Recyclable foaming material and preparation method thereof

A foaming material and a manufacturing method technology, which are applied to the foaming material and the manufacturing field thereof, can solve the problems of unenvironmental recycling performance, high odor, etc., and achieve the effects of high inorganic filling capacity, elongation at break and thermal shrinkage reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below through specific examples, but the examples do not limit the protection scope of the present invention.

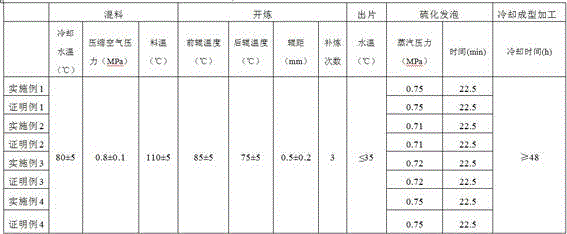

[0036] The manufacturing method of the recyclable foaming material of the present invention comprises the following steps:

[0037] 1) Mixing

[0038] The foaming material that can be recycled and used, its chemical composition weight ratio is shown in Table 1; the chemical composition shown in Table 1 is mixed in the internal mixer, and the order of addition is to first mix PP elastomer, anti-shrinkage masterbatch , heavy calcium carbonate and stearic acid are added to the internal mixer and mixed once, and then the foaming agent, peroxide crosslinking agent, crosslinking aid, zinc oxide and pigment are added after the large materials are grouped together, and all the materials are mixed After uniformity, discharge. Moreover, during the feeding process, the temperature should be controlled below 110°C, and par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com