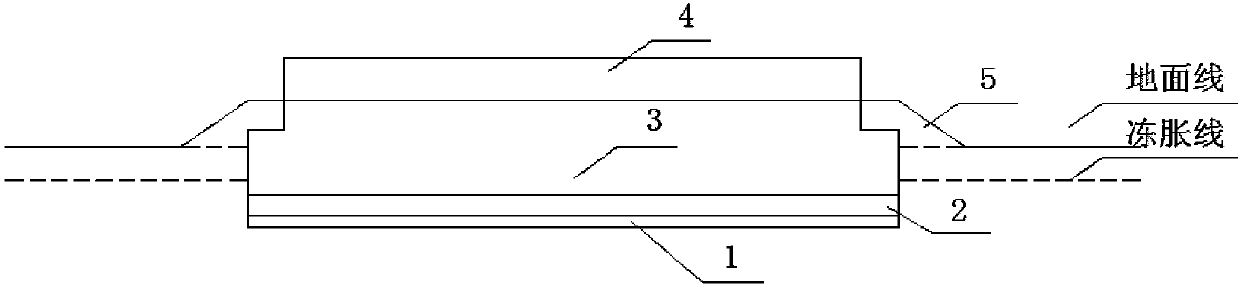

Novel soft soil quality seasonal frozen soil area highway subgrade structure and construction method

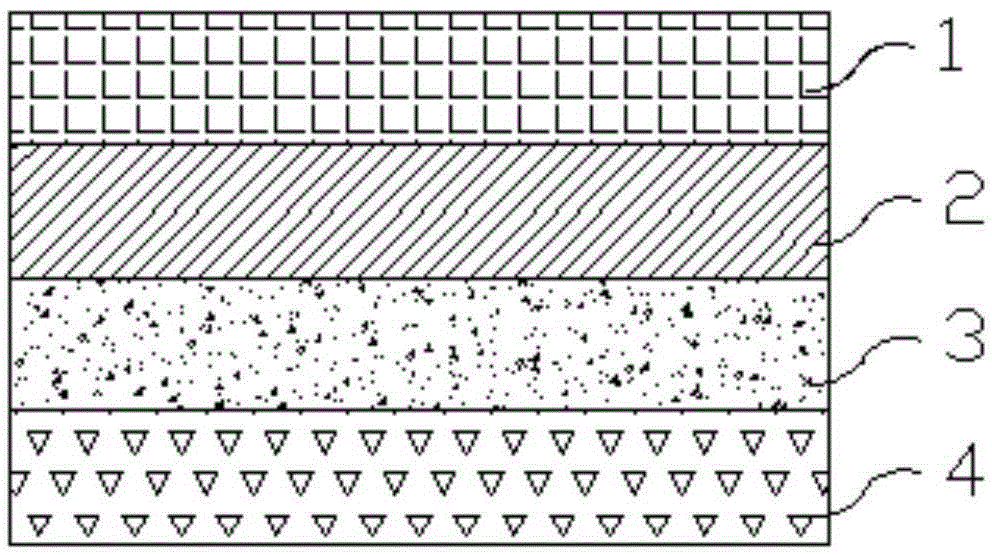

PendingCN107747261AStrong freeze-thaw resistanceGood stress structure layerRoadwaysClimate change adaptationAnti freezingEngineering

The invention discloses a novel soft soil quality seasonal frozen soil area highway subgrade structure and a construction method, which can be used for solving problems of frost heaving and sedimentation of building highway subgrades in soft soil areas. The novel soft soil quality seasonal frozen soil area highway subgrade structure mainly comprises a waterproof layer, a rubble layer, a lightweight concrete layer, a pavement structure layer and a backfill soil slope layer as a main body structure. The novel soft soil quality seasonal frozen soil area highway subgrade structure not only can utilize characteristics of low heat conduction, anti-freezing property, light weight and so on of a lightweight concrete material but also can use the rubble layer as a drainage layer and waterproof geotextile as a water-resisting layer to form an integral structure; good freeze-melt resistance during a low temperature effect is guaranteed; and moreover, as the lightweight concrete layer and the pavement structure layer form a good integral stressed structural layer, the additional stress is reduced and the sedimentation problem is weakened.

Owner:GUYUAN CHENTONG TECH DEV CO LTD

Environment-friendly water-permeable brick prepared with blast furnace slag and sludge as main materials and preparation method of environment-friendly water-permeable brick

InactiveCN106220219ALow costSimple compositionCeramic materials productionCeramicwareEnvironmental resistanceBrick

The invention belongs to the field of building materials, and particularly relates to an environment-friendly water-permeable brick prepared with blast furnace slag and sludge as main materials and a preparation method of the environment-friendly water-permeable brick. The environment-friendly water-permeable brick is prepared from, by weight, 40-60 parts of blast furnace slag with the particle size of 20-40 meshes, 25-55 parts of sludge with the organic matter content smaller than 1% and 5-15 parts of dolomite. The preparation method of the water-permeable brick includes the following steps that 1, water is added to blast furnace slag, sludge and dolomite for mixing, and a mixture is obtained; 2, the mixture obtained in the step 1 is transferred to a brick making machine and subjected to pressure forming, and a water-permeable brick blank is obtained; 3, the water-permeable brick blank obtained in the step 2 is dried; 4, the water-permeable brick blank treated in the step 3 is transferred to a kiln to be sintered and then cooled to the normal temperature in the kiln, and the water-permeable brick is obtained. The water-permeable brick is simple in raw material composition and low in cost, has the advantages of being good in water permeability, high in rupture strength and the like, and has great application value.

Owner:PEKING UNIV

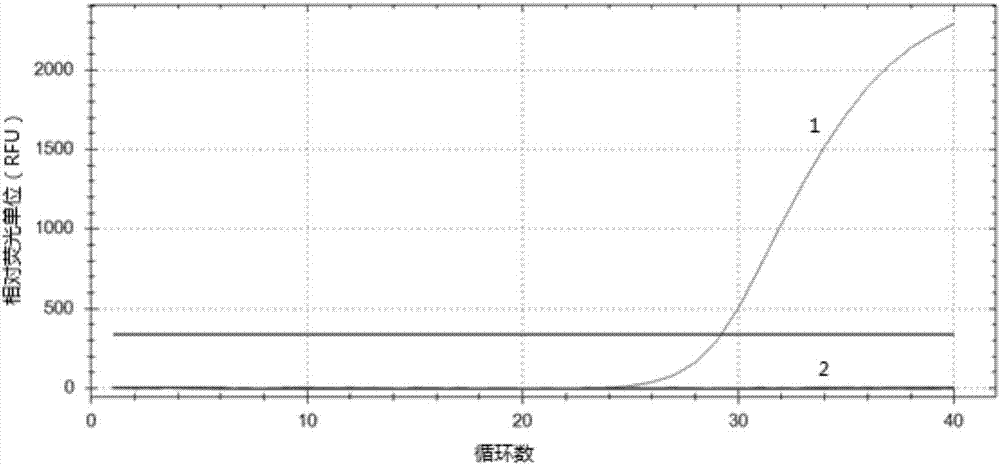

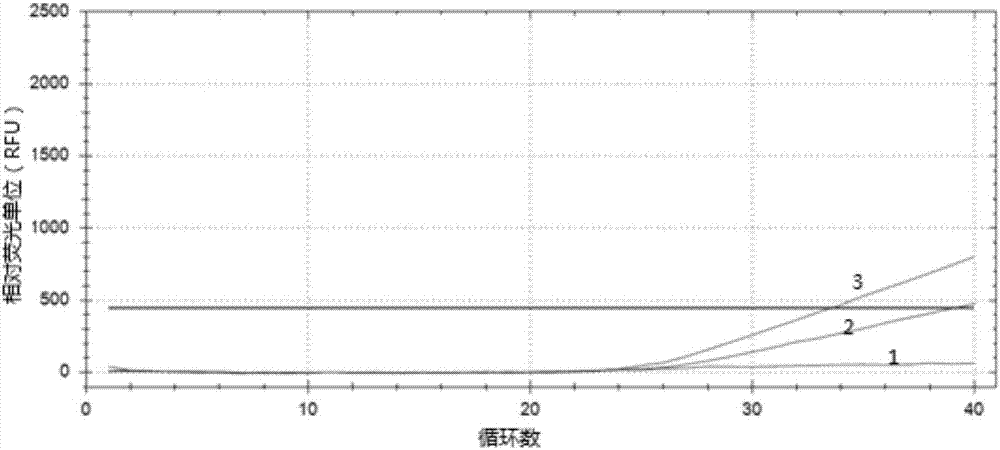

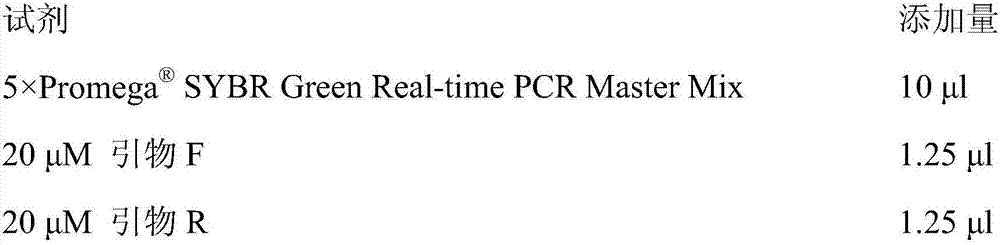

Method for preparing warm start Taq enzyme

InactiveCN107119029AStrong specificityImprove reliabilityTransferasesImmunoglobulins against enzymesEnzyme immunoassaysAntigen-antibody reactions

The invention discloses a real-time warm start Taq enzyme and a preparation method thereof. The real-time warm start Taq enzyme is an antigen-antibody complex of a Taq enzyme and a Taq enzyme nano antibody through antigen-antibody reaction, wherein the Taq enzyme nano antibody is derived from but not limited by animals which can generate nano antibodies through Taq enzyme immunoassay. By forming the antigen-antibody complex, the activity of the Taq enzyme can be released only at relatively high temperature, warm start can be achieved, the specificity, the reliability and the sensitivity of the Taq enzyme are improved, generation of non-specific amplification is avoided, and the Taq enzyme is capable of reducing clone mispairing to a very large extent and achieving efficient specific amplification when being compared with similar products. The nano antibody has high affinity and high stability, is capable of greatly improving specificity, sensitivity and amplification efficiency of warm start PCR (Polymerase Chain Reaction), and is applicable to various PCR reactions.

Owner:GUANGZHOU SUPBIO BIO TECH & SCI

Inorganic heat-storage, energy-saving and temperature-regulating wall material

Disclosed is an inorganic heat-storage, energy-saving and temperature-regulating wall material. The technical scheme includes that a certain quantity of high alumina cement, vitreous beads, aluminum silicate powder, bentonite, redispersible polymer powder, hydroxypropyl methyl cellulose, polypropylene fibers, starch ether 6200, gray calcium powder, water repellent or waterproofing agent, air-entraining agent and asbestos wool are mixed, and are sufficiently mixed in a cyclone separation manner and packaged to form a finished product. When heated (by heat sources such as sunlight and the like), the low-carbon heat-storage, energy-saving and automatic temperature-regulating wall material becomes liquid when reaching saturated temperature, and heat energy is stored; and when external temperature is lower than set temperature, the heat-storage material begins to release heat, after the heat is released thoroughly, the phase-change material becomes solid from the liquid, and the process runs in circle. The inorganic heat-storage, energy-saving and temperature-regulating wall material can be made into a section, a plate, mortar and a perforated brick, can absorb sound wave, is elastic, and vibrates, rebounds and reversely absorbs under sound wave impact, frequencies of the material are different, structural vibration is relieved, and the purpose of eliminating noise is achieved.

Owner:吉林益冠无机相变科技有限公司

Flexible waterproof mortar material

The invention discloses a flexible waterproof mortar material. The flexible waterproof mortar material is prepared from the following raw materials in parts by weight: 140 to 160 parts of cement, 250 to 270 parts of sand, 9 to 11 parts of mica powder, 202 to 214 parts of heavy calcium powder, 290 to 310 parts of dispersible adhesive powder, 3 to 5 parts of thixotropic lubricating agent, 0.3 to 0.6 part of modified starch enzyme, 0.7 to 1.2 parts of cellulose ether, 3 to 6 parts of wood fiber and 7 to 14 parts of de-foaming agent. The flexible waterproof mortar has superior flexibility, water resistance, seepage resistance, water retention property, interference bonding strength, volume stability, freezing-thawing resistance, high temperature aging resistance, water tolerance, alkaline corrosion resistance and the like, the flexibility, seepage resistance, water resistance, high bending resistance and compressive strength are ensured; slight crack leakage of a building shrinkage can be prevented in later use; the defect of susceptibility to aging and cracking in the existing flexible waterproof material is overcome and the stable quality of the mortar is ensured.

Owner:合肥翠鸟节能建材有限公司

Well drilling waste brick making method

ActiveCN106587786AHarmlessAchieving processing powerWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningBrickFreezing thawing

The invention discloses a well drilling waste brick making method. The well drilling waste brick making method comprises the following steps that dirt elimination and desiccation treatment is conducted on well drilling waste to be treated with a dirt elimination and desiccation agent; a construction binding material and a construction aggregate are added to the well drilling waste, to be treated, obtained after dirt elimination and desiccation treatment, even mixing is conducted, and then a brick making mixture is obtained; the brick making mixture is solidified and pressed to be green bricks with the density not smaller than 80% by means of a static pressure type brick making machine; strength maintenance is conducted on the green bricks; the green bricks obtained after strength maintenance is completed are sprinkled or coated with waterborne waterproof coating or dipped in the waterborne waterproof coating, so that an environment-friendly blocking layer with the thickness being 1-10 mm is formed on the surfaces of the green bricks obtained after strength maintenance is completed, and then the finished bricks are made. By the adoption of the well drilling waste brick making method, the well drilling waste can be processed into the brick making raw material which is loose and dry and meets relative environment-friendly standard at a low cost, the brick making raw material can be finally made into the finished bricks which are ideal in compressive strength, ageing resistance, hydrolysis resistance, freezing-thawing resistance, corrosion resistance and environmental protection stability, and therefore harmless and resourceful treatment of the well drilling waste is achieved.

Owner:北京泾渭智能环保有限公司

Tunnel fire-proof and heat-preservation sheet material for alpine region and manufacturing method of tunnel fire-proof and heat-preservation sheet material

PendingCN109849115AGood fire resistanceHigh bond strengthOther plywood/veneer working apparatusFireproof paintsFreeze thaw resistanceWool

The invention relates to a tunnel fire-proof and heat-preservation sheet for an alpine region and a manufacturing method of the tunnel fire-proof and heat-preservation sheet material. The fire-proof and heat-preservation sheet is composed of a surface layer and a heat-preservation layer, the surface layer and the heat-preservation layer are bonded by a high-strength adhesive layer, the surface layer is modified wood, the surface of the surface layer is sprayed with a high-expansion fire-proof coating layer, and the heat-preservation layer is a high density hydrophobic rock wool sheet. Comparedwith the prior art, the fire resistance of the sheet is obvious, the sheet can be rapidly expanded or carbonized when a fire occurs, the fire resistance limit is long, freeze-thaw resistance is high,surface strength is high, and the sheet is not easy to crack and pulverize.

Owner:HEBEI JUNHUI SECURITY TECH CO LTD

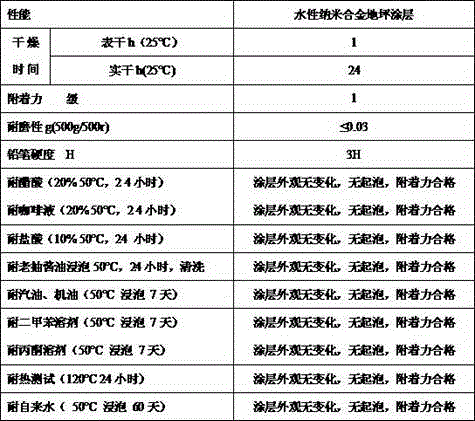

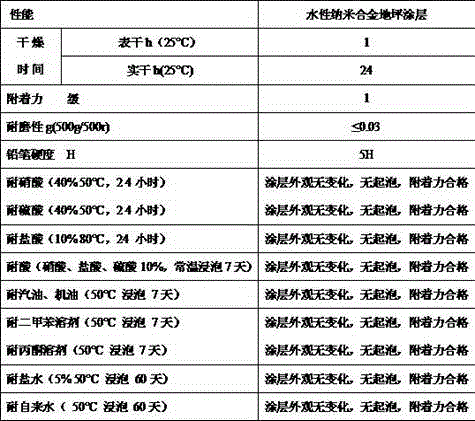

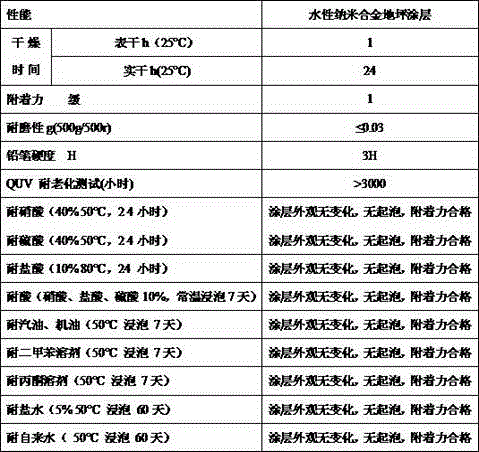

Water-based environment-friendly nano alloy floor paint and preparation method thereof

InactiveCN105694624AImprove adhesionImprove corrosion resistanceFireproof paintsAnti-corrosive paintsWeather resistanceCorrosion resistant

The invention belongs to the field of paints, and particularly relates to a water-based environment-friendly nano alloy floor paint and a preparation method thereof. The water-based environment-friendly nano alloy floor paint comprises the following raw materials in parts by weight: 20-30 parts of active siloxane, 10-40 parts of nano silicon dioxide, 10-40 parts of water-soluble resin, 5-15 parts of nano titanium powder, 10-30 parts of deionized water, 1-15 parts of isopropanol, 5-30 parts of pigment, 5-100 parts of filler, 0.5-6 parts of wetting agent, 0.5-0.8 part of defoaming agent and 1-3 parts of thickener. The preparation method sequentially comprises the following steps: preparing the raw materials, preparing the component A, preparing the component B, mixing and the like. The water-based environment-friendly nano alloy floor paint has the advantages of weather resistance, solvent resistance, chemical resistance, corrosion resistance, ultrahigh hardness, high glossiness, high adhesive force, high flexibility, favorable coated film compactness, impact resistance, wear resistance and the like, and thus, can prolong the service life of the substrate.

Owner:深圳市夸克纳米材料有限公司

Quick-frozen premixed glutinous rice ball flour and preparation method thereof

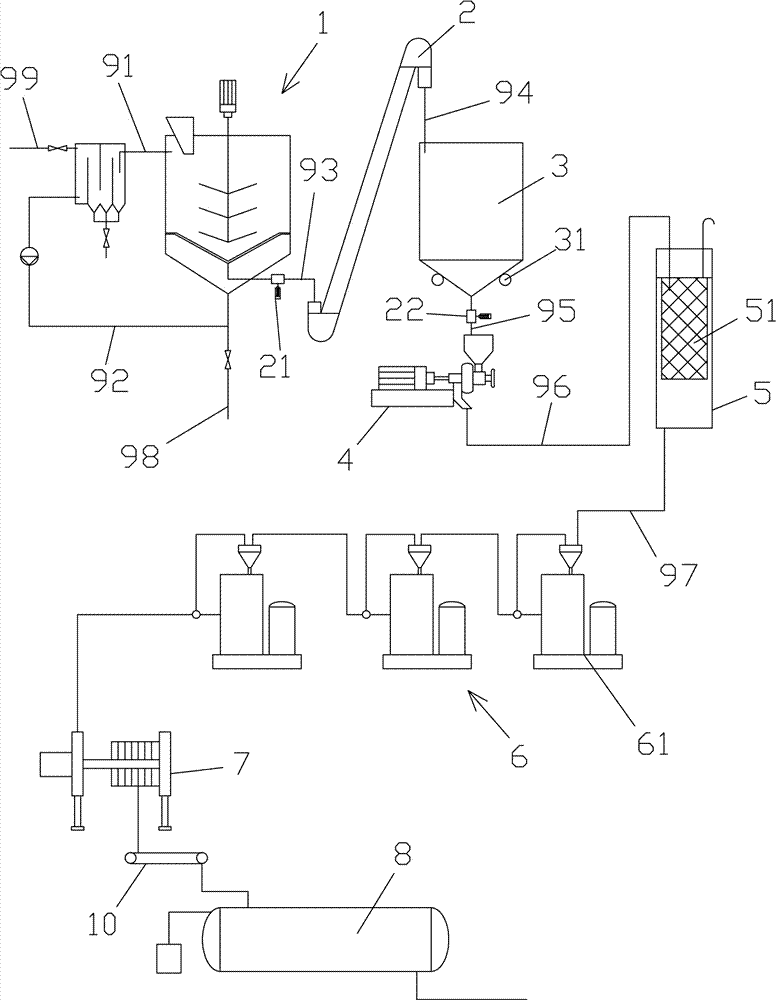

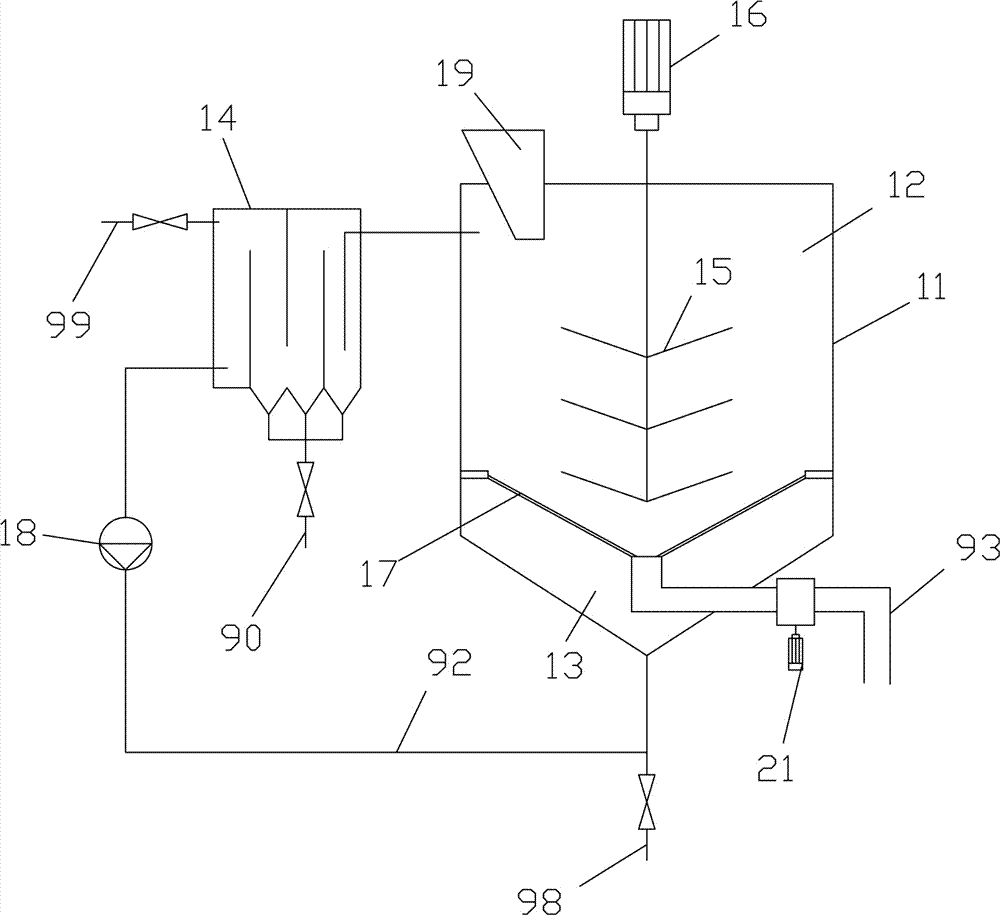

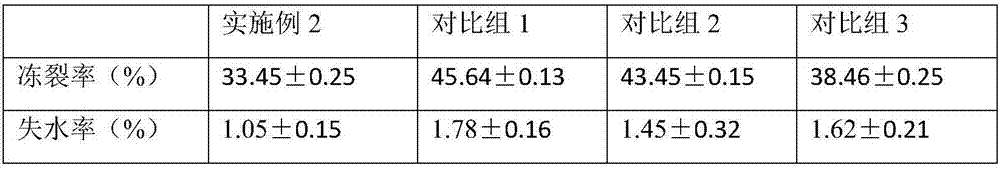

InactiveCN107212255AGood qualityImprove propertiesFood ingredient as viscosity modification agentFood ingredient as antioxidantMaterial storageFreezing environment

The invention discloses quick-frozen premixed glutinous rice ball flour and a preparation method thereof. The quick-frozen premixed glutinous rice ball flour comprises the following ingredients in parts by weight: 100 parts of raw glutinous rice flour, 50-300 parts of modified glutinous rice flour, and auxiliary materials; and the auxiliary materials comprise 5-50 parts of long-shaped rice flour, 1-20 parts of a modifier, and 10-50 parts of white sugar powder. A production system of the raw glutinous rice flour comprises a soaking part, a bucket elevator, a material storage tank, a pulp grinding machine, a pulp storage tank, a fine grinding part, a pressure filter, and a low-temperature vacuum drying machine. According to a preparation method of the quick-frozen premixed glutinous rice ball flour, formulas are screened; and improvement factors, including the modifier, a glutinous rice flour modification method, raw material types (namely, the raw glutinous rice flour, the modified glutinous rice flour, and the long-shaped rice flour are used in collocation), proportion of the raw materials and so on, are adopted so that glutinous rice balls prepared by using the quick-frozen premixed glutinous rice ball flour are suitable for preservation in freezing environment, and thus, the quick-frozen glutinous rice balls are guaranteed for good quality after being cooked.

Owner:黄冈东坡粮油集团有限公司

Heating-layer pavement for cold region and construction technology thereof

The invention discloses a heating-layer pavement for a cold region. The heating-layer pavement comprises a pavement structure layer, a roadbed structure layer, a foam light layer and an original frozen soil layer, wherein the pavement structure layer is arranged at the top part of the roadbed structure layer in parallel; the roadbed structure layer covers the top part of the foam light layer; the foam light layer is arranged at the top part of the original frozen soil layer in parallel and is arranged in a position which is 0.8 to 2.0 m apart from the bottom part of the pavement structure layer; the foam standard density of the foam light layer is 50kg / m<3>. According to the heating-layer pavement for the cold region, disclosed by the invention, in foam light soil, the volume percentage of foam is up to 40 to 70 percent, the content of the foam is high, the volume weight is small, the shock absorption performance is good, a heat conductivity coefficient is small, heat insulation and sound insulation effects are good, and the anti-freezing-and-thawing performance is strong; when the heating-layer pavement is used as a heat insulation layer between frozen soil and an earth fill embankment in the cold region, energy exchange between original frozen soil and the exterior can be well switched off, heat insulation and heat preservation effects are achieved, and the problem of frost failures in the cold region can be effectively solved.

Owner:JIANGSU ZHAOTONG ENG TECH CO LTD

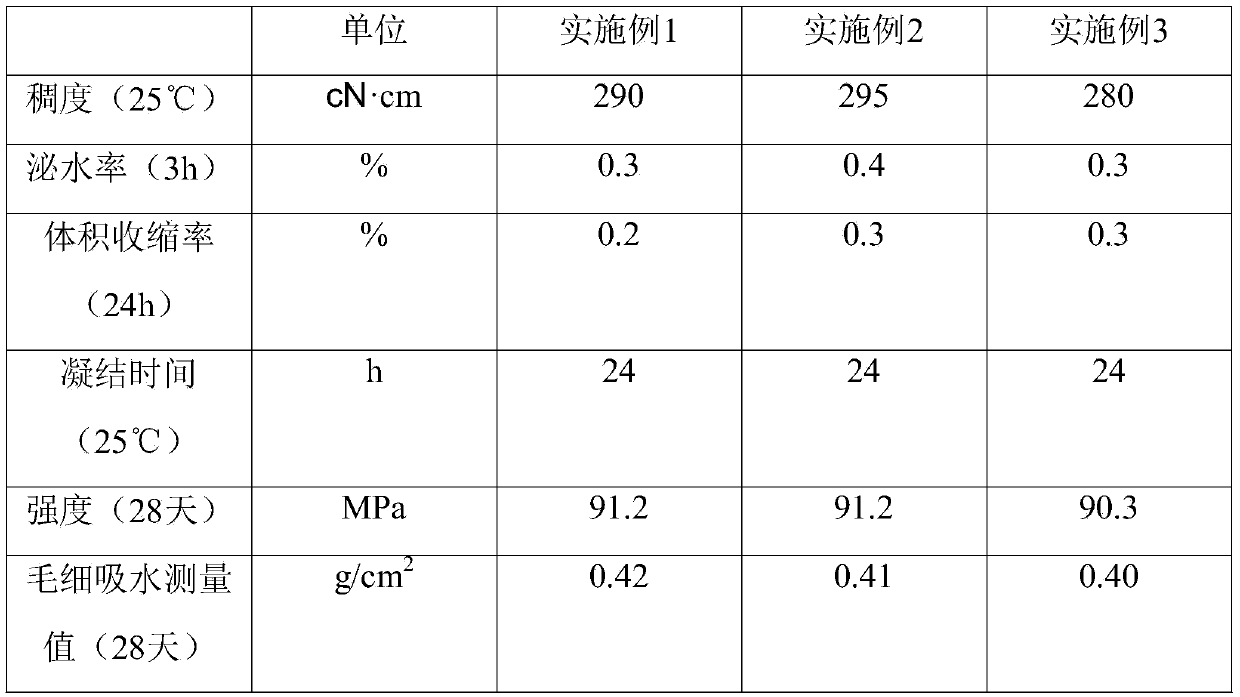

Cement mortar and preparation method thereof

The invention discloses a cement mortar and a preparation method thereof. The cement mortar is prepared from the following raw materials in parts by weight: 50-100 parts of cement, 10-50 parts of zinc sulfide, 55-65 parts of urea-formaldehyde resin, 45-55 parts of sodium chloride, 20-30 parts of hydroxymethyl cellulose, 40-80 parts of diethylene glycol, 100-120 parts of calcium carbonate, 10-50 parts of antimony trioxide, 40-50 parts of chlorinated paraffin, 70-80 parts of methylethylketone, 80-120 parts of porcelain clay powder, 20-30 parts of curing agent and 100-120 parts of water. The preparation method comprises the following steps: uniformly mixing the cement, zinc sulfide, urea-formaldehyde resin, sodium chloride, hydroxymethyl cellulose, diethylene glycol and water, heating to 200-220 DEG C, stirring for 50-70 seconds, adding the calcium carbonate, antimony trioxide, chlorinated paraffin, methylethylketone, porcelain clay powder and curing agent, and uniformly mixing. The cement mortar has the advantages of low bleeding rate (only 0.2-0.3%), high seepage resistance and high freezing resistance.

Owner:广东鑫隆管业有限公司

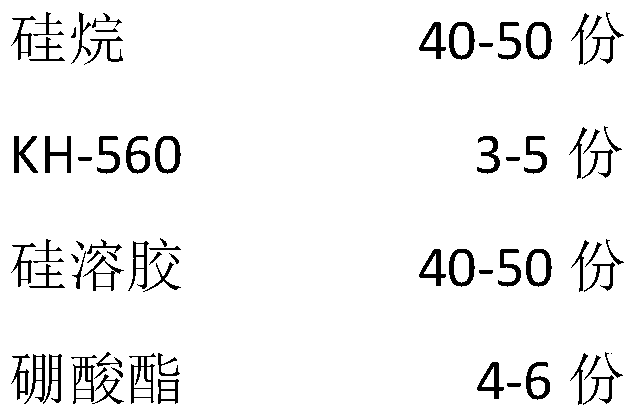

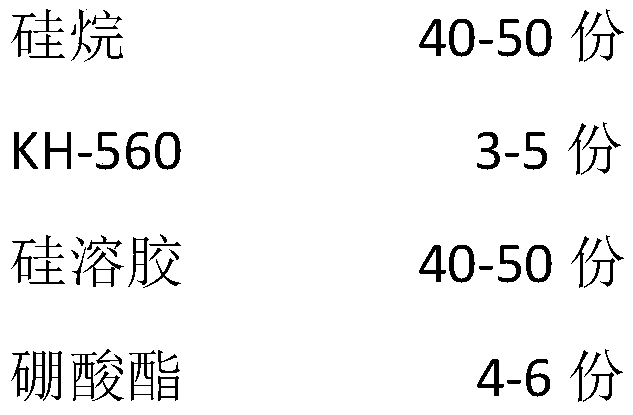

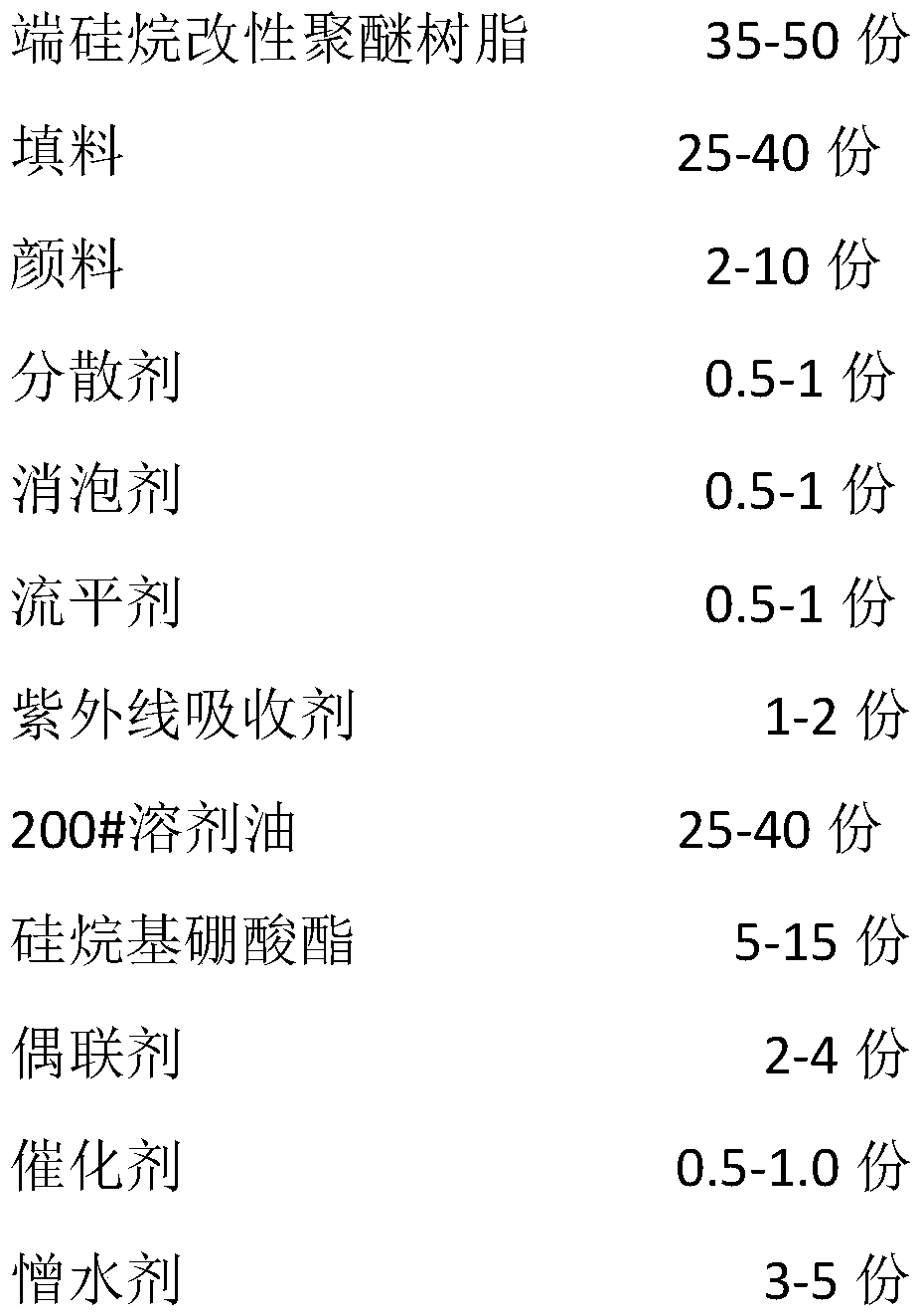

Concrete surface permeation consolidation type self-repairing coating and preparation method thereof

InactiveCN110818448ALow viscosityReduce surface tensionPolyether coatingsPriming paintsPtru catalystWeather resistance

The invention discloses a concrete surface permeation consolidation type self-repairing coating. The coating is composed of a primer and a finishing coat, wherein the primer is composed of the following raw materials in parts by weight: 40 to 60 parts of epoxy resin, 3 to 5 parts of KH-560, 40 to 50 parts of a silica sol and 4 to 6 parts of boric acid ester; and the finishing coat is composed of the following raw materials in parts by weight: 35 to 50 parts of silane-terminated modified polyether resin, 25 to 40 parts of a filling material, 2 to 10 parts of a pigment, 0.5 to 1 part of a dispersing agent, 0.5 to 1 part of a defoaming agent, 0.5 to 1 part of a leveling agent, 1 to 2 parts of an ultraviolet light absorber, 25 to 40 parts of solvent oil No. 200, 5 to 15 parts of silyl borate,2 to 4 parts of a coupling agent, 0.5 to 1.0 part of a catalyst and 3 to 5 parts of a water repellent. The coating provided by the invention has excellent weather resistance, resistance to high and low temperature, resistance to acid, alkali and salt, freeze thawing resistance, hydrophobicity and self-repairability.

Owner:石家庄市油漆厂 +2

Compound sludge curing agent and application thereof

InactiveCN104058640AImprove mud strengthEnhance road durabilitySludge treatment by de-watering/drying/thickeningAbsorption effectRoad construction

The invention discloses a compound sludge curing agent and an application thereof. The curing agent is a mixture mixed from following raw materials, by weight, 8-20 parts of cement, 5-10 parts of medical stone powder and 2-5 parts of pyrophyllite powder. The cement in the sludge curing agent is mainly used for increasing a curing strength of sludge. Strong water-absorption effects of the medical stone powder and the pyrophyllite powder can be developed. The medical stone powder and the pyrophyllite powder are layer silicate minerals. Clay meniral characteristics of both of the medical stone powder and the pyrophyllite powder cooperatively work so that sludge after being cured is ensured to have relatively good anti-washout performance and anti-freeze-thawing performance and finally optimum moisture content in the cured sludge is increased and a compaction requirement during a construction process is satisfied better. The invention develops an application of the medical stone and the pyrophyllite in the technical field of curing agent and reduces cost of road construction.

Owner:TIANJIN MUNICIPAL ENG DESIGN & RES INST

An underwater artificial fish reef prepared from seawater, sea sand and a non-gold rib material, and having a self-repairing function

InactiveCN107698214AReduce shipping costsLow costClimate change adaptationPisciculture and aquariaRebarSeawater

An underwater artificial fish reef prepared from seawater, sea sand and a non-gold rib material, and having a self-repairing function is disclosed. The artificial fish reef is prepared from the non-gold rib material and seawater-sea sand high-toughness concrete. The non-gold rib material is at least one of BFRP, CFRP, GFRP fiber composite rib materials. The seawater-sea sand high-toughness concrete includes, by weight, 20-30 parts of PVA fibers, 750-830 parts of first-grade fly ash, 500-551 parts of ordinary Portland cement, 380-415 parts of sea sand, 300-326 parts of seawater and 2.5-8.3 parts of a polycarboxylate superplasticizer. The non-gold rib material is utilized to replace traditional reinforcing steel bars so that the problem that reinforcing steel bars are corroded under sea is solved radically. The concrete utilizes local materials, and raw materials are easily available. The artificial fish reef has a low cost, good durability, high toughness, high deformation capability, crack harmless dispersing capability, excellent freezing and thawing resistance, good shock resistance, good energy consumption performance, and the high self-repairing function for damage.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA

Soil stabilizer

The invention discloses a soil stabilizer which is prepared by mixing 20-30 parts of sodium carbonate, 15-20 parts of calcium chloride, 15-20 parts of calcium sulfate, 30-40 parts of polyferric sulfate, 5-8 parts of magnesium oxide, 5-8 parts of potassium phosphate, 10-12 parts of modified cellulose, 5-7 parts of nano zeolite and 6-8 parts of repairing microcapsules in proportion. During use, 0.05-1 part by weight of the curing agent, 3-5 parts by weight of red mud, 2-2.5 parts by weight of fly ash, 2-5 parts by weight of ordinary Portland cement and 95-97 parts by weight of plain soil are mixed through a mixing device, and then spreading and curing are performed; and the cured soil has relatively strong impermeability, freeze-thaw resistance, pressure resistance and self-repairing property, also has a very good complexing and curing effect on heavy metal ions, is not easy to seep, has recoverability, is uniformly dispersed with the soil, and has a good overall curing effect.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

Low-temperature-resistant composite plastic wood and preparation method thereof

The invention discloses low-temperature-resistant composite plastic wood and a preparation method thereof. The preparation method comprises: (1) mixing plant fiber with a cellulase C1 solution, and spraying an esterification modifier to further modify the fiber, thus obtaining modified plant fibers; (2) mixing the modified plant fibers, a coupling agent, polyvinyl chloride, antioxidant 264 and nano TiO2 and performing extrusive granulation to prepare a plastic wood material; (3) extruding the plastic wood material with a single screw extruder through a bush die at high temperature, and coolingand sawing the material to prepare a plastic wood product. The components in the composite plastic wood have excellent combination capability, so that the low-temperature resistance of the material is greatly enhanced; besides, the preparation method is simple in process and employs fewer types of additives, is carried out with accessible raw materials, and is simple in steps and convenient in operations.

Owner:安徽爱瑞德新材料有限公司

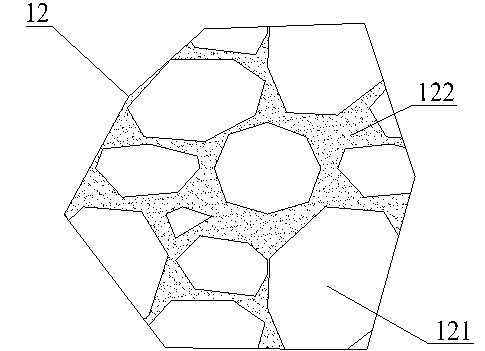

Artificially ecological permeable granite

InactiveCN107445650AEasy to shapeLarge shrinkage ratioLamination ancillary operationsLaminationSurface layerSludge

The invention provides artificially ecological permeable granite. The artificially ecological permeable granite consists of a surface layer, a middle layer and a bottom layer; the surface layer is a ceramic frit layer; the thickness ratio of the middle layer to the bottom layer is 1: (3 to 5); the middle layer consists of ceramic pigment, ceramic waste, waste residue, glass waste, an adhesive and poly light balls; and the bottom layer consists of ceramic waste, waste residue, glass waste, sludge, an adhesive and poly light balls. The novel artificially ecological permeable granite produced by using sludge, ceramic waste and industrial waste residue solves the decorative effect of paving appearance and also solves the problem of ecological environmental protection, is of green development, and benefits the nation and the people.

Owner:上海铭成永美环保科技有限公司

Cement mortar used for masonry

InactiveCN106186910AImprove water retentionStrong freeze-thaw resistanceSodium acetateFreezing thawing

The invention relates to a cement mortar used for masonry. The cement mortar comprises the following raw materials in parts by weight: 8-24 parts of zinc sulfide, 20-25 parts of calcium carbonate, 12-18 parts of porcelain clay powder, 11-17 parts of hydroxymethyl cellulose, 4-8 parts of 2-hydroxy propylamine, 3-6 parts of sodium sulfate, 9-14 parts of gypsum, 0.3-0.9 parts of methyl acrylate, 40-55 parts of Portland cement, 15-22 parts of quartz sand, 4-7 parts of a water reducer, 1.2-2.3 parts of methyl cellulose, 1-2 parts of sodium acetate, 0.5-2.5 parts of gamma-trimethoxysilylpropanethiol, 2.5-4.5 parts of silicon dioxide, 1-4 parts of rosin, and 2-5 parts of alum. The cement mortar has the beneficial effects that the mortar water retention is increased, freeze thaw capability is strong, adhesion stress is strong, engineering quality is greatly increased, and the preparation technology is simple.

Owner:青岛千帆高新技术有限公司

Carpet or automobile trim leftover material recycling technology and prepared lyophobic floor tile

The invention discloses a carpet or automobile trim leftover material recycling technology and a prepared lyophobic floor tile. The carpet or automobile trim leftover material recycling technology comprises the following steps that firstly, leftover materials are crushed; secondly, the leftover materials are heated to be partially melted, a plastomer is formed, and solid particles are prepared; thirdly, the small particles prepared in the second step are taken, preparing materials are added in the small particles, and mixing is uniform; and fourthly, products obtained after mixing in the thirdstep are poured into a die, pressurizing and hardening are conducted, and a finished product is obtained through demoulding. The technology input is low, benefits are high, and the application rangeis wide. The prepared lyophobic floor tile is good in water permeating effect, has elasticity, prevents skidding, and is environment-friendly, free of odor and suitable for outdoor footpaths.

Owner:褚乃博

Sticky steel glue for bi-component anchor rod and preparation method of sticky steel glue

InactiveCN107987771AHigh strengthStrong freeze-thaw resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesGas phaseGlycerol

The invention relates to sticky steel glue for a bi-component anchor rod. The sticky steel glue is prepared from the following components in parts by mass: a component A: 15-25 parts of liquid polysulfide rubber, 125-135 parts of epoxy resin, 3-5 parts of fumed silica, 2-4 parts of a coupling agent, 10-14 parts of a diluent, 1-3 parts of nano-silicon dioxide and 140-160 parts of quartz powder; a component B: 25-35 parts of amine-terminated polyether, 6-10 parts of m-xylylenediamine, 3-5 parts of maleic anhydride, 1-3 parts of benzyl alcohol and 0.2-0.4 parts of glycerol; and the ratio (parts by mass) of the component A to the component B is 2.5 to 1. The sticky steel glue has the beneficial effects that the formula is reasonable, the processing process is scientific and normative, and theprepared sticky steel glue is extremely high in strength and strong in damp-heat aging resistance and freeze thaw resistance and has very strong adhesive property aiming at waterproof, unclean and oil-carrying surfaces, so that great convenience is brought to the engineering construction.

Owner:ANHUI KUNDA CHEM ANCHORAGE

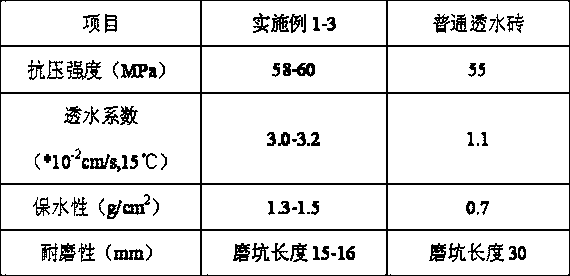

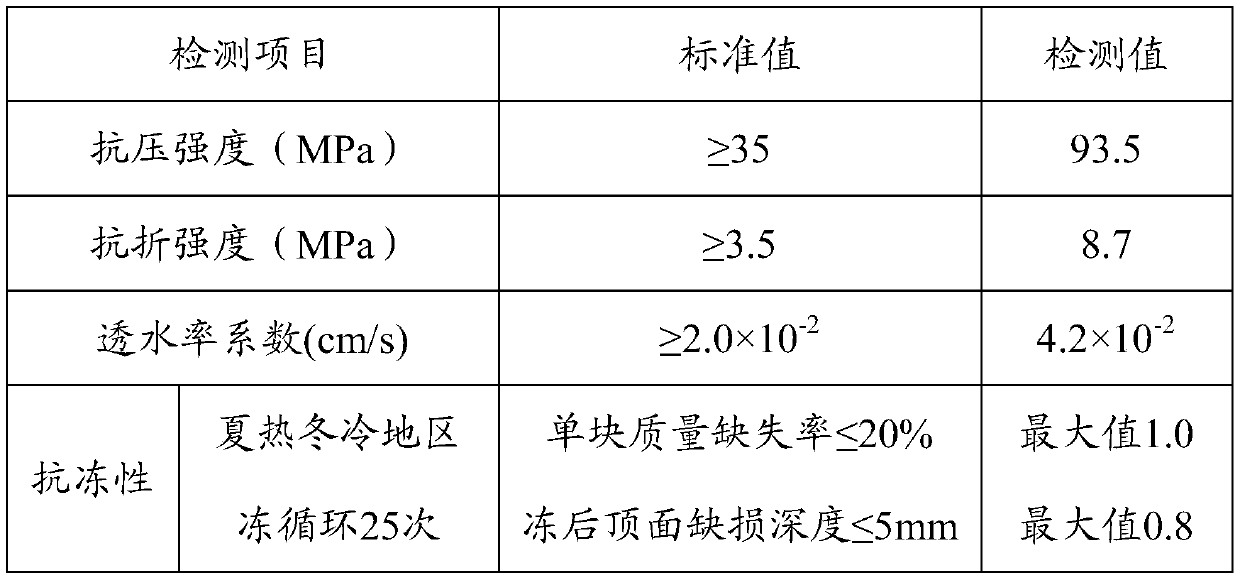

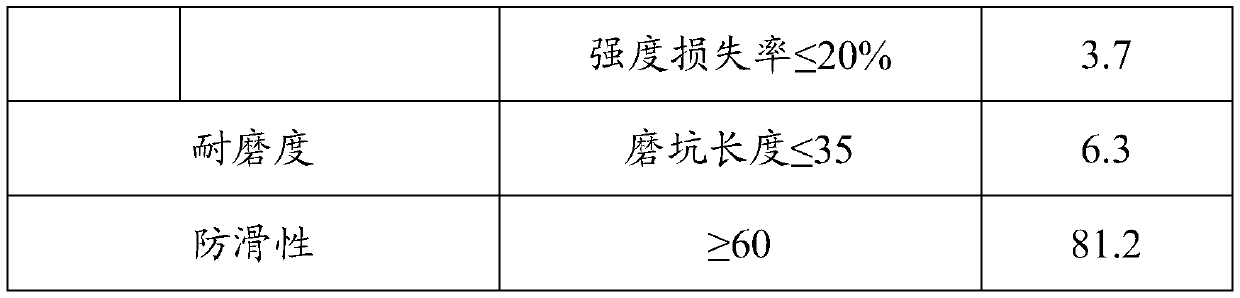

Ecological water permeable pavement brick for sponge city and preparation method of pavement brick

The invention discloses an ecological permeable pavement brick for a sponge city and a preparation method of the pavement brick. The pavement brick comprises the following raw materials: waste tires,a polyurea adhesive, a polyurethane adhesive, a carboxylic acid and a plasticizer. The ecological water permeable pavement brick for the sponge city provided by the invention has compressive strengthof 93.5 MPa, a water permeable rate coefficient of 4.2x10<-2> cm / s, and the characteristics of strong water storage and permeation capacity, good elasticity, strong freeze thawing resistance, wear resistance, corrosion resistance, stripping resistance, easy processing and forming and the like, can be used in areas such as squares, channels and road shoulders, realizes cyclic utilization of waste materials, and can provide better material guarantee for sponge city construction; and the preparation method is simple, has low production costs, and is easy to operate and implement.

Owner:CHANGAN UNIV

Anti-leakage repair-enhanced building coating

The invention relates to an anti-leakage repair-enhanced building coating which is prepared by adopting the following steps of: mixing and uniformly stirring 30-42 percent of 800-mesh silicate dry powder, 1-2 percent of KFA, 1-2 percent of plasticizer, 1-2 percent of air entraining agent and 54-65 percent of 20-40-mesh quartz sand to prepare a mixture; then adding water accounting for 15-25 percent of the gross weight into the mixture, uniformly stirring, and settling for 30 minutes to prepare the anti-leakage repair-enhanced building coating. The anti-leakage repair-enhanced building coating has the advantages of stronger coagulability, cementability, anticorrosive property, excellent anti-leakage performance, simple construction, advanced process and strong freezing and thawing resistance, is particularly suitable for being used in extremely cold regions and can be used for the leak stoppage, the seepage prevention, the reinforcement and the corrosion prevention of roads, bridges, oceans, sewage treatment and concrete structures, such as tunnels, large reservoir dams, and the like without other various additives, thereby lowering the cost of the additives and the construction difficulty, improving the engineering quality and the use durability of concrete and avoiding the mutual exclusive reaction.

Owner:夏凤君

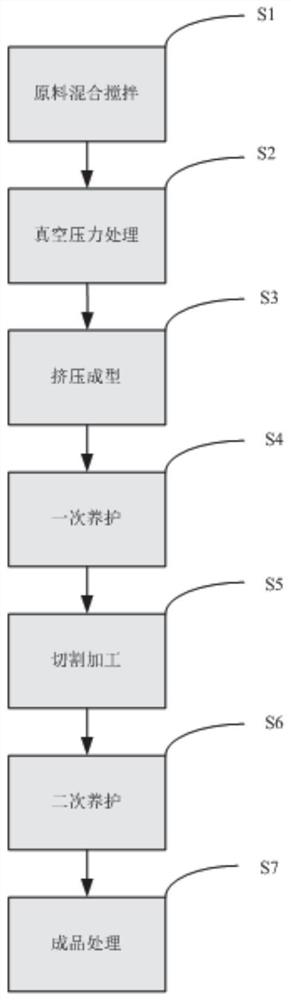

Forming method for prefabricated hollow wallboard

The invention discloses a forming method for a prefabricated hollow wallboard. The forming method comprises the following steps of S1, stirring a siliceous material containing natural stone powder, cement and fibers; S2, pressurizing the stirred material in a vacuum state to enhance the compactness of a plate; S3, performing extrusion molding through a specially-made or customized mold; S4, enabling an extruded forming plate to enter a curing kiln and performing primary curing to gradually harden the forming plate; S5, performing cutting machining according to the design or the requirement ofa customer for the plate; and S6, performing secondary curing on the extruded and molded plate in the high-temperature and high-pressure curing kiln and a high-pressure kettle in order to rapidly increase the strength of the plate and improve the permanent strength of the plate. According to the method, the strength, the compactness and the rigidity are high, and a large span can be supported, sothat the steel consumption in installation can be reduced, columns and keels are greatly reduced, the attractive effect is improved, and the economical efficiency is large.

Owner:东安县波锋建筑材料有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com