Steel strip reinforced PVC pipe and production process thereof

A PVC pipe and production process technology, applied in the field of PVC pipe, steel belt reinforced PVC pipe and its production process, can solve the problem of high linear expansion coefficient, low service life, poor impact resistance, pressure bearing capacity and oxygen barrier performance and other problems, to achieve the effect of excellent impact resistance, long service life and excellent oxygen barrier performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

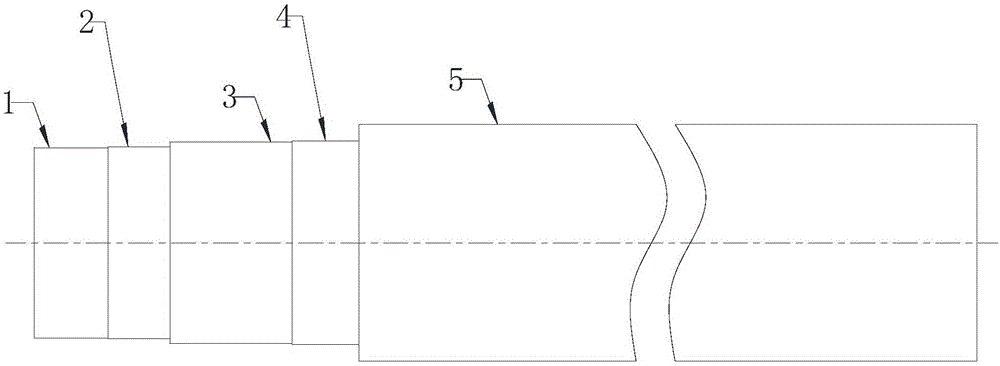

[0034] refer to figure 1 , a steel belt reinforced PVC pipe of the present invention, comprising an inner PVC pipe layer 1, a first hot-melt adhesive layer 2, a steel belt layer 3, a second hot-melt adhesive layer 4 and an outer PVC pipe layer 5, the first hot-melt adhesive layer 5 The melt adhesive layer 2 is distributed between the inner PVC pipe layer 1 and the steel belt layer 3, the second hot melt adhesive layer 4 is distributed between the outer PVC pipe layer 5 and the steel belt layer 3, and the steel belt layer 3 passes through the first A hot-melt adhesive layer 2 and a second hot-melt adhesive layer 4 are sandwiched between the inner PVC pipe layer 1 and the outer PVC pipe layer 5. When a steel belt reinforced PVC pipe is a cold water pipe, the inner PVC pipe layer 1 What adopted with outer PVC pipe layer 5 is PVC-U pipe; When a kind of steel strip reinforced PVC pipe is hot water pipe, what described inner PVC pipe layer 1 and outer PVC pipe layer 5 adopted is PVC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com