Patents

Literature

47results about How to "Excellent oxygen barrier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-barrier layer flexible packaging film for isolating contents of polymer lithium battery

The invention provides a high-barrier layer flexible packaging film for isolating contents of a polymer lithium battery. The high-barrier layer flexible packaging film comprises at least two kinds of films which are combined to form a layer of composite film, wherein the composite film comprises a basic layer, a functional layer and a heat sealing layer; the high-barrier layer flexible packaging film is characterized in that: the basic layer is a copolymer film prepared by combining at least two film base materials of PP (polypropylene), CPP (chlorinated polypropylene or casting polypropylene), PE (polyethylene), PET (poly(ethylene terephthalate)), PA (polyamide) or MXD6 (aromatic polyimide), MPE (elastomer blend), PVDC (polyvinyl dichloride), EVOH (ethylene-vinyl alcohol), PEN (polyethylene naphthalate) and GT, or by complexing pairwise; and a high-barrier water-tolerant modified PVA (poly vinyl alcohol) coating film is coated on the copolymer film base materials. The high-barrier layer flexible packaging film has excellent gas barrier property, remarkably low oxygen permeability, water resistance, corrosion resistance, good high temperature resistance and great barrier property, and resists organic solvents and highly-volatile substances. In the invention, the high-barrier PVA is preferably coated on various base materials to obtain a base layer serving as a high-barrier layer which has great barrier property and excellent performance in resisting gas, water, corrosion, ultraviolet rays and the like.

Owner:刘继福

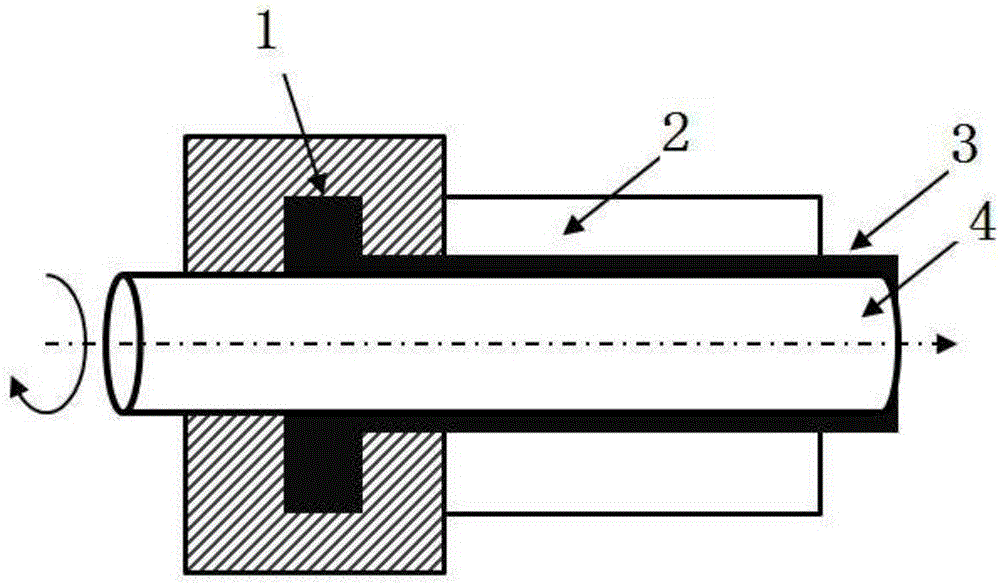

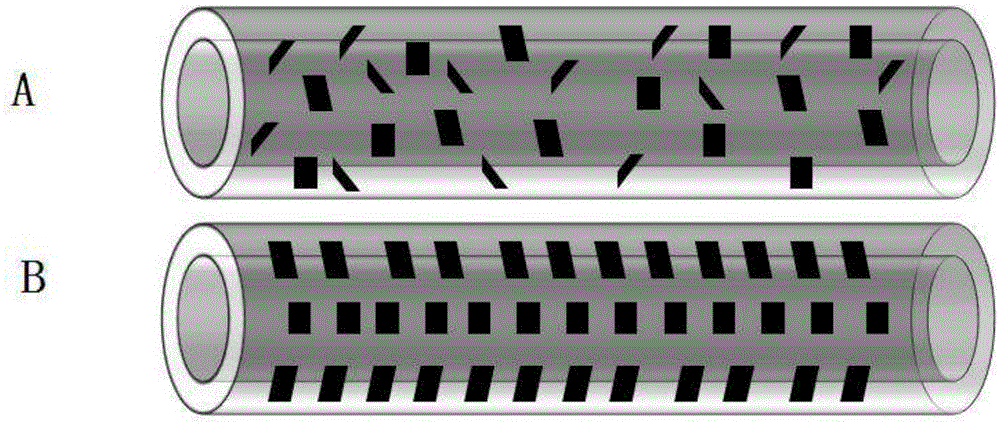

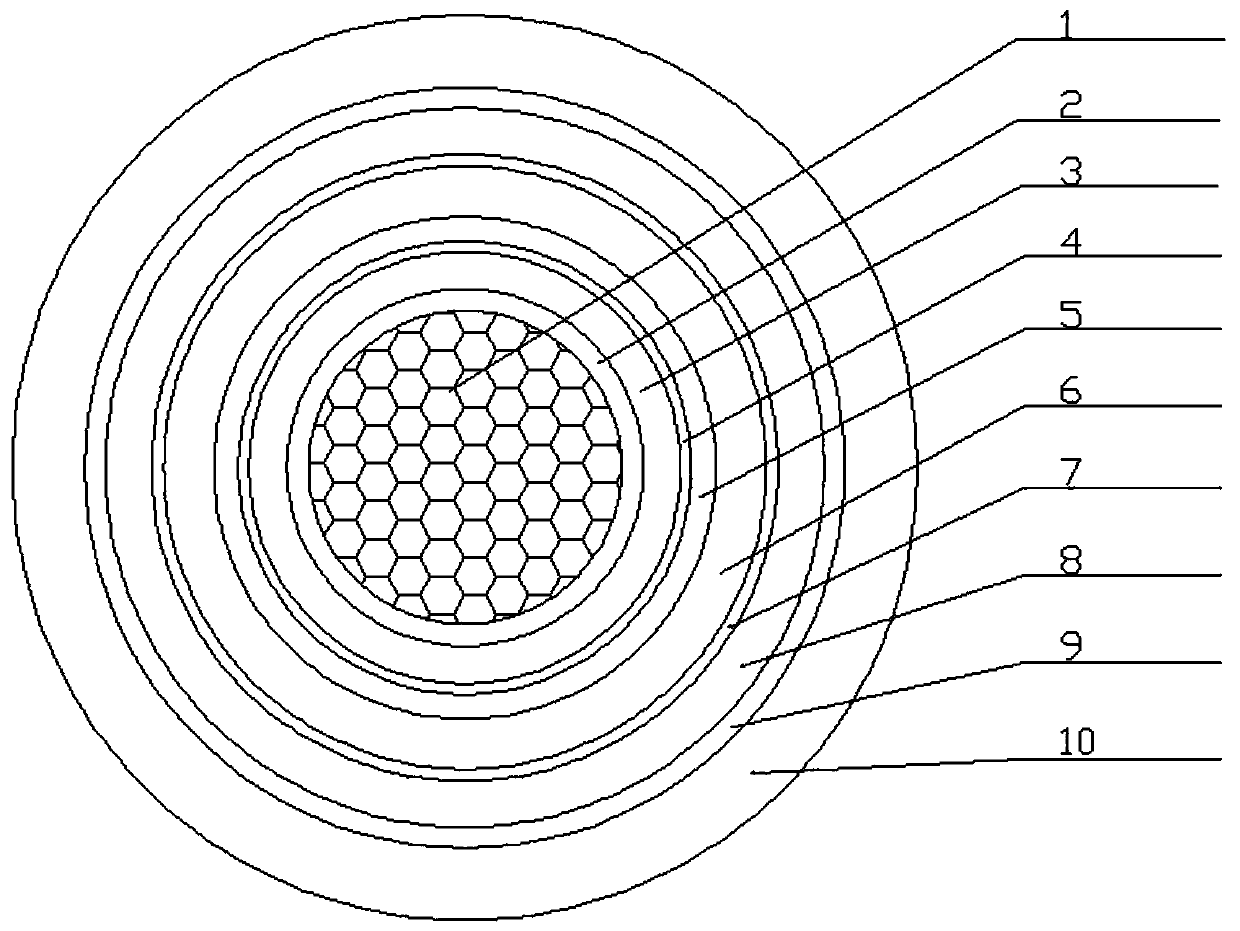

High-oxygen barrier property high-strength polyolefin heat conduction pipe and preparation method thereof

The invention provides a high-oxygen barrier property high-strength polyolefin heat conduction pipe and a preparation method thereof. The high-oxygen resistance high-strength polyolefin heat conduction pipe comprises, by weight, 100 parts of polyolefin resin, 0.1-5 parts of graphene slice layers, 0.1-15 parts of a compatilizer and 0.01-0.2 parts of an anti-oxidant. The graphene slice layers are uniformly distributed in the polyolefin resin in a ring way around a pipe central axis as a center. Through use of the graphene slice layers and a rotary core rod mouth mold, a polyolefin crystallization degree is high, a lot of oriented crystals are formed and pipe mechanical properties, heat conduction and heatproof performances are obviously improved. The graphene slice layers are uniformly distributed in the pipe in a ring way so that graphene slice layer obstruction performances are greatly improved and thus the good oxygen barrier property is kept under the condition of a very small amount of an anti-oxidant.

Owner:TIANJIN KINGFA NEW MATERIAL

Edible composite film and preparation method thereof

The invention discloses an edible composite film and a preparation method thereof, comprising the following components by volume portion: 50-80 portions of chitosan aqueous solution with the concentration in mass percent of 1.5 percent-3 percent, 20-50 portions of modified starch paste aqueous solution with the concentration in mass percent of 2 percent-4 percent, plasticizer accounting for 6-1 percent of the volume summation of the chitosan aqueous solution and the modified starch paste aqueous solution, and aliphatics auxiliaries accounting for 0.05-2 percent of the mass summation of the chitosan aqueous solution and the modified starch paste aqueous solution. In the invention, the edible composite film is prepared by taking the chitosan and the modified starch paste as the main film-forming materials and adopting a method of physical blending through naturally drying in a casting way. The film has good properties of oxygen resistance, oil resistance and rapidlysis in hot water, canreach a certain mechanical strength, and can be used as the internal surface of a food plastic packing bag or the internal package of instant fast food, thereby being a convenient, sanitary and environmental packing material.

Owner:天津大宇包装制品有限公司

Humidity resistance high oxygen barrier packaging film preparation method

InactiveCN101608023AExcellent oxygen barrierBarrier effectFlexible coversWrappersPolyesterPolyolefin

The invention discloses a humidity resistance high oxygen barrier packaging film preparation method, comprising the following steps: coating a barrier coating fluid comprising 5-40% of acrylic homopolymer or copolymer, 0.1-5% of assistant, 0.5-15% of crosslinking agent and 40-94.4% of solvent on the substrate of polyester films of which corona value is 30-60 dynes, nylon films or polyolefin films by using a dry-lamination machine, a wet-lamination machine or an extrusion lamination machine, drying the substrate at 50-110 DEG C, solidifying the dried substrate at 20-150 DEG C and obtaining the humidity resistance high oxygen barrier packaging film. The humidity resistance high oxygen barrier packaging film prepared by the invention can always maintain excellent ability to barrier oxygen, carbon dioxide and nitrogen in high humidity; for instance, the typical oxygen permeance is 3cc / m2 / day in 80% humidity. The film has excellent mechanical properties, can be repeated bended and can not affect the barrier properties.

Owner:ZHEJIANG CHANCING PACKAGE MATERIAL

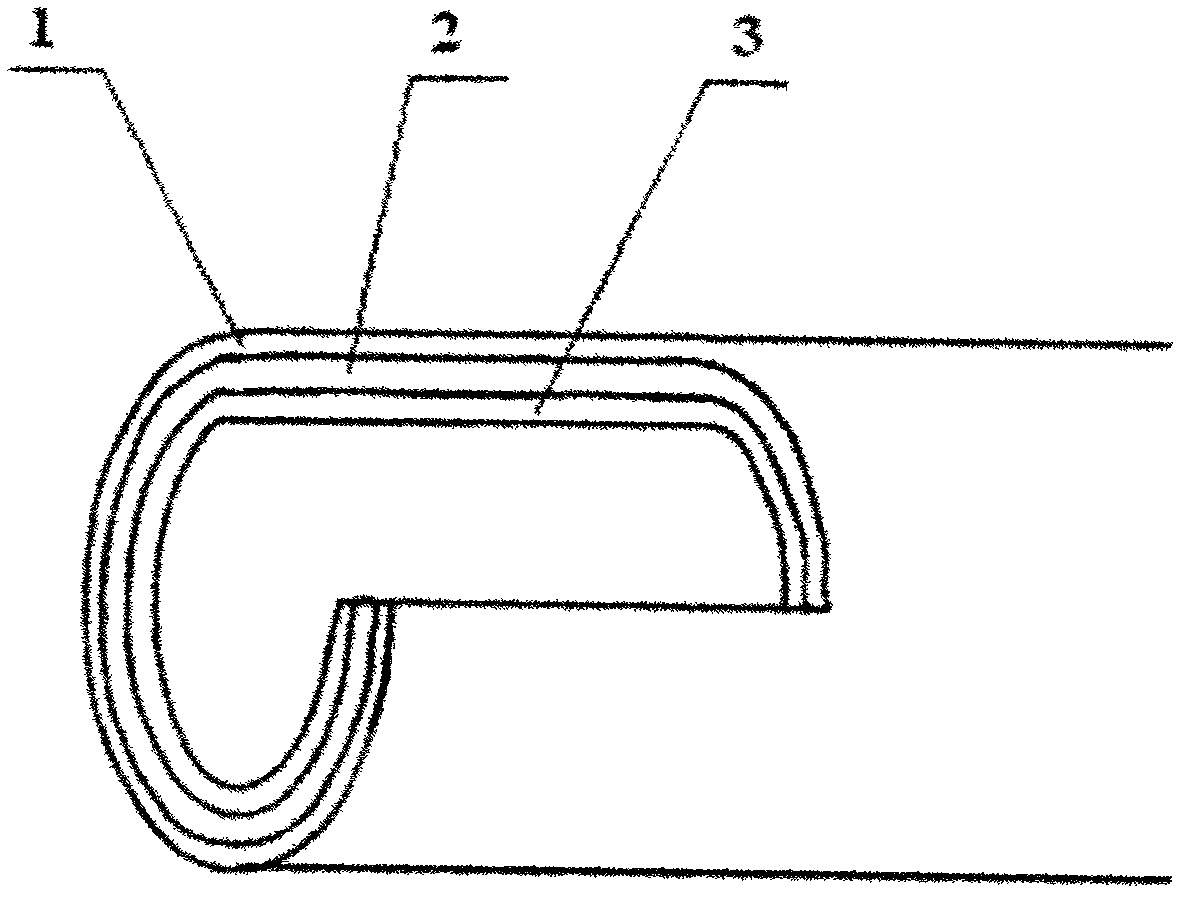

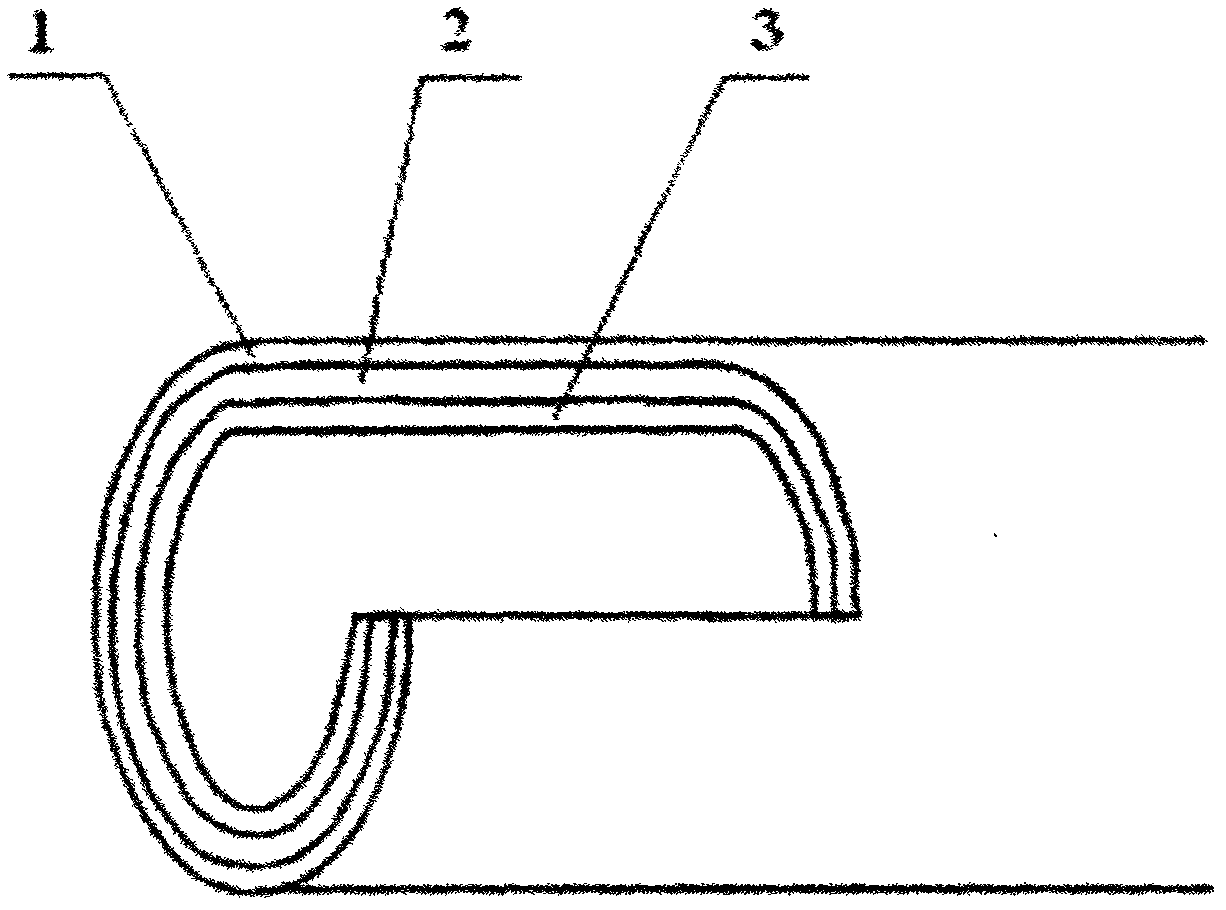

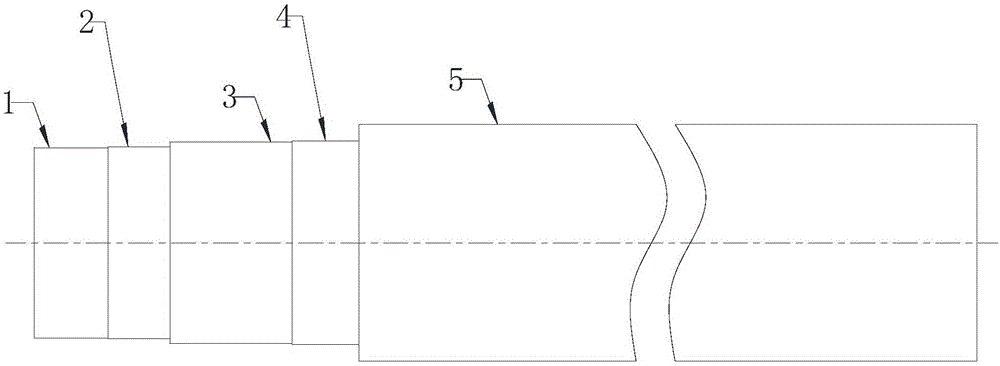

Environmental-protection oxygen barrier antibacterial polypropylene-random (PP-R) pipe

InactiveCN102494201APrevent penetrationPreserve physical and mechanical propertiesRigid pipesPolyvinyl alcoholPolyamide

The invention discloses an environmental-protection oxygen barrier antibacterial polypropylene-random (PP-R) pipe. The environmental-protection oxygen barrier antibacterial PP-R pipe comprises a PP-R outer layer, a PP-R oxygen barrier intermediate layer and a PP-R antibacterial inner layer, wherein a high-performance oxygen barrier agent selected in the PP-R oxygen barrier intermediate layer is polyamide and copolymers thereof or polyving akohol and copolymers thereof. The environmental-protection oxygen barrier antibacterial PP-R pipe has a reasonable production formula and low production cost, keeps inherent physical and mechanical properties by adding the oxygen barrier intermediate layer and performing one-time extrusion molding, has high oxygen barrier performance and can prolong the service life of system equipment. The environmental-protection oxygen barrier antibacterial PP-R pipe has an antibacterial rate up to 90 percent on escherichia coli and staphylococcus aureus and has high physical and mechanical properties.

Owner:合肥安诺新型建材有限公司

Multi-layer composite pipe material and preparation method thereof

ActiveCN109253320AEasy to solveSolve complexityRigid pipesPipe protection against damage/wearPolyolefinHeat resistance

The invention discloses a multi-layer composite pipe material and a preparation method thereof. The pipe material is divided into an inner layer, a middle layer and an outer layer, the inner layer ismade from fluoroolefin polymer, the middle layer is made from macromolecule alloy containing a comb-shaped compatilizer, and the outer layer is made from atactic polyolefin. The pipe material adopts athree-layer co-extrusion one-time forming technology and has the advantages that the precipitation is low, the combination among layers is compact, and the production technology is convenient; the pure polyvinylidene fluoride pipe material is environmentally friendly, the precipitating performance is low, and the chemical stability is good; the anti-impacting strength is high, the anti-abrasion and anti-creep effects are achieved, and the mechanical strength and toughness are good; the heat resistance performance is good, the long-term using temperature is -20-100 DEG C, the surface of the material is smooth, the fluid resistance is low, and the oxygen resistance performance is excellent.

Owner:ZHEJIANG JUHUA NEW MATERIALS RES INST CO LTD +1

Gas-barrier packaging material

ActiveCN105246793AExcellent oxygen barrierConducive to preservationFlexible coversWrappersInfraredPolyester resin

This gas-barrier packaging material is provided with: a support body; an adhesive layer layered on the support body; a first barrier layer layered on the adhesive layer; a second barrier layer layered on the first barrier layer; and a protective layer layered on the second barrier layer and formed from a coating liquid containing a polyvalent metal compound, a polyester resin, and a dispersant which is a sodium salt of a polycarboxylic acid resin. Therein: given that the protective layer is contained in the amount of 100 wt%, the polyvalent metal compound is contained in the amount of 40-90 wt%; and when measuring the infrared absorption spectrum of the second barrier layer after separating the second barrier layer using a transmission method, the ratio ([Alpha] / [Beta]) of the maximum peak height ([Alpha]) in the range of 1490-1659cm-1 to the maximum peak height ([Beta]) in the range of 1660-1750cm-1 is less than 1.

Owner:TOPPAN HLDG INC

Polymer alloy oxygen blocking material and preparation method as well as application thereof

The invention discloses a polymer alloy oxygen blocking material, which is PO-LCP (Polyolefin-Liquid Crystal Polymer) alloy, wherein the alloy is prepared by melting and mixing the following components in percentage by weight: 95-15 percent of polyolefin resin, 4.9-84.3 percent of liquid crystal resin and 1-0.7 percent of compatibilizer. A preparation method comprises the following steps of: melting and plasticizing the LCP resin by an extruder by using a lateral feed two-section extrusion granulator; extruding melt of the resin into another extruder with a second feed port in the waist part in a duck-stuffing manner; converging the PO resin which is being melted, plasticized and extruded in the extruder with the compatibilizer melt; melting and mixing the three components; performing extrusion molding to form strips; and drawing, orientating, cooling and granulating to prepare PO-LCP alloy oxygen blocking material particles. The polymer alloy oxygen blocking material has wide application.

Owner:ZHEJIANG MENRED COMFORT SYST

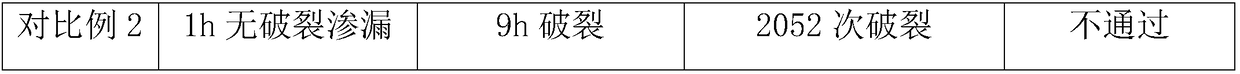

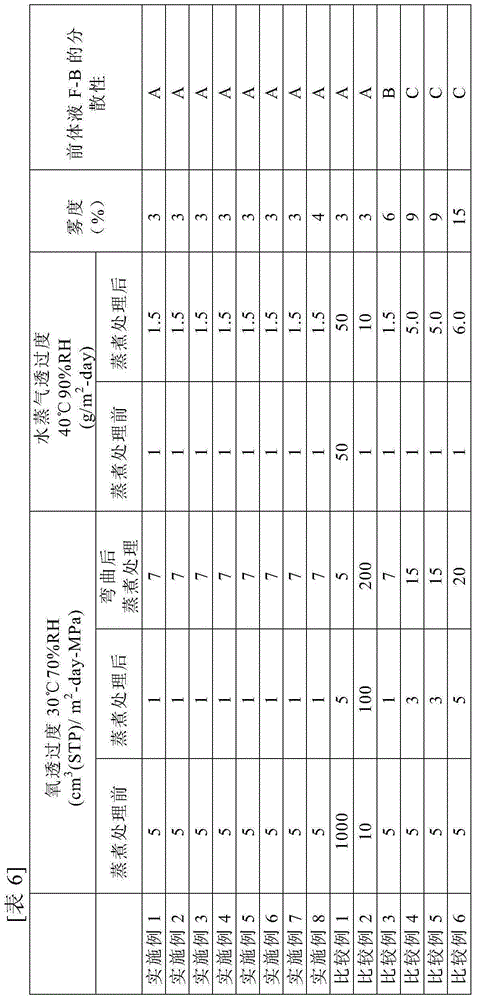

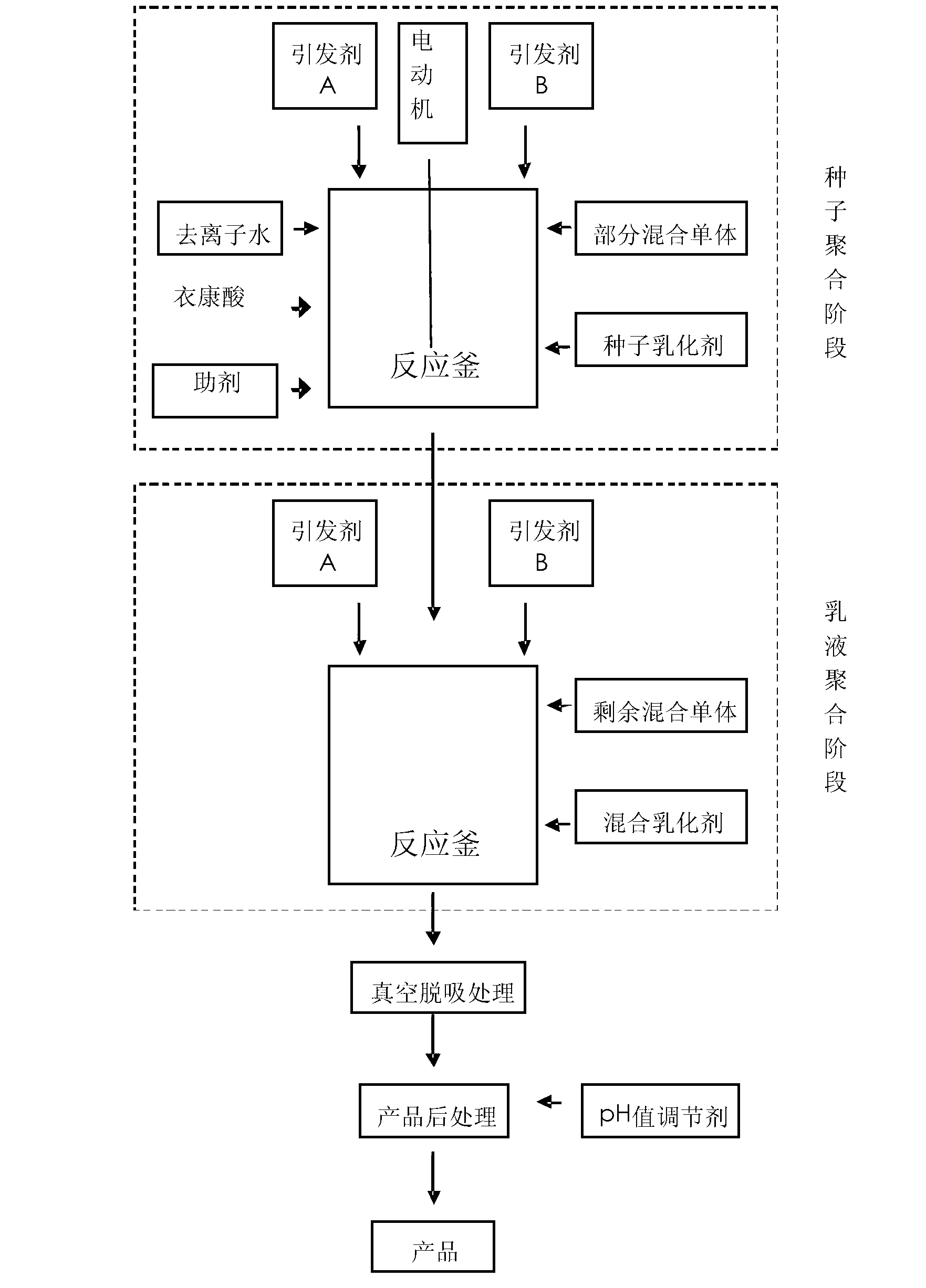

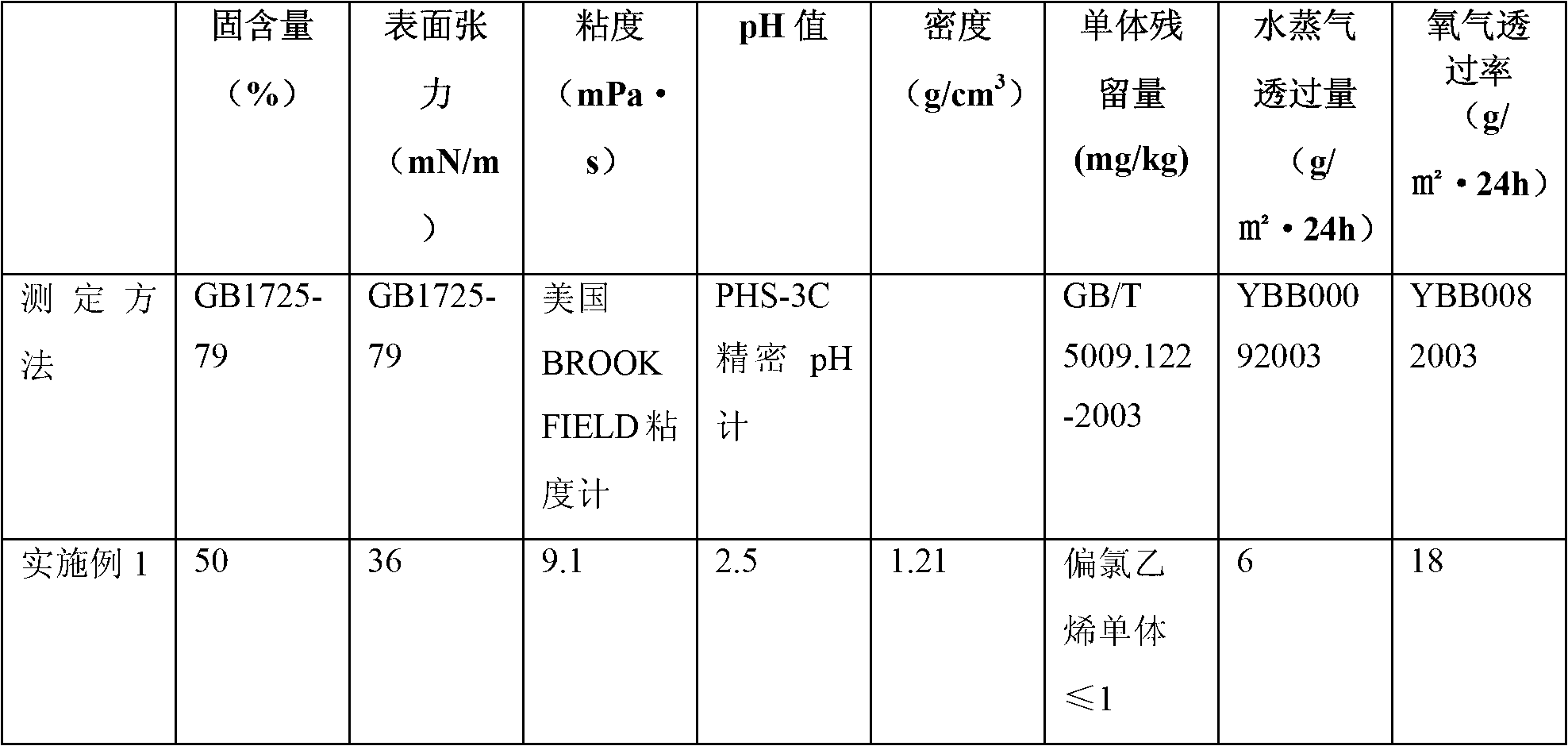

Polyvinyl dichloride (PVDC) emulsion for cellophane coating and preparation method thereof and application thereof

ActiveCN103059200AExcellent oxygen barrierImprove water resistancePaper coatingCoatingsMethacrylateEmulsion

The invention discloses a polyvinyl dichloride (PVDC) emulsion for cellophane coating and a preparation method and application of the PVDC emulsion for the cellophane coating. The PVDC emulsion for the cellophane coating aims at solving the problems that existing cellophane is poor in barrier property, incapable of being used for food packaging and the like. The PVDC emulsion for the cellophane coating is obtained by serving a certain amount of vinylidene chloride, acrylonitrile, methacrylate and itaconic acid as a mixed mononer, selecting specific seeded emulsifier and mixed emulsifier, and adopting seeded emulsion polymerization. The PVDC emulsion for the cellophane coating is low in cost and good in barrier property. The coated cellophane is good in oxygen-resisting and waterproof effects and capable of being used for the food packaging.

Owner:海南海达丰实业有限公司

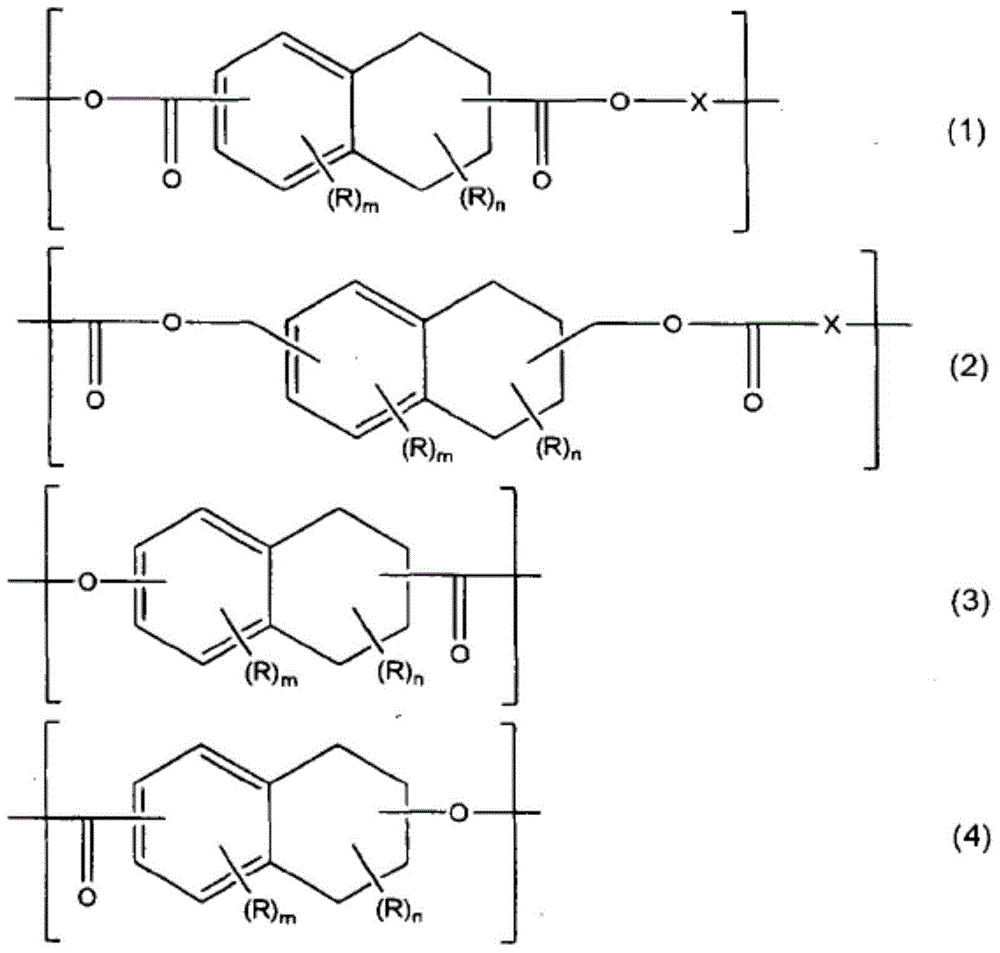

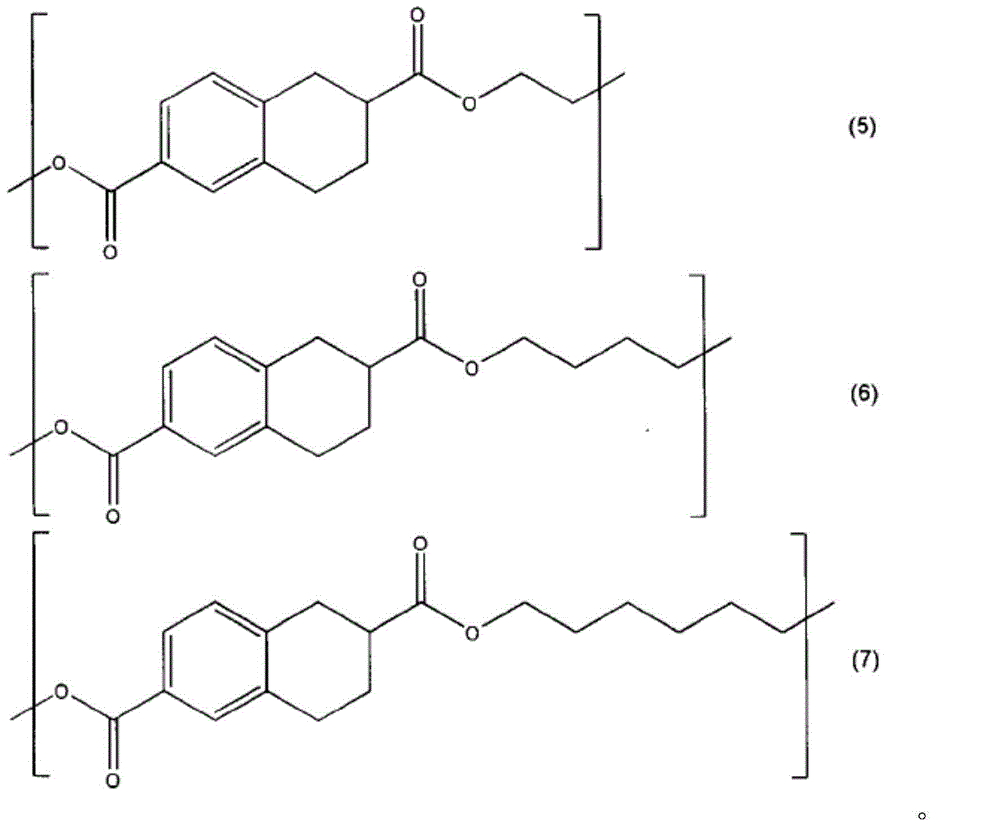

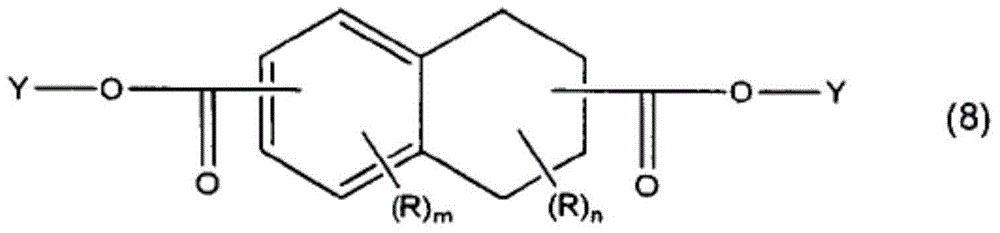

Oxygen-absorbing resin composition, oxygen-absorbing molded body using same, and multilayer body, container, injection molded body and medical container each using oxygen-absorbing resin composition or oxygen-absorbing molded body

ActiveCN103958604AExcellent oxygen absorption performanceReduce intensityBottlesDomestic containersPolyesterHigh humidity

Provided are: a novel oxygen-absorbing resin composition which is not sensitive to metal detectors, does not generate an odor after the absorption of oxygen and exhibits excellent oxygen absorption performance; an oxygen-absorbing molded body which uses this oxygen-absorbing resin composition; and a multilayer body, a container, an injection molded body, a medical container and the like, each of which uses the oxygen-absorbing resin composition or the oxygen-absorbing molded body. Also provided are: an oxygen-absorbing resin composition which exhibits excellent oxygen absorption performance over a wide range of humidity conditions from low humidity to high humidity; and the like. An oxygen-absorbing resin composition of the present invention contains a polyester compound and a transition metal catalyst, and the polyester compound contains at least one constituent unit that has a tetralin ring. An oxygen-absorbing molded body of the present invention is obtained by molding the oxygen-absorbing resin composition into a film form or a sheet form. A multilayer body, container, injection molded body, medical container and the like of the present invention are obtained using the oxygen-absorbing resin composition of the present invention.

Owner:MITSUBISHI GAS CHEM CO INC

High elastic antirust paint

InactiveCN102372984AHigh elongationExcellent oxygen barrierAnti-corrosive paintsAcrylic resinCellulose acetate

The invention discloses a high elastic antirust paint, which is prepared by stirring the following raw materials according to weight proportion: 36 parts of epoxy phenolic resin, 16 parts of ethylene diamine, 27 parts of silicone-acrylic resin, 30 parts of propylene glycol, 10 parts of sodium carboxymethyl cellulose, 5 parts of heavy calcium powder, 6 parts of binder, 15 parts of water dispersion resistance agent, 20 parts of zinc oxide, 10 parts of cellulose acetate, 2 parts of antiseptic, 1 part of mildew inhibitor and 2.5 parts of thickening agent. The high elastic antirust paint has the excellent performances of superior elongation percentage, oxygen inhibition, anticorrosion and the like.

Owner:NANTONG TONGZHOU DISTRICT JINCHEN PAINT FACTORY

Method for producing high temperature-resistance high-barrier polypropylene film

The invention discloses a method for producing a high temperature-resistance high-barrier polypropylene film. According to the method, an isotactic polypropylene-b-polyethylene glycol diblock substance is adopted as a compatibilizer for isotactic polypropylene and polyvinyl alcohol which has excellent oxygen barrier performance, and after the isotactic polypropylene-b-polyethylene glycol diblock substance is adopted as the compatibilizer, good compatibility between the isotactic polypropylene and polyvinyl alcohol is achieved, so that the polyvinyl alcohol phase is dispersed uniformly in the polypropylene resin; therefore, a demi-continuity phase or a lamellar structure is formed, and the barrier performance of the blended film can be improved significantly; the hardness of the thin film is improved through addition of nano-silica so that the energy of heat-resistance deformation is improved, and moreover the tearing effect is improved effectively through addition of palm wax.

Owner:NINGBO RUICHENG PACKING MATERIAL

Preparation method of pullulan polysaccharide based rice fresh keeping agent

InactiveCN108244236AImprove featuresGood film formingFood ingredient as antioxidantSeed preservation by coatingBiotechnologyPullulan

The invention relates to a preparation method of a pullulan polysaccharide based rice fresh keeping agent, and belongs to the technical field of fresh keeping of food grains. Pullulan polysaccharide is used as a film forming substrate, oxidation resistance of ascorbic acid is combined, and after two components namely the pullulan polysaccharide and the ascorbic acid are compounded, the pullulan polysaccharide based rice fresh keeping agent is prepared. The rice fresh keeping agent provided by the invention can be uniformly sprayed onto the surfaces of rice grains in the polishing operation procedure of rice processing, is convenient to use, and is easy to popularize and use. The rice fresh keeping agent provided by the invention has the advantages of being natural and safe in components, green and environmental-friendly in preparation technology, controllable in use cost, significant in fresh keeping effects and the like, the problems of ageing, mildew, rot and the like of the rice during storage period can be effectively controlled, the shelf life of the rice is prolonged, the freshness of the rice is reserved, and the rice fresh keeping agent has important practical significanceon solving the problem that the food grains are difficult to store.

Owner:JIANGNAN UNIV

Steel strip reinforced PVC pipe and production process thereof

InactiveCN106218134AStrong impact resistanceExcellent oxygen barrierSynthetic resin layered productsTubular articlesHot meltPetrochemical

The invention provides a steel strip reinforced PVC pipe which comprises an inner PVC pipe layer, a first hot melt adhesive layer, a steel strip layer, a second hot melt adhesive layer and an outer PVC pipe layer; the first hot melt adhesive layer is distributed between the inner PVC pipe layer and the steel strip layer, the second hot melt adhesive layer is distributed between the outer PVC pipe layer and the steel strip layer, and the steel strip layer is sandwiched between the inner PVC pipe layer and the outer PVC pipe layer through the first hot melt adhesive layer and the second hot melt adhesive layer. The steel strip layer is added on a traditional PVC pipe, and a special production process is used in production and processing, so that a compound pipeline having the advantages of excellent shock resistance, strong loading capacity, excellent oxygen resistance, low linear expansion coefficient and long service life is obtained, and the PVC pipeline can be used in the fields of municipal water supply, high building water supply, petroleum, chemical engineering, buildings, shipbuilding, communication, electric power and underground gas transmission.

Owner:浙江中财管道衍生产品有限公司

Production method for co-blending-method high-barrier-property polypropylene packaging film

ActiveCN109306120AMolecular weight controllableEasy to industrializePolymer sciencePolyethylene glycol

The invention discloses a production method for a co-blending-method high-barrier-property polypropylene packaging film. An isotatic polypropylene-b-polyethylene glycol di-block polymer is used as a compatilizer of isotatic polypropylene and polyvinyl alcohol. The polyvinyl alcohol has excellent antioxygen performance. After the isotatic polypropylene-b-polyethylene glycol di-block polymer is usedas the compatilizer, the isotatic polypropylene and the polyvinyl alcohol have good compatibility, so that a polyvinyl alcohol phase can be uniformly dispersed in polypropylene resin, and a sub-continuity phase or a laminar structure is formed, so that a barrier property of a co-blending film is remarkably improved.

Owner:NINGBO RUICHENG PACKING MATERIAL

Environment-protection weather-proof self-temperature-sensitive fireproof cable and manufacturing method thereof

InactiveCN109949984AImprove heat insulationImprove protectionClimate change adaptationInsulated cablesEnvironmental resistanceIsolation layer

The invention relates to an environment-protection weather-proof self-temperature-sensitive fireproof cable, and overcomes disadvantages in the prior art. The cable comprises a cable core, an inner halogen free taping, an aluminum sheath, a fireproof mud isolation layer, an intermediate halogen free taping, a steel band linked armor layer, an outer halogen free taping and an oversheath; the innerhalogen free taping wraps the cable core, the aluminum sheath wraps the inner halogen free taping, the fireproof mud isolation layer wraps the aluminum sheath, the intermediate halogen free taping wraps the fireproof mud isolation layer, the steel band linked armor layer wraps the intermediate halogen free taping, the outer halogen free taping wraps the steel band linked armor layer, and the oversheath wraps the outer halogen free taping; and the oversheath is a self-temperature-sensitive color-change oversheath.

Owner:浙江万马股份有限公司

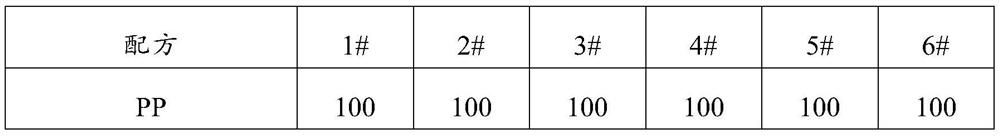

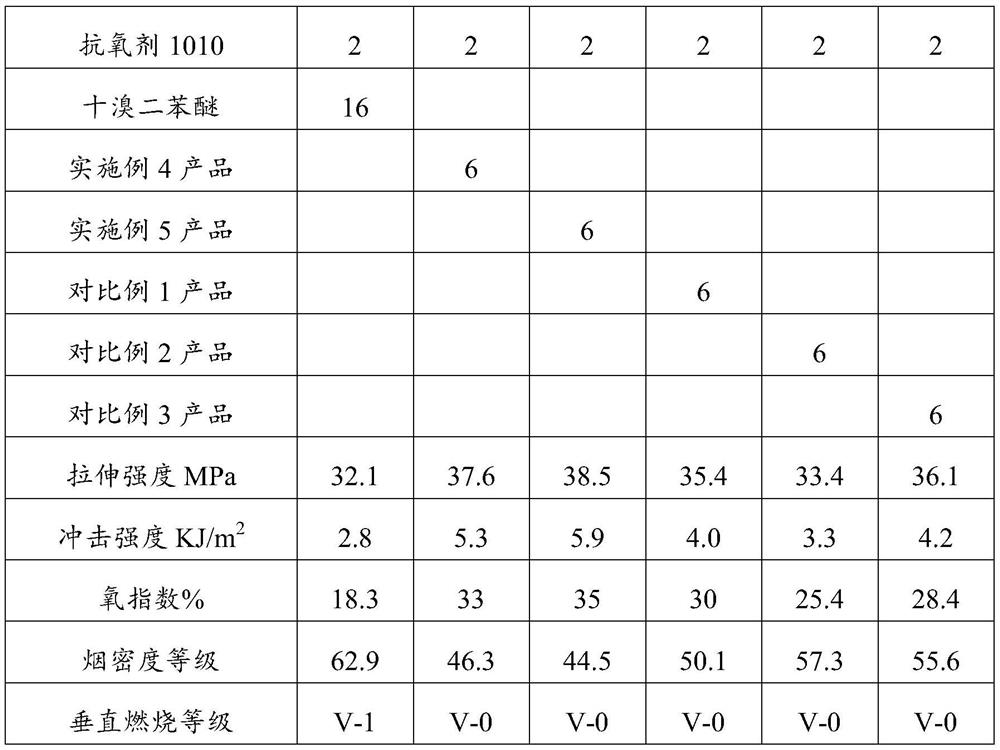

Composite antimony trioxide flame retardant and preparation method thereof

The invention discloses a composite antimony trioxide flame retardant, belonging to the technical field of flame retardants. The omposite antimony trioxide flame retardant disclosed by the invention is prepared from the following raw materials in parts by weight: 40-60 parts of surface-modified antimony trioxide, 10-30 parts of silane modified halloysite nanotubes, 20-30 parts of phosphate amine salt, 2-3 parts of a coupling agent and 3-5 parts of an organic copper salt heat stabilizer, wherein the phosphate amine salt is formed by polymerizing pentaerythritol, phosphorus pentoxide and isobutyramide, and a mass ratio of the pentaerythritol to the phosphorus pentoxide to the isobutyramide is (1.5-2.5): 1: (1.8-3.6). The components of the composite antimony trioxide flame retardant provided by the invention have very good compatibility; and the composite antimony trioxide flame retardant has excellent interface bonding force with a plastic material, is uniformly dispersed, allows a plastic product using the composite antimony trioxide flame retardant to have excellent flame retardance and smoke suppression performance, and improves the mechanical properties of the plastic product.

Owner:HUNAN LOUDI HUAXING ANTIMONY IND

Food packaging film with antibacterial function and preparation method thereof

InactiveCN107337880AExtended shelf lifeReduce corruption loss rateSynthetic resin layered productsFlat articlesLow-density polyethyleneAntioxidant

The invention relates to the technical field of polymer materials, and in particular relates to a food packaging film with an antimicrobial function and a preparation method thereof; the food packaging film comprises the following raw materials in parts by weight from the inside to the outside: an antibacterial layer comprising 40-50 parts of polyvinylidene chloride, 15-30 parts of metallocene polyethylene, 0.1-1 parts of an anti fog agent, 1-10 parts of a composite antibacterial agent and 0.1-3 parts of ethylene bis-stearamide; a preservation layer 20-40 parts of low density polyethylene layer, 20-40 parts of a vinylidene chloride-vinyl chloride copolymer, 5-15 parts of shell powder and 0.5-2 parts of stearic acid and a barrier layer comprising 40-50 parts of an ethylene / vinyl alcohol copolymer, 20-30 parts of high density polyethylene, 0.1-0.5 part of an initiator, 0.1-2 parts of an anti fog agent and 0.1-3 parts of an antioxidant. The food packaging film has good antibacterial property.

Owner:林毅平

Preparation method of high barrier LDPE film

InactiveCN107353467AExcellent oxygen barrierGood chemical stabilityToluene diisocyanateMixed materials

The invention discloses a preparation method of a high barrier LDPE film. The preparation method comprises the following steps: adding LDPE, tetrabutyl titanate, ammonium bicarbonate, and nano calcium carbonate into a sealing type rubber mixing mill, fully stirring to obtain a mixed material; then stirring and fully mixing butyl etherized urea resin, zinc stearate, polyvinylidene difluoride, nano montmorillonite, toluene diisocyanate, and peanut oil, carrying out reactions for 2 to 4 hours in a reactor, after reactions, delivering the reaction product into a double screw granulator to carry out granulation to obtain master batch; finally, fully stirring the master batch and the mixed material for an half hour, delivering the mixture to a double screw extruder to carry out melting and extruding, cooling, cutting, splitting to obtain granules; adding residual raw materials into the granules, stirring and mixing, and finally performing melting, plasticizing, mouth model molding, blowing, corona disposing, and reeling in a film blowing facility. Through the nano material modification, the prepared LDPE film has a good performance on blocking oxygen, high chemical stability, good heat sealing property, excellent waterproof property, and good performance on resisting damp and cold. Moreover, the preparation method is simple. The LDPE film has a good application value.

Owner:苏州奥宇包装科技有限公司

Preparation method of starch-based edible film

The invention discloses a preparation method of a starch-based edible film. The preparation method comprises the following steps: firstly adding corn starch, celluloses and glycerin into water and increasing the temperature to 40-50 DEG C for heat preservation to obtain mixed liquid A; adding gellan gum, sodium alginate and sodium citrate into water and increasing the temperature to 40-50 DEG C for heat preservation to obtain mixed liquid B; then adding the mixed liquid B into the mixed liquid A, regulating pH to 6.0-7.0, adding organic acid, stearic acid, lecithin and lactose, continuously stirring and performing high-pressure homogenization; finally de-gassing obtained mixed film liquid, casting, film-making and drying. The starch-based edible film prepared by the preparation method disclosed by the invention is close to a plastic thin film in appearance, fine and transparent in texture, better in mechanical property, good in folding resistance, excellent in oxygen resistance and simple in film preparation process.

Owner:JURONG XINGWU PACKAGING

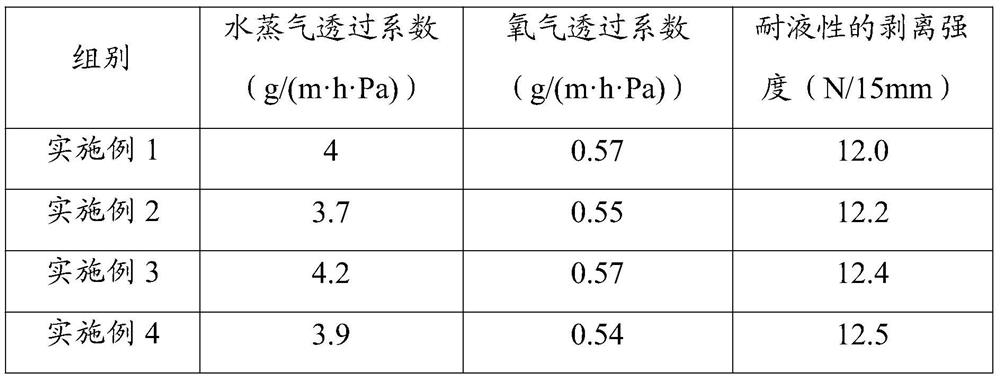

High-temperature-resistant ablation-resistant composite coating and preparation method thereof

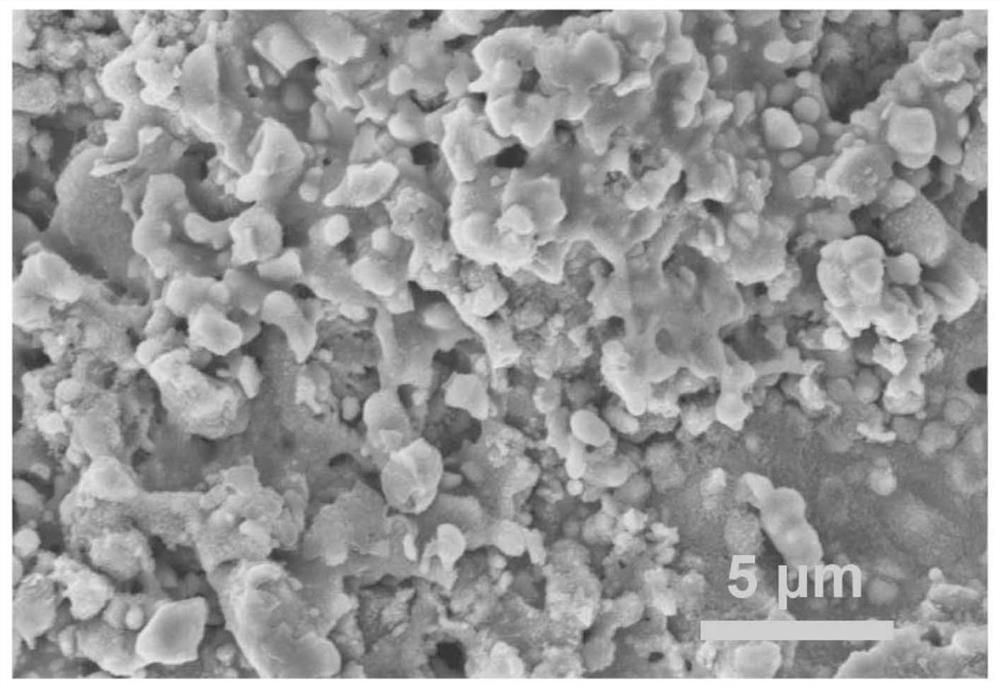

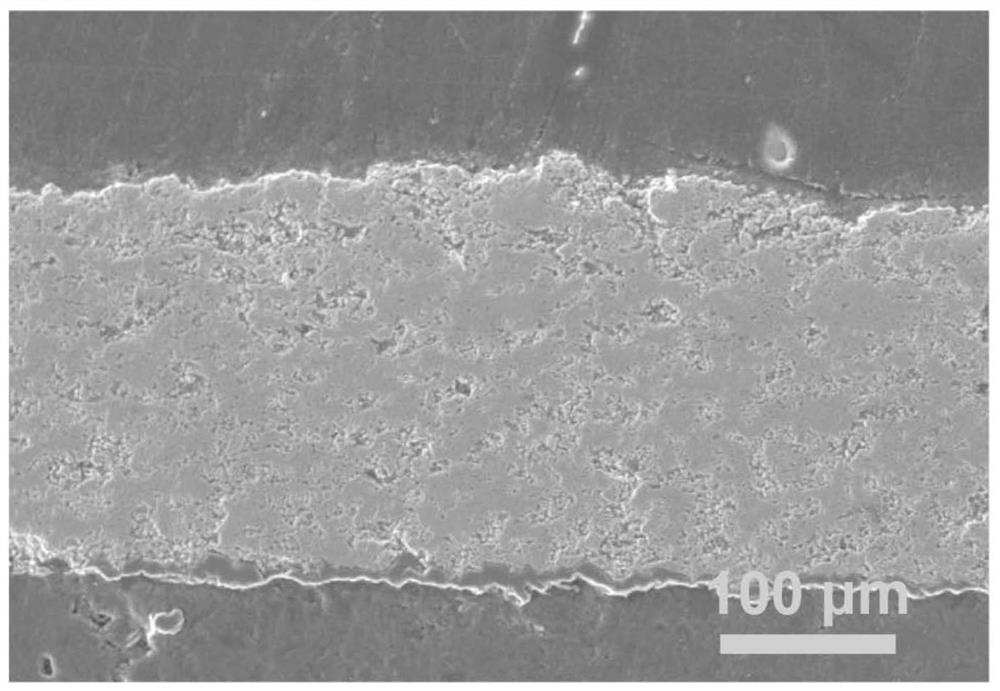

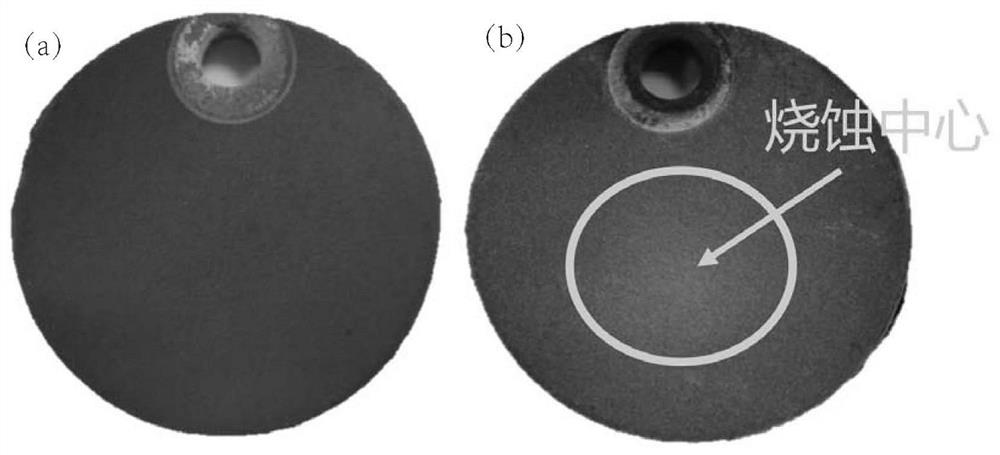

InactiveCN112501538ACompact structurePrevent oxidationMolten spray coatingPhysical chemistryAnalytical chemistry

The invention relates to a high-temperature-resistant ablation-resistant composite coating and a preparation method thereof. The high-temperature-resistant ablation-resistant composite coating comprises a ZrB2 main phase, a MoSi2 second phase and a Yb2O3 third phase, wherein the content of the MoSi2 second phase is 5 to 30 vol.%, the content of the Yb2O3 is 5 to 20 mol.%, and the balance is the ZrB2 main phase.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Preparation method of polypropylene film layer capable of improving barrier property

The invention discloses a preparation method of a polypropylene film layer capable of improving barrier property, which specifically comprises the following steps: (1) in the presence of hydrogen, catalyzing propylene polymerization by using a catalytic system consisting of a metallocene catalyst and an alkylaluminoxane cocatalyst by using a styrene derivative as a chain transfer agent to obtain isotactic polypropylene; (2) blending the isotactic polypropylene with polypropylene random copolymer, an isotactic polypropylene bpolyethylene glycol diblock copolymer, polyvinyl alcohol, a silicon dioxide modifier, a nucleating agent and a compatilizer, performing sufficient melt blending in a screw extruder after blending, and performing extrusion and bidirectional stretching to obtain a polypropylene film layer, wherein the nucleating agent is a beta crystal form nucleating agent. The aluminum-plastic film prepared from the polypropylene film layer provided by the invention is better in gas-liquid barrier property, higher in safety and longer in service life, and has a good application prospect.

Owner:GUANGDONG ANDELI NEW MATERIALS CO LTD

Modified hydrolysis-resistant polyvinyl alcohol high polymer material and production method and application

InactiveCN102504453BEfficient printingGood Composite AdaptabilityFlexible coversWrappersPolymer scienceSilanes

The invention relates to a modified hydrolysis-resistant polyvinyl alcohol high polymer material, a production method and application, which belongs to the field of high polymer materials. The modified hydrolysis-resistant polyvinyl alcohol high polymer material is composed of the following components: by weight parts, 8 to 12 parts of polyvinyl alcohol with the polymerization degree ranging from1500 to 2000 and alcoholysis degree larger than or equal to 99%, 65 to 75 parts of purified water, 5 to 7 parts of sec-butyl alcohol or methyl alcohol, 0.2 to 0.25 part of organic titanate, 0.5 to 3 parts of glycerol, 0.08 to 0.15 part of lauryl sodium sulfate, 2 to 4 parts of alkoxy silane and 2 to 5 parts of melamine resin. Rubber preparation and coating at normal temperature are realized, solution is transparent, and coatings of the modified hydrolysis-resistant polyvinyl alcohol high polymer material have excellent printing and compositing adaptation performance and can meet the requirements of composite of various material structures.

Owner:刘长龙

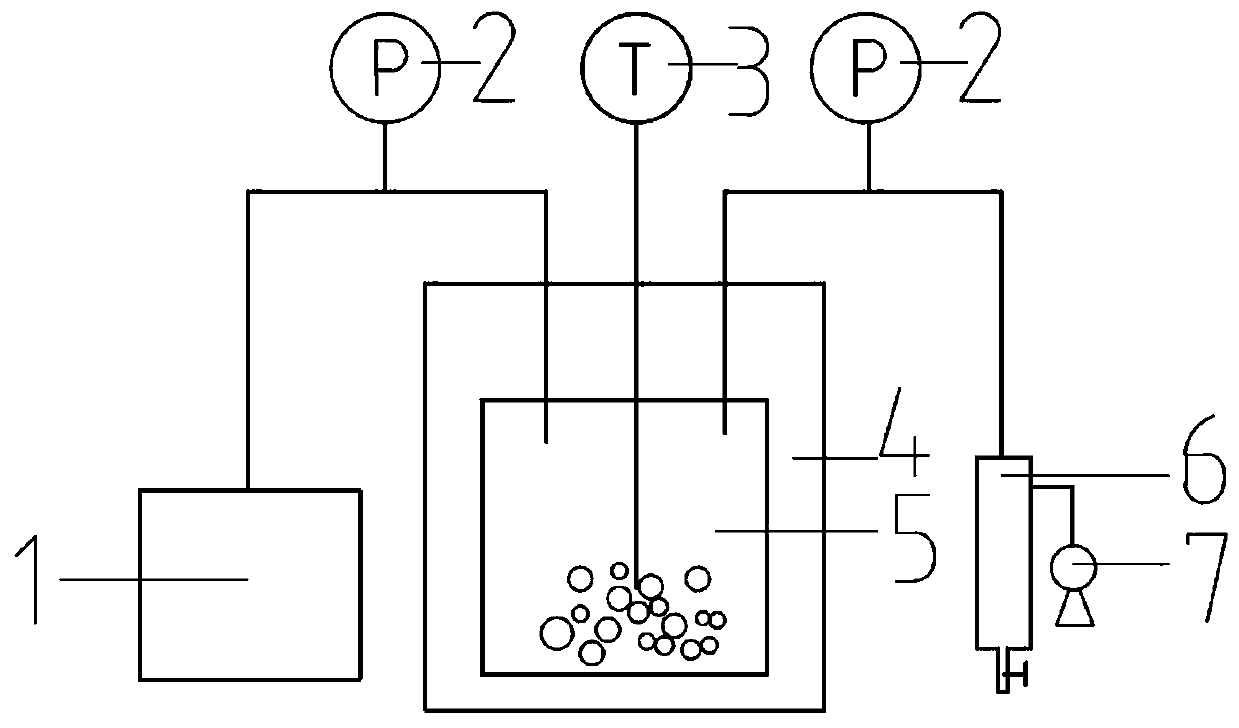

A kind of preparation method of carbon molecular sieve

ActiveCN105460933BLow costRealize comprehensive utilizationNitrogen purification/separationGas treatmentMolecular sievePolyvinyl chloride

The invention provides a preparation method of a carbon molecular sieve, which comprises the following steps: by using agricultural waste nutshell, chestnut shell and a polyvinyl chloride resin as raw materials, preparing raw material powder, forming, carbonizing, and carrying out carbon deposition and the like. Especially in the carbon deposition process, a supercritical carbon dioxide reaction kettle is adopted, so that the reaction can be performed uniformly and thoroughly. The obtained carbon molecular sieve has fine and uniform pores; the produced nitrogen concentration reaches 99.6 vol% (the N2 flow rate is 40 ml / minute during testing); the strength of the carbon molecular sieve determined by the rotating drum reaches 99.9%; the properties of the product are greatly enhanced; and the overall reaction process is combined, thereby saving the energy by 40%.

Owner:桐乡市腾飞家纺股份有限公司

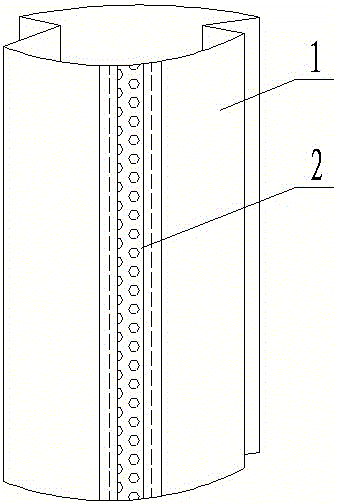

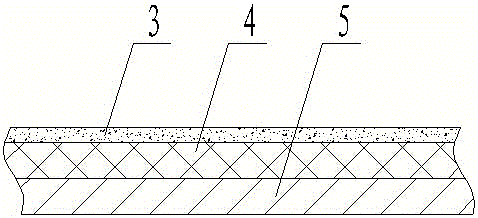

Nano-composite film bag capable of realizing one-way venting and high obstruction

The invention discloses a nano-composite film bag capable of realizing one-way venting and high obstruction, belongs to soft packing bags for food and medicines, and aims to provide a soft packing bag which is applied to the food and medicines, can vent gas inside the bag as well as prevent external gases such as oxygen, nitrogen, hydrogen, dioxides, water vapor and the like from entering the bag and is simple in production technology and low in cost. The nano-composite film bag comprises a bag body made of a heat-seal base material film and nonwoven fabric overlapped at a joint of the bag body, wherein the outer surface of the heat-seal base material film (4) is coated with a PVA film layer (3). The composite film bag is non-toxic and good in obstruction property, is an ideal environment-friendly packing material, and can replace existing high-obstruction packing materials for the food and medicines.

Owner:GUIZHOU RUILONG GRP PLASTIC PACKAGING CO LTD

Seven-layer co-extrusion transparent high-isolation film and preparation method thereof

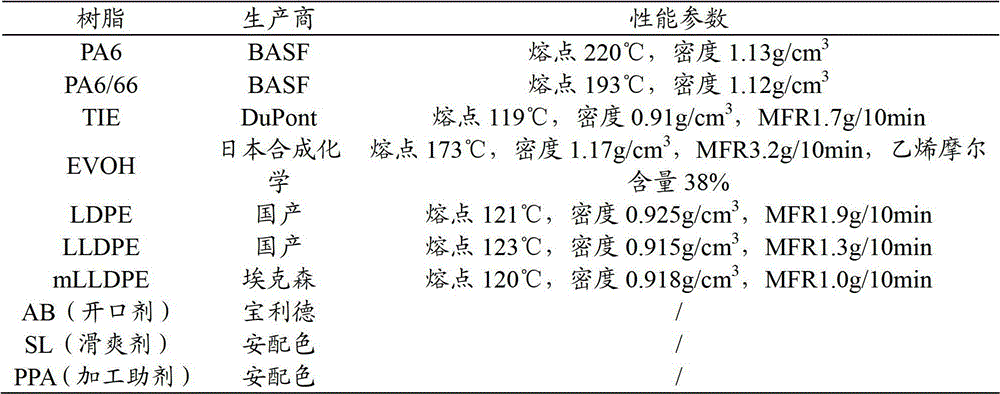

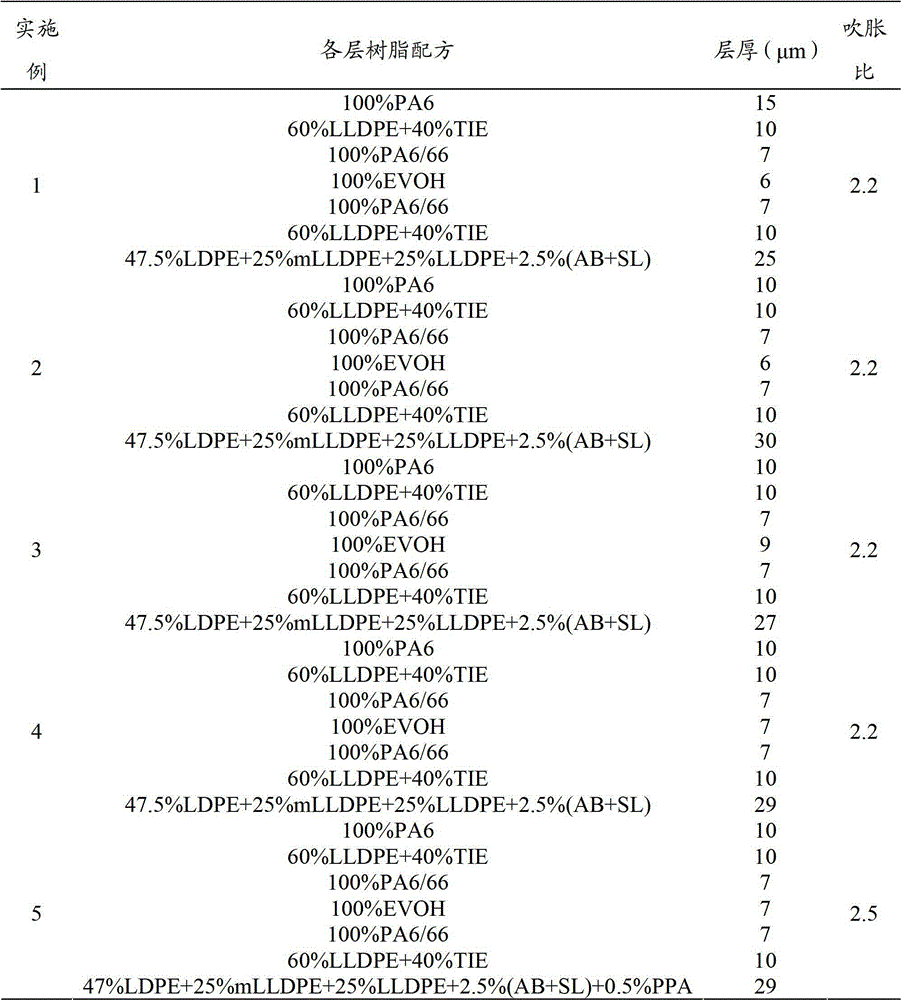

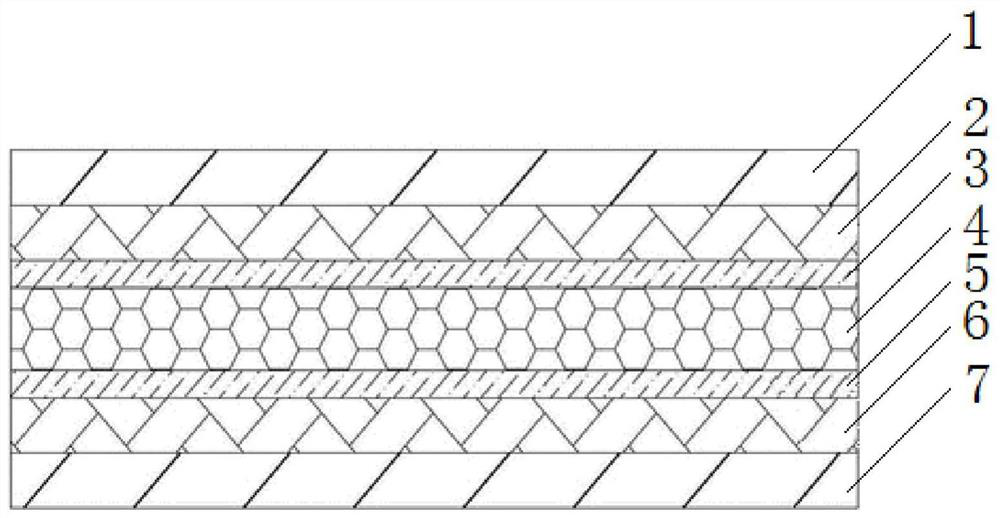

ActiveCN102700210BExcellent oxygen barrierImprove moisture resistanceFlexible coversWrappersLinear low-density polyethyleneLow-density polyethylene

The invention provides a seven-layer co-extrusion transparent high-isolation film and a preparation method thereof. The invention provides a transparent high-isolation film, which comprises a first polyamide layer, a first linear low density polyethylene layer, a second polyamide layer, an ethylene-vinyl copolymer layer, a third polyamide layer, a second linear low density polyethylene layer and a polyethylene layer which are sequentially contacted with one another. According to the transparent high-isolation film, the ethylene-vinyl copolymer has excellent oxygen resistance performance, and can prevent the oxygen from permeating; the polyethylene has excellent moisture resistance performance, and can prevent vapor from permeating; the polyethylene also has excellent low-temperature and heat-sealing performance, and can be used as an inner layer of the transparent high-isolation film; the polyamide has high mechanical strength, has excellent compatibility with the ethylene-vinyl copolymer, and can be used as a support protection layer of the ethylene-vinyl copolymer layer; and the polyamide has excellent printing performance and wear-resisting property, and can be used as an outer layer of the transparent high-isolation film.

Owner:HUANGSHAN NOVEL

Nano-antirust coating

InactiveCN102372978AHigh elongationImprove water resistanceAnti-corrosive paintsExtensibilityCellulose acetate

The present invention discloses a nano-antirust coating. The nano-antirust coating is mainly prepared by stirring the following raw materials, wherein the raw materials comprise, by weight, 46 parts of nano-polyacrylate emulsion, 30 parts of nano-scale titanium dioxide, 20 parts of ethylene glycol, 10 parts of sodium carboxymethyl cellulose, 5 parts of heavy calcium powder, 6 parts of a binder, 10 parts of cellulose acetate, 35 parts of deionized water, 5 parts of tannic acid, 1 part of a pH value adjusting agent and 2.5 parts of a thickening agent. The product of the present invention has excellent performances of excellent extensibility, good elasticity, high tensile strength, water preventing, oxygen preventing, corrosion protection, and the like.

Owner:NANTONG TONGZHOU DISTRICT JINCHEN PAINT FACTORY

A kind of production method of stretch-resistant high-barrier polypropylene film

ActiveCN109233105BMolecular weight controllableEasy to industrializeLaminationLamination apparatusPolymer sciencePolyvinyl alcohol

The invention discloses a production method of a stretch-resistant high-barrier polypropylene film, which uses isophorone diisocyanate as a coupling agent to couple hydroxyl-terminated isotactic polypropylene with polyethylene glycol monomethyl ether to prepare Isotactic polypropylene-b-polyethylene glycol diblock, the synthesis technology method is easy to implement, with low cost and high efficiency, the raw materials used are simple and easy to get, and the price is low. Polyethylene glycol diblock is used as a compatibilizer for isotactic polypropylene and polyvinyl alcohol, polyvinyl alcohol has excellent oxygen barrier properties, and isotactic polypropylene‑b‑polyethylene glycol diblock is used as a compatibilizer After pretreatment, the good compatibility between polypropylene and polyvinyl alcohol makes the polyvinyl alcohol phase uniformly dispersed in the polypropylene resin to form a sub-continuous phase or a lamellar structure, thereby significantly improving the blend film. Excellent barrier properties; clay and ceramic whiskers are blended with polypropylene copolymer to effectively improve the tensile strength of the film.

Owner:NINGBO RUICHENG PACKING MATERIAL

High-oxygen-barrier sealing strip taking co-extruded EVOH film as base material and preparation method of high-oxygen-barrier sealing strip

InactiveCN112078197ALow elongation at breakHigh strengthSynthetic resin layered productsSealingProduction linePolymer science

The invention relates to the technical field of sealing materials, in particular to a high-oxygen-barrier sealing strip with a co-extruded EVOH film as a base material and a preparation method thereof. The high-oxygen-barrier sealing strip comprises a sealing strip body, and the sealing strip body is formed by compositing an MLLDPE + LDPE mixed resin layer, an LDPE resin layer, a primer or polyurethane glue layer, an EVOH film layer, an LDPE resin layer and an MLLDPE + LDPE mixed resin layer. The packaging bag is low in elongation at break, high in strength, good in cutting performance and suitable for a high-speed filling production line and sterile pillow type packaging; due to excellent low-temperature heat sealing performance, temperature resistance and low heat shrinkage rate, the deformation and shrinkage of the film during high-frequency heating or hot plate heating in the use process are avoided, and good dimensional stability is achieved; good water blocking performance and excellent oxygen blocking performance are achieved, and an effective protection effect on the filled food is achieved.

Owner:上海万封新材料技术有限公司

Packaging thin film applicable to prolonging expiration date of foods

InactiveCN106628601AAvoid pollutionExcellent oxygen barrierFlexible coversWrappersUltravioletFood packaging

The embodiment of the invention discloses a packaging thin film applicable to prolonging expiration date of foods. The packaging thin film is of a layering structure and comprises a printing layer, a transparent layer, an adhesive layer, an aluminum film and a heat sealing layer which are compounded into one from outside to inside. By the adoption of the packaging thin film, by means of excellent oxygen barrier performance and high ultraviolet ray barrier performance of the aluminum film, the packaging thin film is applied to food packaging films, avoids contamination to the foods and is applicable to packaging of the fluid foods.

Owner:苏瑞奇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com