Soil stabilizer

A technology of soil stabilizer and calcium chloride, which is applied in the field of soil stabilizer, can solve the problems of easy deformation, shortened construction period, solidified recovery, etc., and achieve the effects of reducing delamination, increasing service life, and not easy to seep out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

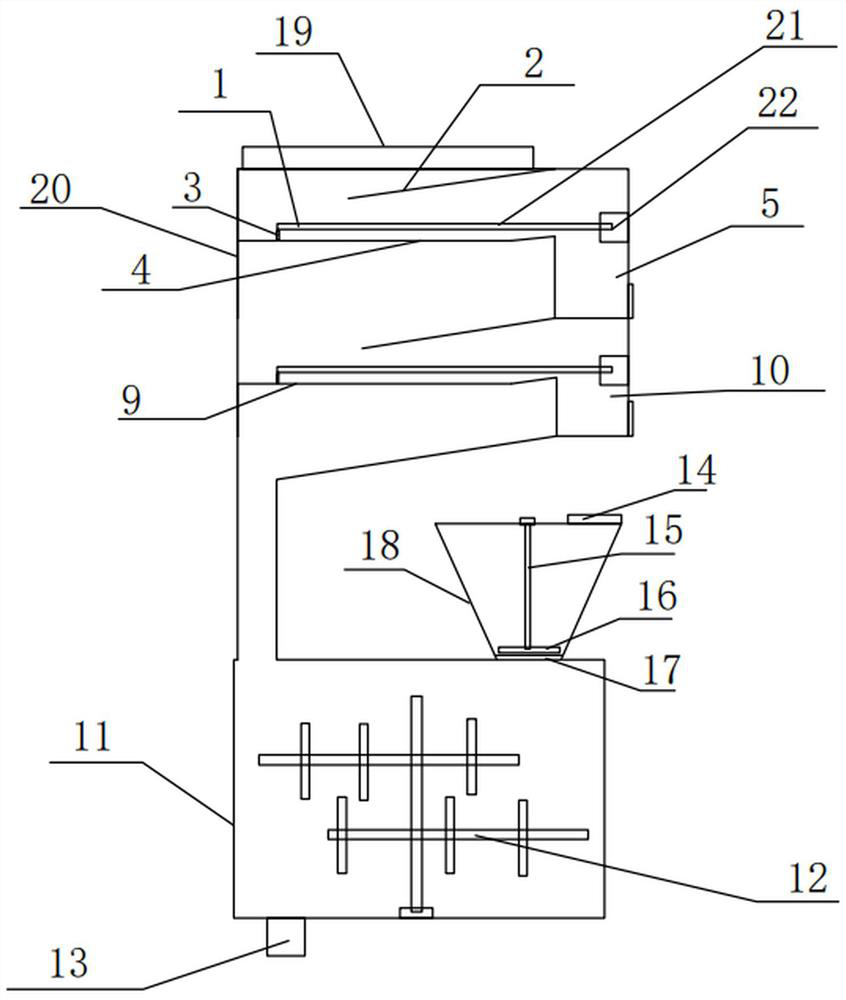

Image

Examples

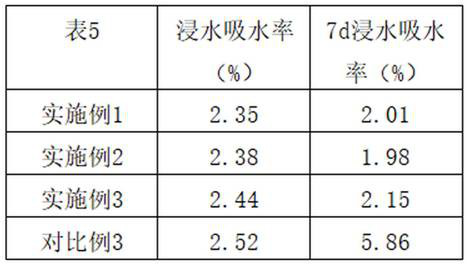

Embodiment 1

[0032] A soil stabilizer, prepared from the following raw materials in parts by weight: 20 parts of sodium carbonate, 15 parts of calcium chloride, 15 parts of calcium sulfate, 30 parts of polyferric sulfate, 5 parts of magnesium oxide, and 5 parts of potassium phosphate. 10 parts of natural cellulose, 5 parts of nano zeolite, 6 parts of repairing microcapsules;

[0033] The preparation of the modified cellulose: (1) FeCl 3 ·6H 2 0 6g and FeS0 4 ·7H 2 0 4g was dissolved in 100mL of deionized water, heated in a water bath at 70°C for 3min, then 15mL of ammonia water was added dropwise, stirred at 600rpm for 20min, and finally the product was subjected to magnetic separation, washed with distilled water until PH = 5, and ferroferric oxide magnetic nanoparticles were obtained (2) Dissolve 6.8g of sodium cellulose sulfate, 4.3g of corn starch, 8.8g of polyacrylonitrile, and 5.5g of α-cyclodextrin in a mixture of 50mL of distilled water and 30mL of DMF, stir at 400rpm for 30min,...

Embodiment 2

[0039] A soil stabilizer, prepared from the following raw materials in parts by weight: 25 parts of sodium carbonate, 17 parts of calcium chloride, 17 parts of calcium sulfate, 35 parts of polyferric sulfate, 6 parts of magnesium oxide, and 6 parts of potassium phosphate. 11 parts of natural cellulose, 6 parts of nano-zeolite, 7 parts of repairing microcapsules;

[0040] The preparation of the modified cellulose: (1) FeCl 3 ·6H 2 0 6.5g and FeS0 4 ·7H 2 0 4.5g was dissolved in 110mL of deionized water, heated in a water bath at 75°C for 4min, then 16mL of ammonia water was added dropwise, stirred at 700rpm for 25min, and finally the product was subjected to magnetic separation, washed with distilled water until pH = 5.5, and ferroferric oxide magnetic nanoparticles were obtained Granules; (2) Dissolve 7.0g of sodium cellulose sulfate, 4.4g of corn starch, 9.2g of polyacrylonitrile, and 6.0g of α-cyclodextrin in a mixture of 55mL of distilled water and 35mL of DMF, stir at 4...

Embodiment 3

[0045] A soil stabilizer, prepared from the following raw materials in parts by weight: 30 parts of sodium carbonate, 20 parts of calcium chloride, 20 parts of calcium sulfate, 40 parts of polyferric sulfate, 8 parts of magnesium oxide, and 8 parts of potassium phosphate. 12 parts of natural cellulose, 7 parts of nano-zeolite, 8 parts of repairing microcapsules;

[0046] The preparation of the modified cellulose: (1) FeCl 3 ·6H 2 0 7g and FeS0 4 ·7H 20 6g was dissolved in 120mL of deionized water, heated in a water bath at 80°C for 5min, then 17mL of ammonia water was added dropwise, stirred at 800rpm for 30min, and finally the product was subjected to magnetic separation, washed with distilled water until PH = 6, and ferroferric oxide magnetic nanoparticles were obtained ; (2) Dissolve 7.2g of sodium cellulose sulfate, 4.5g of corn starch, 10.2g of polyacrylonitrile, and 6.5g of α-cyclodextrin in a mixture of 60mL of distilled water and 40mL of DMF, stir at 500rpm for 45mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com