High-oxygen-barrier sealing strip taking co-extruded EVOH film as base material and preparation method of high-oxygen-barrier sealing strip

A sealing strip, high resistance technology, applied in the directions of sealing, chemical instruments and methods, coatings, etc., can solve the problems of poor oxygen barrier performance, lack of comprehensive performance such as heat sealing performance and sealing, to improve heat sealing performance, excellent Sealing anti-pollution performance, the effect of reducing the heat sealing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

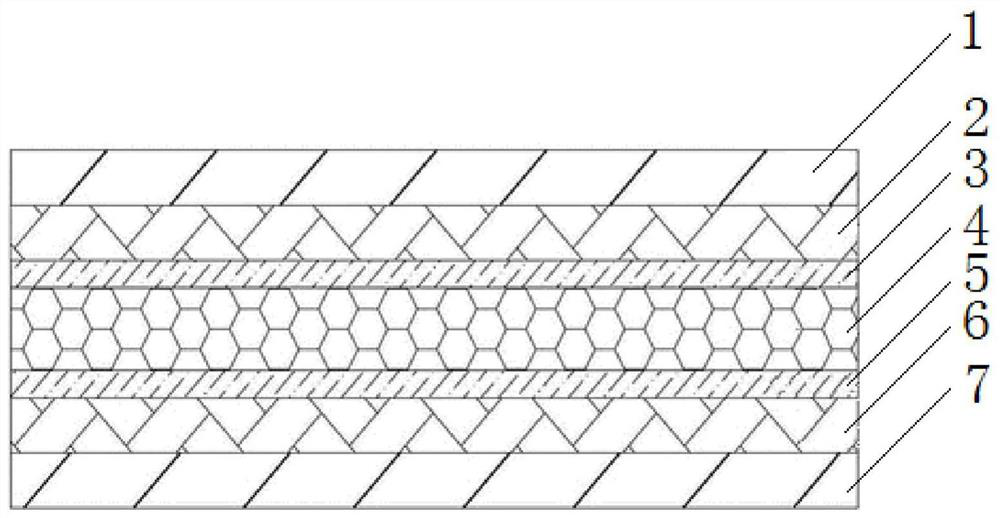

[0042] A kind of preparation method taking co-extrusion EVOH film as the high oxygen resistance sealing strip of base material, comprises the steps:

[0043] (1) Coating the EVOH film layer with a primer or polyurethane glue after corona treatment on the surface, and drying at a drying temperature of 50°C-100°C;

[0044] (2) LDPE resin and MLLDPE+LDPE mixed resin are co-extruded successively with the extruding laminating machine on the glued surface of the EVOH film layer obtained in step (1), and are rolled after composite roll pressing and cooling roll pressing;

[0045] (3) maturing the product after step (2), the maturation temperature is 30°C-80°C, and the maturation time is 2 days-7 days;

[0046] (4) repeat the process of above-mentioned steps (1), (2), (3) to the other side of the EVOH film layer of the product after step (3);

[0047] (5) The finished product obtained in step (4) is cut into strip-shaped film strips of specific width, and wound into disc-shaped film ...

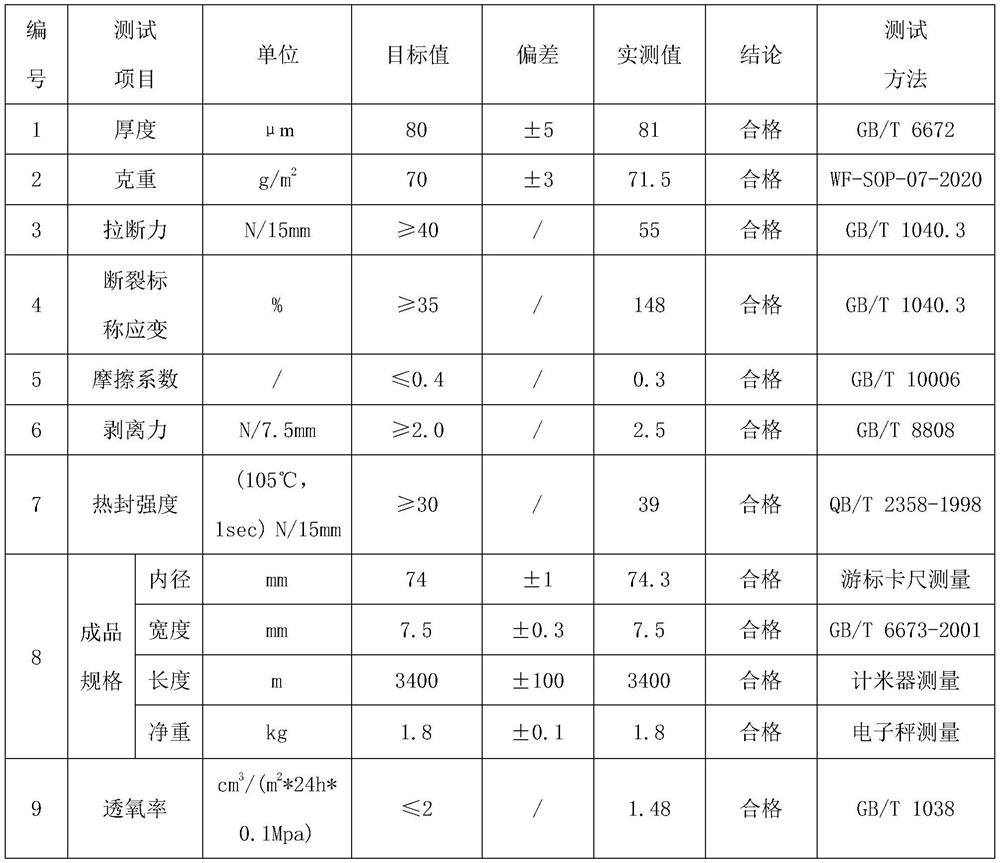

Embodiment 1

[0051] The EVOH film layer is treated with surface corona and coated with a primer, the thickness of the EVOH film layer is 10 μm, and the amount of glue applied to the primer or polyurethane glue layer is 0.3g / m 2 . Drying, the drying temperature is 50°C; the LDPE resin and the MLLDPE+LDPE mixed resin are sequentially co-extruded on the glued surface of the EVOH film layer with an extrusion compounding machine. The melt index of LDPE is 4.5 g / 10min, and the extrusion resin temperature is 250°C, LDPE single-side coating amount is 10 g / square meter; MLLDPE content in MLLDPE+LDPE mixed resin is 0%, melt index of MLLDPE+LDPE mixed resin is 4.5 g / 10min, extrusion resin temperature is 250 °C, the single-side coating amount of the MLLDPE+LDPE mixed resin layer is 10 g / square meter. Rolling after composite roll pressing and cooling roll pressing; film aging, the aging temperature is 30°C, and the aging time is 7 days; repeat the above process on the other side of the EVOH film layer...

Embodiment 2

[0053] Apply polyurethane glue to the EVOH film layer after corona treatment on the surface, the thickness of the EVOH film layer is 15 μm, and the glue amount of the primer or polyurethane glue layer is 1.5g / m 2 . Drying, the drying temperature is 100°C; the LDPE resin and the MLLDPE+LDPE mixed resin are sequentially co-extruded on the glued surface of the EVOH film layer with an extrusion compounding machine. The melt index of LDPE is 15 g / 10min, and the extrusion resin temperature is 350°C, LDPE coating amount on one side is 20 g / m2; MLLDPE content in MLLDPE+LDPE mixed resin is 100%, melt index of MLLDPE+LDPE mixed resin is 20 g / 10min, extrusion resin temperature is 350 ℃; MLLDPE+LDPE mixed resin layer coating amount of one side is 20 grams / square meter;. Rewinding after lamination by compound roll and cooling roll; film curing, the curing temperature is 80°C, and the curing time is 2 days; repeat the above process on the other side of the EVOH film layer to obtain the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com