Layer-by-layer click bonding self-assembly-based polylactic acid material and preparation method thereof

A polylactic acid material and self-assembly technology, which is used in the fields of biomedical materials, polymer chemistry and biomacromolecule self-assembly to achieve the effect of maintaining natural conformation and biological activity, wide sources and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

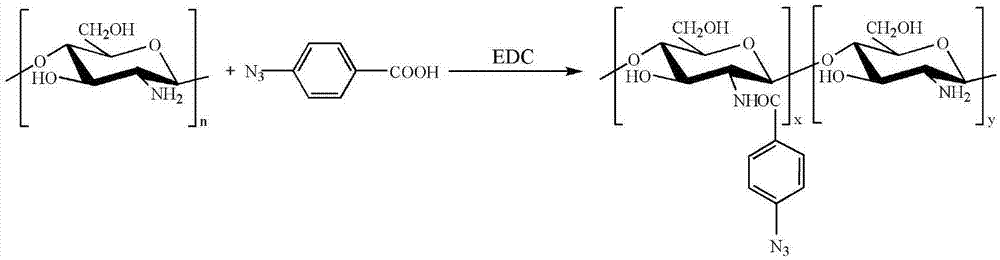

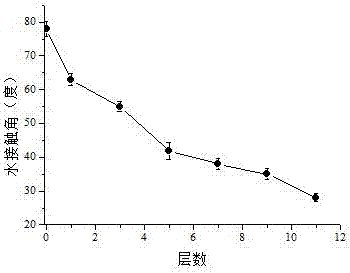

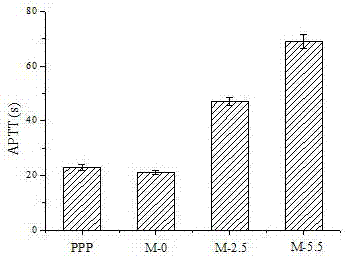

[0031]Example 1: The polylactic acid material based on layer-by-layer click bonding self-assembly is composed of a substrate and a modification layer. It is obtained by surface modification through click-bonding self-assembly; wherein, the modification layer contains alkynyl-containing cellulose sulfate and azido-chitosan which are layer-by-layer click-bonding self-assembled on the surface of the substrate.

[0032] Such as figure 1 , 2 , Shown in 3, the preparation method of above-mentioned material is as follows:

[0033] (1) Azidation treatment on the surface of polylactic acid material

[0034] Preparation of polylactic acid diaphragm: Stir and mix the two raw materials according to the ratio of polylactic acid: dichloromethane = 5g: 50mL. After the polylactic acid is completely dissolved, pour the solution into a flat-bottomed glass cuvette, and dry it at room temperature for 24 hours. A polylactic acid film was obtained. Then, the film was stirred and cleaned with 50...

Embodiment 2

[0048] Embodiment 2: This polylactic acid material based on layer-by-layer click bonding self-assembly is composed of a substrate and a modification layer. The substrate is a surface azide polylactic acid material. It is obtained by surface modification through click-bonding self-assembly; wherein, the modification layer contains alkynyl-containing cellulose sulfate and azido-chitosan which are layer-by-layer click-bonding self-assembled on the surface of the substrate.

[0049] The preparation method of above-mentioned material is as follows:

[0050] (1) Azidation treatment on the surface of polylactic acid material:

[0051] Preparation of polylactic acid membrane: Stir and mix the two raw materials according to the ratio of polylactic acid: dichloromethane = 7.5g: 75mL. After the polylactic acid is completely dissolved, pour the solution into a flat-bottomed glass cuvette and dry it at room temperature for 36 hours. , to obtain a polylactic acid film; then stir and wash t...

Embodiment 3

[0063] Embodiment 3: The polylactic acid material based on layer-by-layer click bonding self-assembly is composed of a substrate and a modification layer. It is obtained by surface modification through click-bonding self-assembly; wherein, the modification layer contains alkynyl-containing cellulose sulfate and azido-chitosan which are layer-by-layer click-bonding self-assembled on the surface of the substrate.

[0064] The preparation method of above-mentioned material is as follows:

[0065] (1) Azidation treatment on the surface of polylactic acid material:

[0066] Preparation of polylactic acid membrane: Stir and mix the two raw materials according to the ratio of polylactic acid: dichloromethane = 10g: 100mL. After the polylactic acid is completely dissolved, pour the solution into a flat-bottomed glass cuvette and dry it at room temperature for 48 hours. A polylactic acid film was obtained. Subsequently, the film was stirred and cleaned with 50% ethanol aqueous soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com