Polyvinyl dichloride (PVDC) emulsion for cellophane coating and preparation method thereof and application thereof

A cellophane and emulsion technology, used in paper coatings, coatings, papermaking, etc., can solve the problems of not mentioning the barrier properties of cellophane, the barrier properties of cellophane cannot meet the required requirements, etc., to improve the vacuum desorption effect and low cost. , The effect of good barrier performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

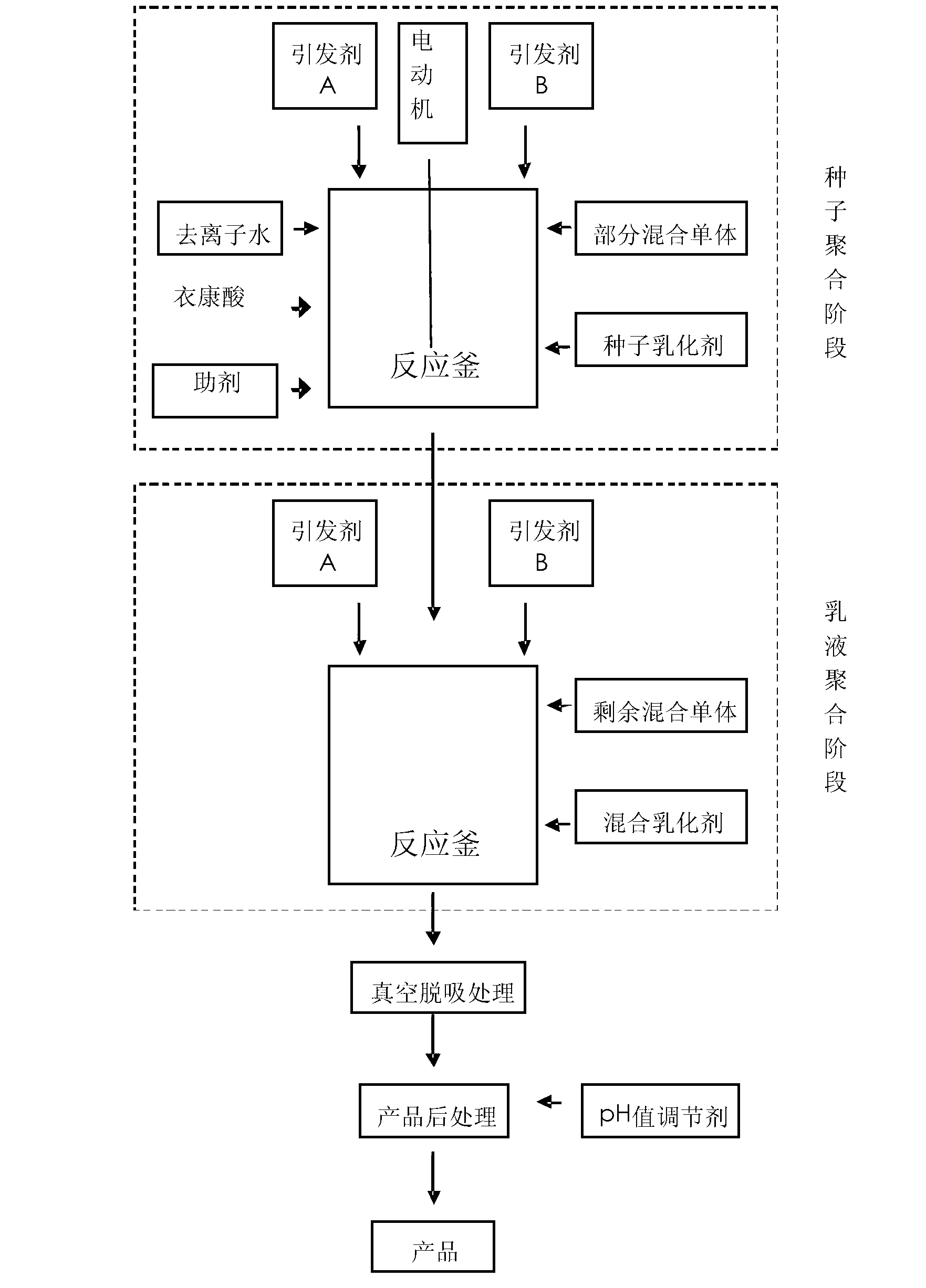

Method used

Image

Examples

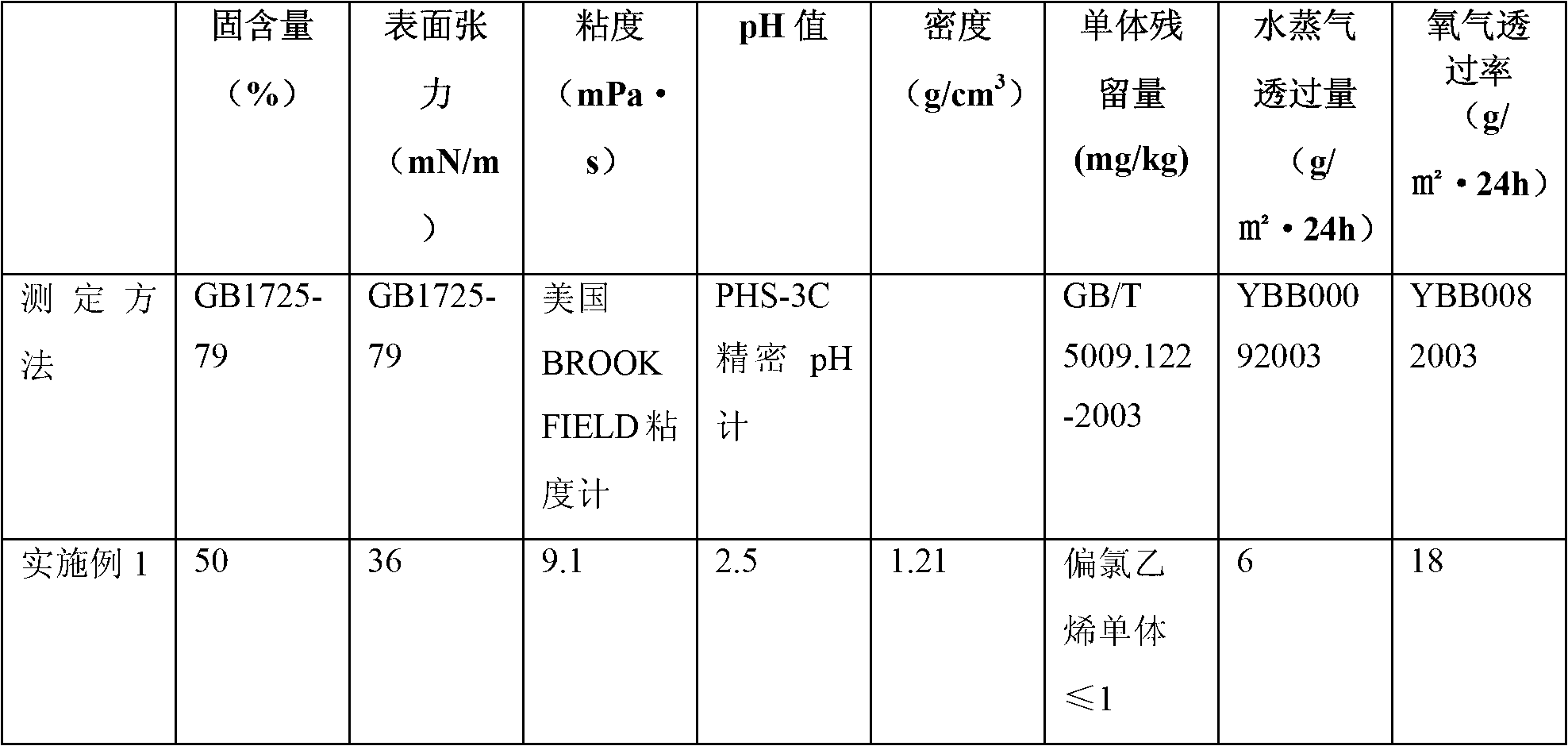

Embodiment 1

[0021] 1. Raw material preparation:

[0022] 1) Mixed monomer preparation: mix 91 kg of vinylidene chloride, 4.5 kg of acrylonitrile, and 3.5 kg of methyl methacrylate to obtain a mixed monomer;

[0023] 2) Initiator preparation: dissolve 160 g of tert-butyl hydroperoxide in 8 kg of water to obtain an aqueous solution of tert-butyl hydroperoxide, and dissolve 160 g of sodium formaldehyde sulfoxylate in 8 kg of water to obtain an aqueous solution of sodium formaldehyde sulfoxylate;

[0024] 3) Mixed emulsifier preparation: Mix 2.2 kg of sodium secondary alkane sulfonate and 1 kg of 2A-1 emulsifier and add water to 20 kg to prepare a mixed emulsifier;

[0025] 2. Seed aggregation:

[0026] Add 50kg of deionized water, 30g of ammonium acetate, 1g of ferrous chloride, 180g of sodium paraffin sulfonate, and 1kg of itaconic acid into the reaction kettle and mix evenly, seal the kettle, replace the gas three times, vacuumize, and inhale the amount of the formula 3% mixed monomer, c...

Embodiment 2

[0032] 1. Raw material preparation:

[0033] 1) Mixed monomer preparation: mix 91 kg of vinylidene chloride, 4.5 kg of acrylonitrile, and 3.5 kg of ethyl methacrylate to obtain a mixed monomer;

[0034] 2) Initiator preparation: dissolve 160 g of tert-butyl hydroperoxide in 8 kg of water to obtain an aqueous solution of tert-butyl hydroperoxide, and dissolve 160 g of sodium formaldehyde sulfoxylate in 8 kg of water to obtain an aqueous solution of sodium formaldehyde sulfoxylate;

[0035] 3) Mixed emulsifier preparation: Mix 2.2 kg of sodium secondary alkane sulfonate and 1 kg of 2A-1 emulsifier and add water to 20 kg to prepare a mixed emulsifier;

[0036] 2. Seed aggregation:

[0037] Add 50kg of deionized water, 30g of ammonium acetate, 1g of ferrous chloride, 180g of sodium paraffin sulfonate, and 1kg of itaconic acid into the reaction kettle and mix evenly, seal the kettle, replace the gas three times, vacuumize, and inhale the amount of the formula 3% mixed monomer, co...

Embodiment 3

[0041] 1. Raw material preparation:

[0042] 1) Mixed monomer preparation: mix 109.2 kg of vinylidene chloride, 5.4 kg of acrylonitrile, and 4.2 kg of methyl methacrylate to obtain a mixed monomer;

[0043] 2) Initiator preparation: dissolve 200 g of tert-butyl hydroperoxide in 8 kg of water to obtain an aqueous solution of tert-butyl hydroperoxide, and dissolve 200 g of sodium formaldehyde sulfoxylate in 8 kg of water to obtain an aqueous solution of sodium formaldehyde sulfoxylate;

[0044] 3) Mixed emulsifier preparation: mix 2.2 kg of sodium paraffin sulfonate and 1.2 kg of 2A-1 emulsifier and add water to 20 kg to prepare a mixed emulsifier;

[0045] 2. Seed aggregation:

[0046] Add 30kg of deionized water, 30g of ammonium acetate, 1g of ferrous chloride, 180g of sodium paraffin sulfonate, and 1.2kg of itaconic acid into the reaction kettle and mix evenly, seal the kettle, replace the gas 3 times, vacuumize, and inhale the formula Measure 3% of the mixed monomer, cold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com