Self-compaction rubber concrete canal lining and preparation method therefor

A rubberized concrete, self-compacting technology, applied in artificial waterways, construction, water conservancy projects, etc., can solve problems such as damage, erosion damage, frost heave damage channels, etc., to reduce accumulation, enhance ductility, and speed up construction progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

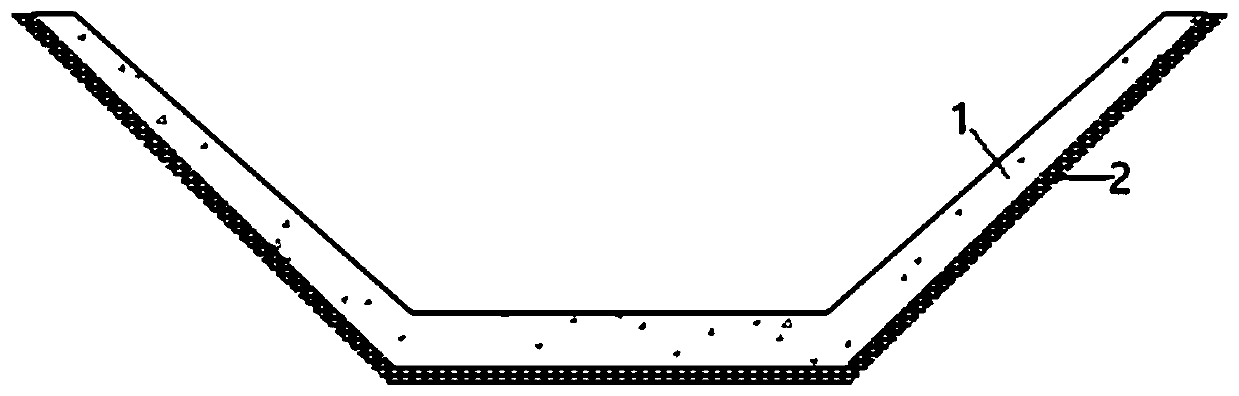

[0036] The preparation method of the self-compacting concrete channel lining structure of the present embodiment, concrete steps:

[0037] S1: Fix the formwork at the channel lining position and close both sides of the formwork;

[0038] S2: produce self-compacting rubber concrete, and pour the self-compacting rubber concrete whose fluidity meets the requirements into the formwork;

[0039] S3: After the pouring is completed, the self-compacting rubber concrete is humidified and cured, and the formwork is removed after the self-compacting rubber concrete is cured to a certain strength in the formwork;

[0040] S4: Steps S1-S3 are repeated until the construction of the entire channel lining is completed.

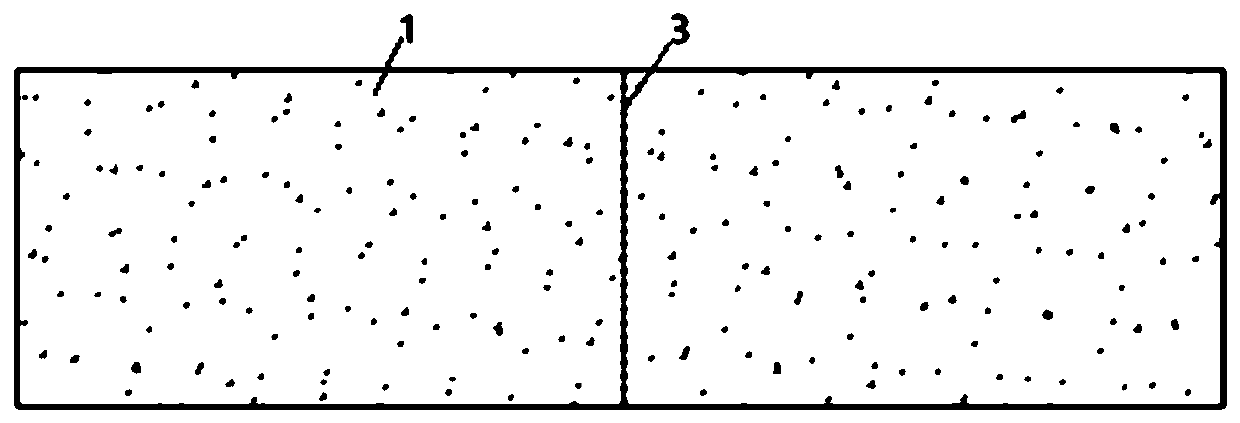

[0041] In this embodiment, a water-stop rubber strip is provided between every two adjacent self-compacting rubber concrete channel linings to reduce the leakage loss of the channel.

[0042] In this embodiment, the mass ratio of raw material components in self-compacting r...

Embodiment 2

[0044] Adopt the method identical with embodiment 1, difference is, the mass ratio of raw material component in self-compacting rubber concrete is: cement: fly ash: gravel: sand: rubber aggregate: water: additive is 325:175: 760:780:50:185:7; the additive components in this embodiment include 100 parts by mass of water, 100 parts by mass of water reducer, 0.16 parts by mass of defoamer and 0.3 parts by mass of air-entraining agent.

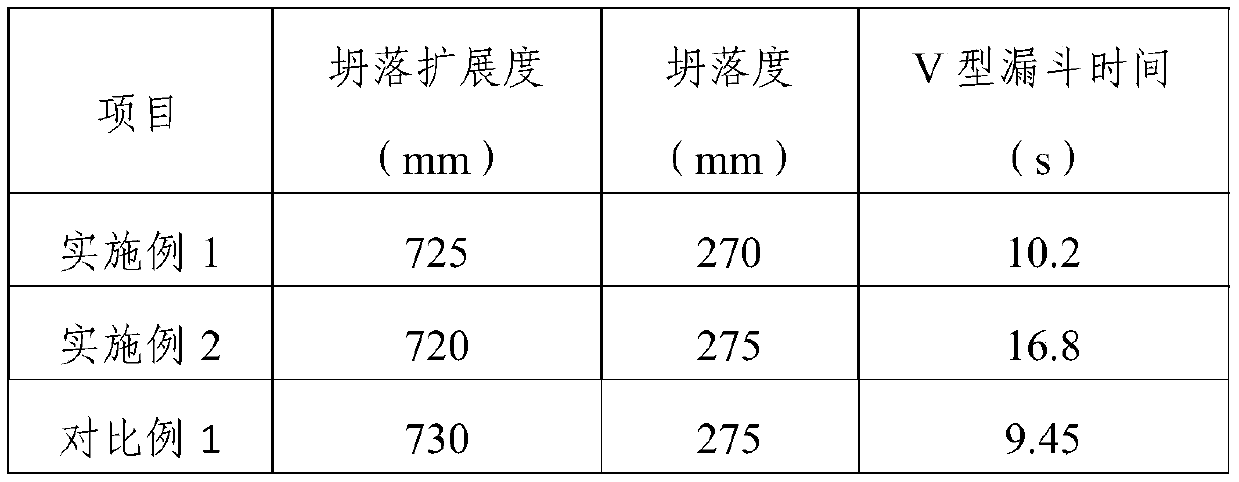

experiment example 1

[0048]According to the "Hydraulic Concrete Test Regulations" SL 352-2006, the self-compacting rubber concrete prepared in the above examples and comparative examples was tested for flow performance and strength. After testing, the implementation effect is shown in the following table:

[0049] Table 1 Flow performance test

[0050]

[0051] Table 2 Strength Test

[0052]

[0053] From the data in Table 1, it can be seen that in the embodiment of the present invention, the self-compacting rubber concrete has a slump greater than 255mm during the pouring process, a slump expansion of 550-750mm, and a V-shaped funnel time of 7-30s. Vibration, self-compacting rubber concrete will fill the formwork under the action of its own weight. Through the data in Table 2, it can be seen that in the examples of the present invention, the elastic modulus of the self-compacting rubber concrete is 33.0GPa and 29.5GPa respectively, which is lower than the elastic modulus 34GPa of the compa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com