Patents

Literature

45 results about "Cellulose sulfate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

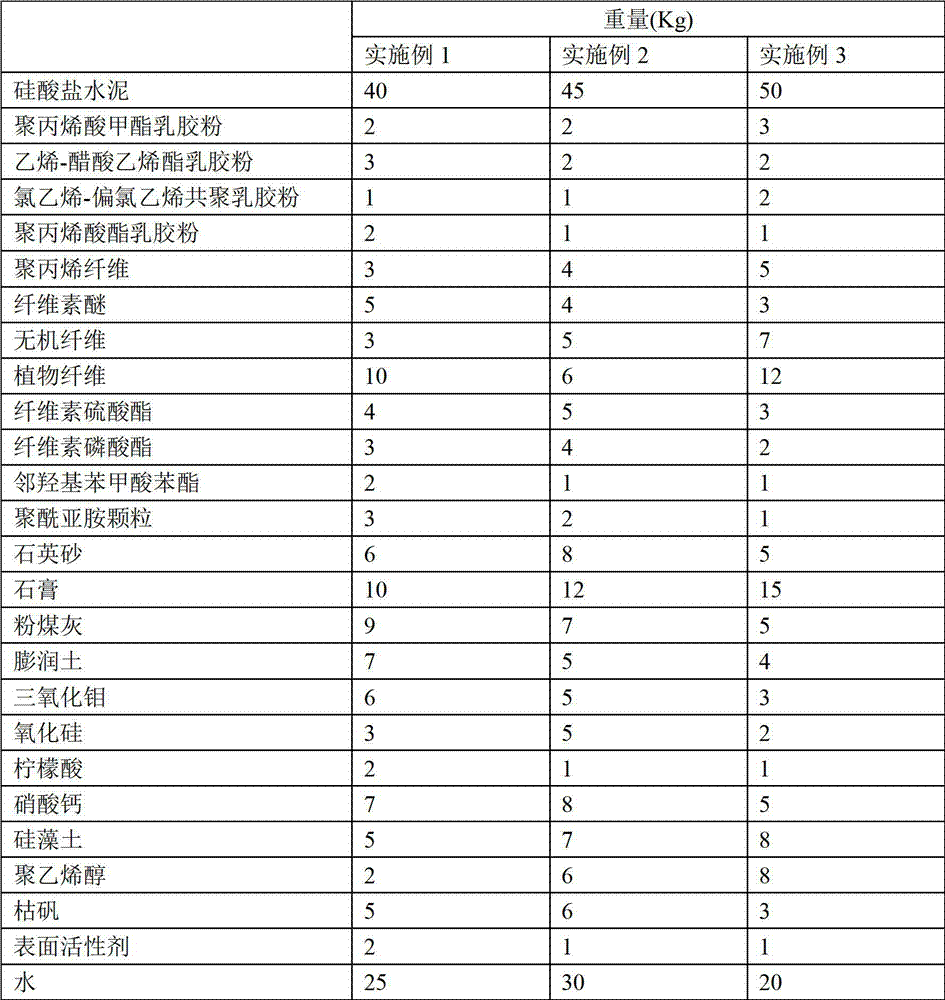

Corrosion-resistant polymer waterproof mortar

The invention provides a corrosion-resistant polymer waterproof mortar, which comprises the following components by weight: 40-50 parts of portland cement, 2-3 parts of polymethyl acrylate latex powder, 2-3 parts of ethylene-vinyl acetate latex powder, 1-2 parts of vinyl chloride-vinylidene chloride copolymerized latex powder, 1-2 parts of polyacrylate latex powder, 3-5 parts of polypropylene fibers, 3-5 parts of cellulose ether, 3-7 parts of inorganic fibers, 6-12 parts of plant fibers, 3-5 parts of cellulose sulfate, 2-4 parts of cellulose phosphate, 1-2 parts of phenyl salicylate, 1-3 parts of polyimide particles, 5-8 parts of quartz sand, 10-15 parts of gypsum, 5-9 parts of fly ash, 4-7 parts of bentonite, 3-6 parts of molybdenum trioxide, 2-5 parts of silicon oxide, 1-2 parts of citric acid, 5-8 parts of calcium nitrate, 5-8 parts of diatomite, 2-8 parts of polyvinyl alcohol, 3-6 parts of dried alum, 1-2 parts of a surfactant, and 20-30 parts of water.

Owner:WUJIANG TIANYUAN PLASTIC

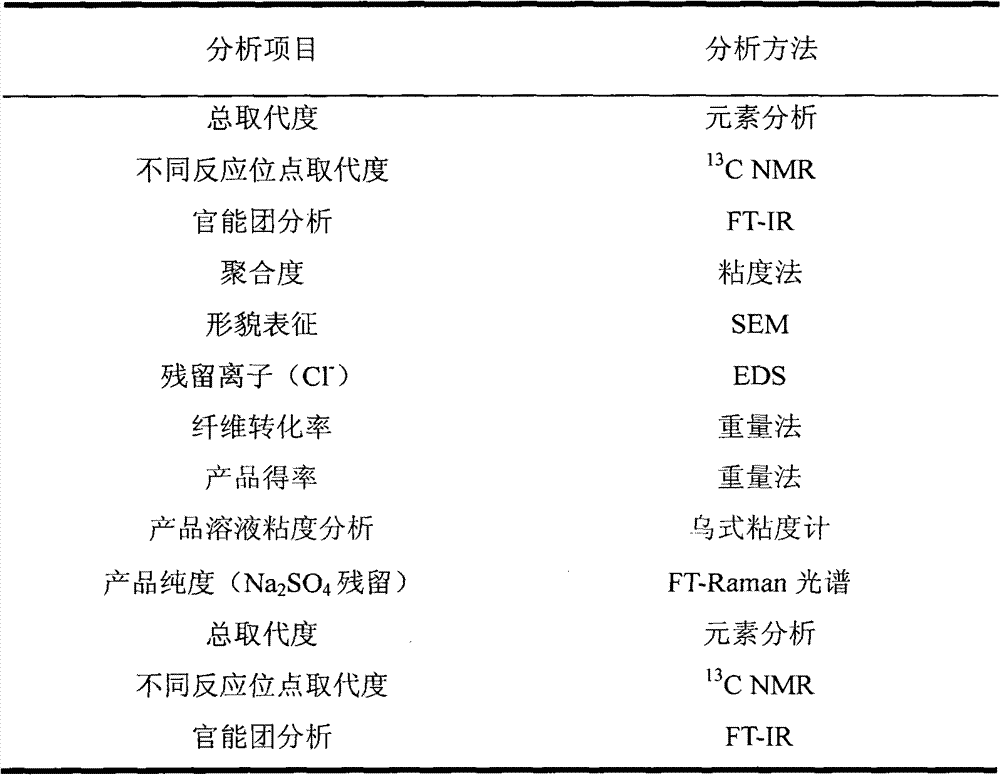

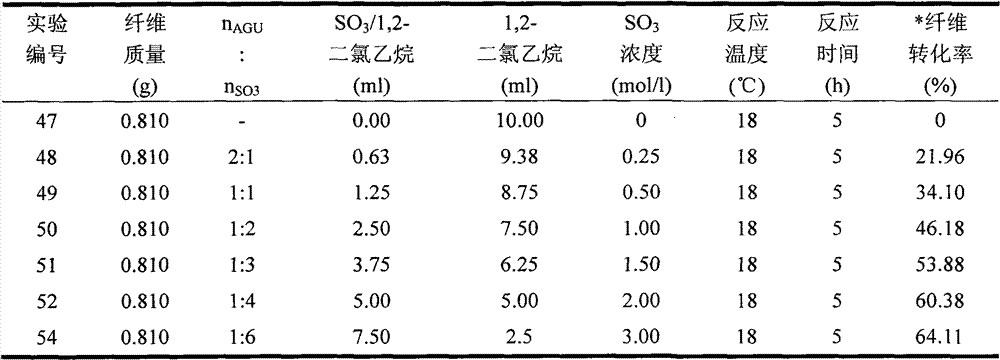

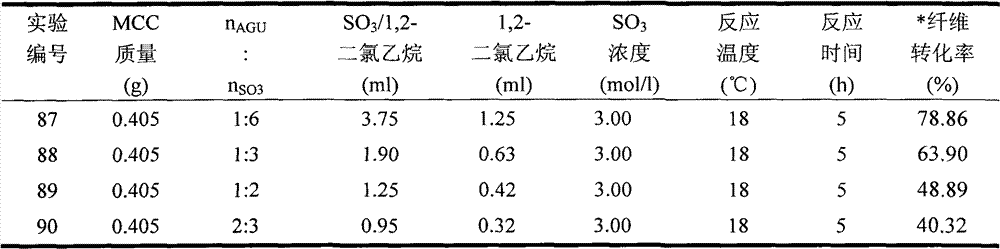

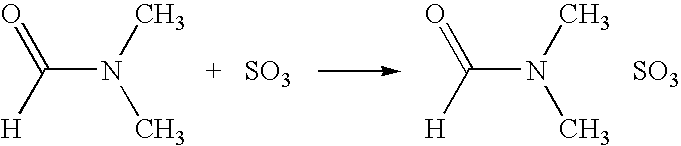

Simple synthesis process of cellulose sulfate

The invention provides a novel clean production process for synthesizing cellulose sulfate at high conversion rate and high quality in an aprotic solvent in the absence of an acid-binding agent based on SO3 and fiber as raw materials. The novel clean production process is simple in process, mild in condition, recyclable in reaction materials, high in conversion rate, good in product quality and free of toxic and side ion and solvent residual; the cellulose sulfate product is wide to apply and has a huge industrial application prospect.

Owner:XIAMEN UNIV +1

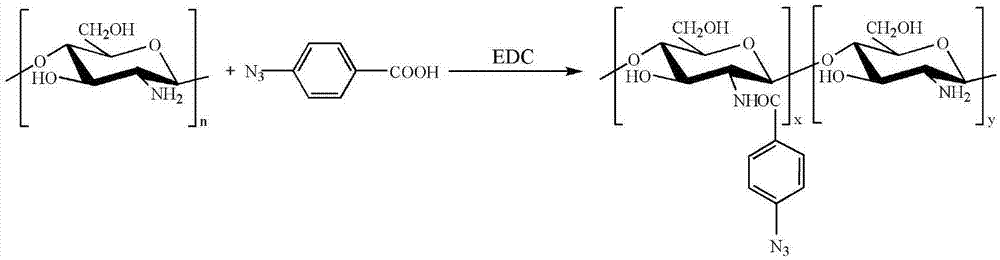

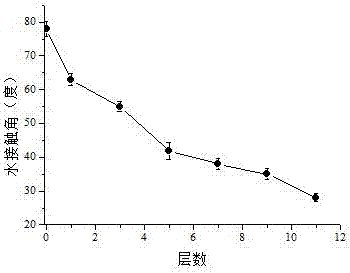

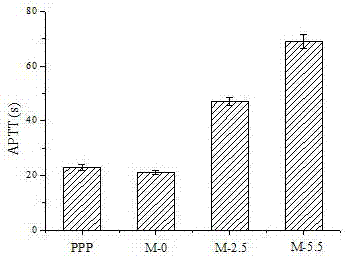

Layer-by-layer click bonding self-assembly-based polylactic acid material and preparation method thereof

The invention discloses a layer-by-layer click bonding self-assembly-based polylactic acid material and a preparation method thereof. The polylactic acid material is prepared from a base material and a modified layer. The preparation method comprises the steps of (1) azidation treatment of the surface of the polylactic acid material; (2) preparation of azide chitosan and alkynyl-containing cellulose sulfate; (3) preparation of an azide chitosan solution and an alkynyl-containing cellulose sulfate solution; and (4) layer-by-layer click bonding self-assembly of the azide chitosan and the alkynyl-containing cellulose sulfate on the surface of the polylactic acid material, namely alternately soaking the treated polylactic acid material into the azide chitosan solution and the alkynyl-containing cellulose sulfate solution for a period of time separately, taking out the polylactic acid material, cleaning by using ultra-pure water, drying and repeating the processes, so that layer-by-layer click self-assembly modification of the chitosan and the cellulose sulfate on the surface of the polylactic acid material is achieved. The material prepared by using the method has excellent protein adsorption resistance, and the surface hydrophilicity is significantly improved, thereby improving the blood compatibility of the surface of the material.

Owner:KUNMING UNIV OF SCI & TECH

Antibacterial towel

InactiveCN104013335AHas antibacterial propertiesAnti-inflammatoryDomestic applicationsLiquid/gas/vapor textile treatmentAloinSoftening

The invention discloses an antibacterial towel, belonging to the technical field of toiletries. The antibacterial towel is produced by the following steps: dissolving cellulose sulfate into water, and uniformly stirring with an aloe water extract and seaweed with particle size being less than 1 micron to obtain a spinning solution; spinning and weaving by use of the spinning solution; and performing boiling, dyeing, washing, softening, dehydration, drying and trimming treatment on the cloth to obtain the antibacterial towel. The antibacterial towel disclosed by the invention has antibacterial and anti-inflammatory functions; moreover, the production cost is low, the raw materials are natural, and no harmful chemical component is contained in the antibacterial towel.

Owner:梁福柳

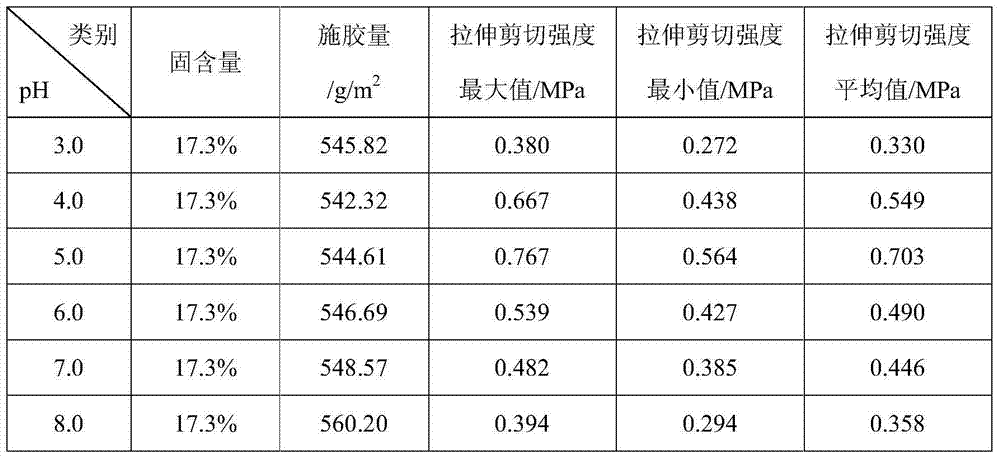

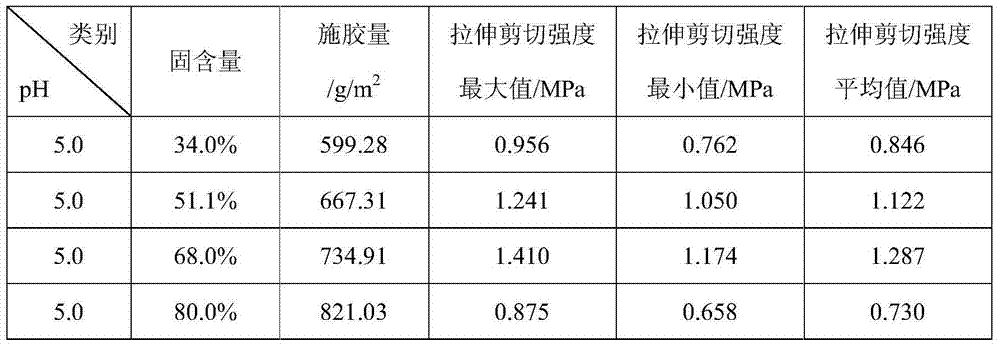

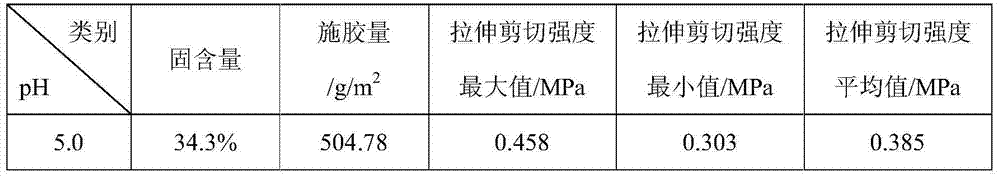

Water-soluble bio-based sulfate/sulfonate preparation process and uses of water-soluble bio-based sulfate/sulfonate as green environmental protection adhesive

ActiveCN104774575ABroaden the prospect of wide applicationHigh yieldCellulose adhesivesChitin adhesivesSolubilityPrice ratio

The present invention provides an adhesive, which comprises, by mass, 30-100% of cellulose sulfate, and less than or equal to 20% of chitosan and / or carboxymethyl chitosan salt. According to the present invention, the newly discovered sulfonation system and the abundant biomass raw material are utilized to develop cheap and green environmental protection water-soluble bio-based adhesive series products, wherein the material having the high performance price ratio is adopted to replace the existing urea-formaldehyde resin, polyvinyl alcohol, polyvinyl formal and soluble starch so as to fundamentally solve problems of fatal disadvantages of high formaldehyde residue, long term release, serious harm on human body health, and the like of the existing urea-formaldehyde resin, polyvinyl formal and other adhesives, and poor adhesion effect and high consumption of soluble starch and other natural high polymers; and the high-yield and stable bio-based sulfate / sulfonate adhesive is obtained, and the wide application prospects of the series of the adhesives can be expanded through the wide raw material sources, the low preparation cost, the excellent water solubility, the polymer performance, the formaldehyde-free green environmental protection, and other multiple advantages.

Owner:SOUTHWEST UNIV +1

Cellulose sulfate and other sulfated polysaccharides to prevent and treat papilloma virus infection and other infections

Owner:RUSH UNIV MEDICAL CENT +1

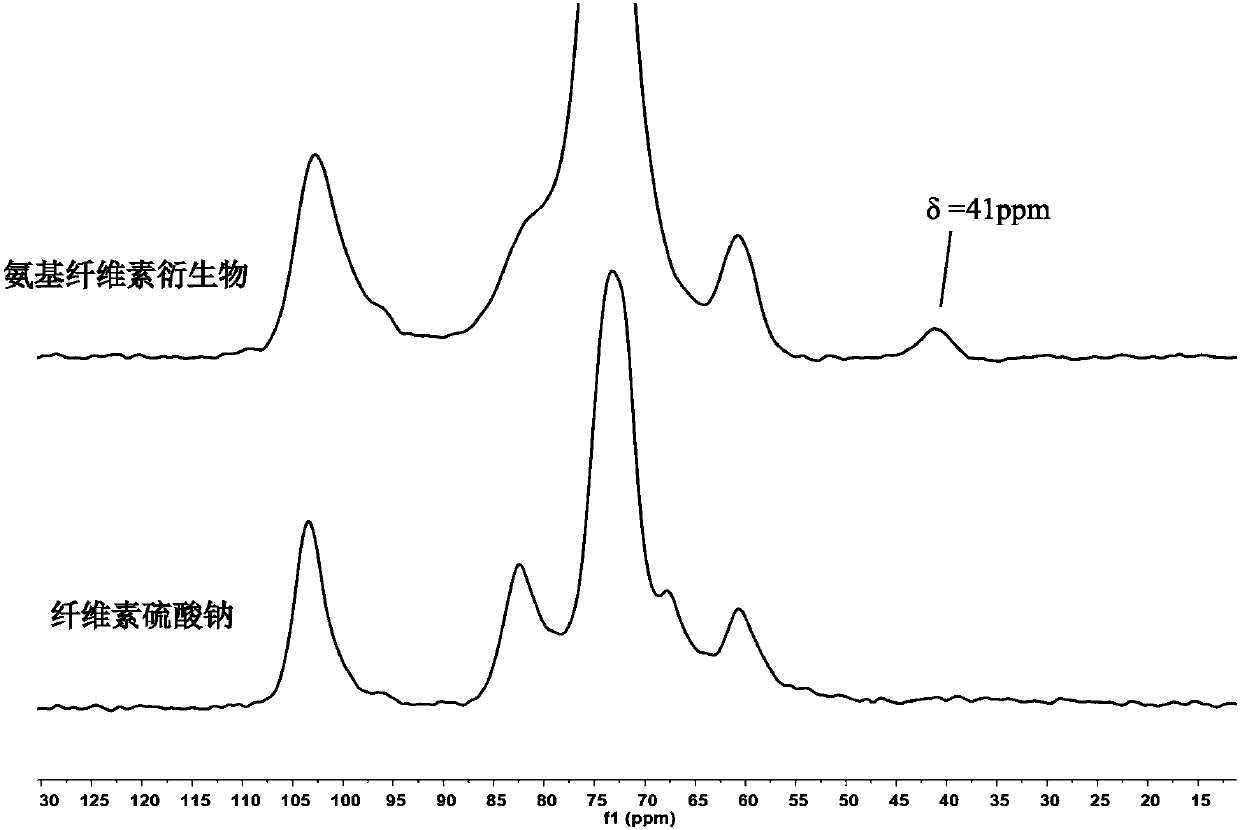

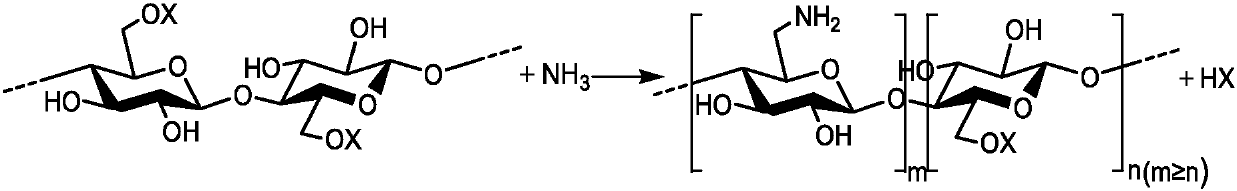

Aminocellulose and application thereof

InactiveCN107597076ALow priceWide variety of sourcesOther chemical processesWater contaminantsSulfateWastewater

The invention discloses aminocellulose and application thereof. A structure formula is shown in the description, wherein X is -SO3Na or -SO3NH4, and has the amino substitution degree DS being 0.50 to1.40. The cellulose sulfate is used as raw materials for synthesizing the aminocellulose together with ammoniation reagents through a one-step method; the raw material price is low; the resources arewide; the process is simple; the cost is low; the defects of complicated production process, severe reaction conditions, high raw material price and high process cost of the existing synthesis methodare overcome. The prepared aminocellulose has the advantages that the adsorption effect on heavy metal ions in the waste water is relatively good; the practical application value is relatively high.

Owner:XIAMEN UNIV

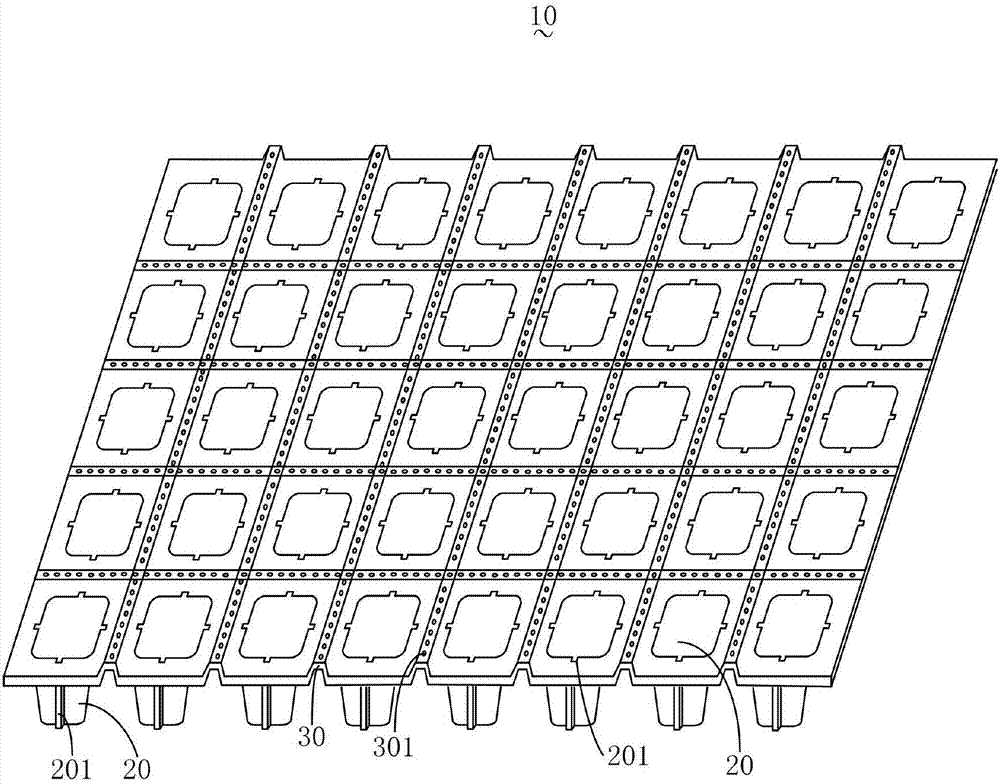

Application of bio-based sulfonate as water-retaining agent and slow-release inhibitor in preparation of seedling hole tray and seedling hole tray

InactiveCN107114144AImprove fertilizer efficiencyProlong degradation timeCultivating equipmentsSulfonateSulfate

The invention provides an application of bio-based sulfonate as a water-retaining agent and a slow-release inhibitor in preparation of a seedling hole tray. The bio-based sulfonate is prepared from cellulose sulfate monoester salt, hemicellulose sulfate monoester salt and lignosulfonate. The invention further provides the seedling hole tray prepared from the bio-based sulfonate. The seedling hole tray prepared from the bio-based sulfonate comprises paper pulp and the bio-based sulfonate, wherein the mass of the bio-based sulfonate accounts for 10-15% of total mass of the seedling hole tray.

Owner:NINGXIA UNIVERSITY +2

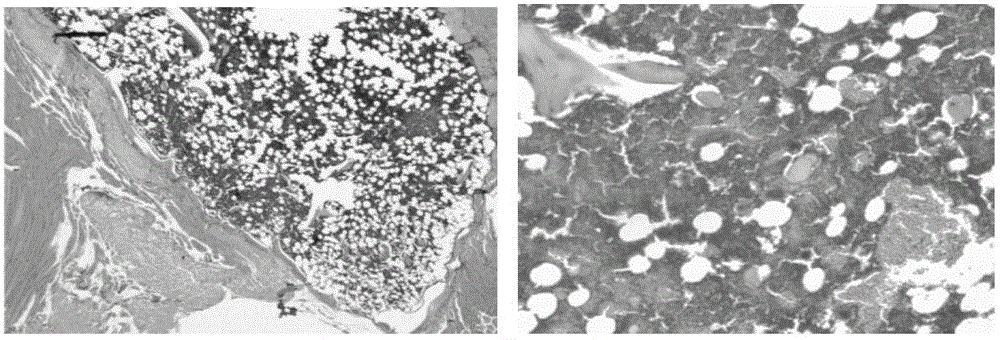

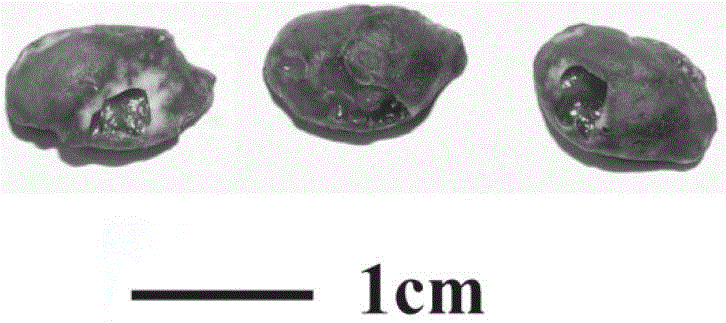

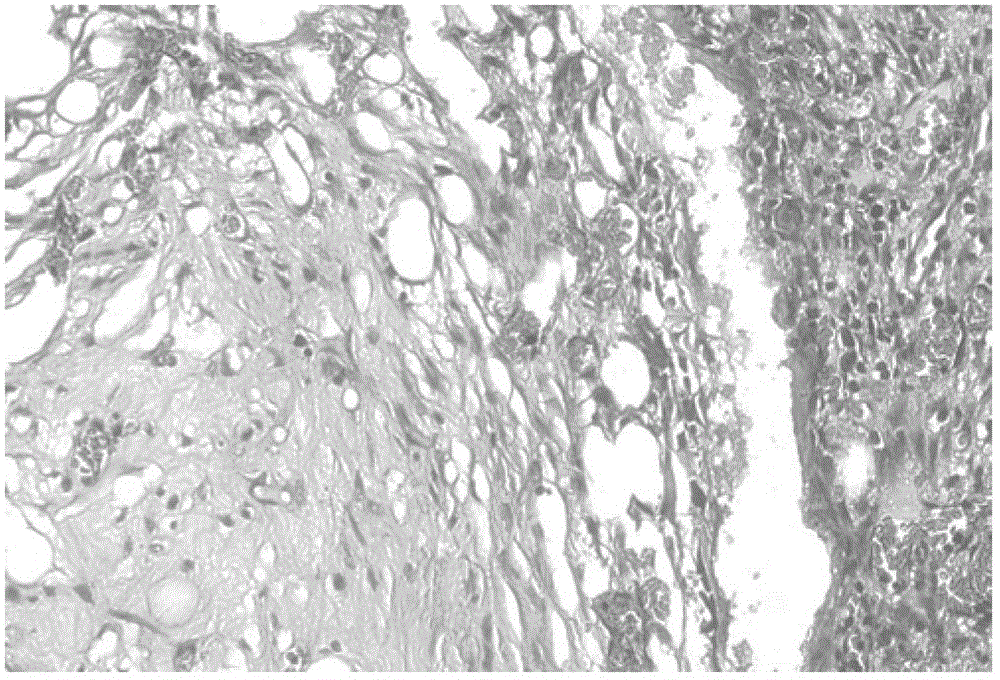

Biological activity factor composition for promoting ossification and vascularization

ActiveCN102895704APromote osteogenesisPromote vascularizationOrganic active ingredientsPeptide/protein ingredientsDrug biological activityGlucan

The invention discloses a biological activity factor composition for promoting ossification and vascularization, which comprises a biological active factor and carboxylated polysaccharide, the biological activity factor is one or more selected from a bone morphogenetic protein, a transforming growth factor, a blood vessel endothelial growth factor, a basic fibroblast growth factor and an ossification protein; and the carboxylated polysaccharide is one or more selected from sulfonated chitosan, sulfonated glucan, heparin, heparin sulfate and sulfate cellulose. The invention also discloses a preparation method of a composition and a transplant containing the composition. The composition provided by the invention can promote the ossification and the blood vessel generation, can be composited with a medically acceptable carrier, and can be used in the field of bone defect repair by employing an implantation mode or an injection mode.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for producing antithrombin composition

ActiveUS20100113754A1High yieldPeptide/protein ingredientsMammal material medical ingredientsSulfateAqueous solution

The provision of an antithrombin composition having a desired α-form content rate or β-form content rate is required. The invention provides a process for producing an antithrombin composition having a desired α-form content rate or β-form content rate which is prepared by contacting an antithrombin-containing aqueous solution with a Cellufine Sulfate chromatography carrier.

Owner:KYOWA HAKKO KIRIN CO LTD

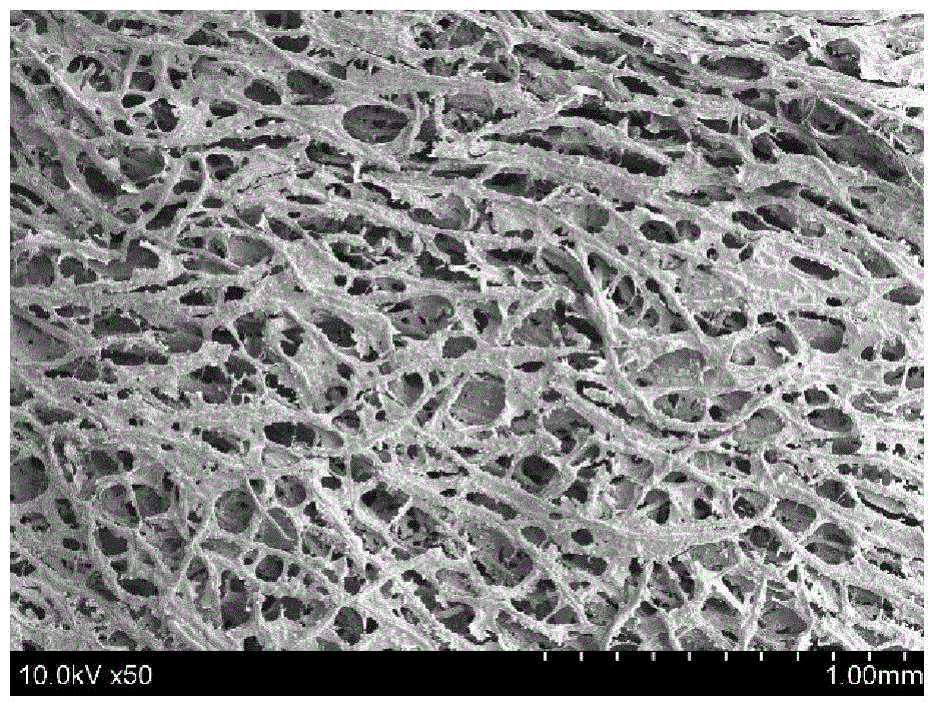

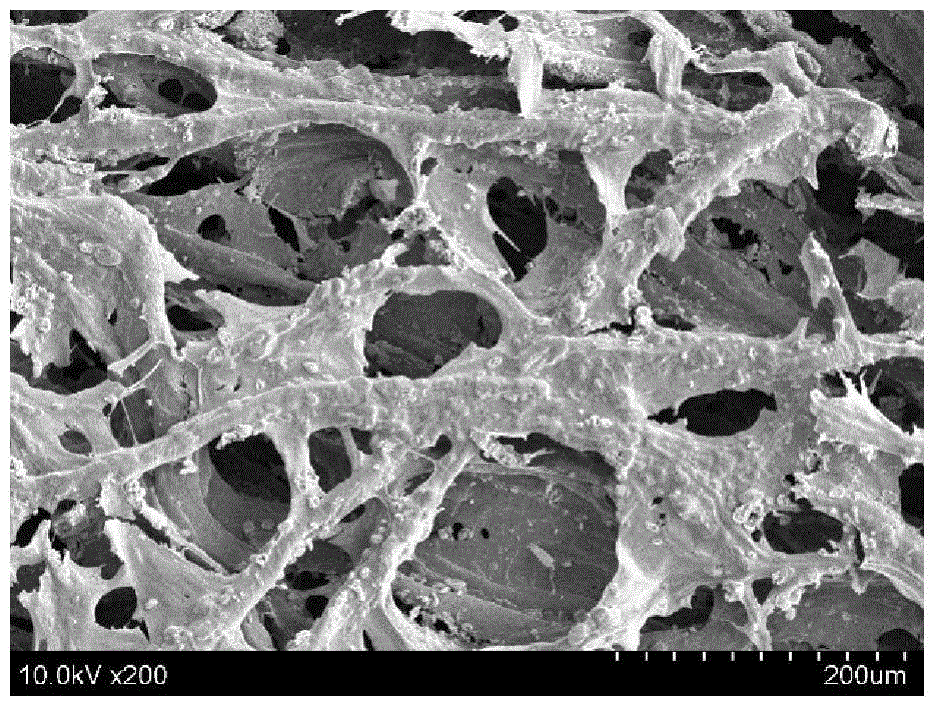

Superabsorbent cellulosic fiber

The present invention describes a modified cellulosic fiber having superabsorbent properties. The modified fiber of the invention has a fibrous structure substantially identical to the cellulosic fiber from which it is derived. The modified fiber is a water-swellable, water-insoluble fiber that substantially retains its fibrous structure in its expanded, water-swelled state. The modified fiber is a sulfated and crosslinked cellulosic fiber having a liquid absorption capacity of at least about 4 g / g. In one embodiment, the modified fiber is an individual, crosslinked, sulfated cellulosic fiber. In another aspect, the invention provides a rollgood that includes the modified fiber, absorbent composites and articles that include the modified fiber, and methods for making the modified cellulosic fiber.

Owner:WEYERHAEUSER CO

Method for preparing cellulose sulfate

The invention discloses a method for preparing cellulose sulfate. The method comprises the following steps: placing a container in a constant temperature environment at -10 DEG C to 0 DEG C, configuring a mixed reaction solution according to a mole ratio of 1:1 to 1:2.5 of waterless ethanol to sulfuric acid; adding 50g cellulose and 0 to 8g waterless sal glauberi into a 0.5L to 3L mixed reaction solution to react for 1 to 10 hours with a maintaining temperature of -10 DEG C to 0 DEG C, carrying out pumping filtration to the reaction solution and washing with ethanol until the pH value of washing liquid presents neutral; dissolving the filtrated residue in water with maintaining a temperature of 0 DEG C to 5 DEG C, dripping aqueous alkali until pH value is regulated to 7-9; carrying out pumping filtration at normal temperature wherein the filtrate is a cellulose sulfate aqueous solution with different polymerization degree and replacement degree, adding 1 to 50 times volume of ethanol in the aqueous solution for obtaining cellulose sulfate by centrifuging or filtering. The method of the invention employs cellulose for preparing cellulose sulfate, molecular weight and degree of substitution are controllable, The waterless ethanol is taken as a reagent with a better security, A food grade safety reagent is employed in the whole process, and no other harmful waste is generated in the reaction process which is environmental-friendly.

Owner:HUAQIAO UNIVERSITY

Preparation method of diesel anti-wear agent

ActiveCN105419889AShort reaction timeHigh catalytic efficiencyLiquid carbonaceous fuelsFuel additivesGlycerolWastewater

The invention discloses a preparation method of a diesel anti-wear agent. The preparation method includes the following steps: 1) adding glycerol, a fatty acid-type diesel anti-wear agent and cellulose sulfate into a reaction kettle with uniform mixing; 2) increasing the temperature to 110-130 DEG C under a vacuum condition and carrying out a reaction for 2-4 h; and 3) when the esterification reaction is finished, cooling and separating a reaction liquid to remove the glycerol and a catalyst in a lower layer to obtain the diesel anti-wear agent. Compared with a method in which a homogeneous catalyst is added to prepare the diesel anti-wear agent in the prior art, the cellulose sulfate, as a catalyst, is insoluble in the reaction system and can be used repeatedly. With dehydration under the vacuum condition, the esterification reaction is accelerated, so that reaction time is greatly reduced. The preparation method is simple, is free of waste water emission and satisfies environment protection demand.

Owner:JIANGXI SILINCO

Cellulose sulfate hydrogel and preparation method thereof

The invention belongs to the technical field of gel materials and discloses a cellulose sulfate hydrogel and a preparation method thereof. The preparation method of the hydrogel comprises the following steps: mixing cellulose and a sulfating agent for a sulfating reaction to obtain cellulose sulfate; suspending the cellulose sulfate in deionized water, and stirring until the solution is transparent; adjusting the pH value; adding glycerin and zwitterion as crosslinking agents, and stirring and mixing uniformly; and cooling and standing to obtain the cellulose sulfate hydrogel. According to the invention, by adopting mild low acid and long-time controllable sulfating, the molecular weight of the product is high; and by adding glycerin and zwitterion for crosslinking, the strength of the cellulose sulfate hydrogel is enhanced, and an important supplement effect is realized on the functional application of cellulose.

Owner:SOUTH CHINA UNIV OF TECH

Cellulose sulfate and other sulfated polysaccharides to prevent and treat papilloma virus infection and other infections

A method for treating and preventing various infections, including papilloma virus and fungal and parasitic infections is provided. In particular, an effective amount of a sulphated polysaccharide, such as cellulose sulphate and dextran sulphate are administered to prevent and treat these infections. The invention also relates to use of these compounds for the prevention and inhibition of malignant epithelial lesions associated with papilloma virus, such as cervical cancer.

Owner:RUSH PRESBYTERIAN ST LUKES MEDICAL CENT +1

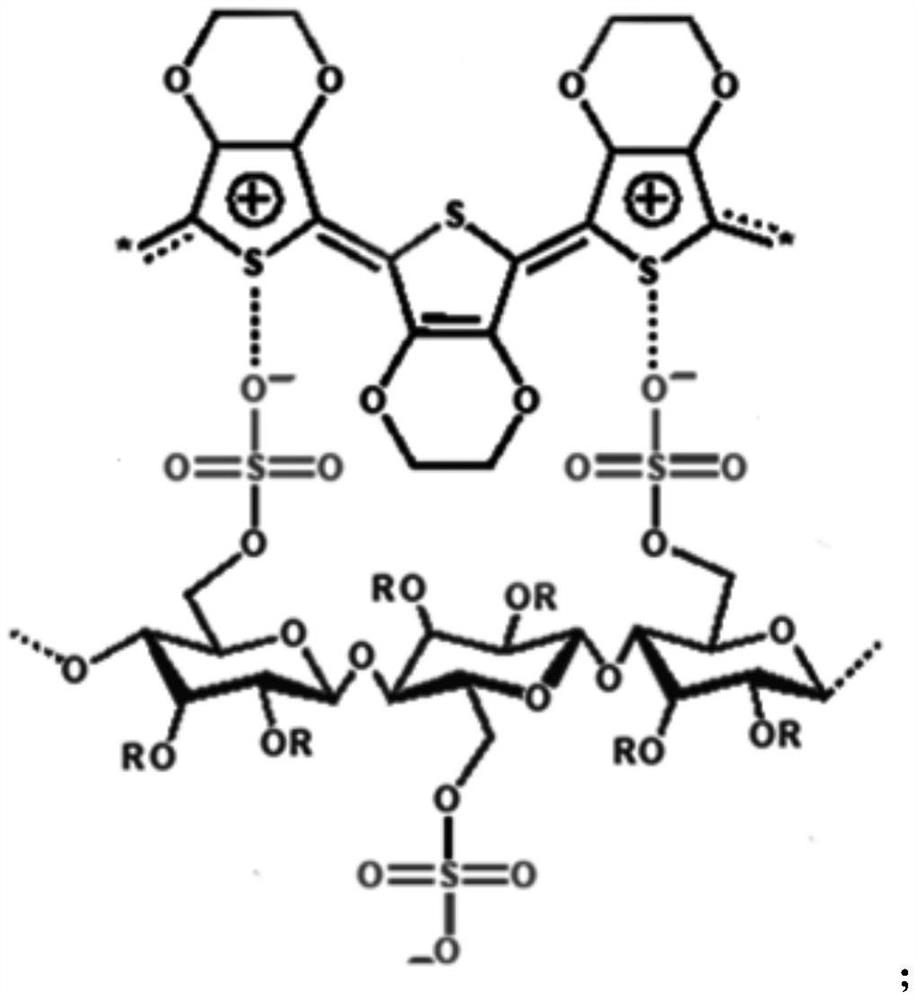

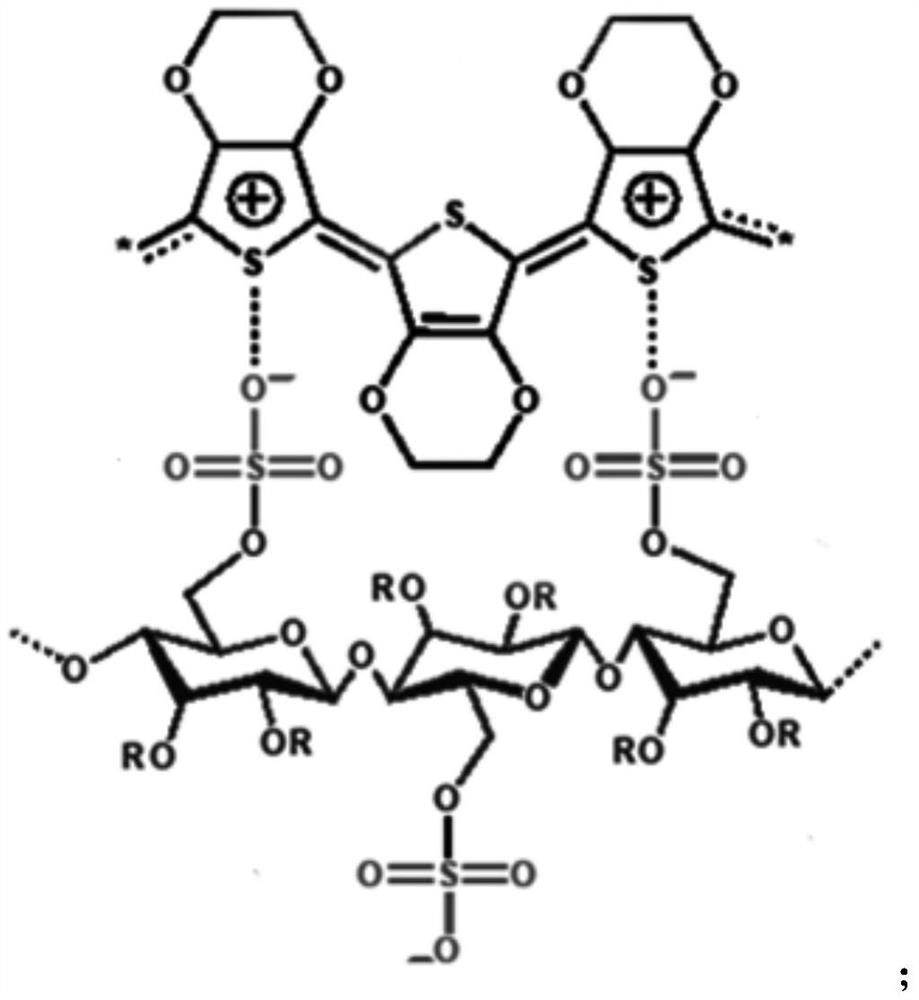

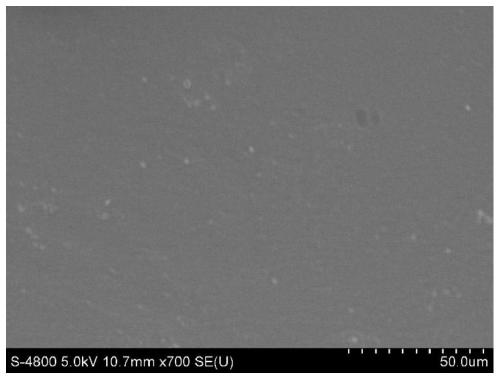

PEDOT:CS water dispersion system taking cellulose sulfate as template and preparation method of PEDOT:CS water dispersion system

The invention discloses a PEDOT:CS water dispersion system taking cellulose sulfate as a template and a preparation method of the PEDOT:CS water dispersion system. The method comprises the following steps: adding cellulose sulfate into water to obtain a cellulose sulfate aqueous solution, and then adding a monomer EDOT to obtain a mixed solution; and adding ammonium persulfate and ferric chlorideinto the mixed solution for polymerization reaction to obtain a PEDOT:CS water dispersion system taking cellulose sulfate as a template. On one hand, the invention provides the method for preparing cellulose sulfate, and provides the new PEDOT water dispersion system by replacing PSS with cellulose sulfate as a polymerization template of PEDOT. On the other hand, the prepared PEDOT:CS aqueous dispersion has good system stability, high PEDOT content and high conductivity, and has good application prospects in the fields of electrochromism, electromagnetic shielding, supercapacitors, electrochemical sensors and the like.

Owner:SOUTH CHINA UNIV OF TECH

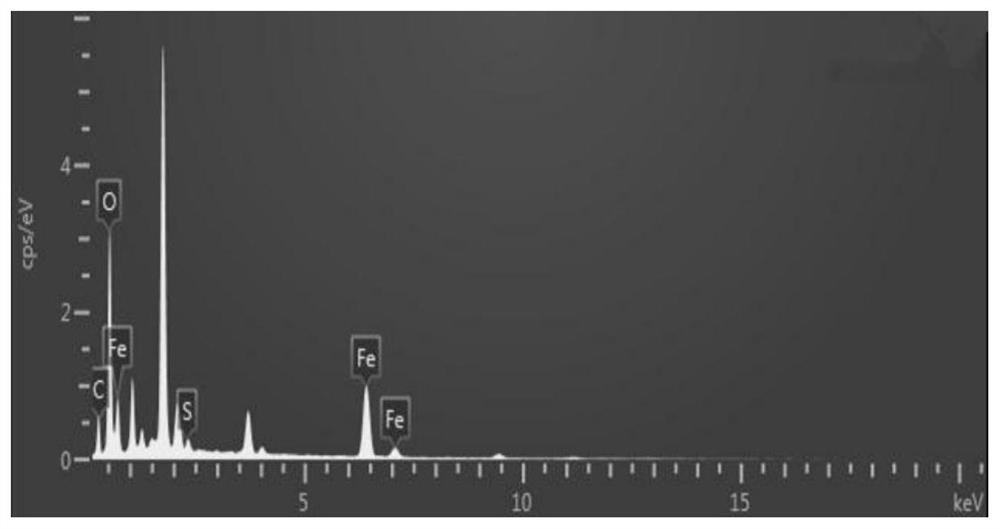

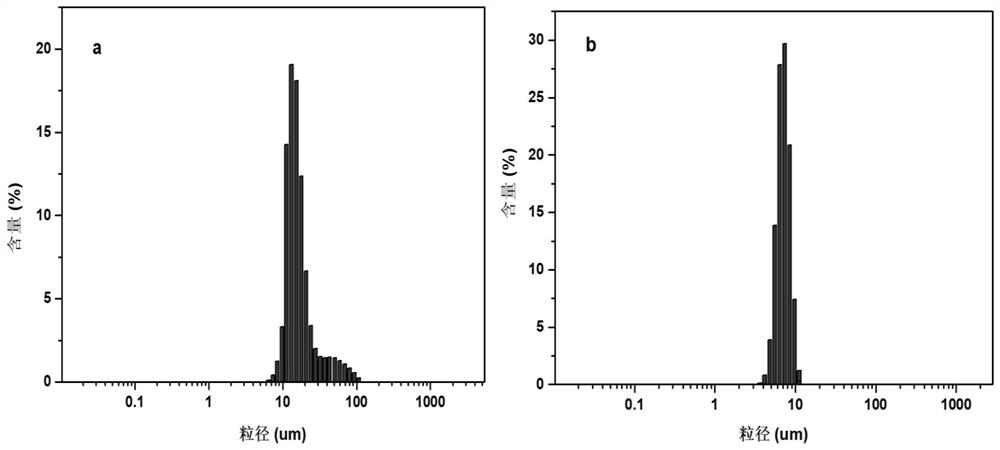

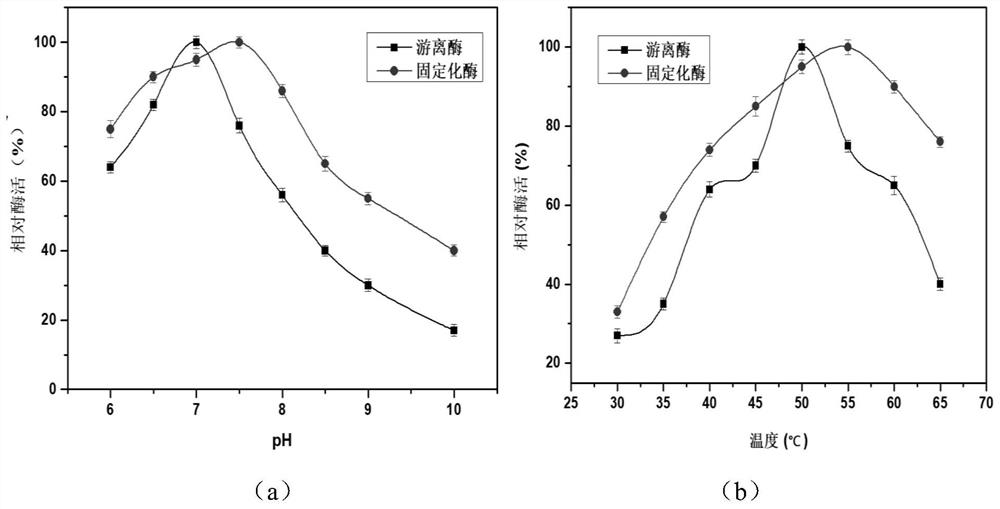

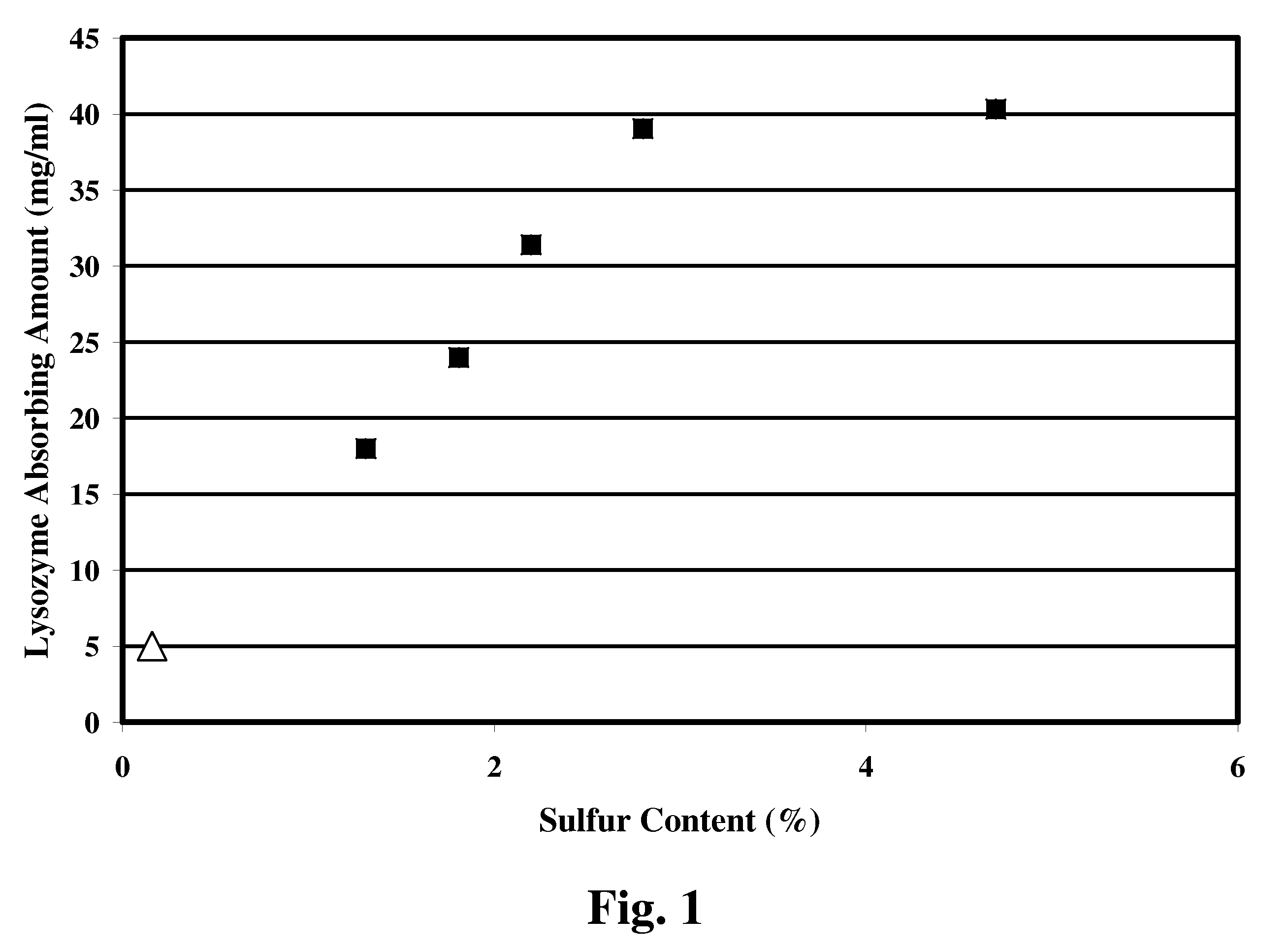

Chitosan-cellulose sulfate magnetic porous composite microsphere as well as preparation and application thereof

InactiveCN111909427AWide variety of sourcesGood biocompatibilityOther chemical processesPeptide preparation methodsProtein adsorptionIonic liquid

The invention belongs to the technical field of porous microspheres, and discloses a chitosan cellulose sulfate magnetic porous composite microsphere as well as preparation and application thereof. The preparation method comprises the following steps: 1) dissolving chitosan and cellulose sulfate in an ionic liquid to obtain a mixed solution; 2) dispersing magnetic particles in the mixed solution to obtain a magnetic suspension; mixing the oil phase, an emulsifying agent and a pore-foaming agent to obtain an emulsifying system; and 3) dispersing the magnetic suspension in an emulsification system, emulsifying under a heating condition, carrying out alcohol precipitation, cooling, and carrying out subsequent treatment to obtain the chitosan cellulose sulfate magnetic porous composite microsphere. The method disclosed by the invention is simple, mild in condition, green and environment-friendly. The prepared magnetic porous composite microspheres are rich in pores, large in specific surface area, multiple in active sites and good in lipase immobilization effect. The magnetic porous composite microsphere is applied to enzyme immobilization, protein adsorption separation and protein drug delivery.

Owner:SOUTH CHINA UNIV OF TECH

Process for preparing macroporous cellulose sodium sulfate-polydimethyl diallyl ammonium chloride biolgoical micro capsule

InactiveCN1586705AChange permeabilityDoes not affect good performanceMicroballoon preparationMicrocapsule preparationBiocompatibility TestingPolymer solution

The preparation process of macroporous sodium cellulose sulfate-polydimethyl diallyl ammonium chloride biological microcapsule includes: compounding starch and sodium cellulose sulfate into mixed solution with starch in 0.7-1.5 wt% and sodium cellulose sulfate in 0.5-5 wt% as the anion polymer solution for the system; dropping the mixed solution into polydimethyl diallyl ammonium chloride solution to form microcapsule through the interface reaction between anion and cation for 40-120 min; washing the microcapsule; transferring to amylase solution of 1-2 % concentration, setting for 1-24 hr and re-washing. The present invention has independently regulated membrane permeability, microcapsule membrane characteristic altered via changing the sort and amount of starch, good biocompatibility of the materials, simple preparation process, and mild condition.

Owner:ZHEJIANG UNIV

Process for preparing controllable entrapped molecular weight biological micro capsule

InactiveCN1587402AChange permeabilityAdjust molecular weight cut offOn/in organic carrierBiocompatibility TestingMechanical property

The present invention adopts sodium cellulose sulfate and PDMDAAC as the basic material of the microcapsule, and inorganic salt as membrane pore size controlling matter. The preparation process includes the following steps: compounding anionic polymer sodium cellulose sulfate solution of 3-5 wt% concentration; dropping into the solution containing sodium chloride or calcium chloride in 0-1.2 wt% and PDMDAAC in 2-8 wt% to produce anionic and cationic ion interface reaction forming capsule for 20-120 min; and washing the capsule. By means of altering the concentration of sodium chloride or calcium chloride in the solution, the capsule membrane pore size may be regulated, the entrapped molecular weight may be controlled and the penetrating performance of the capsule membrane may be altered. The present invention uses cheap materials of good biocompatibility and has simple process and mild condition.

Owner:ZHEJIANG UNIV

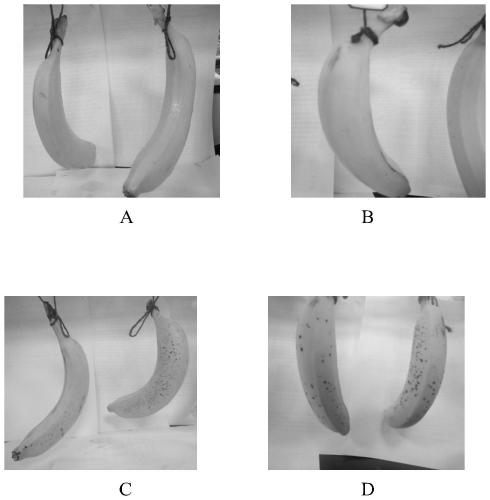

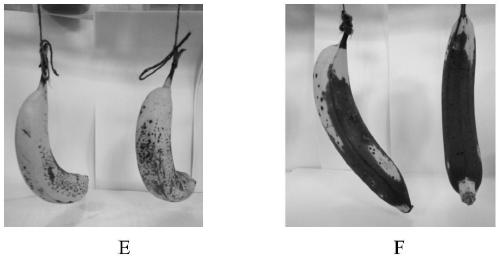

Edible antibacterial food packaging film

InactiveCN109762208AExcellent oxygen barrierGood oil resistanceFlexible coversWrappersSodium cellulose sulfateEugenol

The invention relates to an edible antibacterial food packaging film, and belongs to the technical field of films. The edible antibacterial food packaging film comprises cellulose sulfate or saltof the cellulose sulfate, soy isolate protein, a natural bacteriostatic agent and glycerinum, the edible antibacterial food packaging film is prepared from the compositions in parts by weight: 10-70 partsof the cellulose sulfate or the salt of the cellulose sulfate, 1-70 parts of the soy isolate protein, 1-10 parts of the natural bacteriostatic agent, and 1-5 parts of the glycerinum, the cellulose sulfate salt is sodium cellulose sulfate, and the natural bacteriostatic agent is thymol, eugenol, or cinnamic aldehyde. According to the edible antibacterial food packaging film, adopted materials are all non-toxic and edible materials, the prepared packaging film is edible and has antibacterial function, and has good application prospects.

Owner:DALIAN UNIV

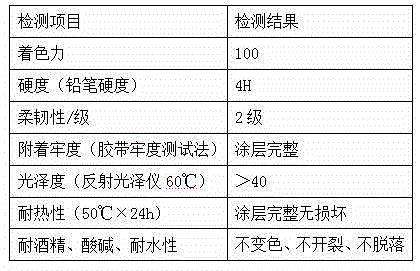

Flexible special extinction printing ink containing modified glass powder and preparation method of flexible special extinction printing ink

The invention relates to special printing ink and particularly relates to flexible special extinction printing ink containing modified glass powder and a preparation method of the flexible special extinction printing ink. The flexible special extinction printing ink is prepared from the following raw materials in parts by weight: 20-30 parts of hydroxyl acrylic resin, 2-3 parts of lead-free glass powder, 30-38 parts of alkyd resin, 2-4 parts of vinyl n-butyl ether, 2-3 parts of amino silicon oil, 4-8 parts of ethylene glycol diglycidyl ether, 2-5 parts of cellulose sulfate, 1-3 parts of borax, 15-20 parts of a DBE solvent, 12-18 parts of ethyl acetate, 20-30 parts of environment-friendly pigment and 2-4 parts of auxiliaries. The flexible special extinction printing ink disclosed by the invention adopts the hydroxyl acrylic resin and the alkyd resin as connecting materials and adopts the environment-friendly low-toxicity solvent to greatly improve the environment friendliness of the printing ink; the lead-free glass powder containing borax molten and mixed in the raw materials is subjected to surface modification with amino silicon oil, and thus the dispersibility of the lead-free glass powder containing borax in a resin solution is improved, and the glass powder mixed with the borax is capable of effectively quickening the curing of the printing ink slurry. The printing ink coating obtained by the special printing ink disclosed by the invention is excellent in mechanical performance after being dried, unlikely to scrape off and soft in gloss. The printed object has a great aesthetic feeling.

Owner:合肥宏图彩印有限公司

Towel and machining process thereof

The invention discloses a towel and a machining process thereof. The towel comprises the following components in mass percent: 30%-50% of mixed fibers, 10%-20% of milk protein fibers, 20%-30% of soybean protein composite fibers, 15%-25% of bamboo fibers and the balance of antibacterial functional polypropylene fibers, wherein the mixed fibers are formed by mixing 50%-60% of cellulose sulfate, 30%-35% of aloe water extract and 5%-20% of alga with the grain diameter less than 1 micron. According to the towel, the soft performance of the product is remarkably improved and the towel has the characteristics of water-absorbing property and the like; in a finishing process, a hydrophilic agent and a soft auxiliary agent do not need to be added, and the soft performance is not gradually weakened along the increasing of the use frequency, so that the service life of the towel is prolonged.

Owner:HUAIAN COMNEER TEXTILE

A bioactive factor composition for promoting osteogenesis and vascularization

ActiveCN102895704BPromote osteogenesisPromote vascularizationOrganic active ingredientsPeptide/protein ingredientsFactor iiDrug biological activity

The invention discloses a biological activity factor composition for promoting ossification and vascularization, which comprises a biological active factor and carboxylated polysaccharide, the biological activity factor is one or more selected from a bone morphogenetic protein, a transforming growth factor, a blood vessel endothelial growth factor, a basic fibroblast growth factor and an ossification protein; and the carboxylated polysaccharide is one or more selected from sulfonated chitosan, sulfonated glucan, heparin, heparin sulfate and sulfate cellulose. The invention also discloses a preparation method of a composition and a transplant containing the composition. The composition provided by the invention can promote the ossification and the blood vessel generation, can be composited with a medically acceptable carrier, and can be used in the field of bone defect repair by employing an implantation mode or an injection mode.

Owner:EAST CHINA UNIV OF SCI & TECH

Anti-wear agent for mechanical lubricating oil and preparation method of anti-wear agent

The invention discloses an anti-wear agent for mechanical lubricating oil and a preparation method of the anti-wear agent. The anti-wear agent is prepared from components in parts by weight as follows: 10-20 parts of sulfurized isobutene, 15-30 parts of chlorinated paraffin, 4-12 parts of ricinoleic acid, 3-8 parts of silica powder, 3-14 parts of nano titanium dioxide powder, 2-8 parts of magnesium oxide, 4-10 parts of cellulose sulfate, 2-8 parts of sulfonated graphene and 5-15 parts of nano-molybdenum disulfide. The preparation method is simple, and by means of the prepared anti-wear agent, engine wear can be reduced, and working life of each friction part can be prolonged.

Owner:马鞍山中粮生物化学有限公司

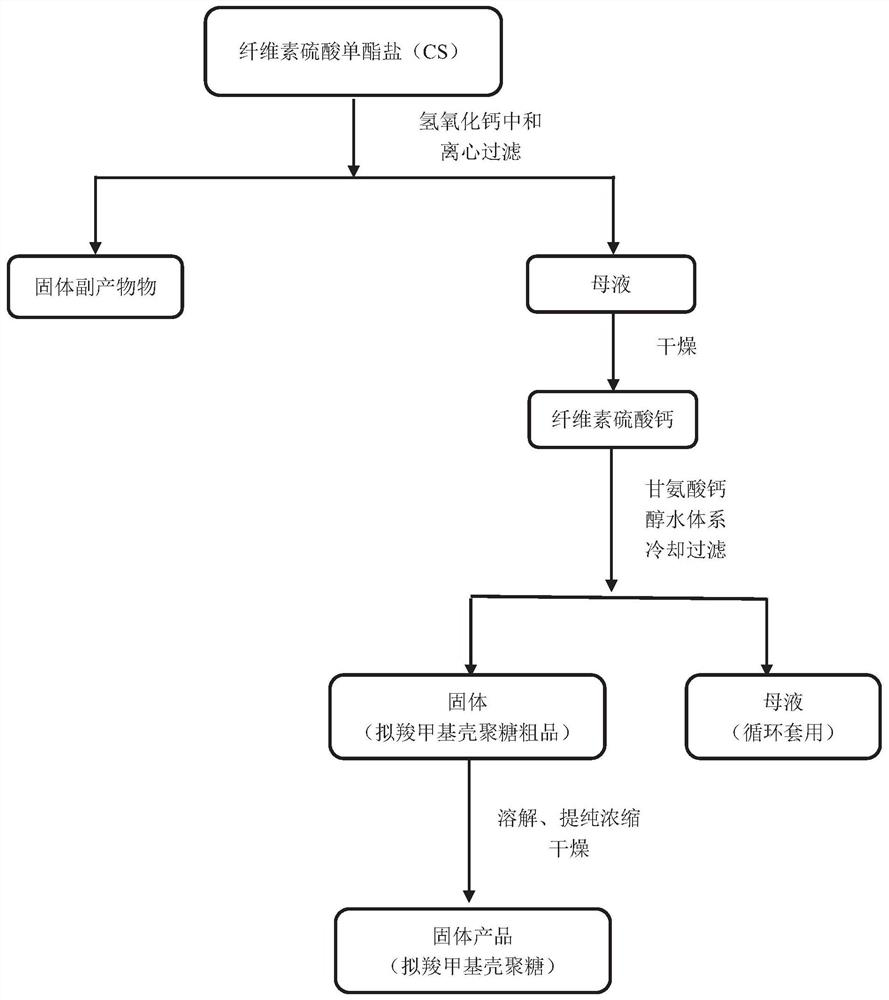

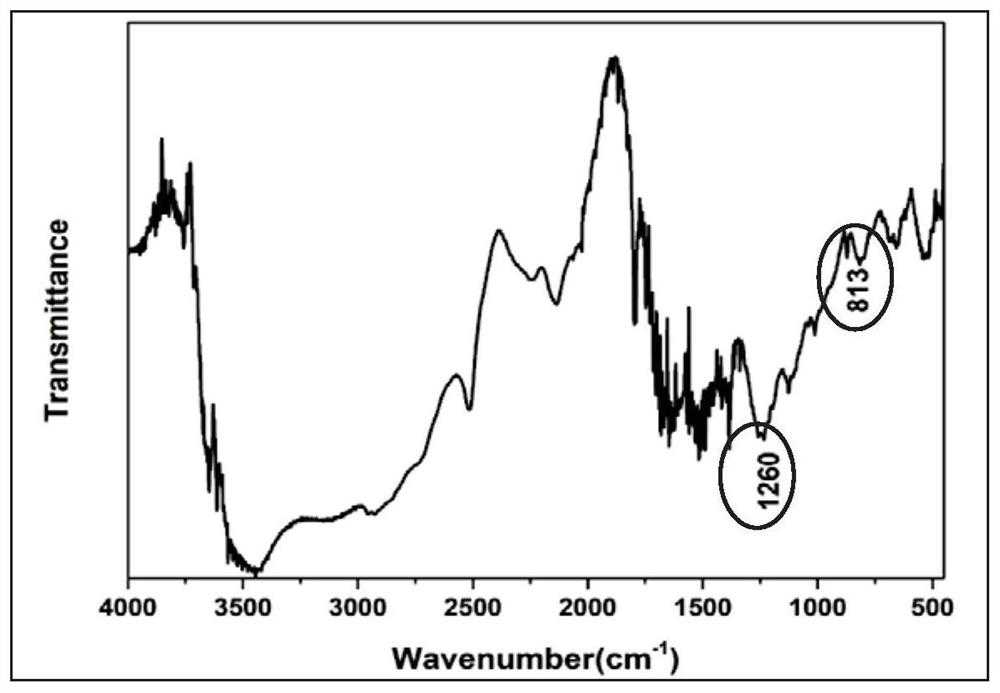

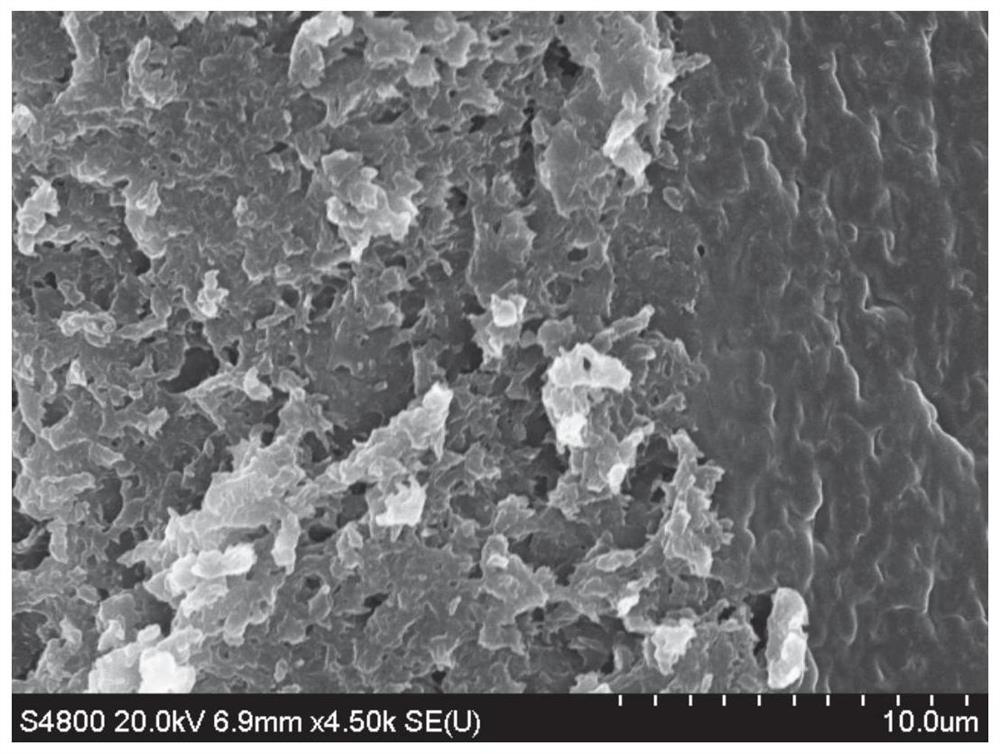

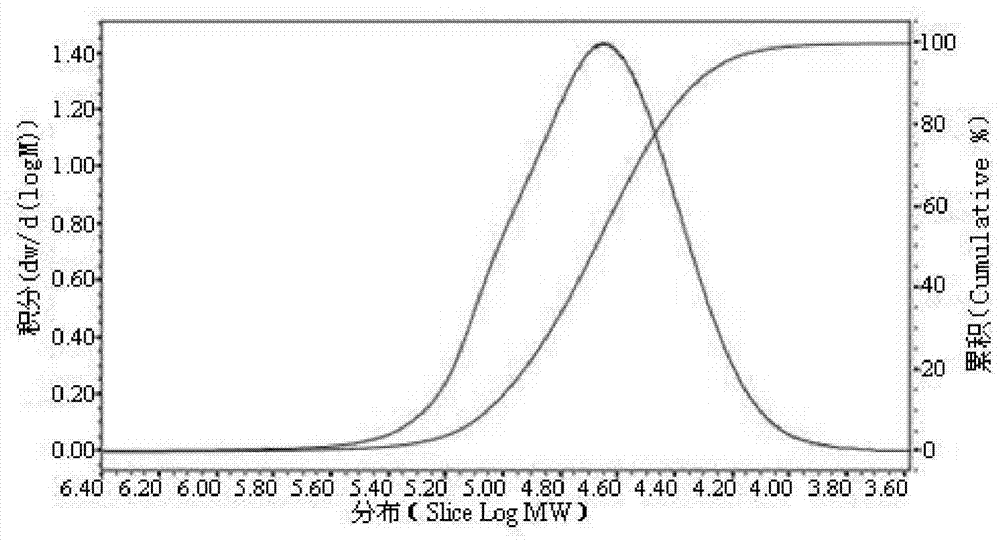

Quasi-carboxymethyl chitosan and new one-step synthesis process

ActiveCN112175096AStickyAbsorbentCellulose derivative adhesivesNitrogenous fertilisersProcess engineeringSubstitution reaction

The invention relates to a quasi-carboxymethyl chitosan polymer, a new process for synthesizing the polymer in one step and a composition containing the polymer. The cellulose sulfate monoester salt or bio-based mixed sulfate monoester salt is used as a raw material, a novel method for synthesizing the quasi-carboxymethyl chitosan polymer by one step through a substitution reaction with calcium glycinate in a water or alcohol-water system, in particular to the method for producing quasi-carboxymethyl chitosan with higher conversion rate and higher substitution degree in a shorter time and at lower temperature by using the alcohol-water system, and the process is simple and convenient in synthesis process, few in byproducts, high in substitution degree and suitable for industrial production, and separation and purification are easily carried out. According to the breakthrough technology, low-cost and large-scale production of the quasi-carboxymethyl chitosan becomes possible, and wide application of the quasi-carboxymethyl chitosan polymer with high cost performance in the fields of water-retaining agents, sustained and controlled release fertilizers, liquid foliar fertilizers, adhesives and the like is certainly promoted.

Owner:XIAMEN UNIV +2

A kind of preparation method of diesel oil antiwear agent

ActiveCN105419889BShort reaction timeHigh catalytic efficiencyLiquid carbonaceous fuelsFuel additivesGlycerolWastewater

The invention discloses a preparation method of a diesel antiwear agent, which comprises the following steps: adding glycerol, fatty acid type diesel antiwear agent, and cellulose sulfuric acid into a reaction kettle and mixing evenly, and raising the temperature to 110-130°C under vacuum conditions. After the esterification reaction is completed, the reaction liquid is cooled and separated, and the glycerin and catalyst in the lower layer are removed to obtain a fatty acid ester type diesel antiwear agent. Compared with the diesel antiwear agent prepared by adding a homogeneous catalyst in the prior art, the cellulose sulfuric acid catalyst of the present invention is insoluble in the reaction system and can be reused; dehydration under vacuum conditions promotes the rapid esterification reaction, greatly shortening the reaction time. Therefore, the preparation process of the present invention is simple, no waste water is discharged, and the requirements of environmental protection are met.

Owner:JIANGXI SILINCO

A kind of cellulose sulfate hydrogel and preparation method thereof

Owner:SOUTH CHINA UNIV OF TECH

A preparation process of water-soluble bio-based sulfate/sulfonate and its use as a green and environmentally friendly adhesive

ActiveCN104774575BBroaden the prospect of wide applicationHigh yieldCellulose adhesivesChitin adhesivesEnvironmental resistanceHuman health

The invention provides an adhesive agent, comprising cellulose sulfate, chitosan or / and carboxymethyl chitosan salt, cellulose sulfate accounts for 30-100%, chitosan and / or carboxymethyl chitosan Polysaccharide salt is less than or equal to 20%, calculated by mass ratio. The invention utilizes the newly discovered sulfonation system and abundant biomass raw materials to develop high-quality, low-cost, green and environmentally friendly water-soluble bio-based binder series products, and replaces the existing urea-formaldehyde resin, polyvinyl alcohol, Polyvinyl formal and soluble starch fundamentally solve the fatal defects of existing adhesives such as urea-formaldehyde resin and polyvinyl formal that have high formaldehyde residues, long-term release, and serious harm to human health, as well as natural high levels of soluble starch. The problem of poor molecular bonding effect and large dosage. The present invention obtains a high yield of stable bio-based sulfate / sulfonate adhesives. Extensive sources of raw materials and cheap preparation costs, excellent water solubility and high molecular properties, and multiple advantages such as formaldehyde-free and green environmental protection can expand the wide application prospects of this series of adhesives.

Owner:SOUTHWEST UNIV +1

Antiviral fiber assembly with cellulose sulfate

ActiveUS10201561B2Gentle to human bodySolve the lack of activityBiocideOrganic active ingredientsFiberHyaluronidase

An object of the present invention is to provide an antiviral fiber assembly in which an antiviral agent is retained with chemical stability over a long period of time, and which is gentle to the human body. A further object of the present invention is to provide a fiber assembly with cellulose sulfate that can exhibit sufficient antiviral activity over a long period of time. Further, another object of the present invention is to provide a textile product obtained using such a fiber assembly.The present invention provides a fiber assembly with cellulose sulfate, wherein the hyaluronidase inhibitory activity is 50% or higher; and a process for producing a fiber assembly with cellulose sulfate, including treating a fiber assembly with an aqueous cellulose sulfate solution and drying, then treating the same with a pH buffer solution and drying.

Owner:FIBERVISIONS LP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com